Low-caking-rate water-soluble organic fertilizer retreatment process

An organic fertilizer and reprocessing technology, applied to organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of low caking rate and loss, and achieve the effects of improving reprocessing efficiency, avoiding nutrient loss, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

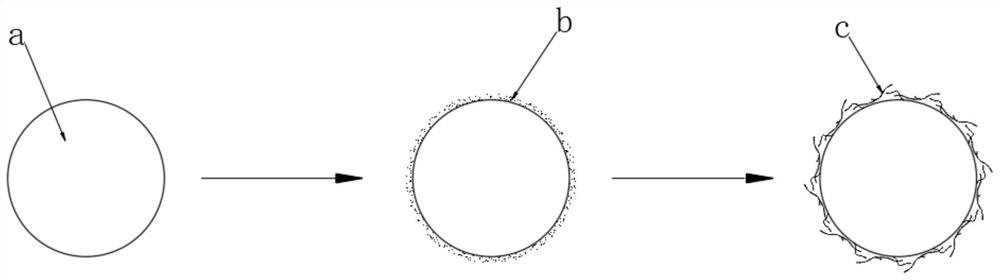

[0051] see figure 1 , in the figure, a represents fertilizer granules, b represents sprayed atomized water, and c represents fiber ball net, a water-soluble organic fertilizer reprocessing process with low caking rate, including the following steps:

[0052] S1. Water-soluble organic fertilizer raw materials are dispersed and dissolved, and then passed into a homogenizing pump and a grinding pump for dispersion, stirring, homogenization and emulsification to obtain raw material ultrafine particles, and then the ultrafine particles are granulated by a granulator to obtain fertilizer granules ;

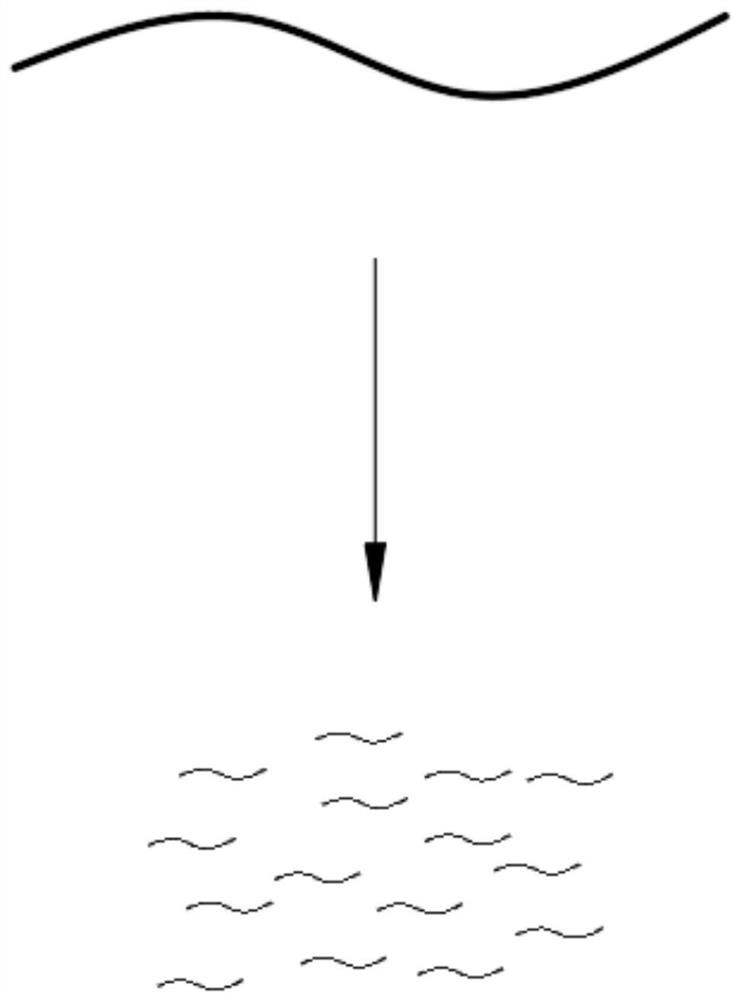

[0053] S2. Please refer to figure 2 , drying the plant fibers, and then crushing the plant fibers to obtain fiber particles for subsequent use;

[0054] S3. Spray atomized water on the surface of the fertilizer granules first, and then spray the fiber granules after 1-2 seconds, so that the fiber granules adhere to the surface of the fertilizer granules and form a fiber ball net. Und...

Embodiment 2

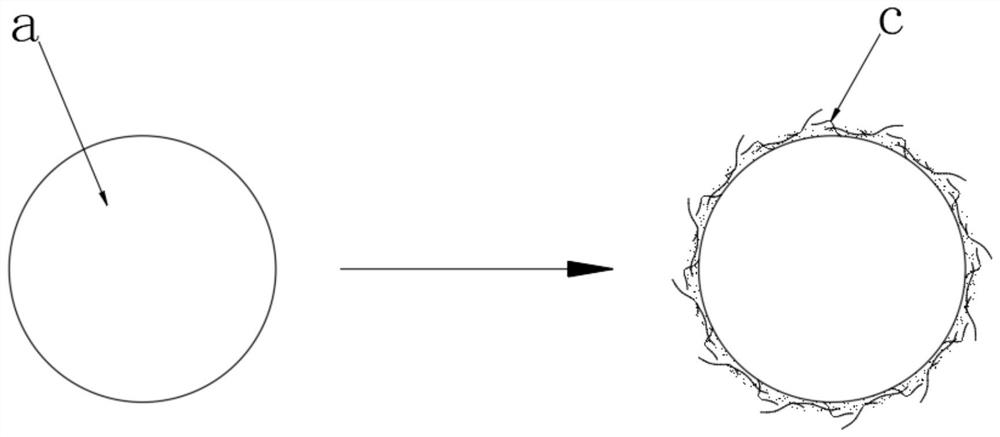

[0057] see image 3 , a water-soluble organic fertilizer reprocessing process with low caking rate, comprising the following steps:

[0058] S1. Water-soluble organic fertilizer raw materials are dispersed and dissolved, and then passed into a homogenizing pump and a grinding pump for dispersion, stirring, homogenization and emulsification to obtain raw material ultrafine particles, and then the ultrafine particles are granulated by a granulator to obtain fertilizer granules ;

[0059] S2, drying the plant fiber, then crushing the plant fiber to obtain fiber particles for later use, and magnetizing the fiber particles by applying an external magnetic field;

[0060] S3. Spray the fiber particles and atomized water on the surface of the fertilizer particles, so that the fiber particles adhere to the surface of the fertilizer particles, and form a mutually adsorbed fiber ball net. Adhered to the surface of cellulose particles;

[0061] S4, drying to solidify the water-soluble...

Embodiment 3

[0064] A water-soluble organic fertilizer reprocessing process with low caking rate comprises the following steps:

[0065] S1. Water-soluble organic fertilizer raw materials are dispersed and dissolved, and then passed into a homogenizing pump and a grinding pump for dispersion, stirring, homogenization and emulsification to obtain raw material ultrafine particles, and then the ultrafine particles are granulated by a granulator to obtain fertilizer granules ;

[0066] S2, drying the plant fibers, and then crushing the plant fibers to obtain fiber particles for subsequent use;

[0067] S3, first spray the atomized water-soluble film to form a water-soluble film layer on the surface of the fertilizer granules, and then spray the fiber granules on the surface of the fertilizer granules to make the fiber particles adhere to the surface of the water-soluble film layer and form a fiber ball net;

[0068] S4, drying to solidify the water-soluble film layer on the surface of the fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com