Drum type feeding device for garbage incinerator of circulating fluidized bed and feeding method

A waste incinerator and circulating fluidized bed technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of hardening, insufficient combustion, and high cost of exhaust gas treatment, and achieves low flue gas volume and sufficient waste combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

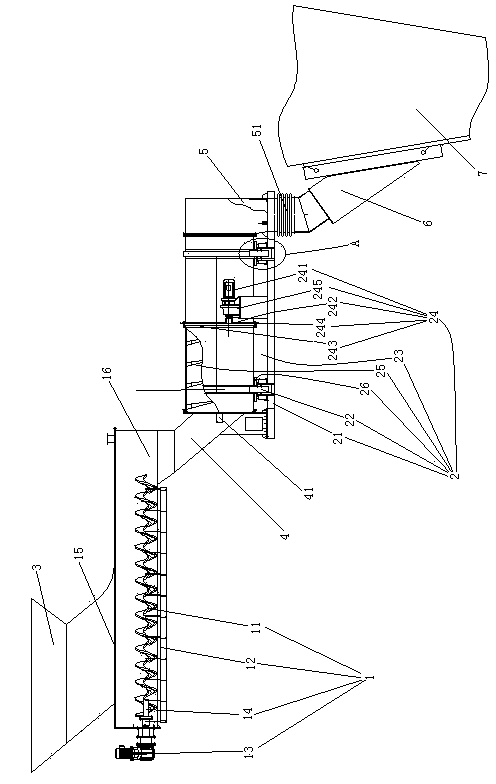

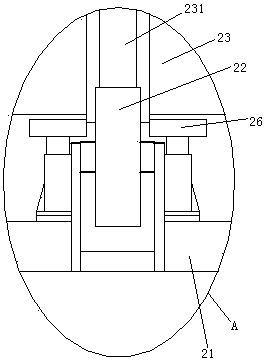

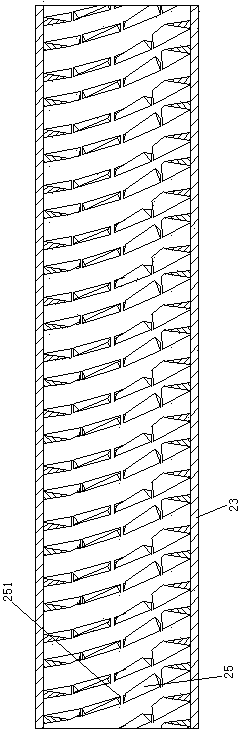

[0024] Embodiment one, see figure 1 A drum-type feeding device for a circulating fluidized bed garbage incinerator includes a primary feeder 1 and a secondary feeder 2 . The primary feeder 1 is located above the axial left end of the secondary feeder 2 .

[0025] The primary feeder 1 is set horizontally. The primary feeder 1 includes a screw feed blade 11 , a shell 12 of the primary feeder and a driving motor 13 of the primary feeder. There are two screw feed blades 11. Two screw feeding blades 11 are located in the same horizontal plane and arranged in parallel. Two screw feeding blades 11 are distributed along the front and rear direction (in the figure because the screw feeding blade at the rear is blocked by the screw feeding blade in front, so only one screw feeding blade can be seen). The screw feed vane 11 is located in the shell 12 of the primary feeder. Each screw feeding blade 11 is connected with a primary feeder drive motor 13 through a primary feeder drive sh...

Embodiment 2

[0034] Embodiment two, see Figure 4 , the difference from the first embodiment is: it also includes a suspension frame 9 and a coating heating mechanism 8 . Suspension frame 9 and coating type heating mechanism 8 each have two.

[0035] The feed hopper 3 is only supported on the primary feeder 1 by the hanger 9 . The suspension frame 9 includes a connecting rod 91 and five shock absorbing rods 92 . The connecting rod 91 is an arc-shaped structure that arches downward (certainly upward is also possible). The five damping rods 92 are a horizontal damping rod 921 , two longitudinal damping rods 922 and two vertical damping rods 923 . One end of the connecting rod 91 is connected with the feed hopper 3 . The other end of the connecting rod 91 is connected with one end of the horizontal damping rod 921 . The other end of the horizontal damping rod 921 is connected with one end of the two longitudinal damping rods 922 . One ends of the two vertical shock absorbing rods 923 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com