High-molecular copolymer dispersant for paint and preparation method thereof

A technology of high molecular copolymer and dispersant, applied in coating and other directions, can solve the problems of complex process, environmental pollution, increase cost, etc., and achieve the effect of simple process, good viscosity reduction effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

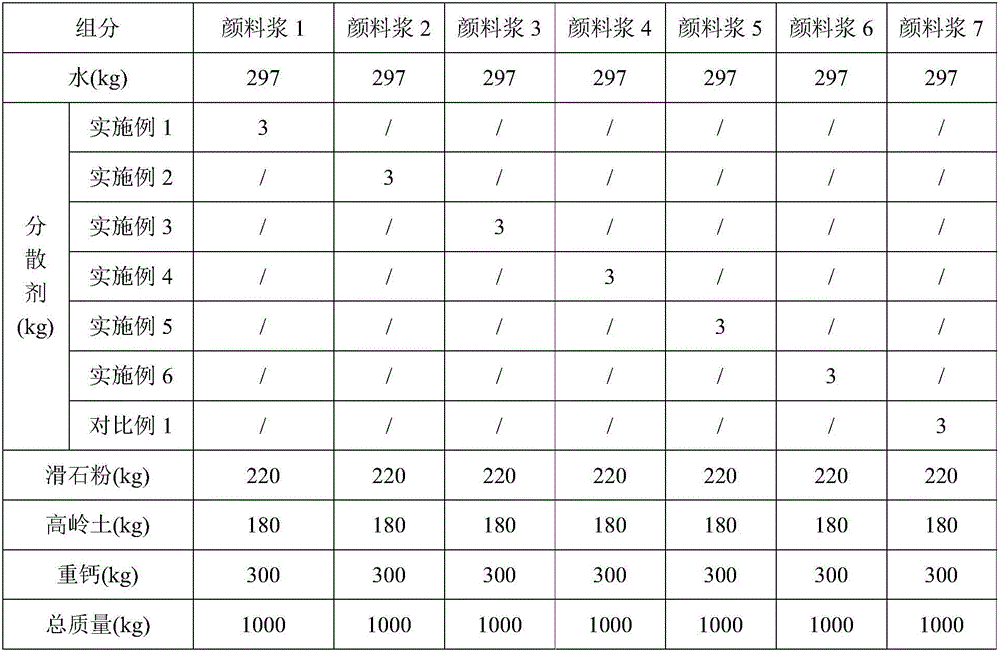

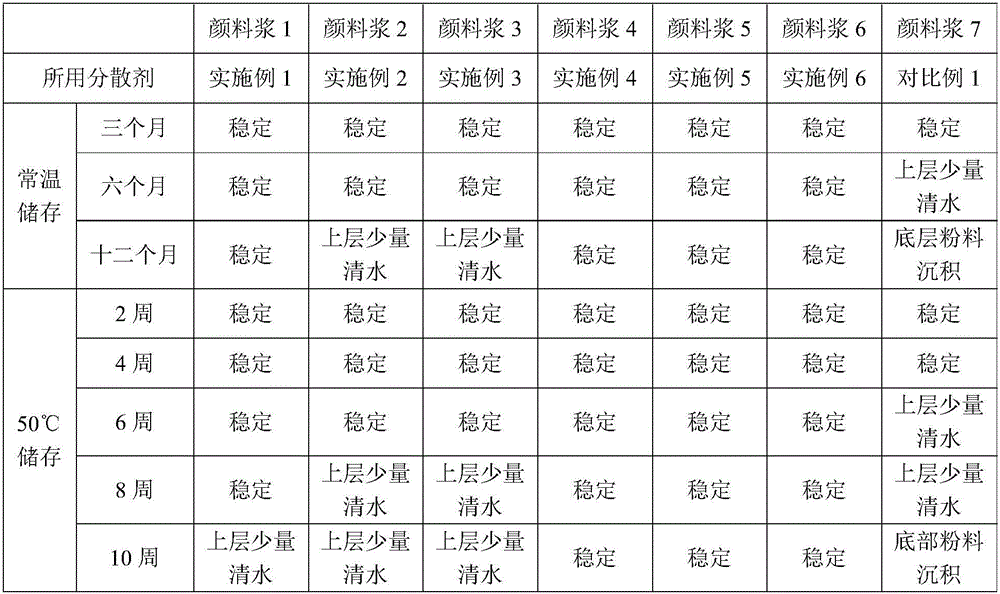

Examples

Embodiment 1

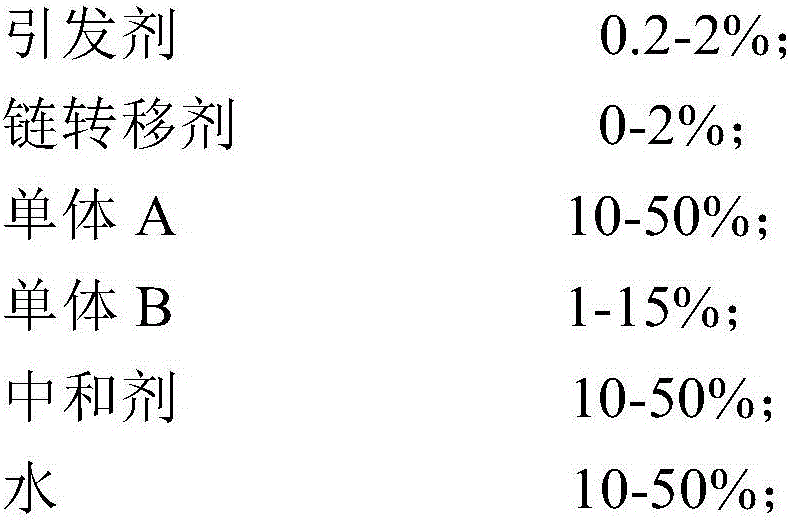

[0028] A polymer copolymer dispersant for coatings is made of the following components by mass percentage:

[0029] 5kg of potassium persulfate, 10kg of sodium bisulfite, 150kg of acrylic acid, 100kg of maleic anhydride, 420kg of aqueous sodium hydroxide solution with a mass fraction of 40%, and 315kg of water.

[0030] The preparation method is as follows:

[0031] 1) Mix water, sodium bisulfite and maleic anhydride, and then heat up to 50°C to obtain the first mixed solution;

[0032] 2) adding 10% potassium persulfate aqueous solution and acrylic acid to the first mixed solution dropwise, and the addition was completed within 2 hours, and then kept at 60° C. for 3 hours to obtain the second mixed solution; The second mixed liquid was cooled to room temperature, and the pH value of the second mixed liquid was adjusted to 7 with a 40% aqueous sodium hydroxide solution by mass fraction to obtain a polymer copolymer dispersant. The polymer copolymer dispersant is a yellow tra...

Embodiment 2

[0034] A polymer copolymer dispersant for coatings is made of the following components by mass percentage:

[0035] 8kg of ammonium persulfate, 14kg of sodium pyrophosphate, 150kg of acrylic acid, 50kg of methacrylic acid, 50kg of maleic anhydride, 368kg of aqueous sodium hydroxide solution with a mass fraction of 40%, and 360kg of water.

[0036] The preparation method is as follows:

[0037] 1) Mix water, sodium pyrophosphate and maleic anhydride, and then heat up to 80°C to obtain the first mixed solution;

[0038] 2) Add dropwise an aqueous solution of ammonium persulfate, acrylic acid and methacrylic acid with a mass percentage of 9% to the first mixed solution, and complete the dropwise addition within 3 hours, and then keep the temperature at 70° C. for 2 hours to obtain the second mixed solution liquid; the second mixed liquid was cooled to room temperature, and the pH value of the second mixed liquid was adjusted to 7 with a 40% aqueous sodium hydroxide solution by m...

Embodiment 3

[0040] A polymer copolymer dispersant for coatings is made of the following components by mass percentage:

[0041] 10kg of ammonium persulfate, 10kg of sodium hypophosphite, 200kg of acrylic acid, 50kg of methacrylic acid, 50kg of sodium allyl sulfonate, 280kg of aqueous sodium hydroxide solution with a mass fraction of 40%, and 400kg of water.

[0042] The preparation method is as follows:

[0043] 1) Mix water, sodium hypophosphite and sodium allyl sulfonate, and then heat up to 80°C to obtain the first mixed solution;

[0044] 2) Add dropwise an aqueous solution of ammonium persulfate, acrylic acid and methacrylic acid with a mass percentage of 10% to the first mixed solution, and complete the dropwise addition within 3 hours, and then keep the temperature at 70° C. for 2 hours to obtain the second mixed solution liquid; the second mixed liquid was cooled to room temperature, and the pH value of the second mixed liquid was adjusted to 7 with a 40% aqueous sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com