Efficient KR desulfurizer and preparation method and use method thereof

A desulfurizer and high-efficiency technology, applied in the metallurgical field, can solve the problem of not significantly improving the use efficiency of the desulfurizer, and achieve the effects of low cost, not easy to form lumps, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

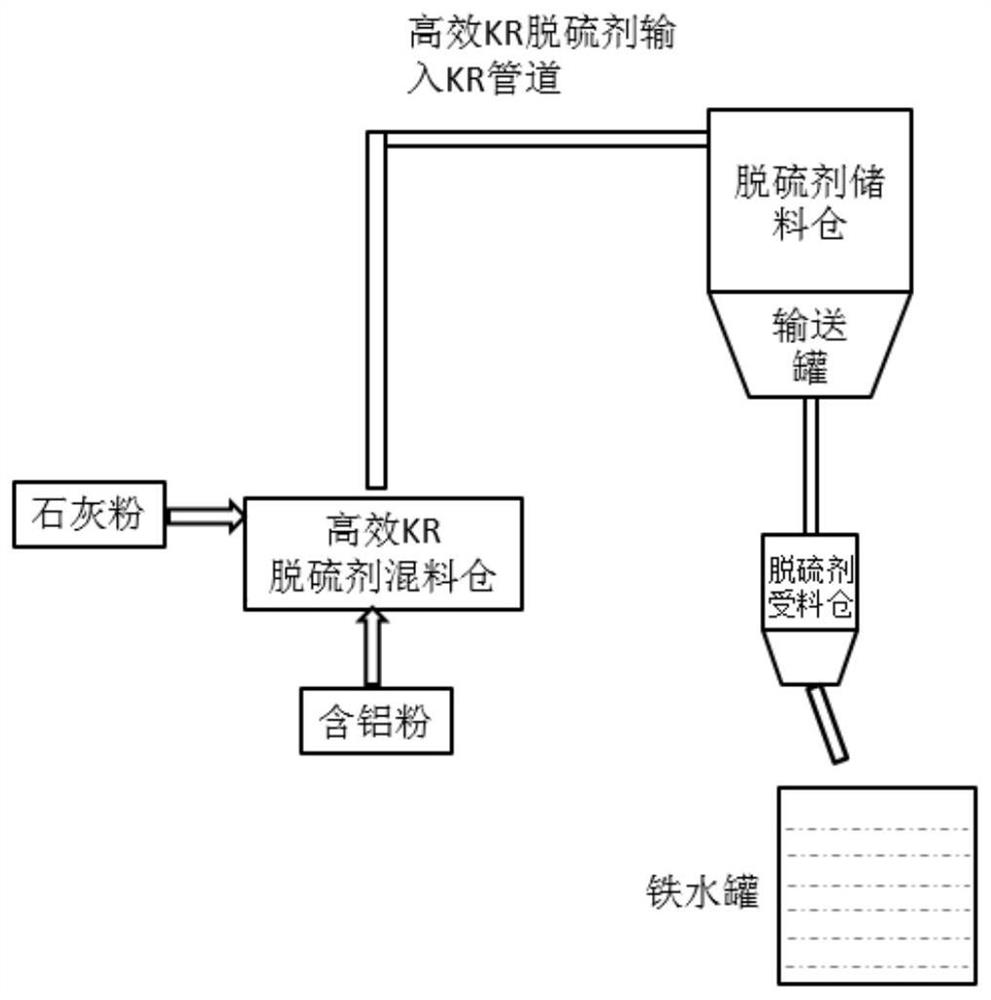

Image

Examples

Embodiment 1

[0043] A preparation method of high-efficiency KR desulfurizer, specifically:

[0044] Mix CaO powder: aluminum-containing powder at a mass ratio of 85:15, and the CaO mass content in the CaO powder is ≥ 95%; the particle diameter of the CaO powder is ≤ 1mm; the particle diameter of the aluminum-containing powder is 200 Mesh (74μm); the aluminum-containing powder contains the following mass percentage components: Al 2 o 3 : 50%-60%, TAl: 15%-25%, MgO+SiO 2 : ≤35%.

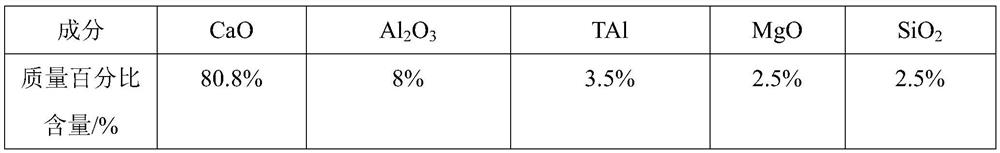

[0045] The components of the mixed environment-friendly high-efficiency KR desulfurizer are shown in Table 1, and there are no unavoidable impurities in Table 1. In the high-efficiency KR desulfurizer powder, particles below 200 mesh (74 μm) account for more than 30%, and the size of the rest of the particles is less than 1000 μm.

[0046] Table 1 Composition of high-efficiency KR desulfurizer

[0047]

[0048] The method of using the above-mentioned high-efficiency KR desulfurizer is as follows:

[0049] Mi...

Embodiment 2

[0052] A preparation method of high-efficiency KR desulfurizer, specifically:

[0053] Mix CaO powder: aluminum-containing powder at a mass ratio of 83:17, the CaO mass content in the CaO powder is ≥ 95%; the particle size of the CaO powder is ≤ 1mm; the particle size of the aluminum-containing powder is 200 mesh (74μm); The aluminum-containing powder comprises the following mass percentage composition: Al 2 o 3 : 50%-60%, TAl: 15%-25%, MgO+SiO 2 : ≤35%.

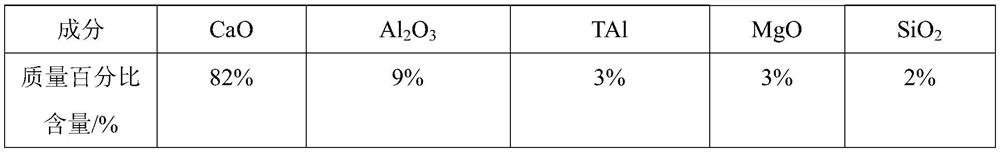

[0054] The components of the mixed environment-friendly high-efficiency KR desulfurizer are shown in Table 2, and there are no unavoidable impurities in Table 2. In the high-efficiency KR desulfurizer powder, particles below 200 mesh (74 μm) account for more than 30%, and the size of the rest of the particles is less than 1000 μm.

[0055] Table 2 Composition of high-efficiency KR desulfurizer

[0056]

[0057] The method of using the above-mentioned high-efficiency KR desulfurizer is as follows:

[0058] Mix the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com