Sludge crushing feeder

A feeder and sludge technology, applied in the field of sludge crushing feeder, can solve the problems of difficult to achieve continuous and uniform feeding, slow conveying speed, difficult recycling of waste materials, etc., to ensure normal production and application, not easy to pollute Mud clumps, good balling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

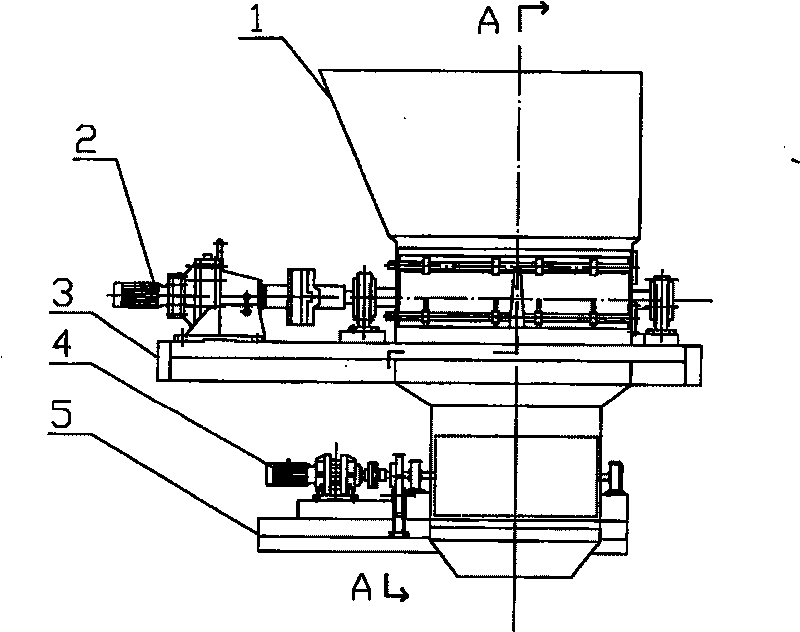

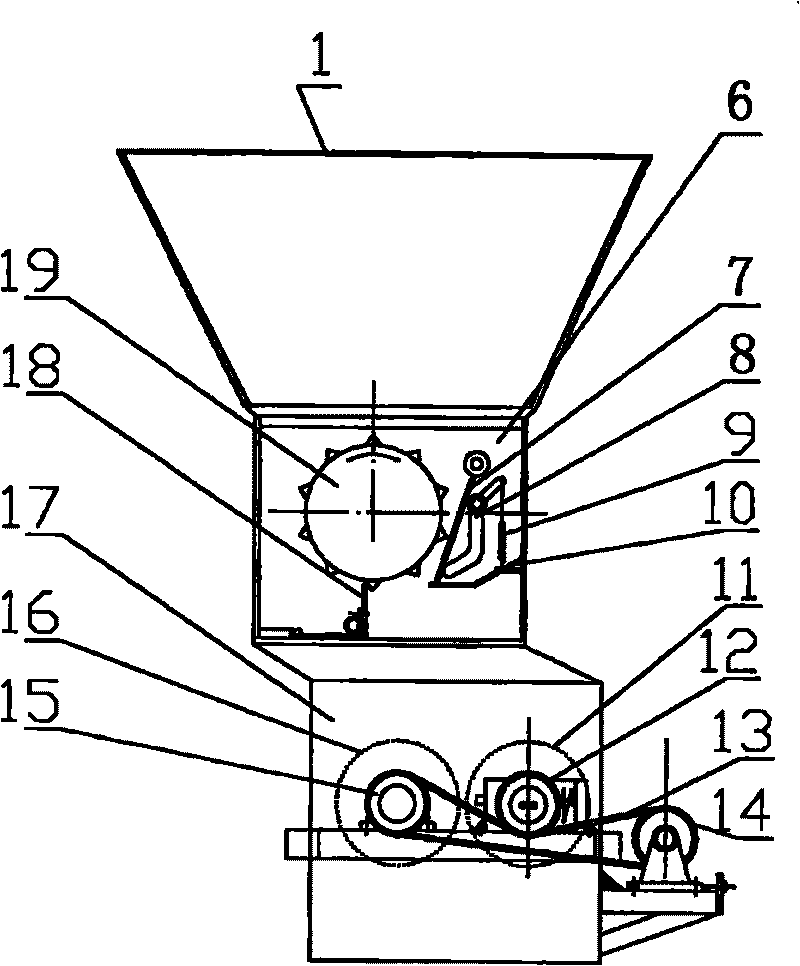

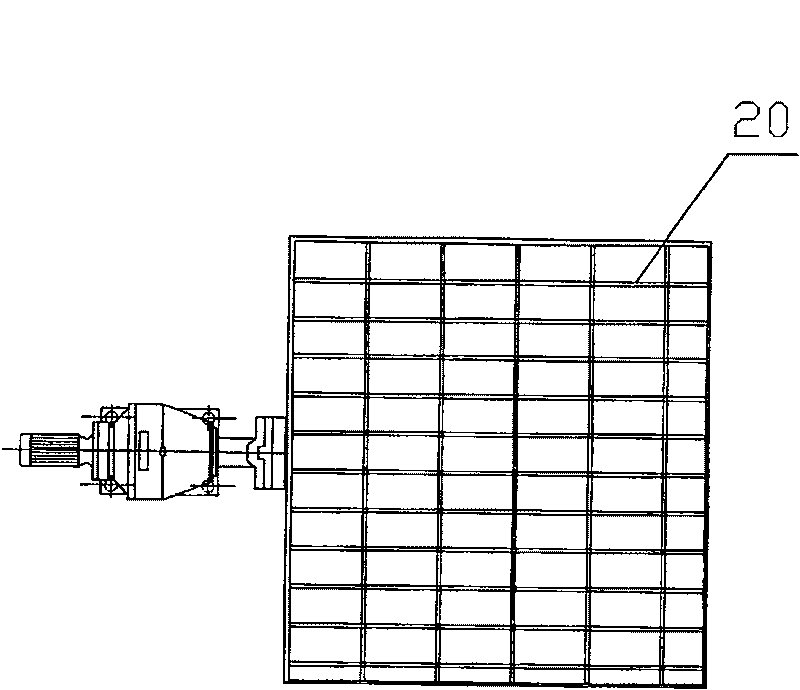

[0013] like figure 1 , figure 2 and image 3 A kind of specific embodiment shown, it comprises hopper 1, motor I 2, feeding part frame 3, motor II 4, breaks part frame 5, feeding box 6, buffer plate 7, crank arm 8, pulls Spring 9, material distribution tooth 10, driven crushing roller 11, driven sprocket 12, chain 13, reversing sprocket 14, driving sprocket 15, active crushing roller 16, crushing material box 17, scraping device 18. Feed roller 19 and grate plate 20.

[0014] Motor I 2, feeding part frame 3, feeding box 6, buffer plate 7, crank arm 8, extension spring 9, material distributing tooth 10, scraping device 18 and feeding roller 19 form feeding part. like figure 2 As shown, the buffer plate 7, the crank arm 8, the extension spring 9, the distributing tooth 10, the scraping device 18 and the feeding roller 19 are arranged in the feeding box 6, and the scraping device 18 is arranged under the feeding roller 19, The scraping device 18 can remove the remaining ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com