Patents

Literature

38results about How to "Not prone to clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-molecular copolymer dispersant for paint and preparation method thereof

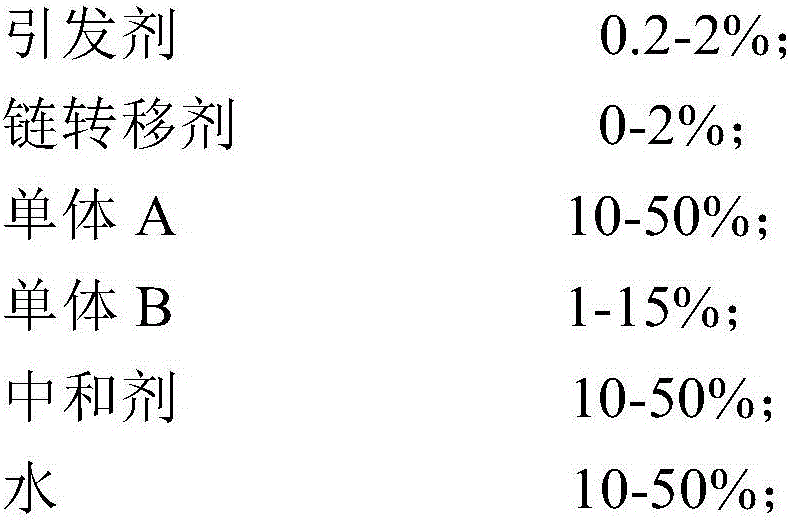

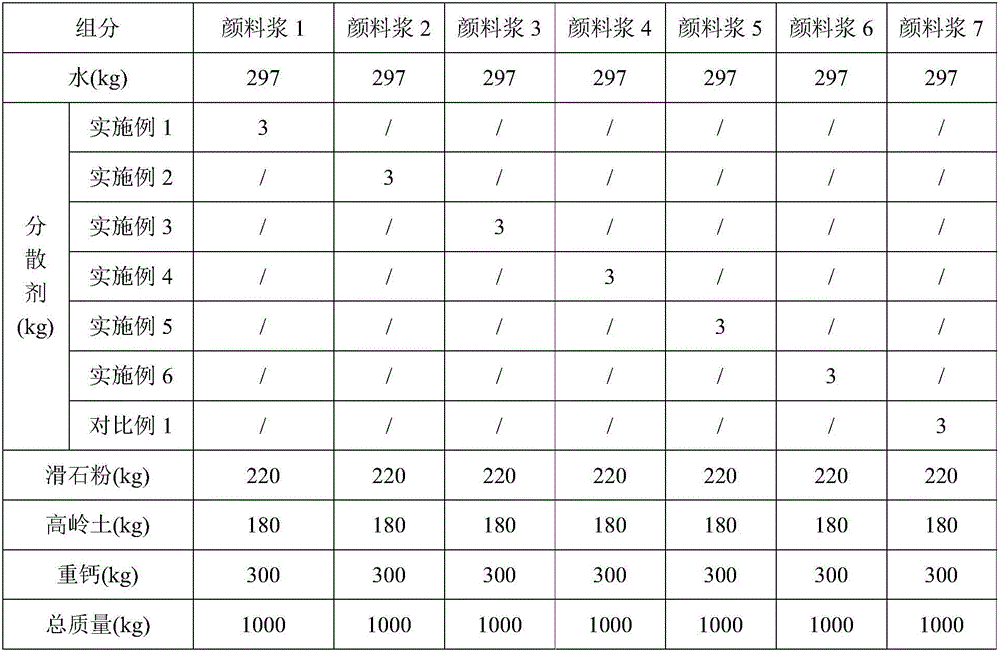

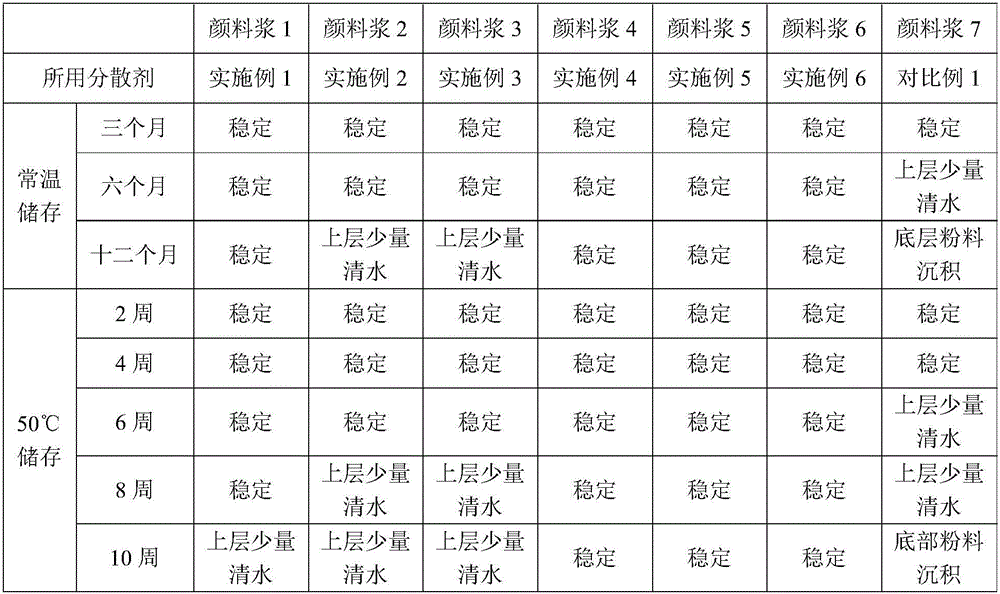

The invention discloses a high-molecular copolymer dispersant for paint. The high-molecular copolymer dispersant is prepared by the following components in percentages by mass: 0.2-2% of an initiator, 0-2% of a chain transferring agent, 10-50% of a monomer A, 1-15% of a monomer B, 10-50% of a neutralizer, and 10-50% of water. Organic solvents are not added in a preparation process of the high-molecular copolymer dispersant, so recovery of the organic solvents is not needed, the technology is simple, the cost is low, and environment is not polluted. The paint is produced by utilization of the high-molecular copolymer dispersant, and the paint has the advantages of fast viscosity reduction speed for the powder and good viscosity reduction effects in the production process; water separation and agglomeration phenomenon of the paint does not disappear, an appropriate formula is used for preparing the paint, and after one year of storage, the water separation and agglomeration phenomenon does not disappear.

Owner:BEIJING MAYOR CHEM TECH

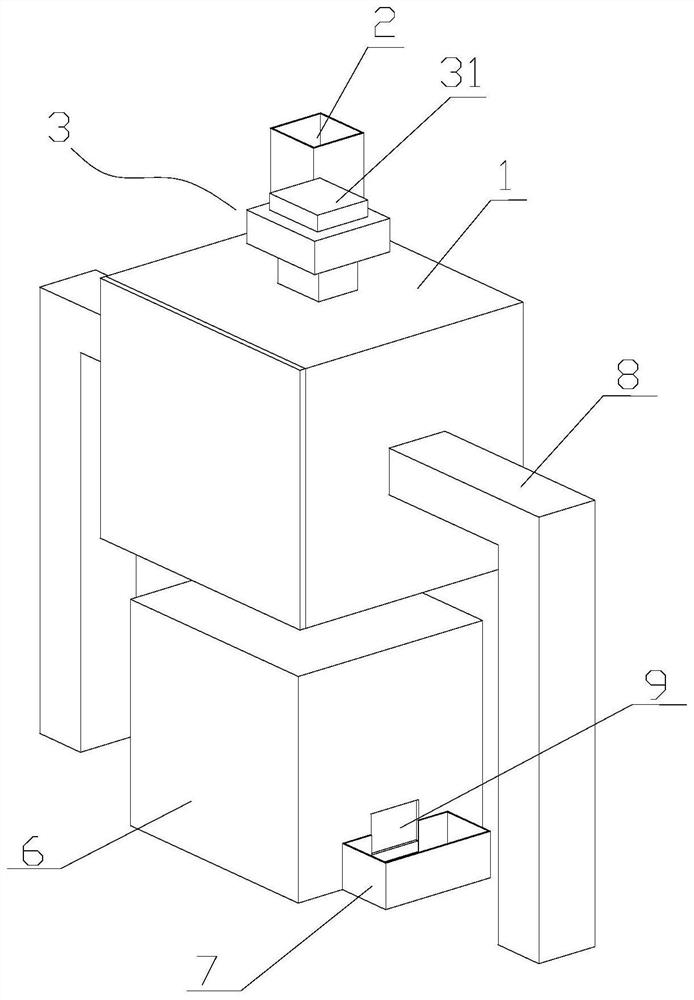

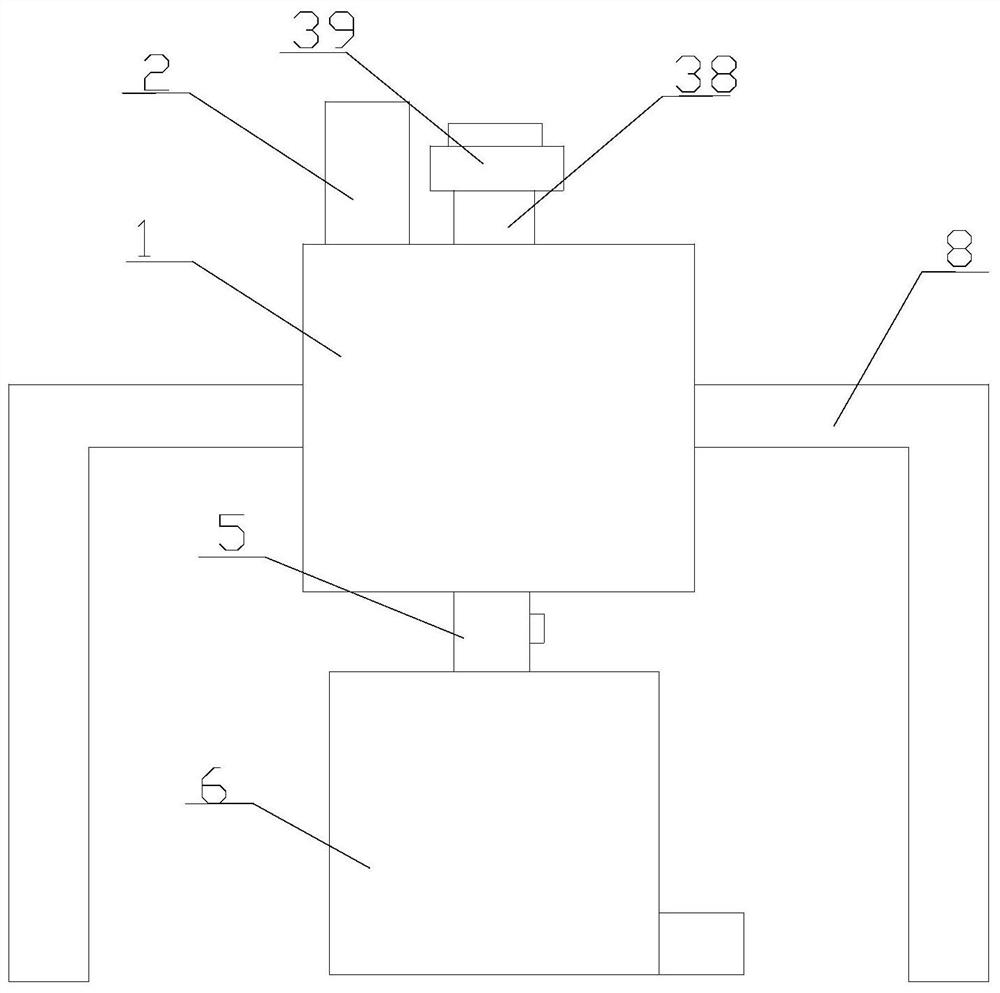

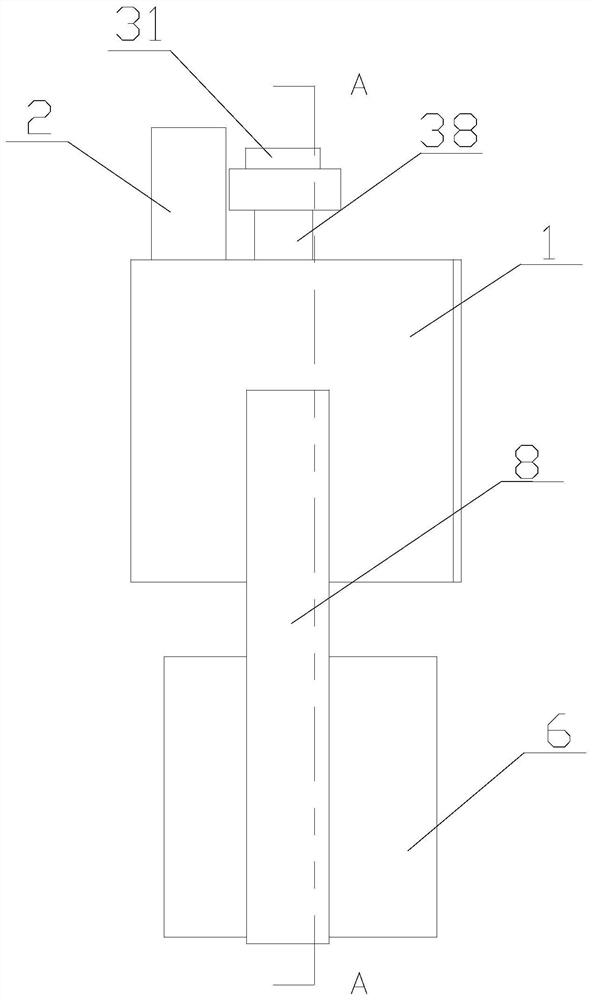

Road construction sediment mixer

PendingCN106827231AEfficient mixingReduce adhesionsMixing operation control apparatusClay mixing apparatusRoad engineeringArchitectural engineering

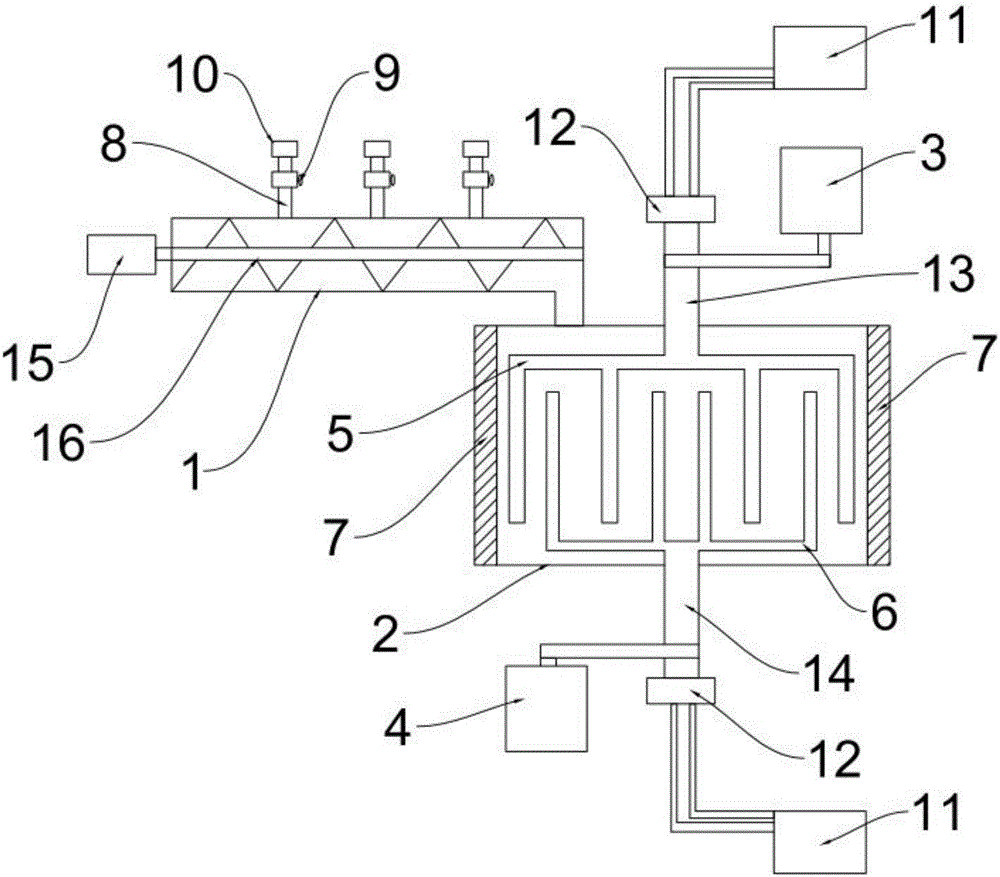

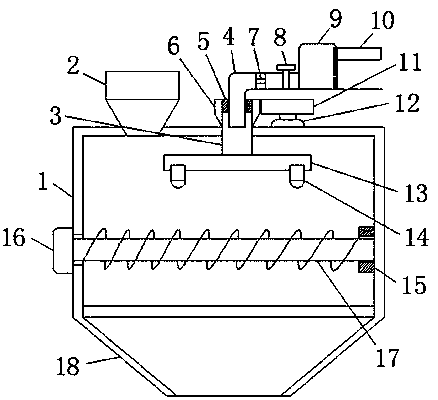

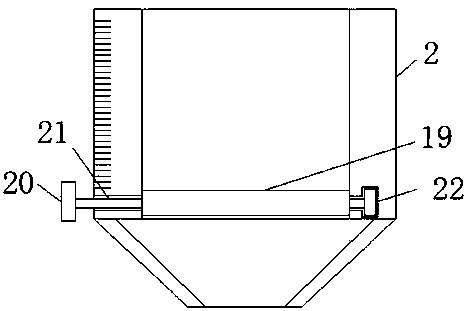

The invention discloses a road construction sediment mixer, and belongs to the technical field of road engineering equipment. The road construction sediment mixer comprises a mixing tank, wherein a feeding pipeline is arranged on the mixing tank, and a spiral conveyer is arranged in the feeding pipeline; one end of the spiral conveyer is connected with a conveying motor to drive, and the top part of the mixing tank is provided with an active shaft; one end of the active shaft is provided with an active shaft, and the other end of the active shaft is in driving connection with the main motor; the bottom part of the mixing tank is provided with an assistant rotary shaft, and one end of the assistant rotary shaft is provided with an assistant roller; the other end of the assistant rotary shaft is in driving connection with an assistant motor; the rotating direction of the main motor is opposite to that of the assistant motor; the active roller and the assistant roller are arranged to be several longitudinal branches and staggered and distributed mutually; thus the road construction sediment mixer realizes the high-efficient sediment mixing, improves the mixing speed, reduces the sediment adhesion status, prolongs the service life of the equipment, and reduces the labor burden of the worker.

Owner:梁正

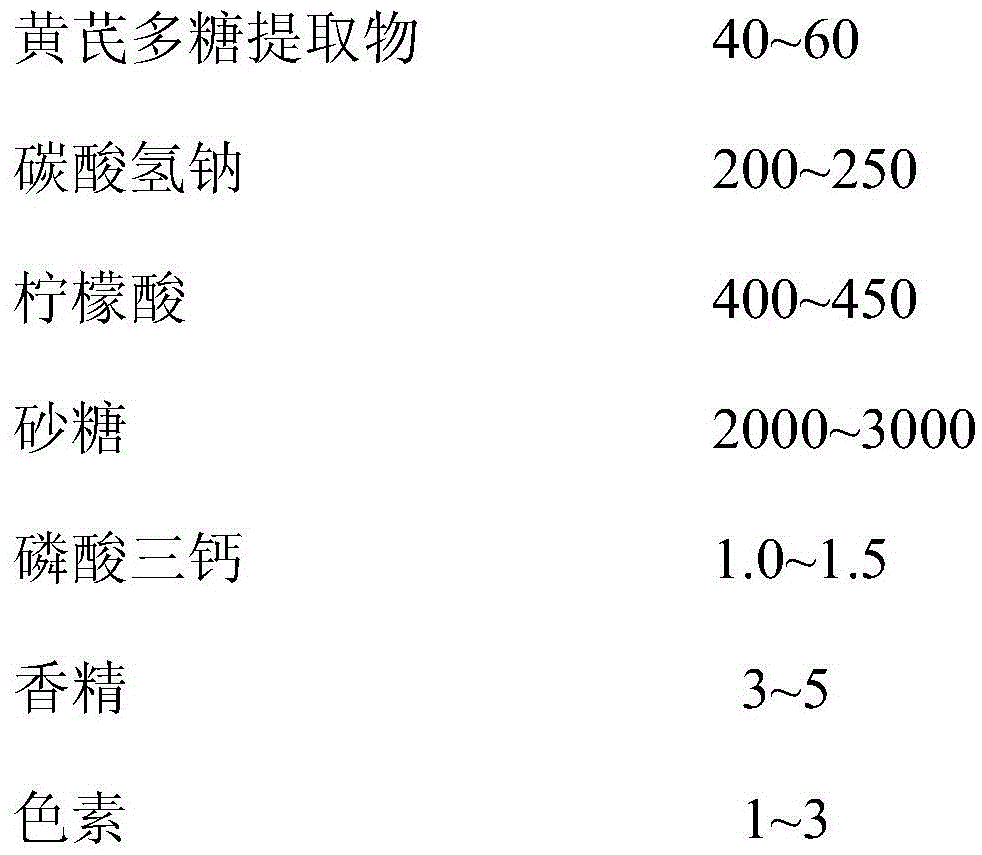

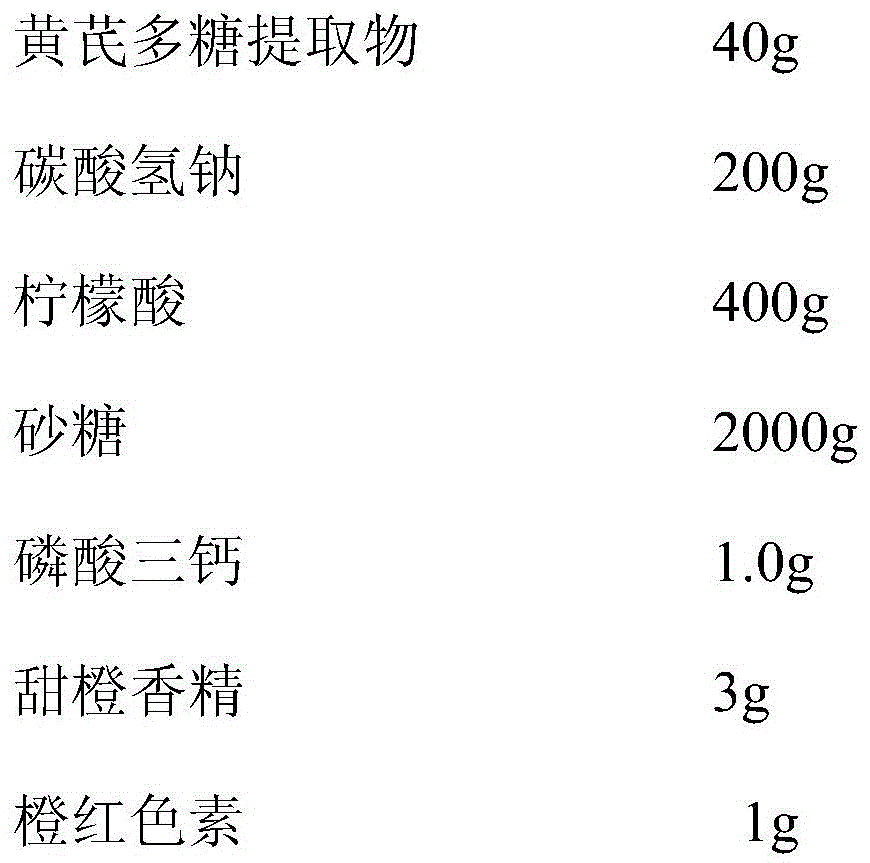

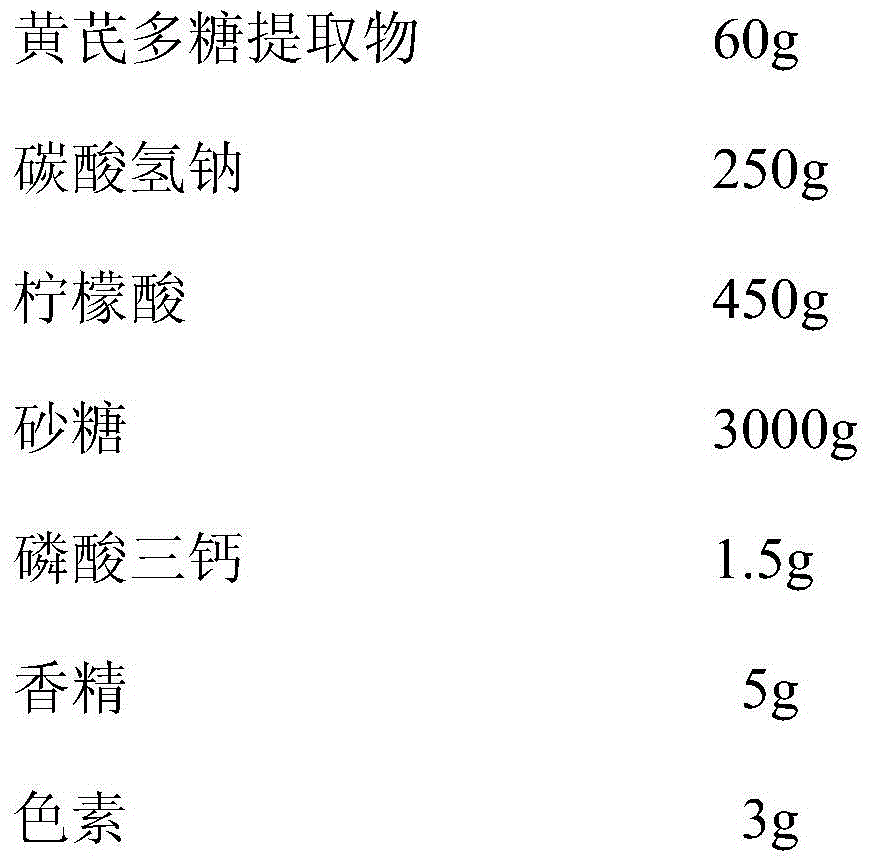

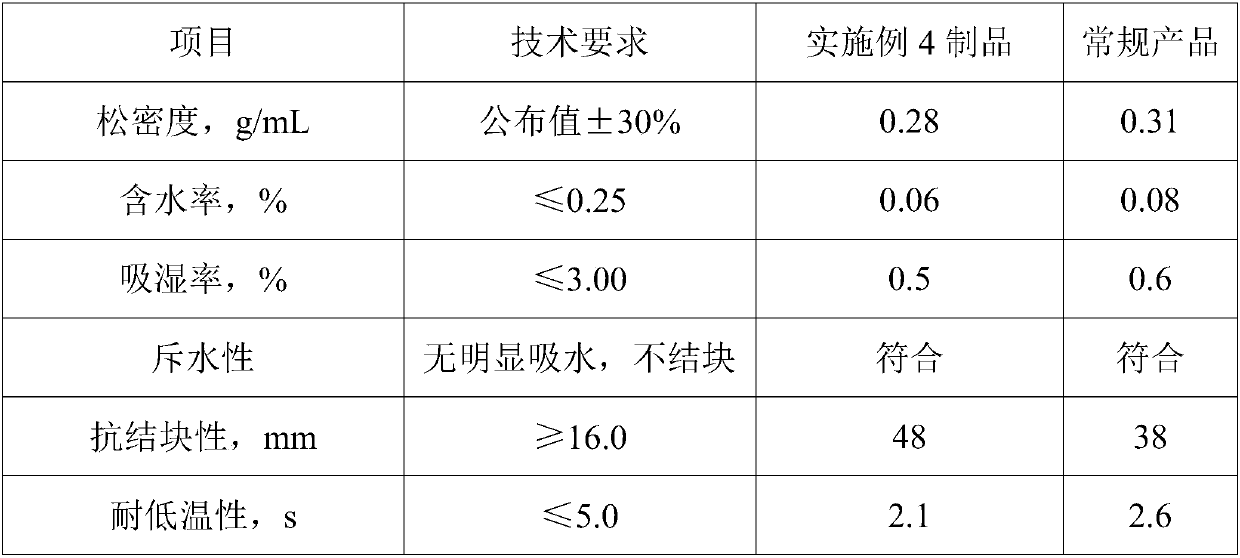

Astragalus polysaccharide solid beverage

InactiveCN105475797ANot prone to clumpingEasy to transportFood scienceSodium bicarbonateAstragalus polysaccharide

The invention specifically relates to an astragalus polysaccharide solid beverage, which belongs to the field of processing of health food. According to the invention, active components of astragalus polysaccharide are extracted and mixed with sodium bicarbonate, citric acid, granulated sugar and the like to prepare the bubble-type solid beverage with agreeable sour-sweet taste; to overcome the problems of instability and proneness to coking of bubble-type solid beverages, sodium bicarbonate coated by organic matters is employed and does not directly contact with acidic substances under a dried condition, so stability and storage life of the bubble-type solid beverage are improved; and astragalus polysaccharide added into the solid beverage is capable of improving immunity, resisting viruses, tumors, ageing, radiation and oxidation, etc.

Owner:YU HAN

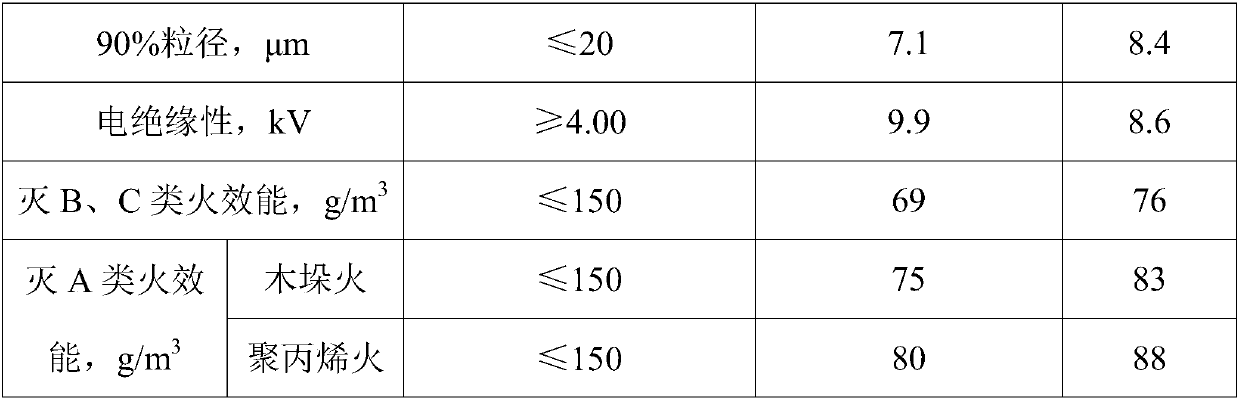

Small-grain-diameter ABC dry powder extinguishing agent and preparing method thereof

InactiveCN107648788AHigh fire extinguishing efficiencyGood dispersionFire extinguisherChemistrySodium oleate

The invention discloses a small-grain-diameter ABC dry powder extinguishing agent and a preparing method thereof. The preparing method includes the following steps that nano calcium carbonate, stearicacid and myristic acid are stirred, microcrystalline wax and water are added to be evenly mixed, sulfating sodium oleate is added in the stirring state, and heating, stirring, filtering, washing, drying and smashing are carried out to obtain a first material; monoammonium phosphate, monopotassium phosphate, potassium perchlorate, glass fibers and the first material are evenly mixed, and homogenization treatment is carried out to obtain a second material; hydrogen containing silicone oil and water are evenly mixed, then acetone is added to be evenly stirred, and a mixed material is obtained; and the mixed material is atomized and sprayed into the second material in the stirring state, heating and even mixing are carried out, water is removed, nanosilicon dioxide and magnesium stearate areadded, and vacuum smashing is carried out to obtain the small-grain-diameter ABC dry powder extinguishing agent.

Owner:BENGBU LONGTAI FIRE FIGHTING

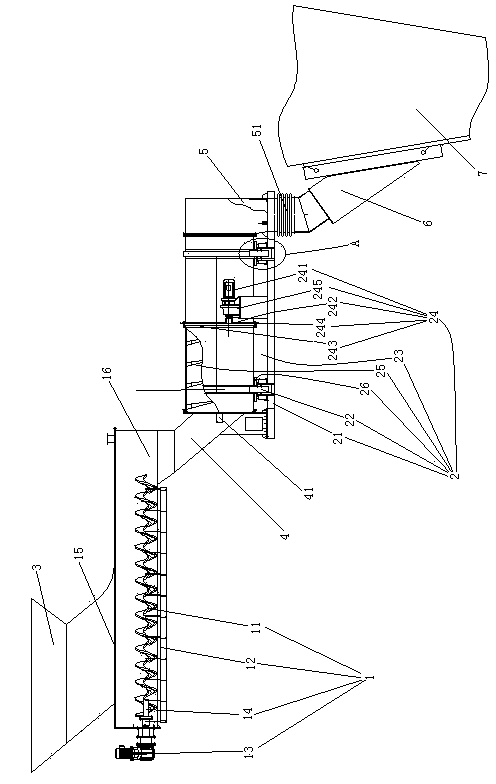

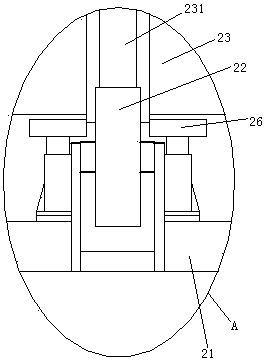

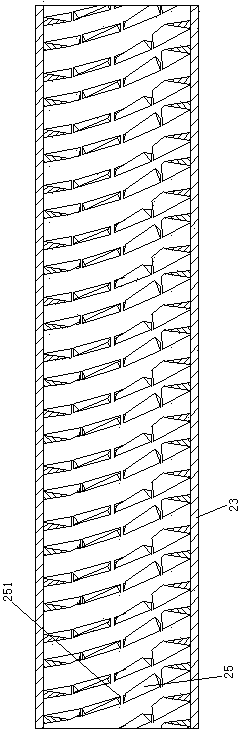

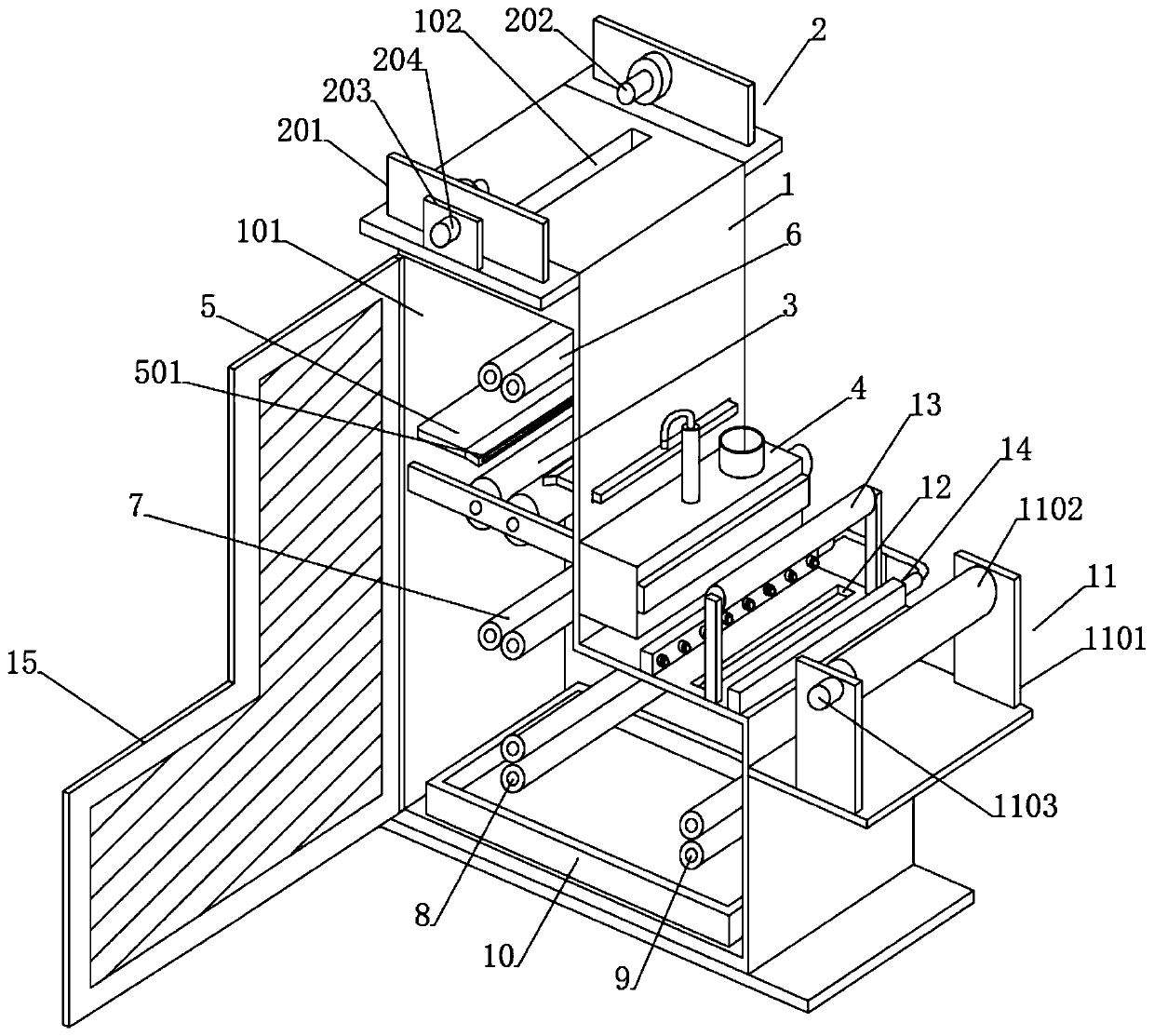

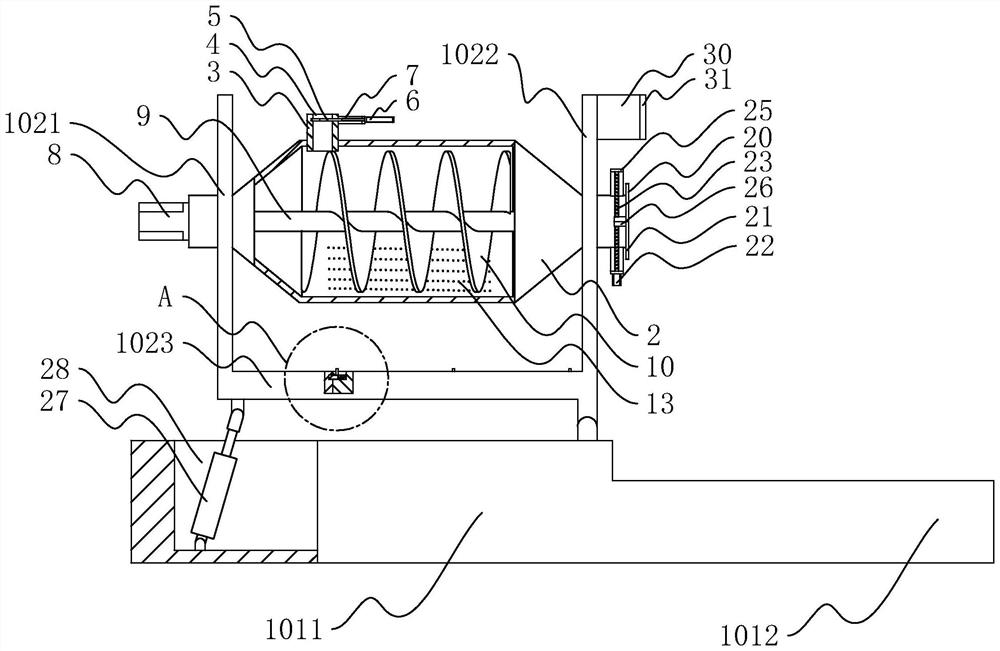

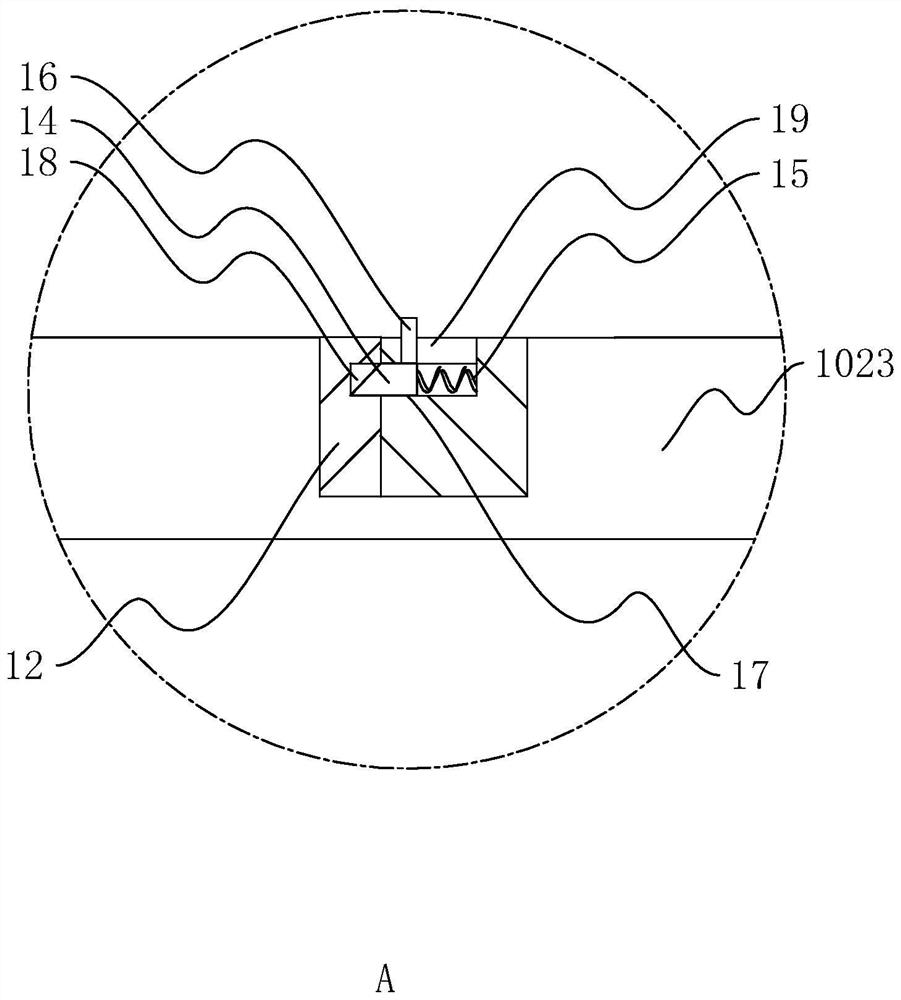

Drum type feeding device for garbage incinerator of circulating fluidized bed and feeding method

The invention relates to the field of garbage incineration disposal, in particular to a drum type feeding device for a garbage incinerator of a circulating fluidized bed. The drum type feeding device for the garbage incinerator of the circulating fluidized bed comprises a primary feeding machine and a secondary feeding machine, wherein the primary feeding machine is connected with the secondary feeding machine through a seal leg; the primary feeding machine is positioned above the secondary feeding machine; the secondary feeding machine comprises a supporting roller, a feeding drum and a driving mechanism for driving the feeding drum to rotate; the feeding drum is supported on the supporting roller under the condition that a peripheral surface of the feeding drum is in contact to the supporting roller; the feeding end of the feeding drum is rotatably and hermetically connected with the seal leg; a plurality of spiral guide blades are arranged in the feeding drum; the radial outer ends of the spiral guide blades are fixedly connected with an inner peripheral surface of the feeding drum; and feeding space is surrounded by radial inner ends of the spiral guide blades. The drum type feeding device for the garbage incinerator of the circulating fluidized bed has the advantages that the increasing amount of the compactness of garbage is reduced along with increasing of a feeding distance, and the garbage can enter the incinerator in a loose state. The problems that materials are hardened during conveying of the existing feeding device, combustion is insufficient, and tail gas treatment cost is high are solved.

Owner:银川中科环保电力有限公司

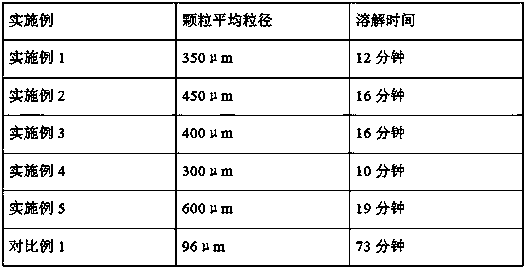

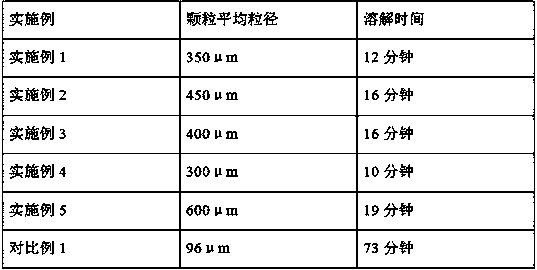

Method for preparing instant-soluble cationic high molecular weight polyacrylamide by two-step method

The invention discloses a method for preparing instant-soluble cationic high molecular weight polyacrylamide by a two-step method. The method comprises the following steps: (1) adding a dispersing agent to a reaction vessel containing a hydrocarbon solvent, and heating the materials to dissolve the dispersing agent; (2) adding 20 to 40% by mass of an acrylamide aqueous solution, a water-soluble initiator, and a cationic comonomer to the reaction vessel and stirring the materials to form a water-in-oil reaction system; (3) introducing nitrogen gas, and removing oxygen in the reaction system; (4) heating the reaction system to a reaction for a period of time to form primary particles of polyacrylamide; 5) adding an alcohol-water mixed solution to the reaction vessel, stirring the materials,and aggregating the primary particles of polyacrylamide to form solid particles similar to a grape bunch structure; and (6) heating and boiling to remove the alcohol and the aqueous solution, and obtaining the instant-soluble high molecular weight polyacrylamide solid. The polyacrylamide obtained by the two-step method has a faster dissolution rate when used, and is not easily agglomerated.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

Grain production drying equipment

InactiveCN113390246ANot prone to clumpingImprove practicalityDrying solid materialsDrying machines with non-progressive movementsProcess engineeringManufacturing engineering

The invention relates to the technical field of grain drying equipment, in particular to grain production drying equipment. A feeding pipe is located above a drying box, a rotating assembly is located above the drying box, a drying assembly is located in the drying box, one end of a conveying pipe is fixedly connected with the drying box, and the other end of the conveying pipe is fixedly connected with the drying box. Grains are poured into the feeding pipe and enter the drying box, the drying assembly dries the interior, the rotating assembly turns over the internal grains, then the grains are conveyed into the drying box through the conveying pipe to be dried, so that the grains are not prone to caking, the drying efficiency is improved, and the practicability is improved.

Owner:东台恒禾丰食品有限公司

Textile fabric double-sided printing and dyeing equipment for open-width fabric processing

InactiveCN111593512AUniform printing and dyeingImprove permeabilityLiquid/gas/vapor removalTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses textile fabric double-sided printing and dyeing equipment for open-width fabric processing, and belongs to the technical field of textile fabric printing and dyeing. Accordingto the textile fabric double-sided printing and dyeing equipment for open-width fabric processing, the fact that dyes in a magnetization box are sprayed out is realized through a strip-shaped sprayingnozzle through cooperation of a dye magnetization device and a strip-shaped dye spraying pipe, the jet dyes are uniformly distributed on printing and dyeing rollers, the pair of printing and dyeing rollers print and dye the dyes to the two end faces of a fabric in the opposite rotating movement process, the dyes are printed and dyed to the fabric through transmission of the printing and dyeing rollers, uniform printing and dyeing of the dyes are effectively achieved, the phenomena of uneven dyeing, wrinkling and the like are not likely to be caused; meanwhile, magnetizing the dyes is carriedout in the dye magnetizing device, so that the permeability of the dyes is effectively improved; and in addition, after the fabric is printed and dyed, the fabric is guided out of a fabric guide-out cavity and then heat dissipation and blow-drying are carried out through a heat dissipation and drying mechanism, so that cooling and drying the two end faces of the fabric are realized, and the winding operation is carried out on the dried fabric through a winding roller.

Owner:陈式好

Additive for stone-like paint protecting adhesive

The invention discloses an additive for stone-like paint protecting adhesive. The additive is prepared by mixing the following components in parts by weight: 70-80 parts of sodium alginate, 5-10 partsof sodium carboxymethyl cellulose and 15-20 parts of urea. The additive for the stone-like paint protecting adhesive has stable performance, does not change after storage at normal temperature for half a year, has good solubility at normal temperature and is convenient to use; the additive comprises sodium alginate, sodium carboxymethyl cellulose and urea, wherein sodium alginate has good thixotropy and thickening properties, and can be crosslinked with metal ions such as calcium to form particles with moderate softness; sodium carboxymethyl cellulose and sodium alginate play a synergistic role in thickening and suspending functions; and urea can prevent sodium alginate and sodium carboxymethyl cellulose from agglomerating during dissolution, and is easy to dissolve at normal temperatureand more convenient to use.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Color master batch dehydration device

The invention discloses a color master batch dewatering device, and belongs to the technical field of color master batch processing. The color master batch dewatering device comprises a frame body and a storage barrel, the frame body comprises a base and a mounting frame, the mounting frame is rotationally connected to the base, the base is provided with a driving part for driving the mounting frame to rotate, the storage barrel is mounted on the mounting frame, the mounting frame is provided with at least one hot air fan facing the storage barrel, the storage barrel is provided with a feeding port and a discharging port, the storage barrel is provided with a feeding opening and closing mechanism for opening and closing the feeding port and a discharging opening and closing mechanism for opening and closing the discharging port, the storage barrel is provided with a stirring mechanism for stirring materials, and when the storage barrel rotates to a vertical state along with the mounting frame, the discharge port is located at the bottom of the storage barrel. The color master batch dehydration device has the effects that the color master batch can be uniformly dried, and then the final forming quality of the color master batch is guaranteed.

Owner:东莞市顺东新材料有限公司

Probiotic solid beverage and preparation method thereof

PendingCN113632989AImprove immunityGood for healthSugar food ingredientsFood ingredient functionsBiotechnologyIntestinal inflammation

The invention discloses a probiotic solid beverage. The probiotic solid beverage comprises a probiotic composition, a prebiotic composition and an auxiliary material composition, wherein the probiotic composition comprises the following components in parts by weight: 5 to 8 parts of bifidobacterium bifidum, 4 to 8 parts of bifidobacterium lactis, 3 to 5 parts of bifidobacterium longum, 2 to 4 parts of lactobacillus acidophilus and 1 to 3 parts of lactobacillus casei; the prebiotic composition comprises the following components in parts by weight: 8 to 12 parts of inulin, 4 to 7 parts of galactooligosaccharide, 3 to 5 parts of fructo-oligosaccharide, 3 to 5 parts of maltulose and 2 to 3 parts of xylooligosaccharide; and the auxiliary material composition comprises the following components in parts by weight: 25-30 parts of maltodextrin, 15-20 parts of corn flour, 8-10 parts of maltitol and 8-10 parts of maltose. Through the synergistic effect of probiotics and prebiotics, intestinal flora is balanced, intestinal mucosa barrier is protected, organism immunity is improved, intestinal inflammation is inhibited, anaphylactic reaction and other problems are solved, and human health is improved.

Owner:合肥中科艾迪尔生物科技有限公司

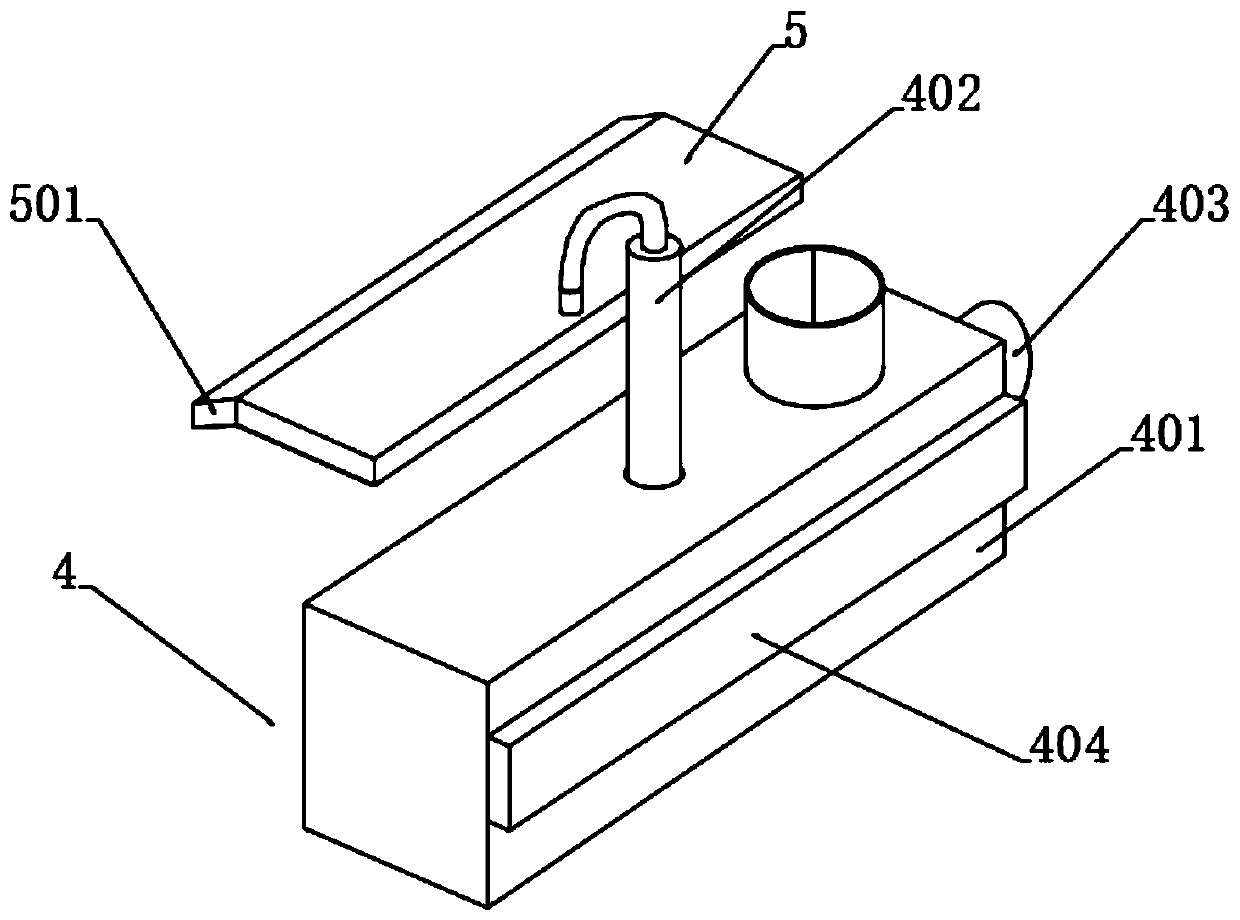

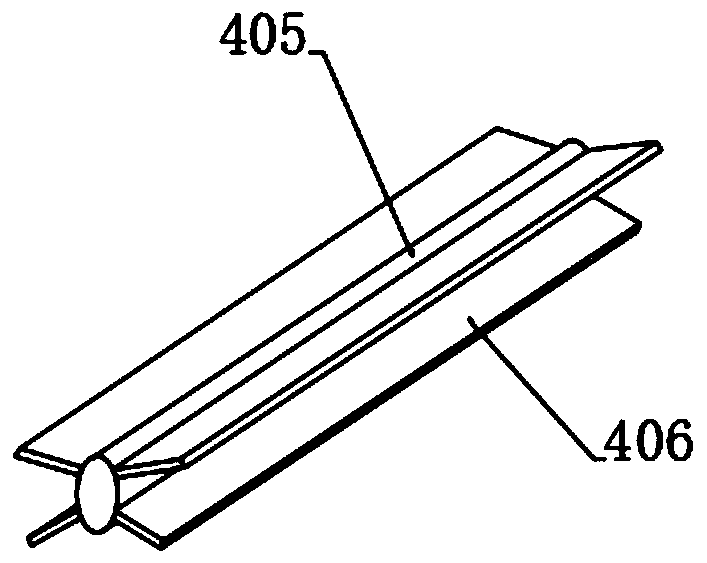

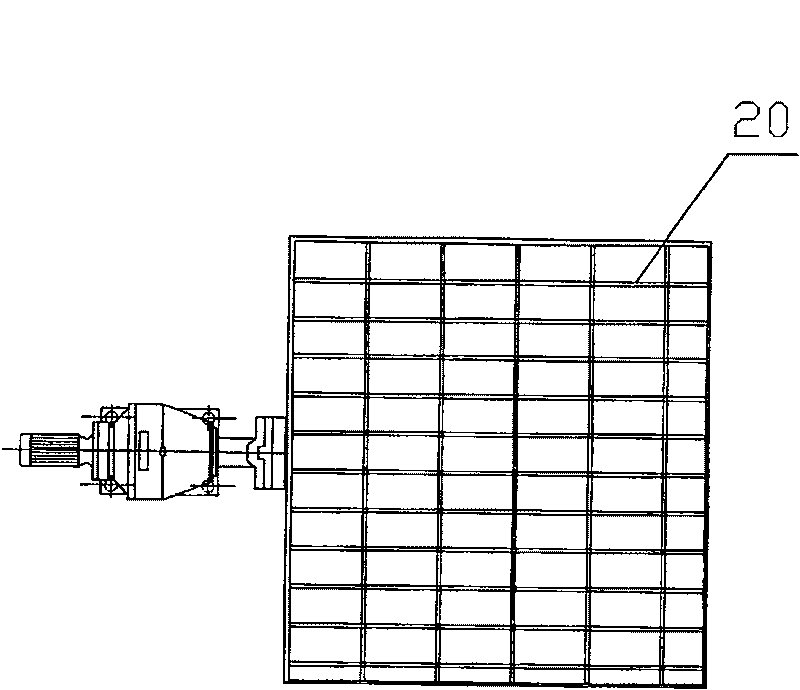

Efficient wet mixing device for vanadium-nitrogen alloy ball production

InactiveCN109092118AExpand the spraying rangeIncrease productivityRotary stirring mixersTransportation and packagingNitrogenEngineering

The invention discloses an efficient wet mixing device for vanadium-nitrogen alloy ball production. The device comprises a box body housing, one side of the box body housing is provided with a drivingmotor, one end of the driving motor is provided with a spiral stirring shaft, a connecting pipe penetrates through the upper end of the box body housing, a spraying pipe is arranged at the lower endof the connecting pipe, atomizing nozzles are symmetrically arranged on the two sides of the spraying pipe, a first bearing is arranged on the inner wall of the upper end of the connecting pipe, a liquid outlet pipe is sleeved with the first bearing, a flow meter is arranged in the liquid outlet pipe, a liquid storage box is communicated with the end, away from the connecting pipe, of the liquid discharging pipe, a liquid inlet pipe is connected with the other side of the liquid storage box, a first gear is arranged on the outer wall of the upper end of the connecting pipe, and a feeding hopper is arranged on the part, located on one side of the connecting pipe, of the upper end of the box body housing. The device has the advantages of simple structure, easy operation, wider liquid raw material spraying range and higher production efficiency, the use of the device is convenient and ingenious, and the device is suitable for wide popularization.

Owner:吴志锋

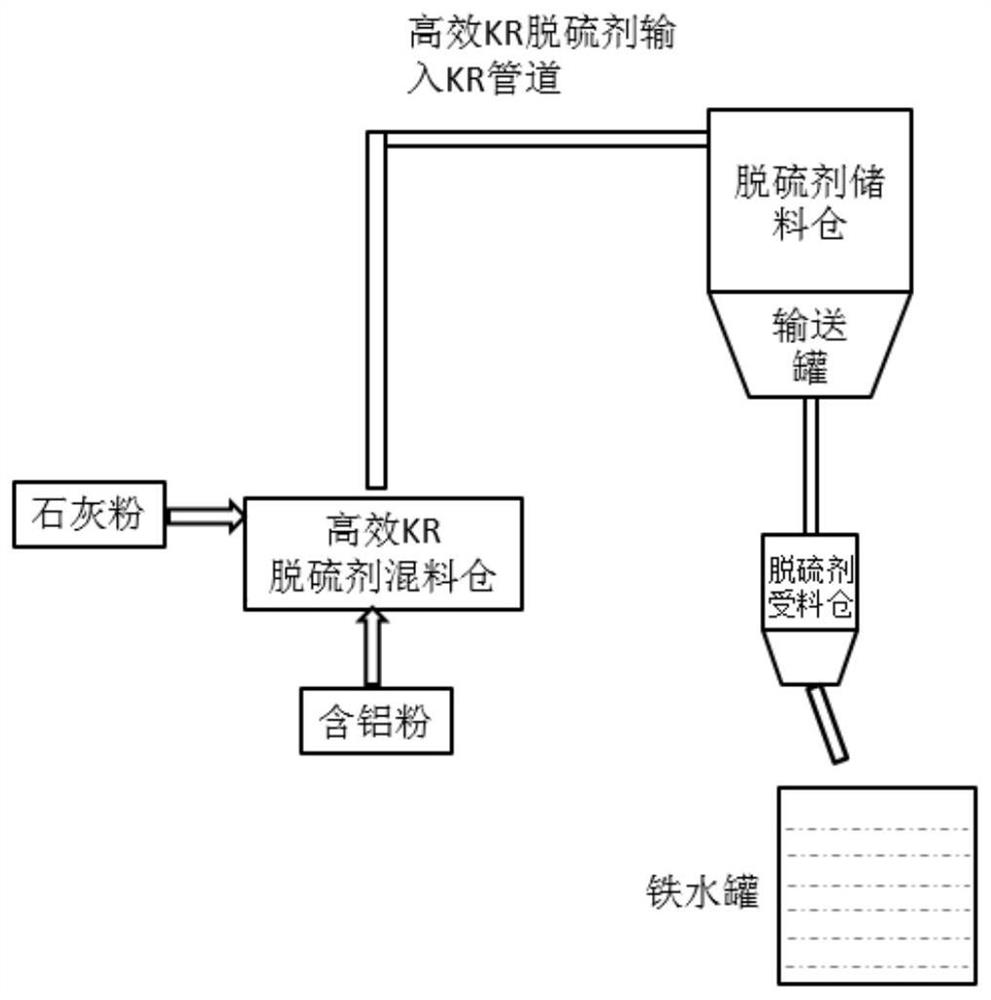

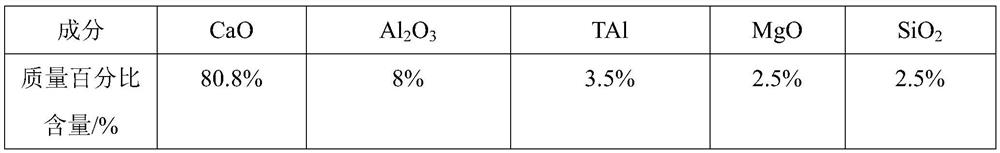

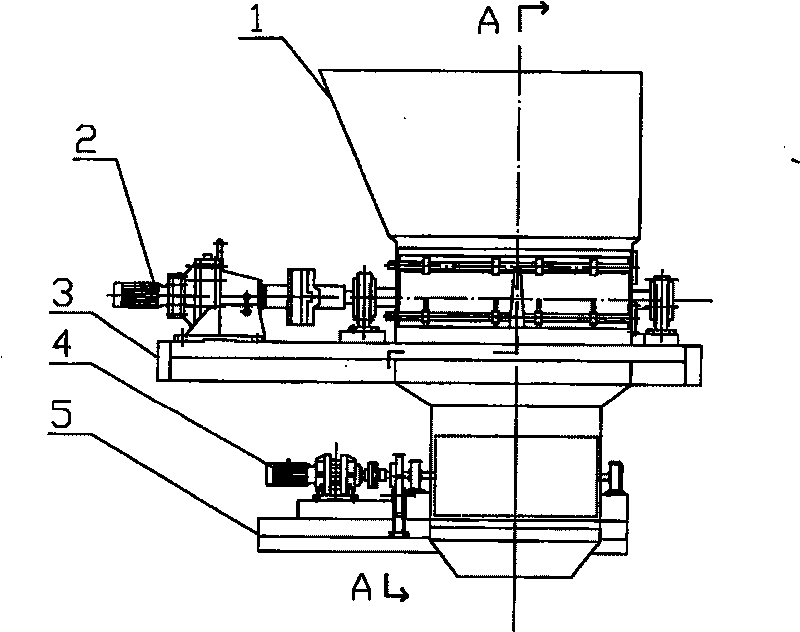

Efficient KR desulfurizer and preparation method and use method thereof

The invention provides a high-efficiency KR desulfurizer as well as a preparation method and a use method thereof. The high-efficiency KR desulfurizer comprises the following components: CaO powder and aluminum-containing powder in a mass ratio of (8-9): (2-1). Compared with the prior art, the preparation method changes the proportion of powder in the lime desulfurizing agent and increases part of aluminum-containing powder; therefore, the reaction activity of lime in molten iron is improved, the reaction area of the lime and the molten iron is increased, and the desulfurization efficiency is improved; and CaF2 in the desulfurizing agent is removed such that fluorine pollution generated by desulfurization residues is avoided, and the using effect of the desulfurizing agent is not reduced; in addition, the method is simple in product material, easy to implement and low in cost. By adopting the desulfurizing agent disclosed by the invention, the desulfurization rate can stably reach 93% or above, and the content of S in molten iron subjected to desulfurization treatment can be stably controlled to be less than or equal to 0.001%.

Owner:MAANSHAN IRON & STEEL CO LTD

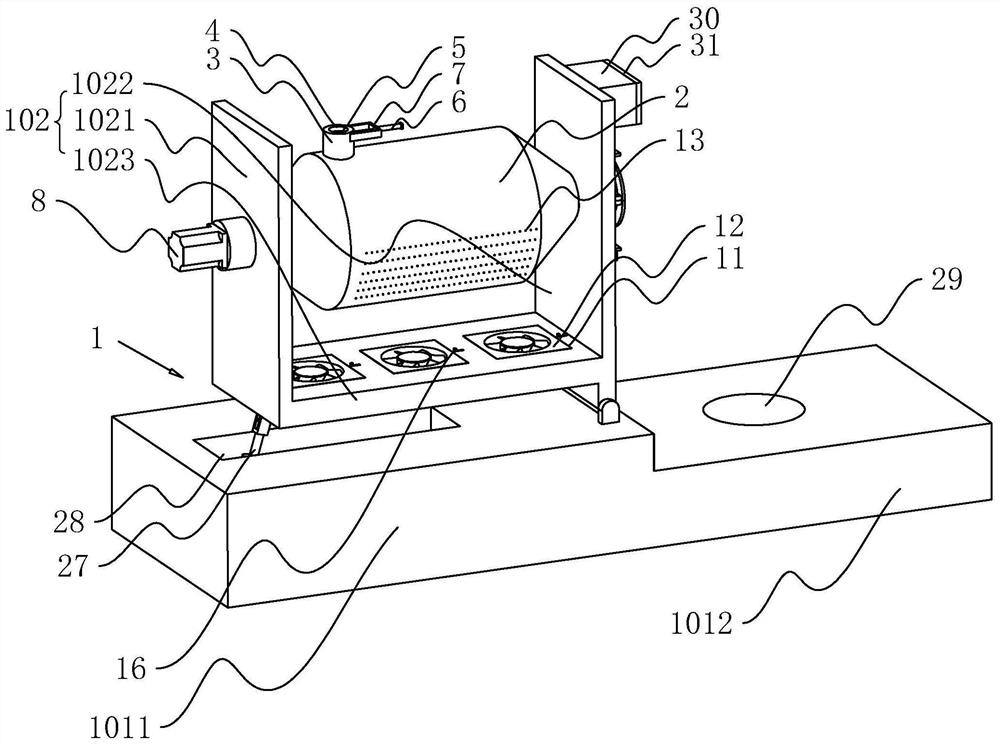

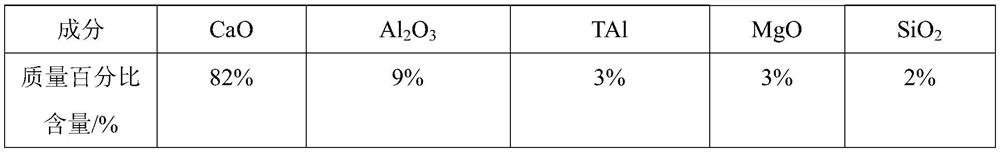

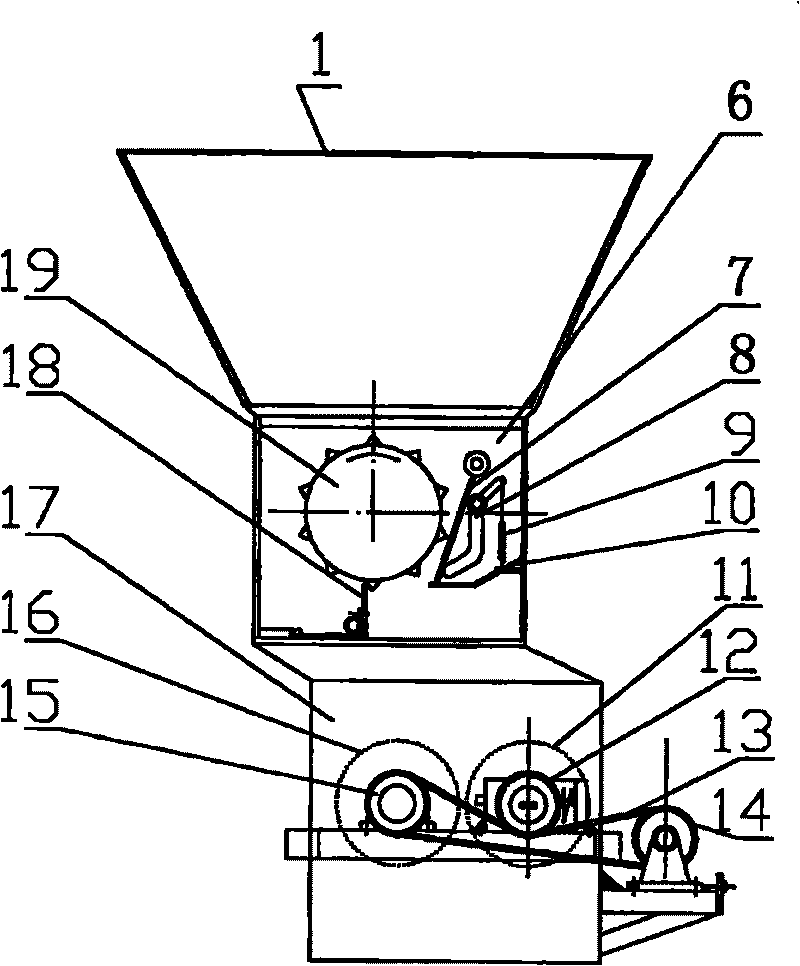

Sludge crushing feeder

The invention discloses a sludge crushing feeder, which comprises a hopper, a feeding part and a crushing part which are arranged from the top down, wherein, the feeding part comprises a feed box, a feeding part stander and a feed roller which is arranged inside the feed box; the crushing part comprises a crushing hopper, a crushing part stander and a crushing roller set which is arranged inside the crushing hopper; and the feed roller and the crushing roller set are respectively connected with a drive unit which respectively drives the feed roller and the crushing roller set to rotate. The sludge crushing feeder changes the prior spiral feeding means and adopts a two-stage drum for feeding, thereby the phenomenon of sludge agglomeration is difficult to generate and sludge can be continuously and uniformly conveyed onto a mixing belt and can be completely uniformly mixed with mineral powder before sintering on the mixing belt. The sludge crushing feeder successfully solves the problemsof spherulization, cementation, equipment blockage and so on which are common during the mixing process of steel-making and iron-making sludge and the mineral powder before sintering.

Owner:唐承祯

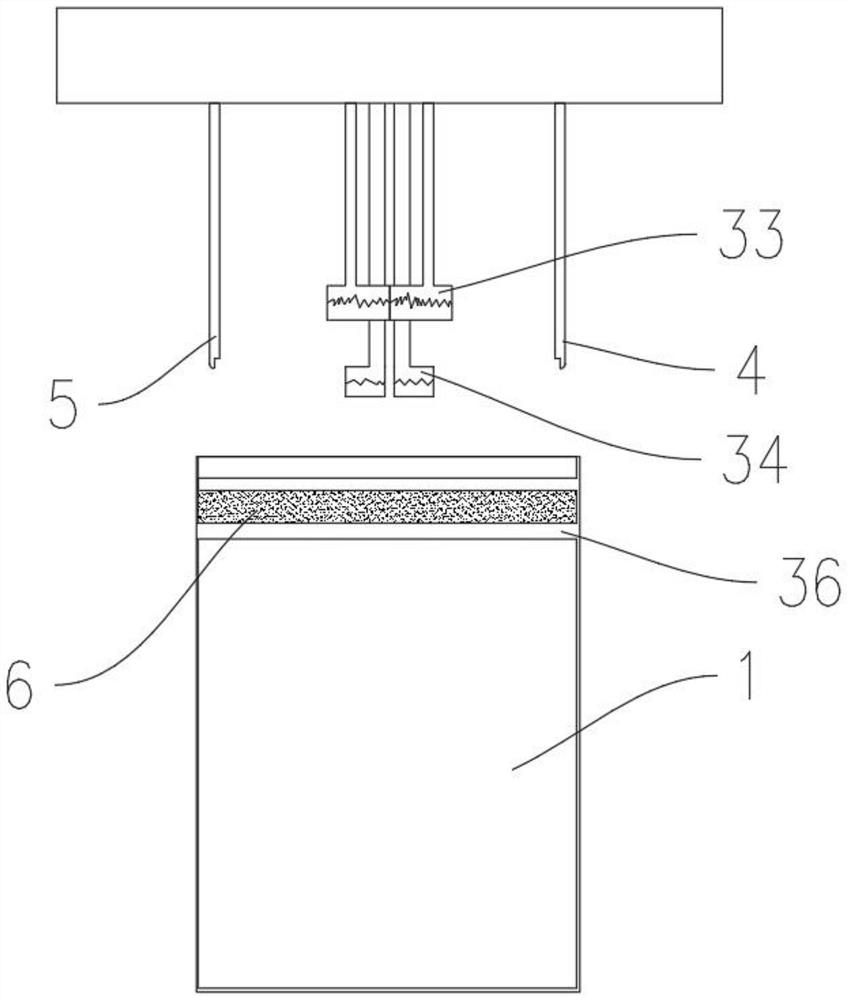

Bagged food powder not prone to caking and production equipment thereof

PendingCN113412925ASolve agglomerationEasy to agglomerateSugar food ingredientsBio-packagingPlastic packagingPotato starch

The invention discloses a bagged food powder not prone to caking and production equipment thereof, and the bagged food powder is characterized in that according to the formula of the food powder, aiming adjustment based on powder caking prevention is carried out, talcum powder and starch are added in the raw material and production steps of the powder, and granulation is carried out by adding the starch, the problems that ethyl maltol and iron generate chemical reaction in the machine, caking is prone to being generated, and the color can become dark red are effectively solved, secondly, in order to guarantee that powder is not prone to caking, production equipment is further designed, the bag opening of a food packaging bag with a unique opening is sealed, a double plastic packaging structure is designed, the interlayer cavity is filled with potato starch for moisture absorption, through the design that the hollow thermoplastic pipe and the hollow air suction pipe on the production equipment are matched with the plastic packaging chuck, double plastic packaging and potato starch filling are performed and it is further guaranteed that the food powder is not prone to caking in the conveying and storing process.

Owner:福建泉州味中皇食品有限公司

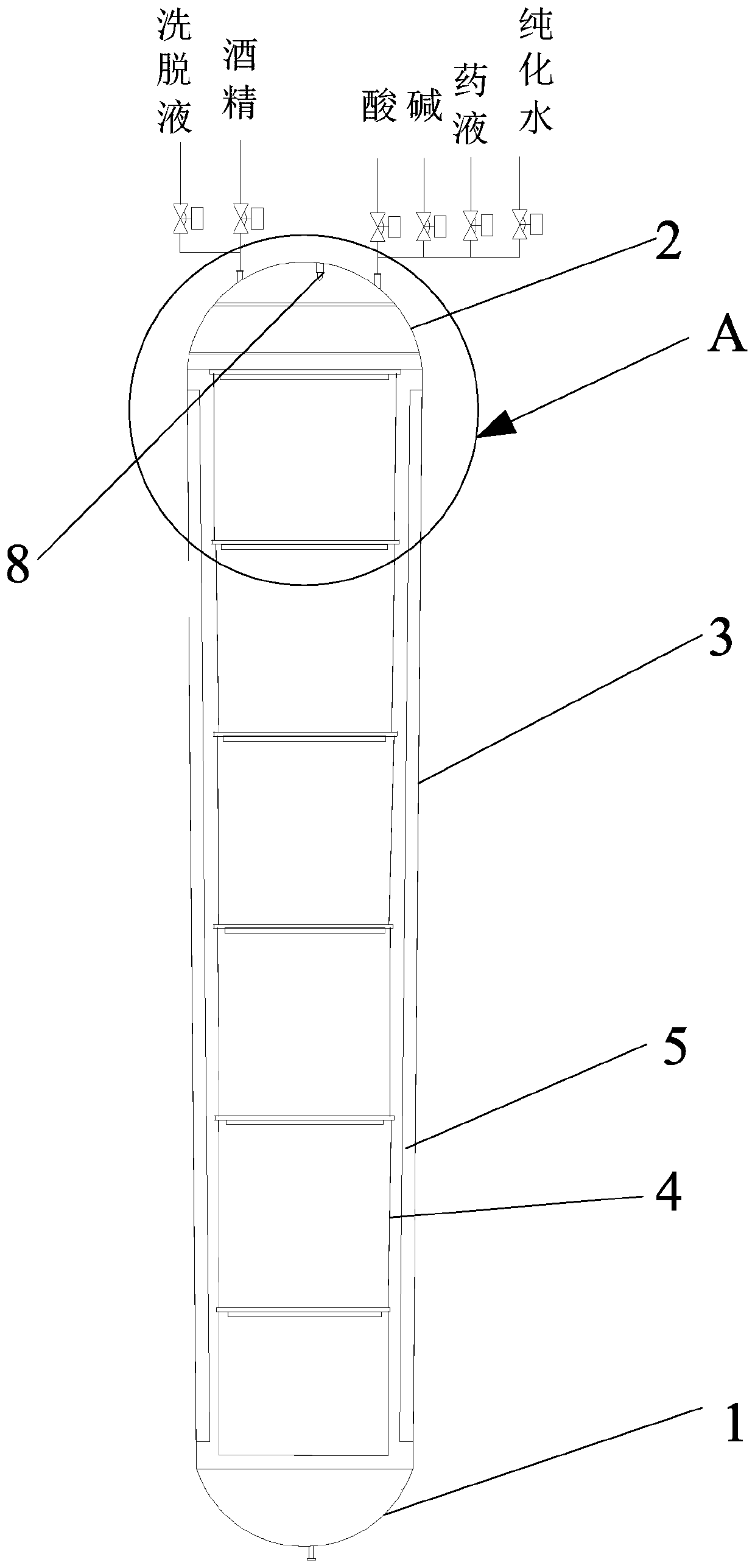

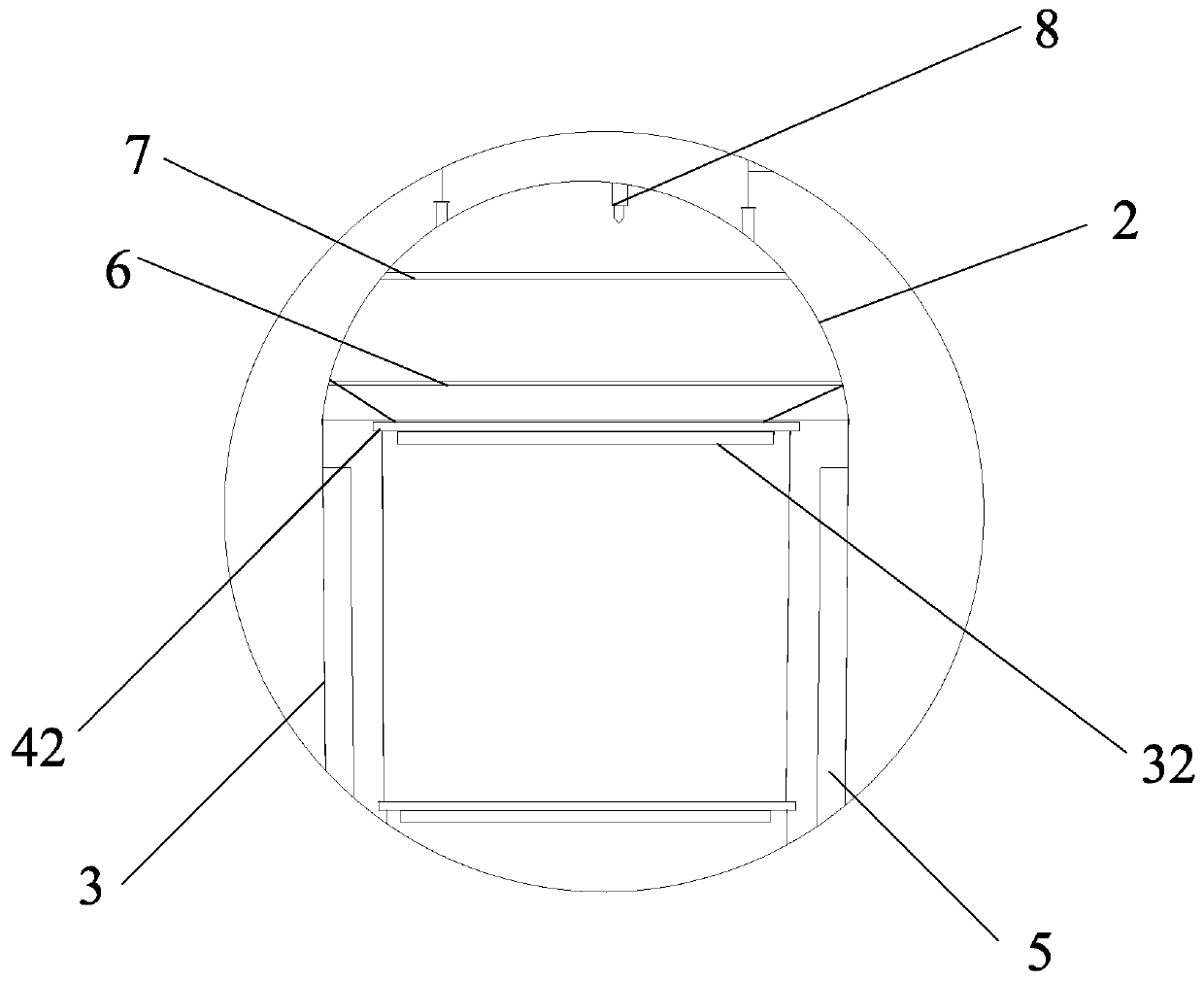

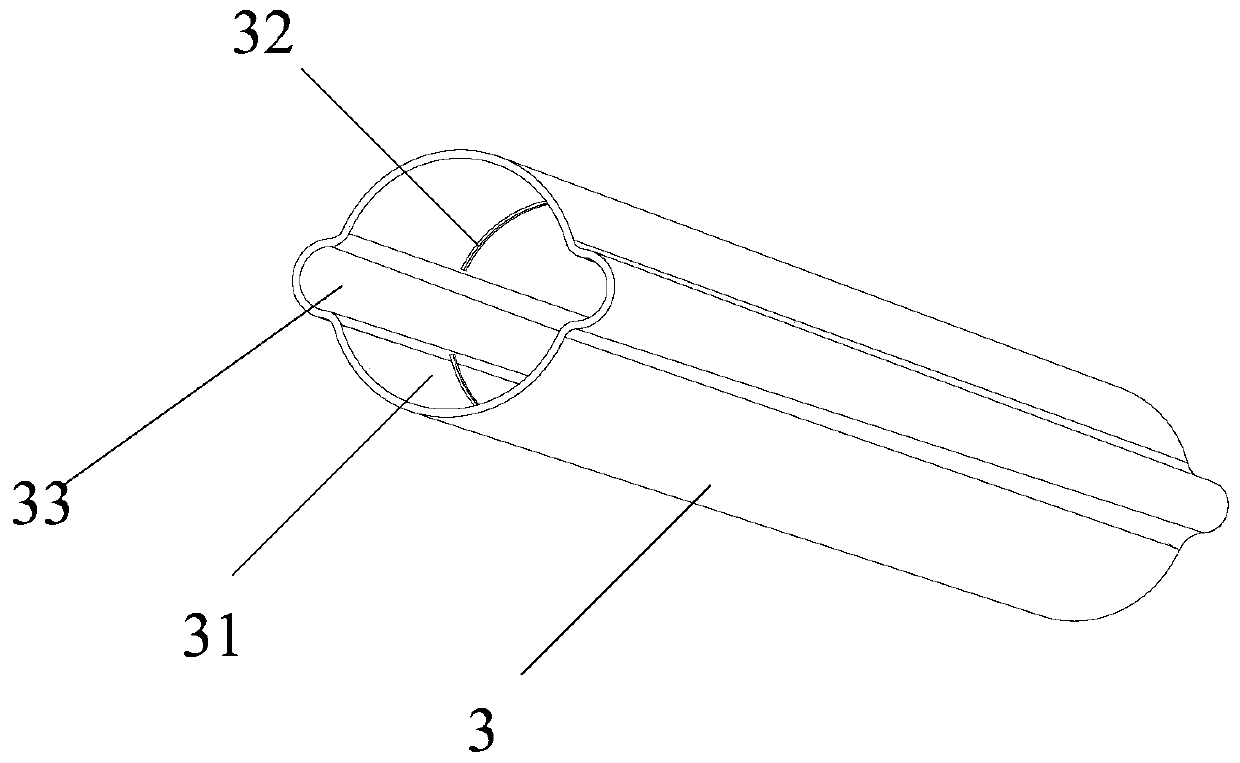

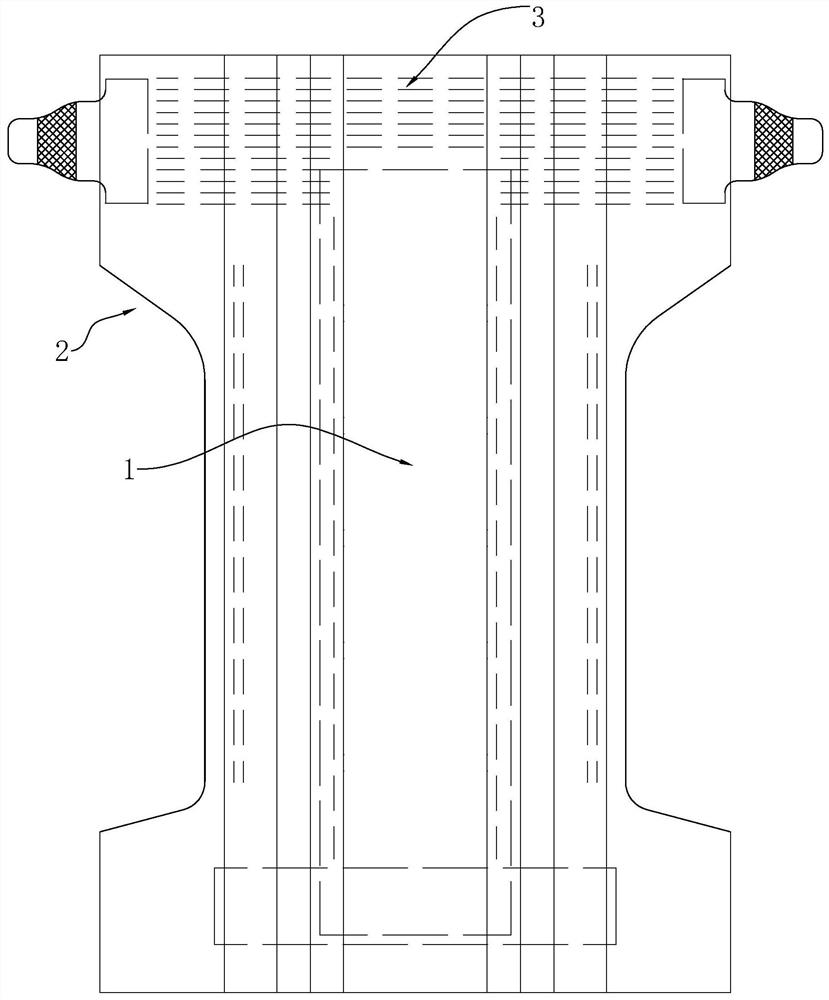

Multilayer resin chromatographic column

PendingCN111111263ANot prone to clumpingNot easy to happenSolid sorbent liquid separationPolymer sciencePolymer chemistry

The invention belongs to the technical field of chemical medicine extraction equipment, and particularly relates to a multilayer resin chromatographic column which comprises a columnar shell, an uppercover and a base, wherein a big-end-up conical resin column cavity is formed in the columnar shell, a plurality of horizontal arc convex strips are vertically distributed on the inner wall of the resin column cavity, a plurality of resin columns are mounted in the resin column cavity, the lower end faces of the resin columns are porous sieve plates, flanges are arranged at the upper ends of the resin columns, and the flanges are in lap joint with the convex strips to enable the resin columns to be mounted in the resin column cavity; the porous sieve plate of the resin column on the upper layer is butted into the resin column on the lower layer; and the outer diameter of the resin column on the lower layer is smaller than that of the resin column on the upper layer. A quite high resin column in the prior art is divided into a plurality of resin columns which are separated from one another and convenient to take and replace, the resin is not prone to caking or being crushed and damaged,it can be guaranteed that the resin in each layer of resin column is evenly filled, a resin column with inactivated or damaged resin can be flexibly replaced, and convenience and flexibility are achieved.

Owner:浙江天甘科技有限公司

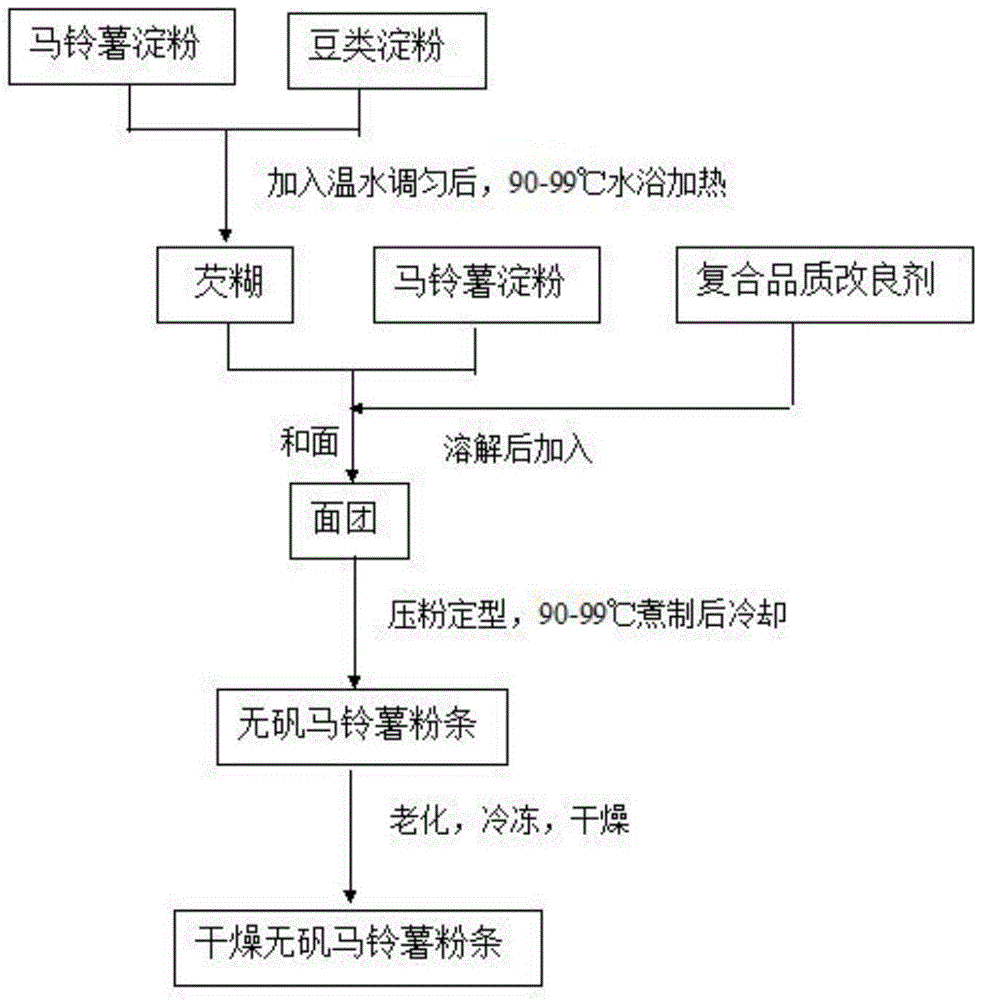

A kind of alum-free potato vermicelli and preparation method thereof

The invention discloses alum-free potato vermicelli and a preparation method thereof. The alum-free potato vermicelli is prepared from the following components in parts by weight: 70-110 parts of potato starch, 2-15 parts of bean starch, 40-70 parts of water and 0.2-13 parts of a compound quality modifying agent. The compound quality modifying agent comprises 0.1-5 parts of salt substance and 0.1-8 parts of protein powder; the salt substance can be NaCl, KCl or CaCl2; and the protein powder is one of vital gluten, whey powder, egg white powder and a yeast extract or a mixture thereof. The preparation method comprises the following steps: thickening with a mixture of starch and water; taking 2-15 parts of the potato starch to be mixed with the bean starch; adding warm water and agitating; heating in a water bath of 90-99 DEG C to obtain starch paste; kneading dough: mixing the residual potato starch, the compound quality modifying agent and the starch paste to knead the dough; and pressing powder and shaping: carrying out powder pressing on the obtained dough, and boiling with water and curing after the water powder pressing is carried out, wherein the water boiling temperature is 90-99 DEG C, and curing and cooling to obtain the alum-free potato vermicelli.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

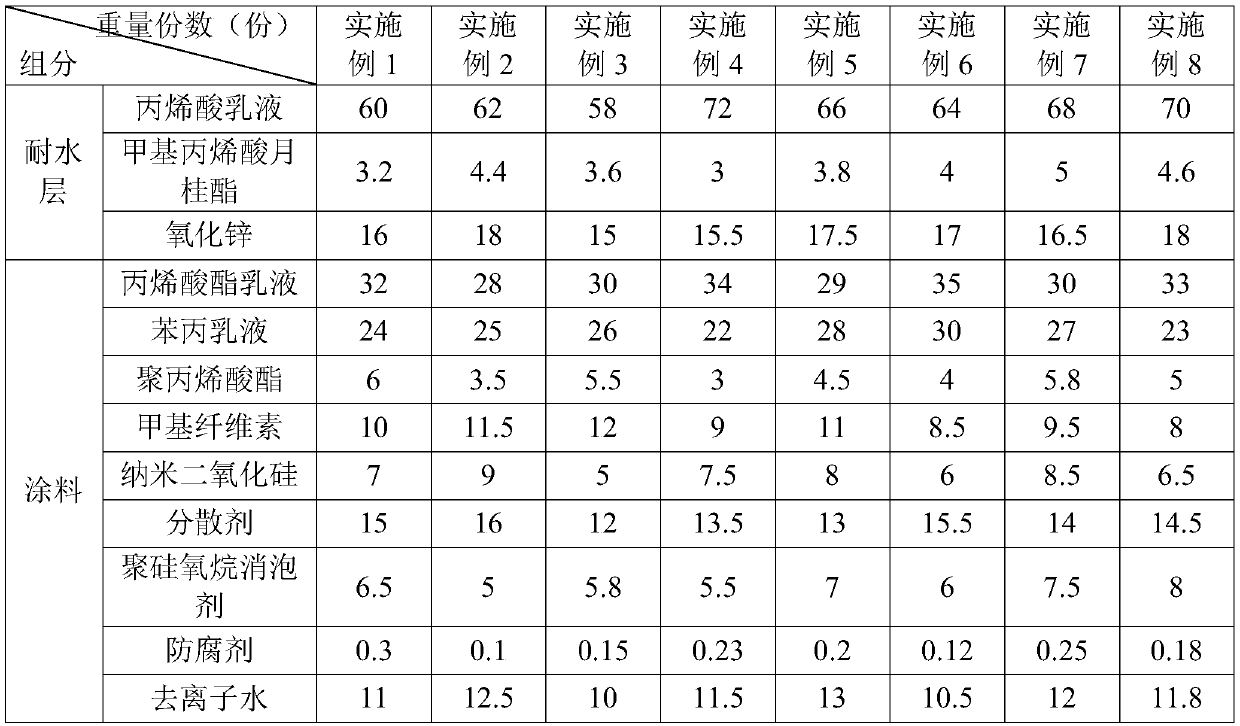

A kind of lightweight brick wall technology

InactiveCN107327147BGood scrub resistanceGood water permeabilityBuilding material handlingEmulsion paintsBrickSurface layer

The invention discloses a light brick wall building technology. The light brick wall building technology comprises the following steps that 1, mortar is applied to the surfaces of light bricks, the light bricks are built, and a light brick wall surface is formed; 2, an interface agent is coated on the surface of the light brick wall surface obtained in the step 1, then the surface of the light brick wall surface is enclosed with an anti-cracking strengthened net, a leveling layer is coated on the surface of the anti-cracking strengthened net, and a flat wall surface layer is formed; 3, a water resistant layer is evenly coated on the flat wall surface layer obtained in the step 2, and a water resistant wall surface layer is formed; and 4, a coating is coated on the water resistant wall surface layer obtained in the step 3, and a final wall surface is obtained. According to the light brick wall building technology, the wall surface has the advantages of being smooth and flat in surface and good in water permeability.

Owner:浙江康源装饰有限公司

A two-step method for preparing instant high molecular weight polyacrylamide

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

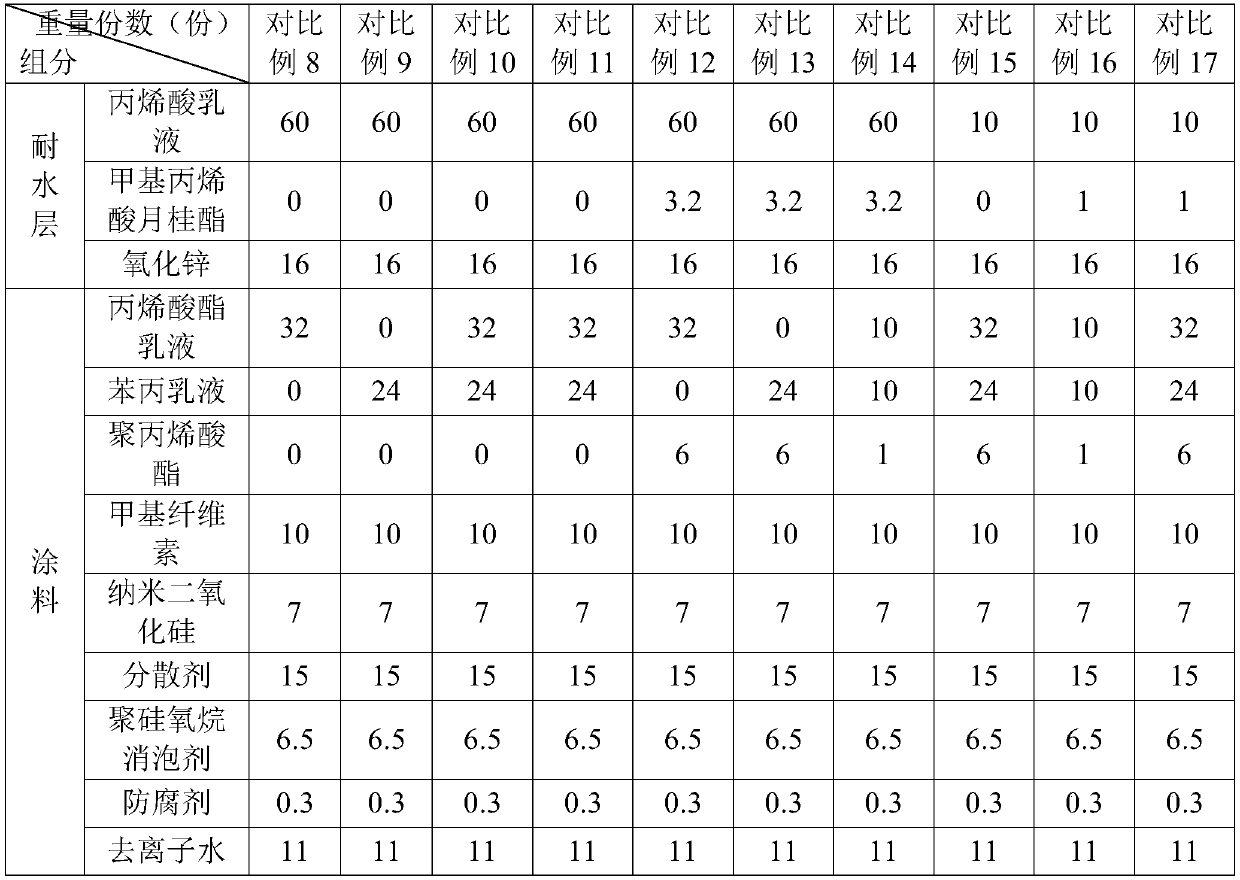

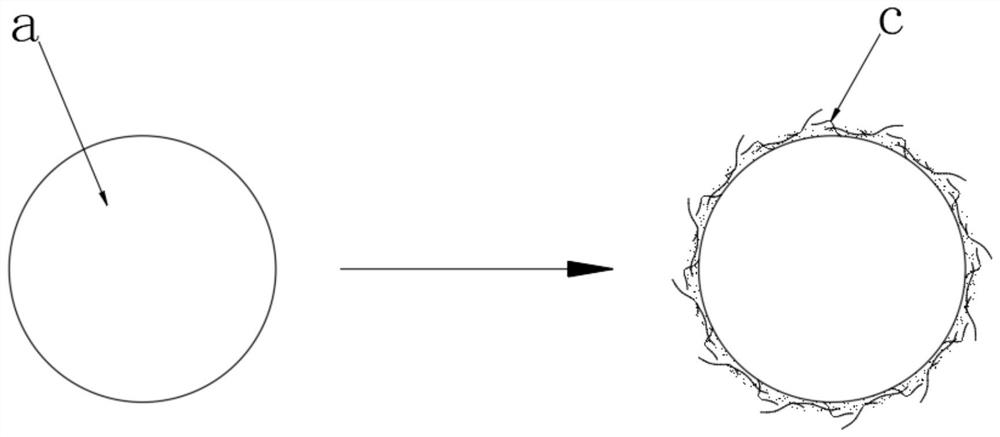

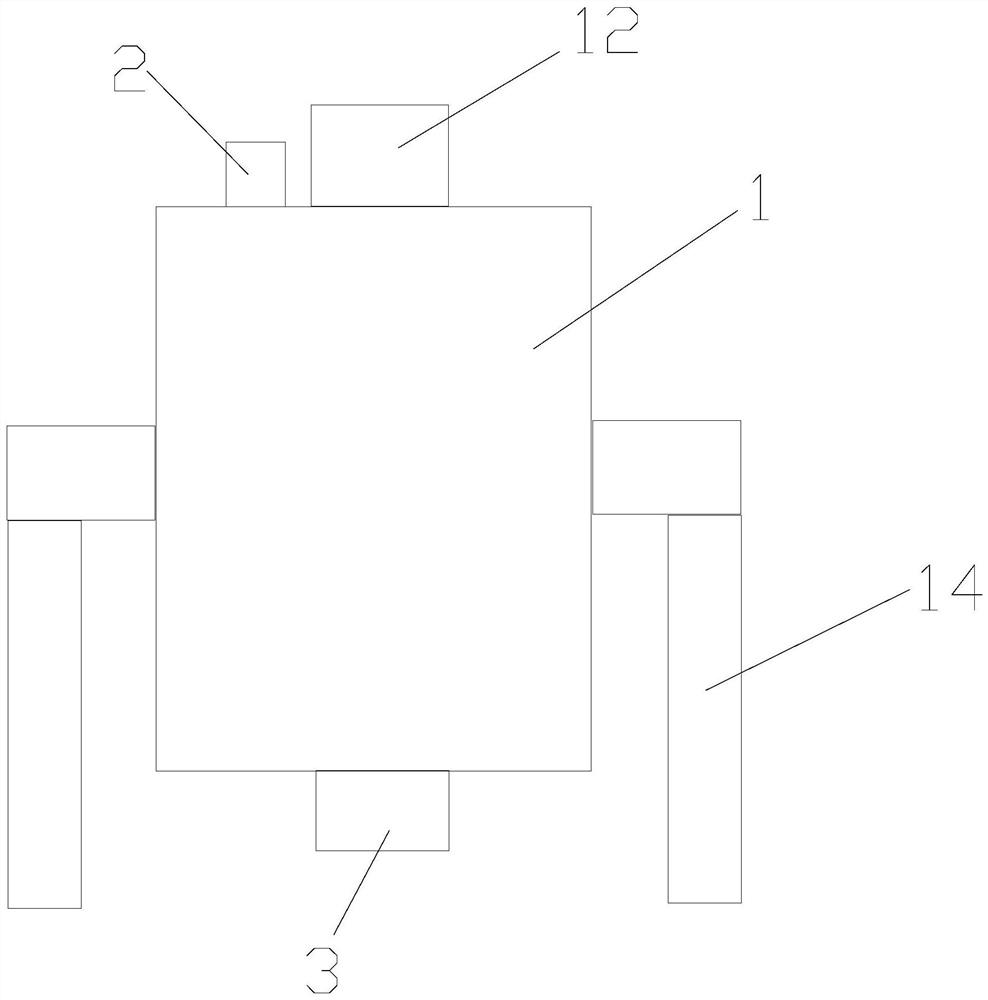

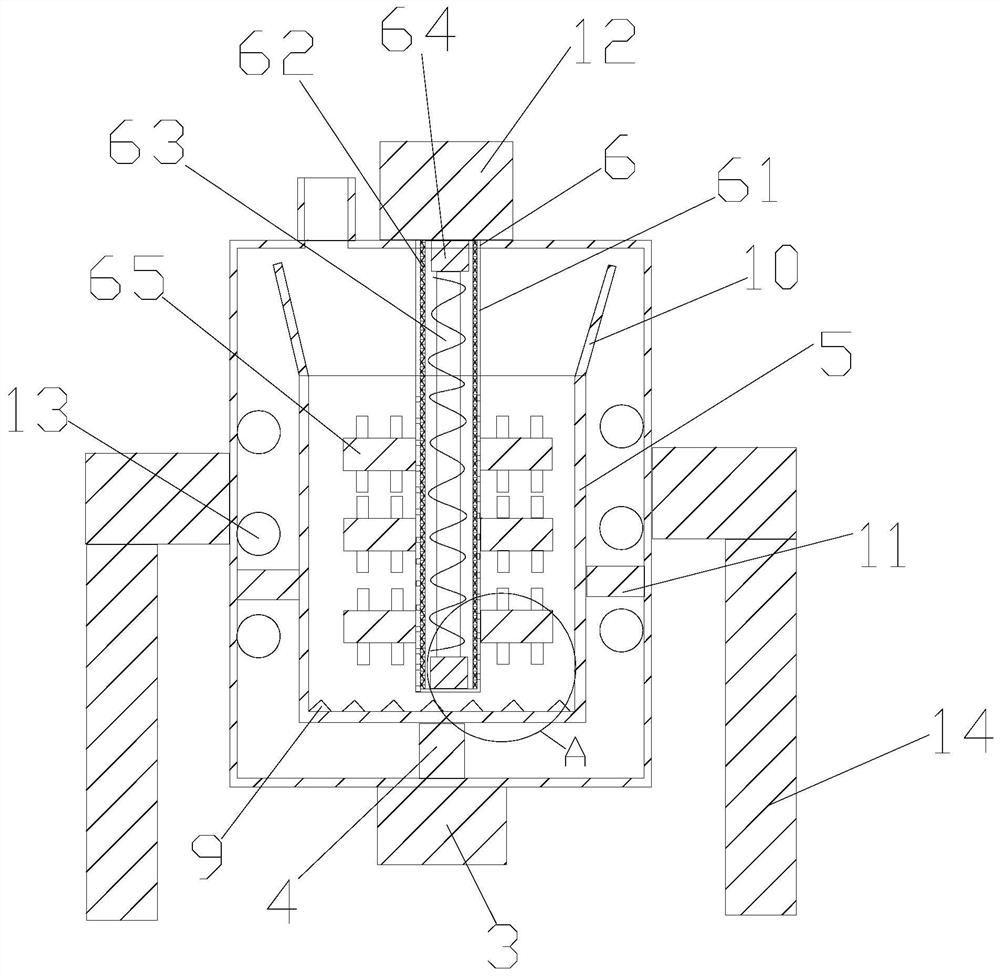

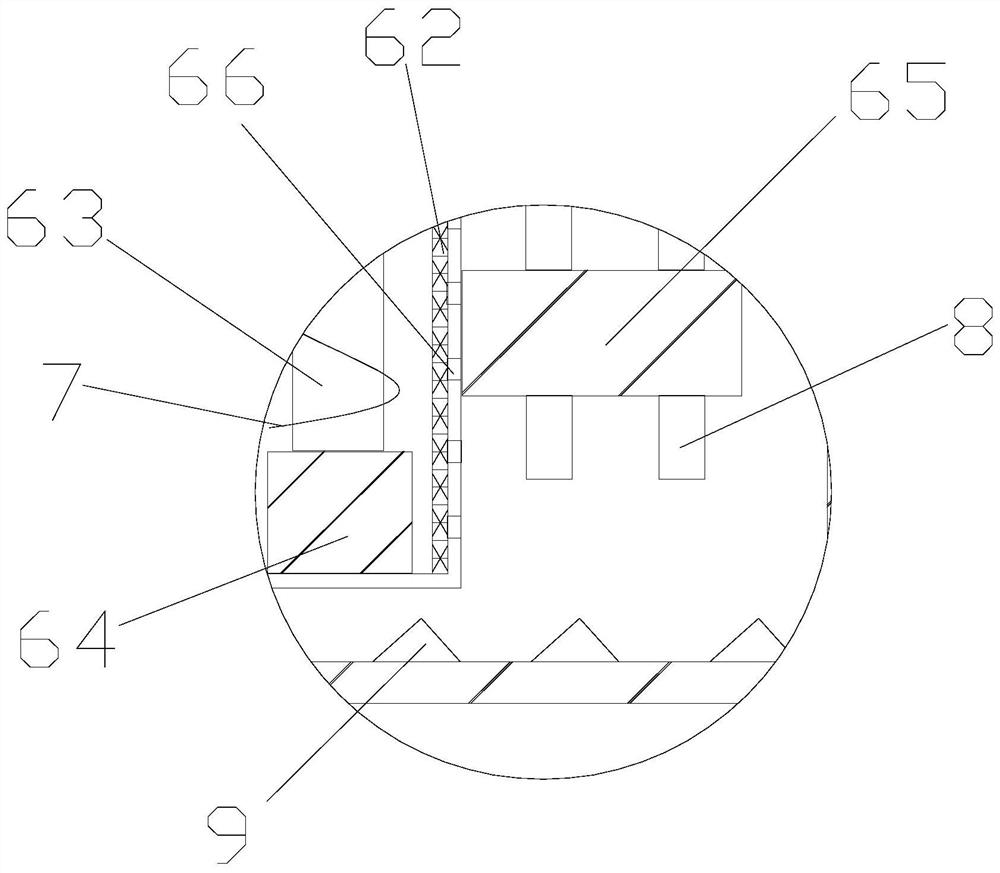

Low-caking-rate water-soluble organic fertilizer retreatment process

InactiveCN113354468ANot easy to affect water solubilityAvoid churnOrganic fertilisersSolid/semi-solid fertilisersFiberSoil science

The invention discloses a low-caking-rate water-soluble organic fertilizer retreatment process, and belongs to the field of organic fertilizers, the low-caking-rate water-soluble organic fertilizer retreatment process is characterized in that fertilizer granules are retreated, so that fiber ball nets are formed on the surfaces of the fertilizer granules, and the fiber ball nets can form isolation between every two adjacent fertilizer granules; two adjacent fertilizer granules do not touch each other under the barrier of the fiber ball net, compared with the prior art, when the water-soluble fertilizer absorbs moisture and is slightly soluble due to long-time storage or high environmental humidity, the water-soluble fertilizer is not prone to caking under the barrier of the fiber ball net, which can effectively guarante that the particle size of the fertilizer granules is not prone to large change under the slightly water-soluble condition, therefore, nutrient loss is effectively avoided, the situation that the application effect of the same number of fertilizer particles becomes poor is not prone to occurring, in addition, the fiber particles and the fiber rods are randomly distributed on the surfaces of the fertilizer particles in a disordered mode, gaps exist between the fiber particles and the fiber rods, and when the fiber net is used, the water solubility of the fiber net is not prone to being affected.

Owner:夏志全

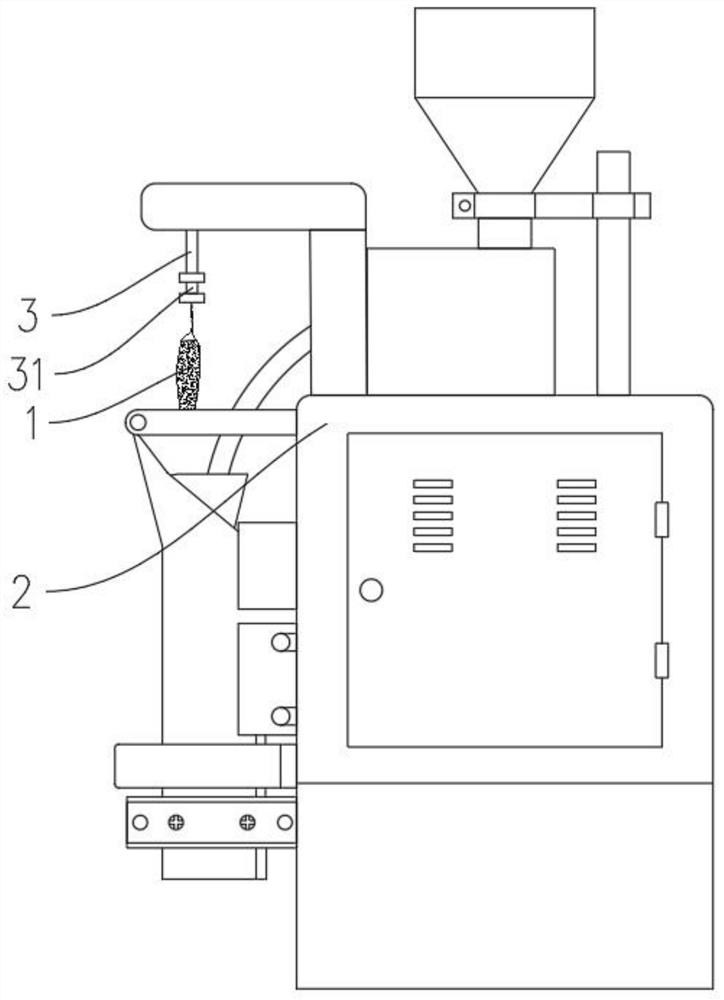

Device for extracting and drying cordycepin

InactiveCN113357894ADoes not affect extractionDry evenlyDrying machines with non-progressive movementsDrying solid materialsElectric machineCordyceps militaris

The invention discloses a device for extracting and drying cordycepin. The device is characterized in that a feeding pipe is located above a drying box; a motor is located below the drying box; one end of a rotating shaft is fixedly connected with the output end of the motor; the other end of the rotating shaft penetrates through the drying box and is fixedly connected with a fixing cylinder; a drying component is located in the fixing cylinder; a connecting pipe is located in the drying box; a plurality of heat dissipation holes are formed in the side wall of the connecting pipe; a fixing net plate is located on the inner wall of the connecting pipe; a heating column is located in the connecting pipe; the two ends of the heating column are fixedly connected with supporting brackets; and a plurality of fixing rods are located on the two side edges of the connecting pipe respectively. Through the structural design, the device for extracting and drying cordycepin can evenly dry cordyceps militaris, the caking phenomenon is not prone to occurring, and therefore the extracting effect of cordycepin cannot be affected.

Owner:江苏辰羽堂生物科技有限公司

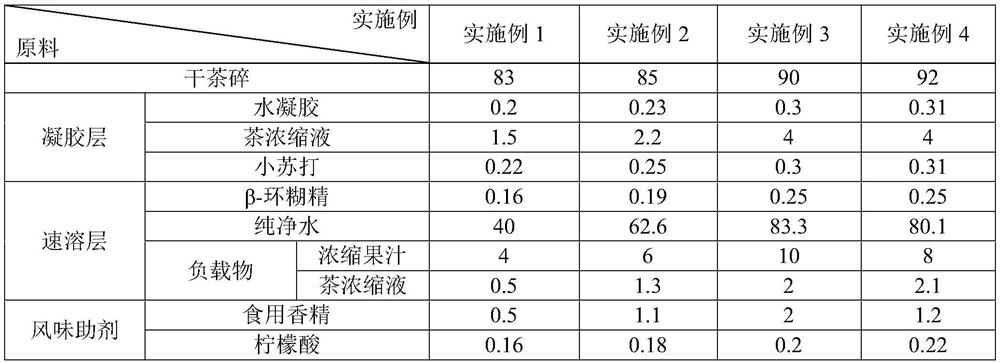

Cold brewing fruit tea and preparation method thereof

PendingCN114680209APromote decompositionPromote dissolutionPre-extraction tea treatmentTea extractionBiotechnologyFruit juice

The invention relates to the technical field of tea processing, and particularly discloses cold brewing fruit tea and a preparation method thereof. Wherein the cold-brewed fruit tea comprises dry broken tea particles and a flavor auxiliary agent, the dry broken tea particles are composed of dry broken tea, a gel layer and an instant layer, the gel layer and the instant layer wrap the outer surface of the dry broken tea, and the flavor auxiliary agent is a mixture formed by citric acid and edible essence or citric acid; the raw materials of the gel layer are hydrogel, a tea concentrated solution and baking soda; the instant layer is composed of a beta-cyclodextrin layer and a load loaded on the beta-cyclodextrin layer, the raw material of the beta-cyclodextrin layer is a beta-cyclodextrin aqueous solution with the concentration of 0.3-0.4 wt%, and the load comprises at least one of concentrated fruit juice and a tea concentrated solution; the size of the dry broken tea is 10-20 meshes; the water content of the cold-brewed fruit tea is lower than 13wt%. According to the cold-brewing tea disclosed by the invention, rich tea soup can be obtained only by short cold-brewing time.

Owner:杭州茗宝生物科技有限公司

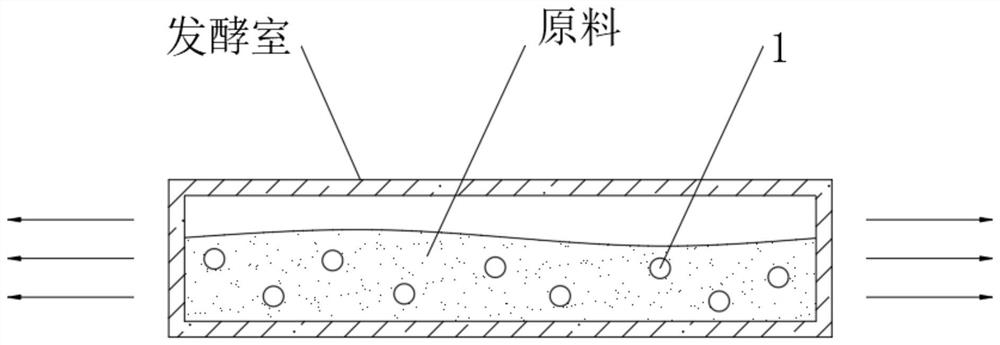

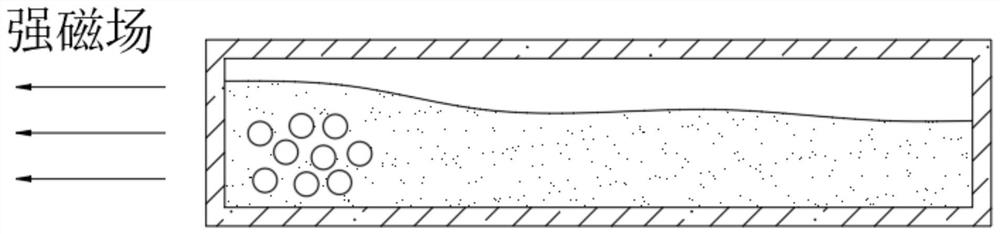

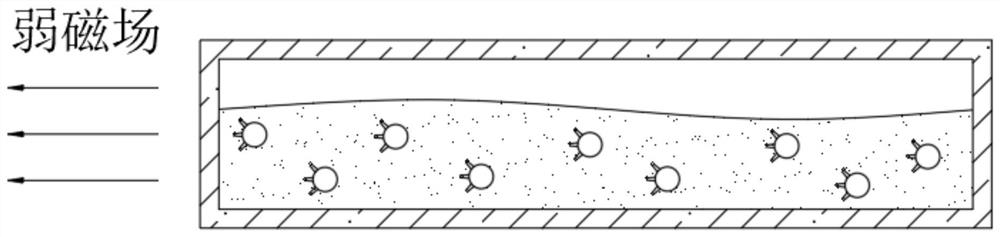

Dynamic fermentation method of organic feed

PendingCN113832001AImprove loosenessImprove distributionBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFodder

The invention discloses a dynamic fermentation method of an organic feed, and belongs to the technical field of organic feeds, in a manner of uniformly mixing fermentation-assisting balls in raw materials, magnetic fields with different intensities are applied in a fermentation process, and when a weak magnetic field is applied, fermentation-assisting balls do not migrate, but locally deform towards a direction of the magnetic field, the raw materials are locally loosened, a caking phenomenon is not prone to occurring, meanwhile, oxygen can be supplied in real time in multiple directions, when a strong magnetic field is applied, the fermentation assisting balls are locally deformed and migrated at the same time, and therefore the raw materials are wholly turned over, and a distribution situation of the raw materials in a fermentation chamber is further improved. Compared with the prior art, the method can loosen raw materials better and supply oxygen from the inside in real time, make the raw materials fully aerobic fermentation, and improve fermentation effect and molding quality of organic feed.

Owner:王伟波

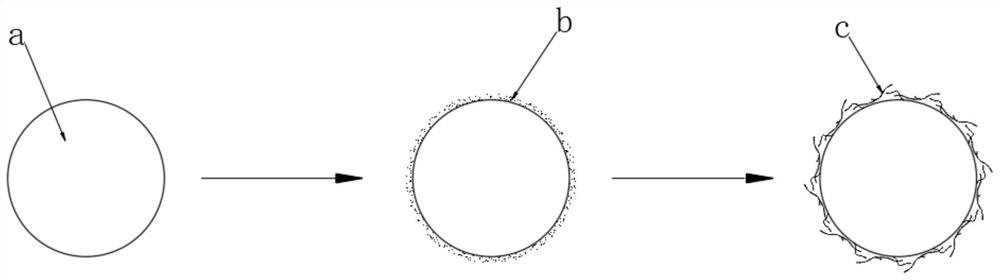

A two-step method for preparing instant cationic high molecular weight polyacrylamide

The invention discloses a method for preparing instant-soluble cationic high molecular weight polyacrylamide by a two-step method. The method comprises the following steps: (1) adding a dispersing agent to a reaction vessel containing a hydrocarbon solvent, and heating the materials to dissolve the dispersing agent; (2) adding 20 to 40% by mass of an acrylamide aqueous solution, a water-soluble initiator, and a cationic comonomer to the reaction vessel and stirring the materials to form a water-in-oil reaction system; (3) introducing nitrogen gas, and removing oxygen in the reaction system; (4) heating the reaction system to a reaction for a period of time to form primary particles of polyacrylamide; 5) adding an alcohol-water mixed solution to the reaction vessel, stirring the materials,and aggregating the primary particles of polyacrylamide to form solid particles similar to a grape bunch structure; and (6) heating and boiling to remove the alcohol and the aqueous solution, and obtaining the instant-soluble high molecular weight polyacrylamide solid. The polyacrylamide obtained by the two-step method has a faster dissolution rate when used, and is not easily agglomerated.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

Raw material pretreatment process for extracting vanadium by using vanadine

The invention discloses a raw material pretreatment process for extracting vanadium by using vanadine, and particularly relates to the technical field of vanadium extraction by using vanadine. The raw material pretreatment process comprises the steps of vanadine crushing, vanadium slag ball milling, iron removal treatment, auxiliary material addition, microcomputer batching and mixing and high-pressure balling. The vanadium is crushed, the vanadium slag is subjected to ball milling, the vanadium slag meets the qualified particle size requirement, in order to avoid dust flying, 4%-5% of water is added into a mixed material, materials can be wetted, the contact area between dressing and the vanadium slag is increased, and roasting is facilitated. According to the scheme, compared with a traditional pretreatment process, the problems of dust flying, raw material waste and serious pollution during vanadium slag processing are effectively solved, the auxiliary material is sodium salt, the materials and the sodium salt in a specified proportion are added with water and sodium carbonate for uniform mixing, waste liquid obtained after spraying of an absorption tower plays an energy-saving and environment-friendly role, so that the sodium salt is not prone to caking, the utilization rate of the sodium salt is increased, and the production cost is reduced, and applicability is achieved.

Owner:郧西九丰钒业投资有限公司

A two-step method for preparing instant anionic high molecular weight polyacrylamide

The invention discloses a method for preparing instant anionic high-molecular-weight polyacrylamide by a two-step method. The method comprises the following steps: (1) adding a dispersing agent into areaction kettle containing a hydrocarbon solvent, and heating to dissolve the dispersing agent; (2) adding 20-40% by mass of an acrylamide aqueous solution, a water-soluble initiator and a hydrolyticagent into a reaction kettle, and stirring to form a water-in-oil reaction system; (3) introducing nitrogen to remove oxygen in the reaction system; (4) heating the reaction system to react for a period of time to form polyacrylamide primary particles; hydrolyzing the primary particles; (5) dropwise adding an alcohol-water mixed solution into the reaction kettle, and stirring so that the polyacrylamide primary particles are aggregated to form solid particles similar to a'grape cluster 'structure; and (6) performing azeotropy to remove the alcohol and the aqueous solution to obtain the instantpolyacrylamide solid with high molecular weight. The polyacrylamide obtained by the two-step method has a fast dissolving speed in use and is not liable to cake.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

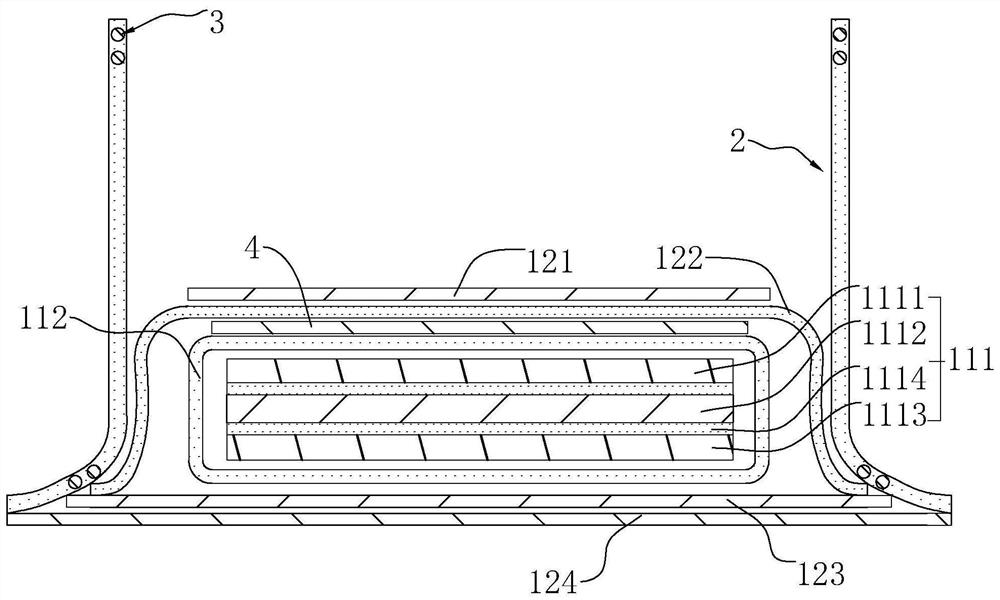

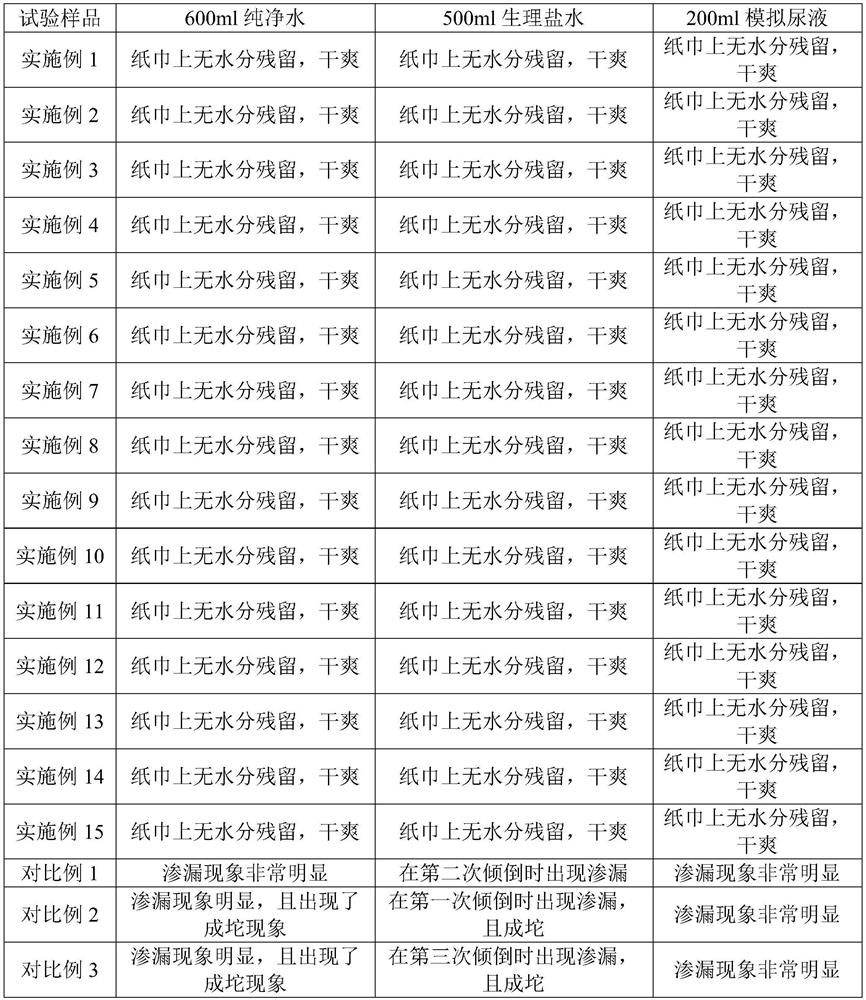

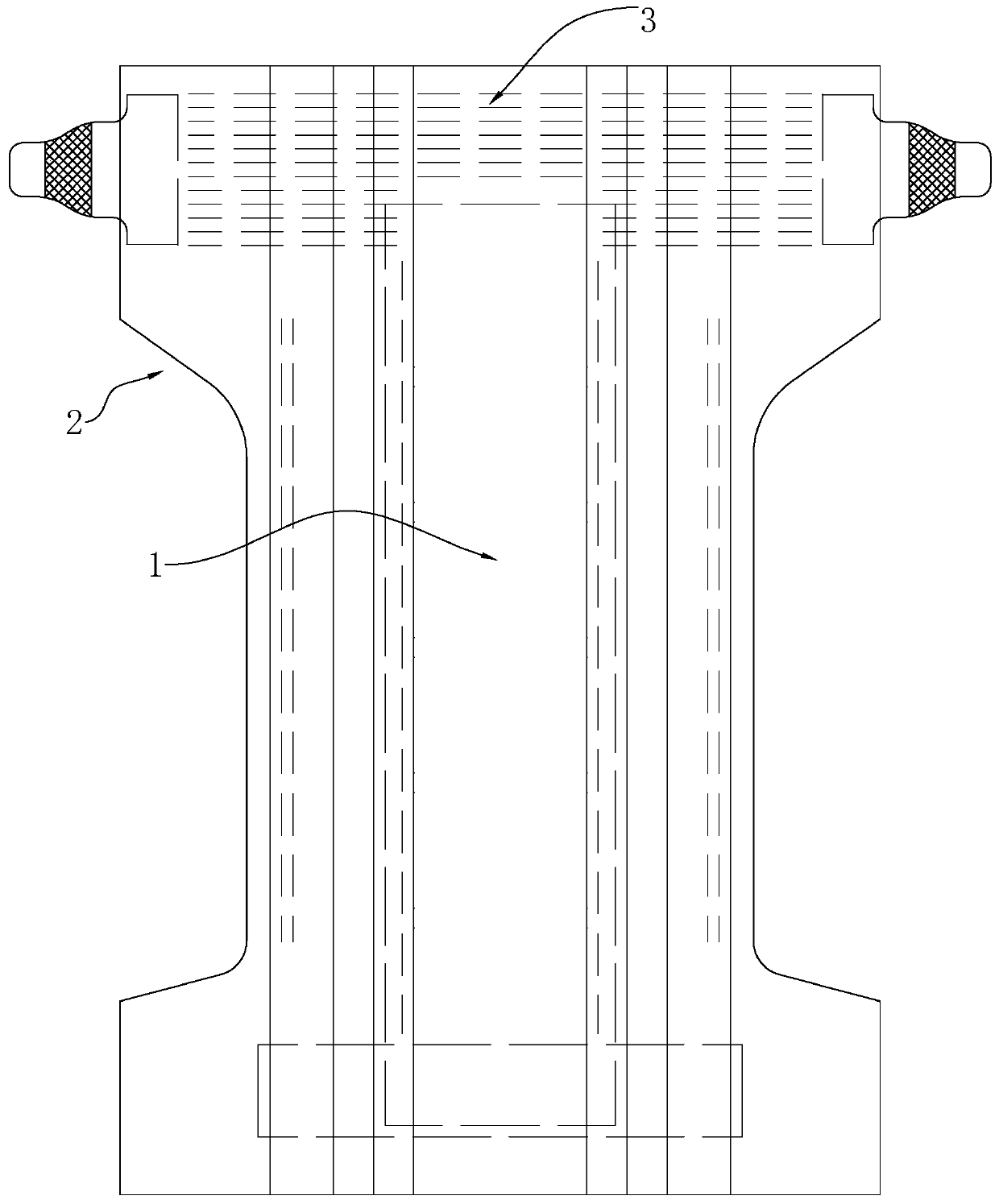

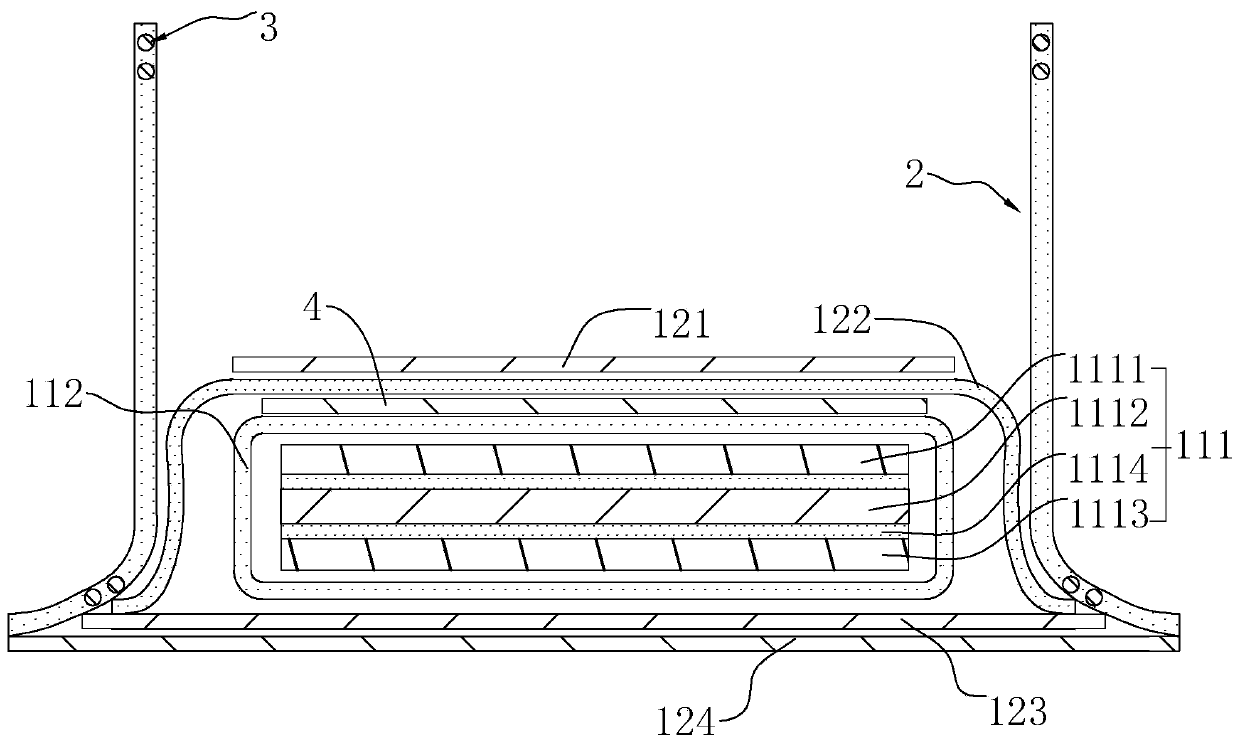

A dry and breathable paper diaper and its production process

ActiveCN110215350BImprove the liquid absorption effectBreathableAbsorbent padsBaby linensPolymer scienceEngineering

The invention discloses a dry and breathable diaper and its production process. The diaper comprises a diaper body, a composite core layer and a cladding structure coated on the outside of the composite core layer; The outer core of the inner layer is wrapped with non-woven fabric; the inner layer of the core includes the upper core air-permeable cloth, the middle fluffy fiber net, the lower core air-permeable cloth, between the upper non-woven fabric and the middle fluffy fiber net, the middle fluffy fiber net and the There is a layer of water-absorbing particles between the breathable cloth on the lower layer of the core; the covering structure includes the upper layer of non-woven fabric, the lower layer of non-woven fabric, the breathable waterproof membrane and the bottom layer of non-woven fabric, and the lower layer of non-woven fabric is bonded to the composite core layer. Then, the lower non-woven fabric is bonded to the breathable waterproof membrane, and the breathable waterproof membrane is bonded to the bottom non-woven fabric. The paper diaper has the advantages of good water absorption effect, dryness and breathability, and is not easy to cause the baby to have red buttocks.

Owner:杭州贝高母婴用品有限公司

Two-step method for preparing instant high molecular weight polyacrylamide

The invention discloses a two-step method for preparing instant high molecular weight polyacrylamide. The two-step method comprises the following steps: (1) adding a dispersing agent into a reaction still containing a hydrocarbon solvent, and heating so that the dispersing agent is dissolved; (2) adding 20% to 40% of acrylamide water solution in percentage by weight and a water-soluble initiator into the reaction still in the step one, stirring so that the water solution is dispersed into the hydrocarbon solvent, and thus forming a water-in-oil reaction system; (3) introducing nitrogen, and removing reaction liquid and oxygen inside the reaction still; (4) heating the reaction system until a reaction, and reacting for a period of time to form polyacrylamide primary particles; (5) dropwiseadding an alcohol-water mixed solution into the reaction still, stirring, and gathering the polyacrylamide primary particles by controlling the using amount of the alcohol-water mixed solution and theratio of alcohol to water so as to form solid particles of similar grape cluster structures; and (6) heating until boiling, and azeotropically removing the alcohol and water solution so that the instant polyacrylamide solid with high molecular weight can be obtained. The polyacrylamide obtained through the two-step method is relatively high in solution rate when in use, and is unlikely to cake.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

Edible refined salt and production method thereof

PendingCN112293721AReduce contact areaNot prone to clumpingFood sciencePotassium ferricyanideSalt water

The invention belongs to the technical field of edible refined salt preparation, and discloses edible refined salt and a production method thereof. The method comprises the following steps that S1, saturated edible salt water is prepared, 3-5 mg / kg of potassium ferrocyanide is added into the saturated edible salt water, high-speed mixing is conducted till potassium ferrocyanide is completely dissolved, and a mixed aqueous solution is obtained; S2, the mixed aqueous solution is taken as a raw material, and modified edible salt is prepared through an evaporative crystallization process; S3, drying, crushing, grinding and filtering are carried out on peels to obtain ultra-micro peel powder with the particle size of not more than 100 meshes; and S4, ultrasonic resonance mixing is performed onthe ultra-micro fruit peel powder and modified edible salt in proportion to obtain required edible refined salt. In conclusion, sodium chloride crystals are improved in advance by changing the addingmode of potassium ferrocyanide, so that the contact area between the crystals is effectively reduced, the crystals are not prone to caking, and the problem that the anti-caking effect is poor due to uneven mixing of the anti-caking agent is effectively solved.

Owner:重庆合川盐化工业有限公司

Dry, comfortable and breathable paper diaper and manufacturing technique thereof

ActiveCN110215350AImprove the liquid absorption effectBreathableAbsorbent padsBaby linensBiochemical engineeringNonwoven fabric

The invention discloses a dry, comfortable and breathable paper diaper and a manufacturing technique thereof. The paper diaper includes a paper diaper body, a composite core layer and a covering structure which covers the composite core layer; the composite core layer includes an inner layer of a core body and a covering nonwoven of the core body which covers the inner layer of the core body; theinner layer of the core body includes an upper breathable cloth of the core body, a middle fluffy fiber web and a lower breathable cloth of the core body, a water absorbing particle layer is arrangedbetween the upper breathable cloth of the core body and the middle fluffy fiber web, and a water absorbing particle layer is arranged between the middle fluffy fiber web and the lower breathable clothof the core body; the covering structure includes an upper covering nonwoven, a lower covering nonwoven, a breathable waterproof membrane and a base covering nonwoven, the lower covering nonwoven isbonded to the composite core layer, the lower covering nonwoven is bonded to the breathable waterproof membrane, and the breathable waterproof membrane is bonded to the base covering nonwoven. The paper diaper has the advantages of being good in water absorption effect, dry, breathable and not easy to cause red buttock phenomena of infants.

Owner:杭州贝高母婴用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com