Dynamic fermentation method of organic feed

A technology of dynamic fermentation and organic feed, applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of inconsistent temperature and humidity of raw materials, large energy consumption of turning and throwing machine, poor turning and throwing effect, etc., to improve the distribution, good The effect of loosening and improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

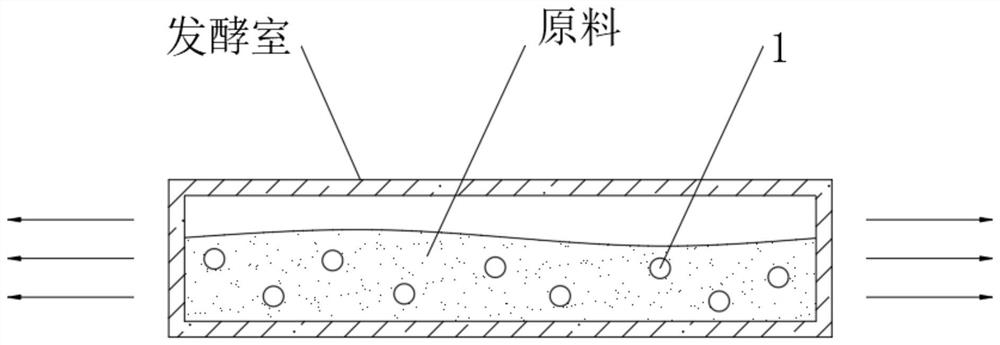

[0048] see Figure 1-3 , a kind of organic feed dynamic fermentation method, comprises the following steps:

[0049] S1. Evenly mix the raw materials and a plurality of fermentation-promoting balls 1 and stack them flatly in the fermentation room to keep the temperature and humidity required for the fermentation of the raw materials;

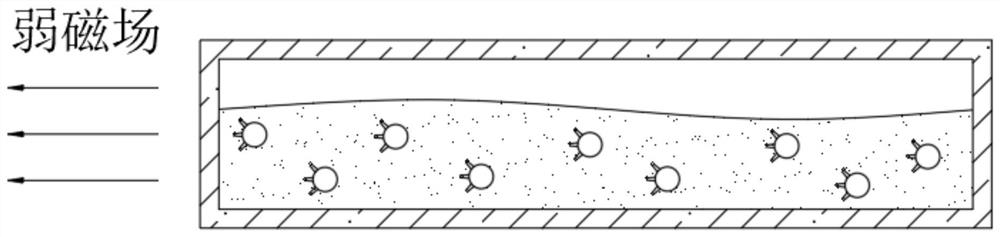

[0050] S2. Apply a weak magnetic field in different directions of the fermentation chamber, so that the fermentation-promoting ball 1 is locally deformed in the direction of the magnetic field, and the raw materials are locally loosened;

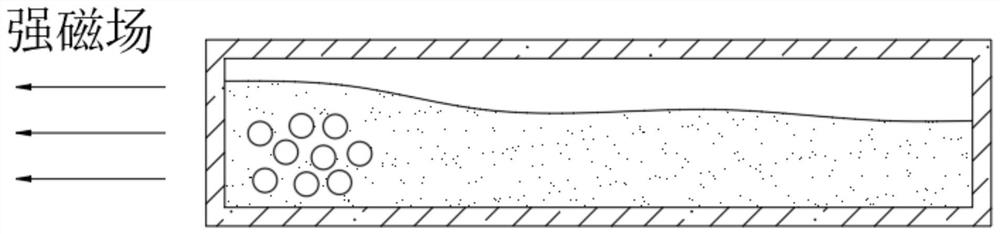

[0051] S3. Apply a strong magnetic field in different directions of the fermentation room every 2 hours, so that the fermentation-promoting balls 1 migrate towards the direction of the magnetic field, thereby driving the raw materials to turn over as a whole;

[0052] S4. After fermenting for a required period of time, the fermentation-promoting balls 1 in the raw material are adsorbed by a magnetic field, an...

Embodiment 2

[0058] see Figure 6-7 , the deformable outer membrane 13 is replaced by a shape-setting layer 131 and a plurality of uniformly distributed deformable diaphragms 132, and the shaped layer 131 and the deformable diaphragm 132 are combined into a whole. When the extension magnetic needle 2 is attracted, the deformation diaphragm 132 is driven to deform and extend outward, so that the extension magnetic needle 2 can fully loosen the raw material. Compared with the deformable outer membrane 13, it can achieve a better multi-point loosening effect.

[0059] The shape-setting layer 131 is made of hard air-permeable material, the deformable diaphragm 132 is made of elastic air-permeable material, and the deformable diaphragm 132 is inwardly inward toward the outer shape-setting spherical shell 11 .

[0060] see Figure 8-9 The extension magnetic needle 2 includes an outer needle 21, a middle magnetic ball 22 and an inner elastic backguy 23 connected in sequence, the middle magnetic ...

Embodiment 3

[0063] see Figure 10-11 In this embodiment, the middle magnetic ball 22 is made of a hollow structure made of ordinary hard heat-conducting material, and the end of the middle magnetic ball 22 close to the outer needle 21 is provided with an air inlet, and a constant temperature bag 3 is inserted at the air inlet, and the middle magnetic ball The inner side of 22 is filled with self-heating material. When the internal temperature of the raw material is not enough, the effect of the thermostatic bag 3 can be used to make the self-heating material react with oxygen to release heat to supply and maintain the internal temperature of the raw material.

[0064] The thermostatic bag 3 includes an outer mesh 31, a middle elastic bag 32 and an inner hard bag 33 connected in sequence, the outer mesh 31 is fixedly connected to the outer end of the air inlet, the middle elastic bag 32 is located in the air inlet, and the inner hard bag 33 is located in the air inlet. Inside the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com