Method for preparing nano SiO2/polyurethane/acrylic ester composite emulsion and miniemulsion polymerization

A technology of acrylate and composite emulsion, which is applied in the treatment of dyed organosilicon compounds and fibrous fillers, etc. It can solve the problems of dynamic differences, achieve improved dispersion, improve mechanical properties, and improve the effect of "hot sticky and cold brittle"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

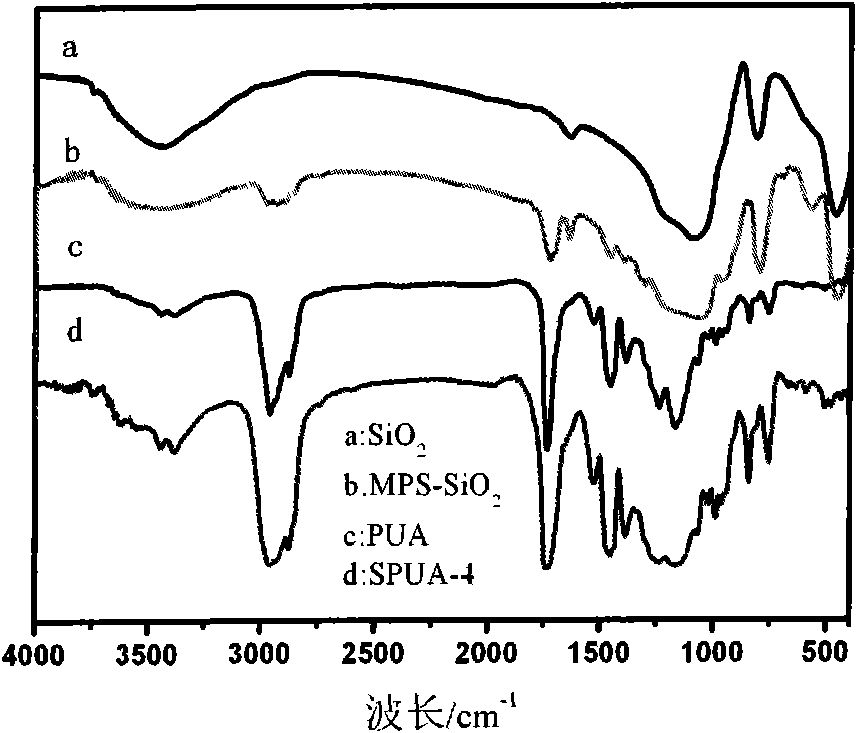

[0048] 1. Nano SiO 2 Particle preparation

[0049] Add 100g of absolute ethanol and 2g of ammonia water into the Erlenmeyer flask, and under magnetic stirring, drop the ethanol TEOS solution with a ratio of 1:1 into the Erlenmeyer flask at a constant pressure, control the dropping rate 1d / min, and the magnetic stirring speed 60r / min. After the dropwise addition, add 2g of ammonia water, 3.64g of water, and 1.74g of methacryloxypropyltrimethoxysilane KH-570 into the Erlenmeyer flask, and continue stirring for 24 hours, then dry the above alcohol solution in a vacuum oven , to obtain MPS-modified solid nano-silica.

[0050] 2. Preparation of polyurethane prepolymer

[0051] First, wash and dry the electric stirring rod, thermometer, reflux condenser and 250mL four-necked flask, and then install them for use. Weigh the dehydrated N210 into it, and then add diisocyanate (N210: IPDI molar ratio = 3:1) into it meteredly, and the two carry out initial polymerization reaction. He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com