Road construction sediment mixer

A technology for mixing and silting, which is applied to clay mixing devices, mixing operation control devices, clay preparation devices, etc., can solve problems such as unsatisfactory effects, increased capital consumption, and increased equipment investment, so as to reduce labor burden and reduce The probability of downtime for cleaning, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

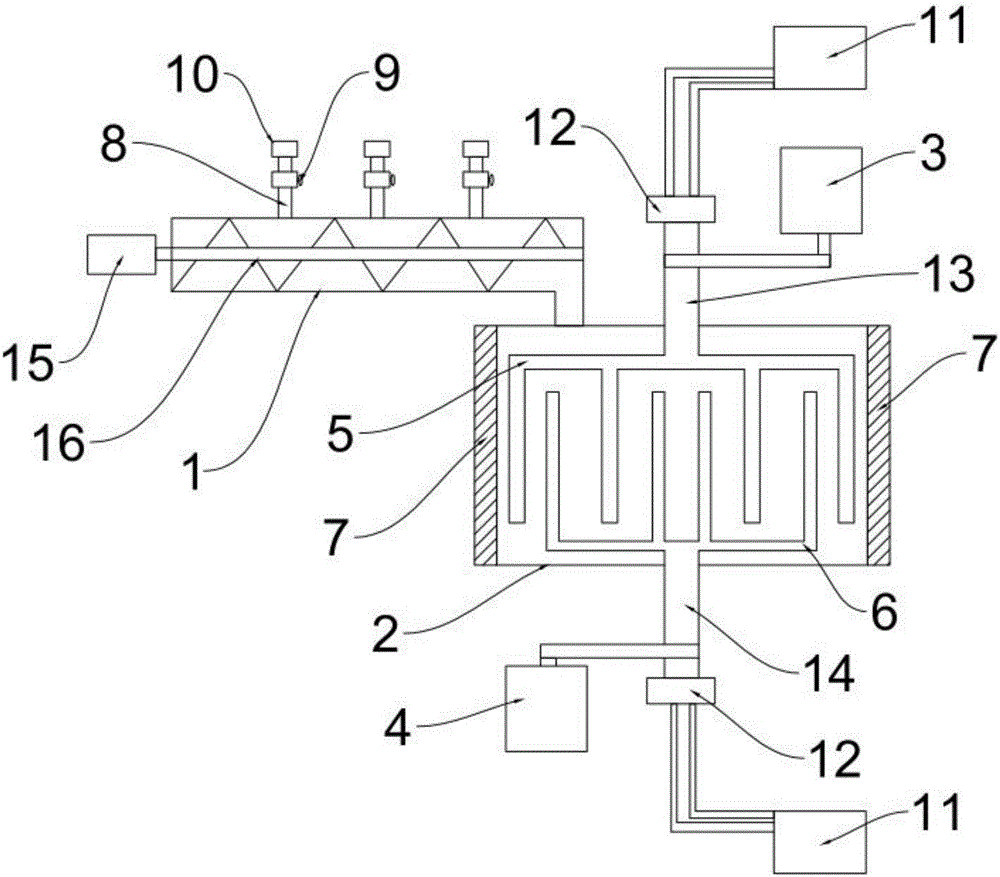

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 A road construction silt mixing device shown includes a mixing box 2, the side wall of the mixing box 2 is provided with a wear-resistant layer 7, and the mixing box 2 is provided with a feed pipeline 1. The feeding pipeline 1 is provided with a screw conveyor 16, and one end of the screw conveyor 16 is connected with a conveying motor 15 to drive, and the feeding pipeline 1 is provided with a number of adding pipes 8, and the adding pipes 8 are connected to the feeding pipeline 1. Add materials such as water and additives inside, so that the sediment is initially mixed in the feed pipe 1, which speeds up the mixing efficiency. The adding pipe 8 is equipped with a valve 9, and the valve 9 controls the addition of The switch of the pipe 8 avoids backflow when not in use. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com