Method for preparing instant-soluble cationic high molecular weight polyacrylamide by two-step method

A technology of polyacrylamide and high molecular weight, which is applied in the field of two-step preparation of instant cationic high molecular weight polyacrylamide, which can solve the problems of affecting the use effect, difficulty in dissolving, large dust, etc., and achieves not easy to agglomerate, large specific surface area , the effect of fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

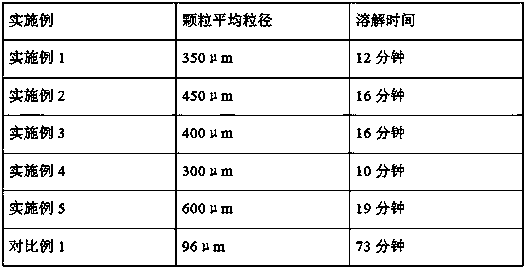

Embodiment 1

[0029] Add 300 g of cyclohexane into a 1 L four-neck flask, add 1.15 g of sorbitan monostearate and 1 g of sucrose fatty acid ester with an HLB value of 3, and heat until dissolved. Dissolve 95g of acrylamide and 0.8g of potassium persulfate in 200g of water in a beaker, and add them to a four-necked flask under a nitrogen atmosphere; add cationic comonomer DAC to the four-necked flask, and the amount of DAC is the mass of acrylamide monomer 20% of. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heat to 70°C, react for 2 hours, then raise the temperature to 75°C and keep for 1 hour. In another flask, add 20g of ethanol and 100g of water to form a mixed solution. The alcohol-water mixed solution was added dropwise into the four-neck flask, and the dropwise addition was completed within half an hour, and the stirring was continued for half an hour. Azeotropic removal of water yielded white solid particles with an average particle size...

Embodiment 2

[0031] Add 300g of n-hexane into a 1L four-neck flask, add 2g of hydrophobic nano-silica and 1g of diethylene glycol fatty acid ester, and heat until dissolved. Dissolve 95g of acrylamide and 0.8g of sodium persulfate in 200g of water in a beaker, and add them to a four-necked flask under a nitrogen atmosphere; add cationic comonomer DMC to the four-necked flask, and the amount of DMC is the mass of acrylamide monomer 30% of. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heat to 70°C, react for 2 hours, then raise the temperature to 75°C and keep for 1 hour. In another flask, add 6g of ethanol and 50g of water to form a mixed solution. The alcohol-water mixed solution was added dropwise into the four-neck flask, and the dropwise addition was completed within half an hour, and the stirring was continued for half an hour. Azeotropic removal of water yielded white solid particles with an average particle size of 450 μm.

Embodiment 3

[0033]Add 300 g of toluene into a 1 L four-neck flask, add 3 g of glyceryl monostearate, and heat until dissolved. Use a beaker to dissolve 95g of acrylamide and 0.8g of azobisisobutylimidazoline hydrochloride in 200g of water, and add it to a four-necked flask under a nitrogen atmosphere; add cationic comonomer dimethylaminomethylpropene to the four-necked flask Acyloxyethyltrimethylammonium chloride, the amount of dimethylaminomethacryloyloxyethyltrimethylammonium chloride is 45% of the mass of acrylamide monomer. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heat to 60°C, react for 2 hours, then raise the temperature to 75°C and keep for 1 hour. In another flask, add 10g of isopropanol and 100g of water to form a mixed solution. The alcohol-water mixed solution was added dropwise into the four-neck flask, and the dropwise addition was completed within half an hour, and the stirring was continued for half an hour. Azeotropic remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com