A kind of lightweight brick wall technology

A light-weight brick and wall-building technology, which is applied in the direction of coating, latex paint, and building materials, can solve the problems that the wall surface cannot meet consumers' pursuit of home decoration aesthetics, water seepage, etc., so as to improve the connection effect and increase the durability. Scrubbing, water seepage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: a kind of lightweight brick wall technology, comprises the steps:

[0057] S1, apply mortar to the surface of lightweight bricks and build lightweight bricks to form lightweight brick walls;

[0058] S2, the surface of the lightweight brick wall obtained in step S1 is coated with an interface agent, and then an anti-crack reinforcement net is attached, and the surface of the anti-crack reinforcement net is coated with a 3-layer leveling layer, and the thickness of each leveling layer 10mm, forming a flat wall layer;

[0059] S3, the flat wall surface layer obtained in step S2 is evenly coated with a water-resistant layer, and the thickness of the water-resistant layer is 2.2mm, forming a water-resistant wall surface layer;

[0060] S4, two layers of paint are coated on the surface of the water-resistant wall surface layer obtained in step S3, and the thickness of each layer of coating is 1.1mm, obtained.

[0061] The components of the water-resistant layer...

Embodiment 2-8

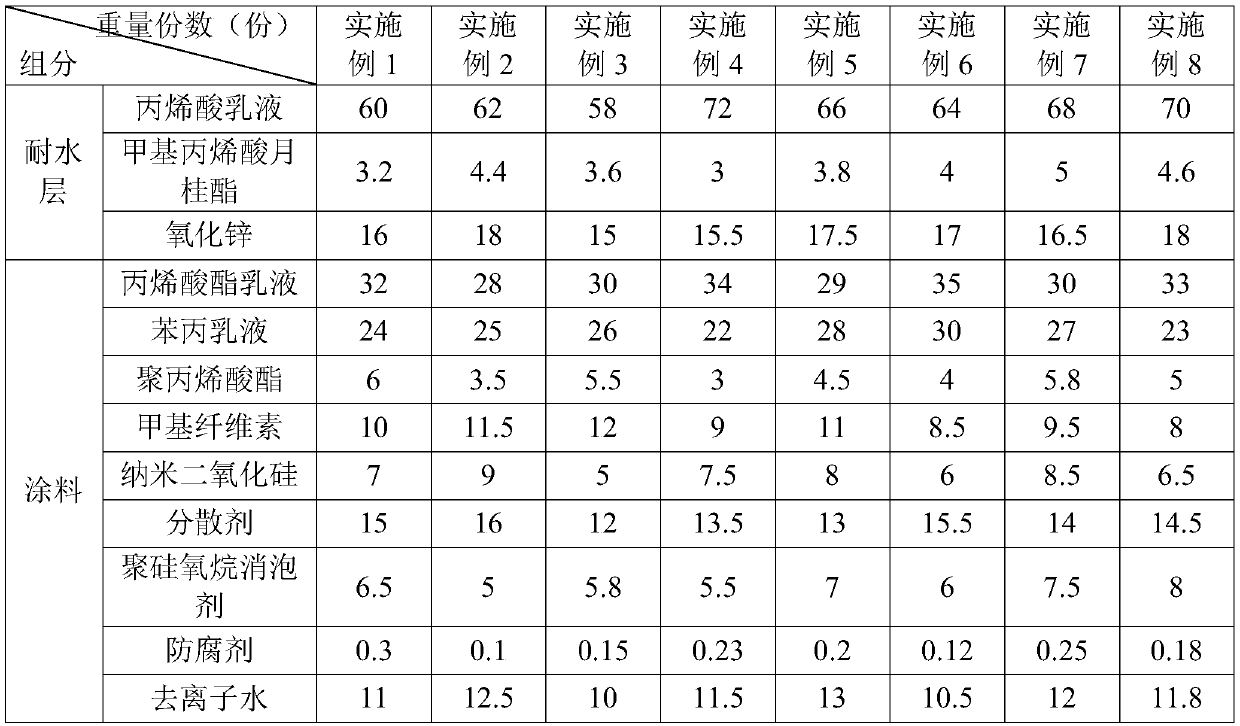

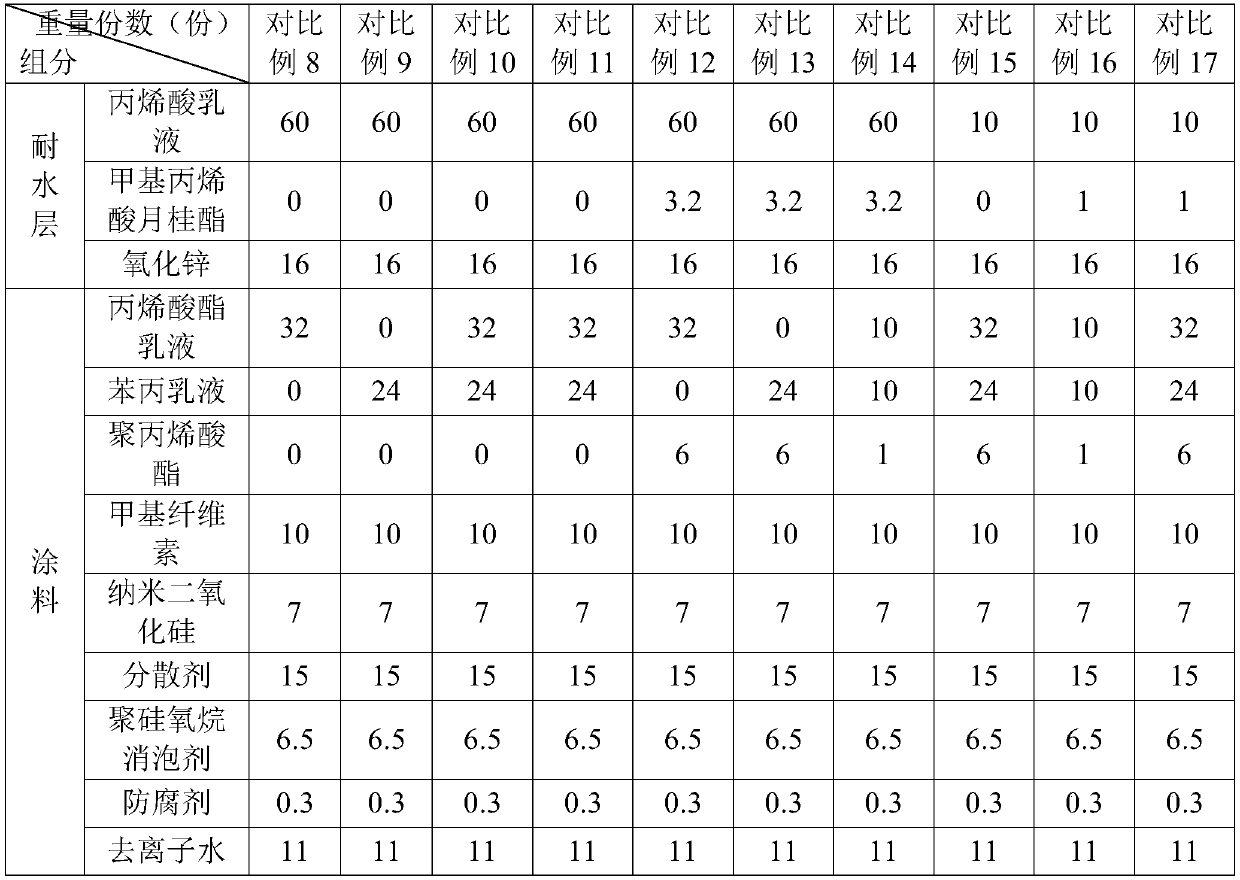

[0062] Embodiment 2-8: A kind of lightweight brick wall technology, the difference with embodiment 1 is that the components of the water-resistant layer and their corresponding parts by weight are as shown in Table 1; the components in the coating and their corresponding The parts by weight are shown in Table 1.

[0063] Components and corresponding parts by weight of water-resistant layer and coating in Table 1 Embodiment 1-8

[0064]

Embodiment 9

[0065] Embodiment 9: A lightweight brick wall process, the difference from Embodiment 1 is that the dispersant is all nano material dispersant TAZ-ND1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com