Color master batch dehydration device

A dehydration device and a technology for color masterbatch, applied in the field of color masterbatch processing, can solve the problems of color masterbatch clumping, affecting the molding quality of color masterbatch, uneven drying of color masterbatch, etc., to achieve the effect of ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

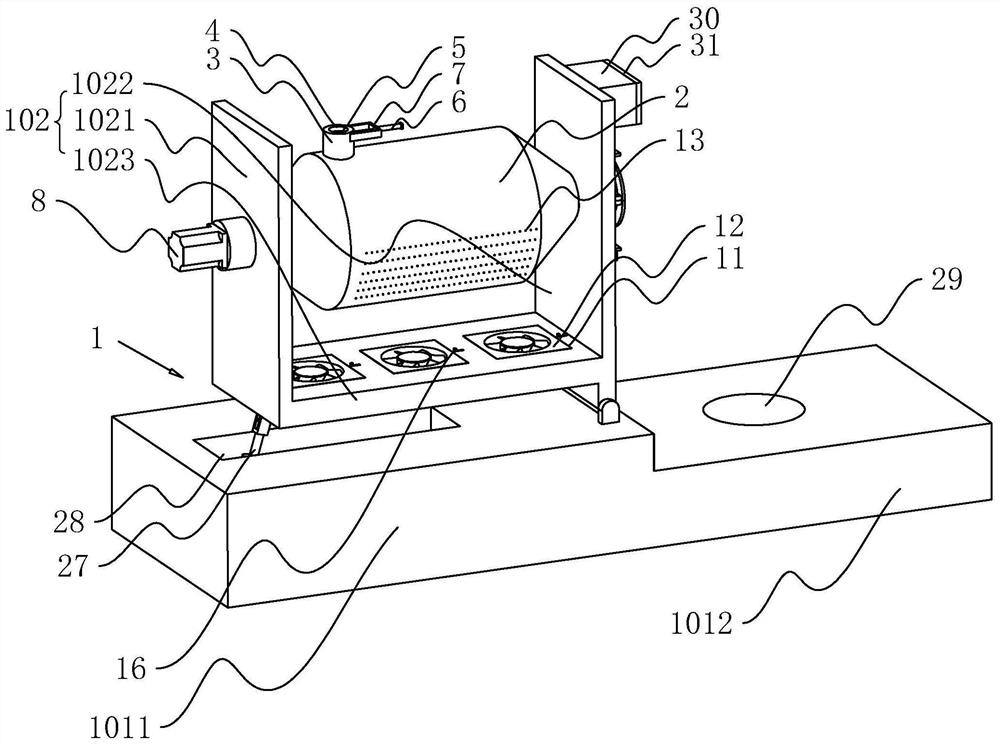

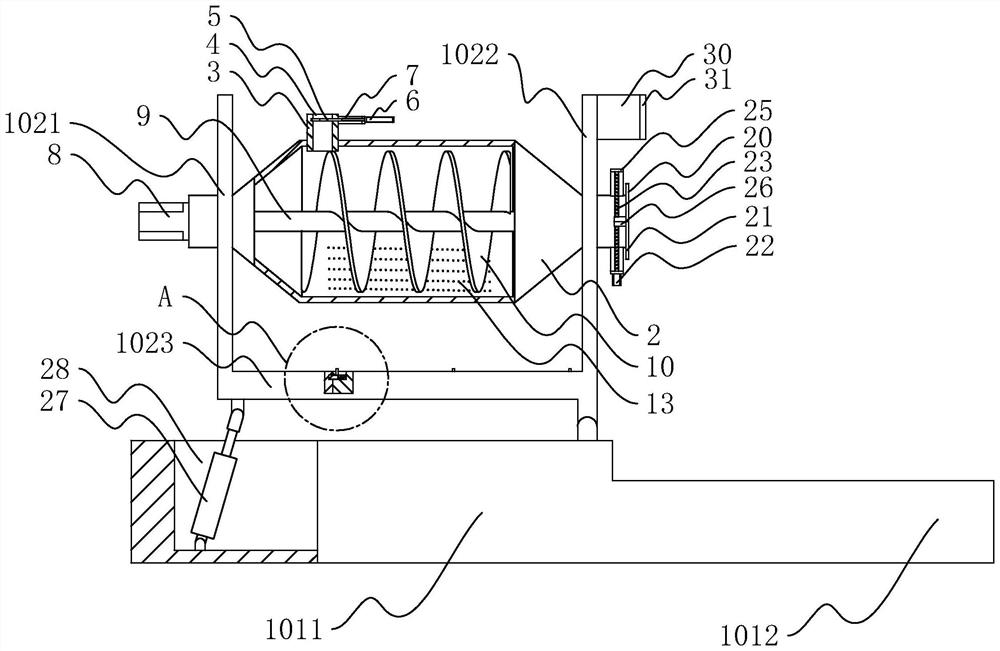

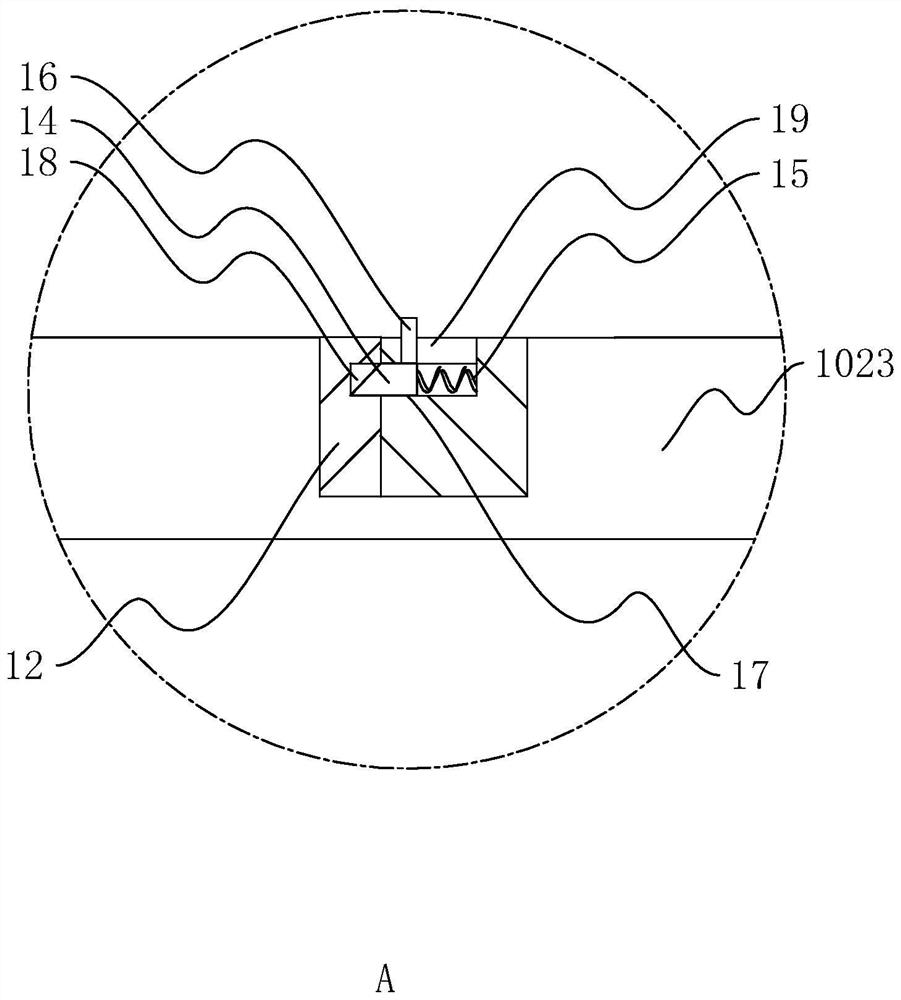

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the application discloses a color masterbatch dehydration device. refer to figure 1The color masterbatch dehydration device includes a frame body 1 and a storage tank 2, wherein the frame body 1 includes a base 101 and a mounting frame 102, the base 101 includes a first fixing part 1011 and a second fixing part 1012, and the first fixing part 1011 and The second fixing parts 1012 are generally in the shape of a rectangular block. The second fixing parts 1012 are integrally connected to one side of the first fixing part 1011 in the longitudinal direction, and the thickness of the second fixing part 1012 is smaller than that of the first fixing part 1011 .

[0040] refer to figure 1 and figure 2 , the installation frame 102 is located on the top of the base 101, and the longitudinal section of the installation frame 102 is roughly in the shape of "凵". It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com