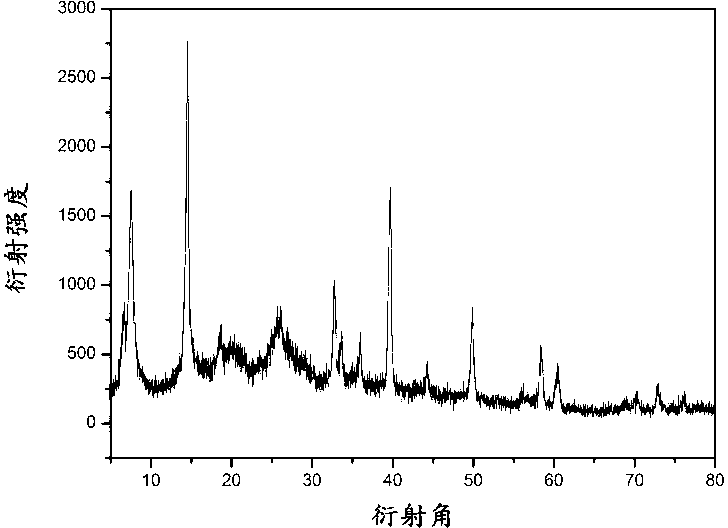

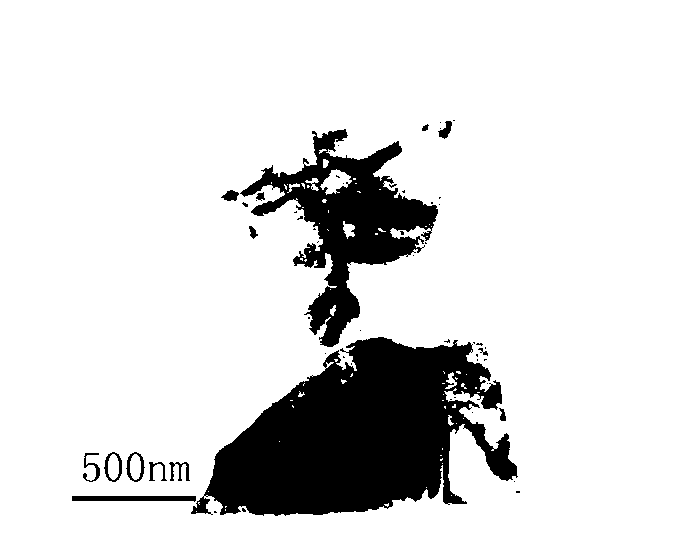

Preparation method of polyaniline and molybdenum disulfide intercalated composite material

A molybdenum disulfide and composite material technology is applied in the field of preparation of polyaniline and molybdenum disulfide intercalated composite materials, which can solve the problems of polyaniline being insoluble, unevenly dispersed, and difficult to process, and achieves a simple synthesis method and a uniform structure. , the effect of improving the photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The specific preparation steps of polyaniline and molybdenum disulfide intercalation composite material are as follows:

[0018] Step 1, preparation of graphene-like molybdenum disulfide suspension:

[0019] Weigh 10 g of molybdenum disulfide with a particle size of 45 μm, and place molybdenum disulfide in n-hexane solution of n-butyllithium under the protection of dry nitrogen, and stir for 48 hours. Filter, wash the solid with n-hexane, dry, then add 500mL of water, and ultrasonically react for 30 minutes to obtain a suspension of graphene-like molybdenum disulfide; A mixed solution prepared by adding 30 mL of n-butyllithium solution with a concentration of 2.5 mol / L to n-hexane solution; the molar ratio of molybdenum disulfide to n-butyllithium is 1:1.2;

[0020] Step 2, preparing polyaniline and molybdenum disulfide intercalation composite material:

[0021] Take 100mL of graphene-like molybdenum disulfide suspension and place it in a 250mL three-necked flask, the...

Embodiment 2

[0026] Step 1, preparation of graphene-like molybdenum disulfide suspension:

[0027] Weigh 10 g of molybdenum disulfide with a particle size of 45 μm, and place the molybdenum disulfide in n-butyl lithium in n-hexane solution under dry nitrogen protection conditions, and stir for 72 hours. Filter, wash the solid with n-hexane, dry, then add 800mL of water and ultrasonically react for 30min to obtain a suspension of graphene-like molybdenum disulfide; the n-hexane solution of n-butyllithium is 95% n-hexane A mixed solution prepared by adding 25 mL of n-butyllithium solution with a concentration of 2.5 mol / L to the alkane solution; the molar ratio of the amount of molybdenum disulfide to the amount of n-butyllithium is 1:1;

[0028] Step 2, preparing polyaniline and molybdenum disulfide intercalation composite material:

[0029] Take 100mL of the graphene-like molybdenum disulfide suspension and place it in a 250mL three-necked flask, add 10mL of aniline monomer, 8g of potassi...

Embodiment 3

[0031] Step 1, preparation of graphene-like molybdenum disulfide suspension:

[0032] Weigh 10 g of molybdenum disulfide with a particle size of 45 μm, and place the molybdenum disulfide in n-butyl lithium in n-hexane solution under dry nitrogen protection conditions, and stir for 48 hours. Filter, wash the solid with n-hexane, dry, then add 1000mL of water and ultrasonically react for 10min to obtain a suspension of graphene-like molybdenum disulfide; the n-hexane solution of n-butyllithium is 95% n-hexane A mixed solution prepared by adding 40 mL of n-butyllithium solution with a concentration of 2.5 mol / L to the alkane solution; the molar ratio of the molybdenum disulfide dosage to the n-butyllithium dosage is 1:1.6;

[0033] Step 2, preparing polyaniline and molybdenum disulfide intercalation composite material:

[0034]Take 50mL of graphene-like molybdenum disulfide suspension and place it in a 250mL three-necked flask, add 5mL of aniline monomer, 5g of ammonium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com