High-hydroxy silicon-acrylate aqueous glass coating emulsion and synthesis method thereof

A silicon acrylate and glass coating technology, applied in the coating and other directions, can solve the problems of environmental pollution, high price of water-based amino resin, no mention of coating emulsion synthesis, etc., and achieve the effect of simple preparation process and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

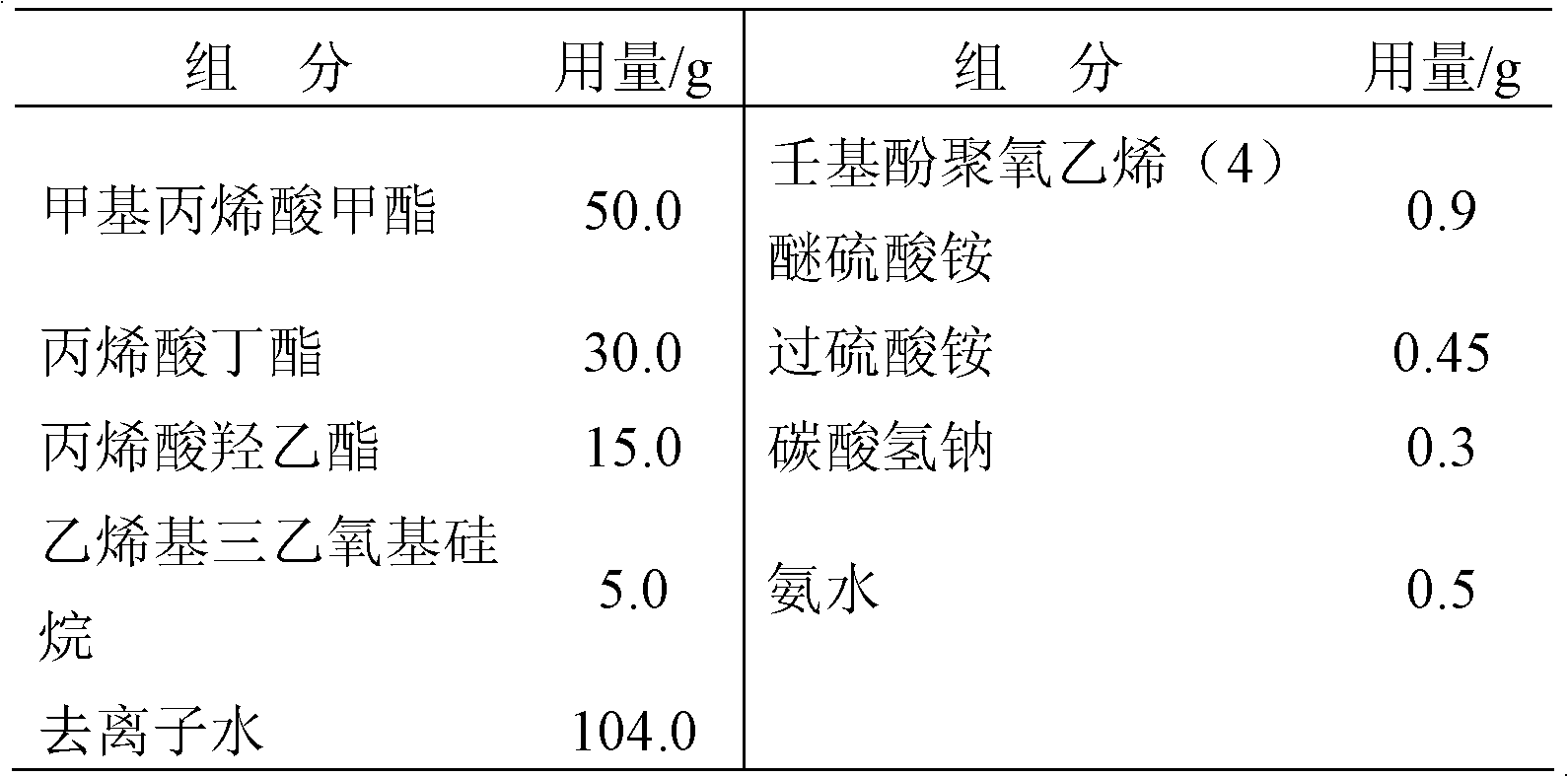

[0044] The raw material formula of high hydroxyl silicon-containing acrylate water-based glass coating emulsion is shown in Table 1:

[0045] Table 1 High hydroxyl silicon-containing acrylate emulsion formula

[0046]

[0047] Its synthesis method is:

[0048] ① Mix emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate 0.6g, deionized water 34g, hydroxyethyl acrylate 15g, methyl methacrylate 50g, butyl acrylate 30g, vinyltriethoxysilane 5g Sequentially add to the pre-emulsification tank, and continue to stir at room temperature at a stirring rate of 500rpm for 15 minutes to pre-emulsify it to obtain a pre-emulsion;

[0049] ② Add emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate 0.3g, sodium bicarbonate 0.3g and deionized water in sequence in the reaction kettle equipped with thermometer, constant pressure dropping funnel, reflux condenser and stirrer 40g, put into a water bath, mix evenly at a stirring rate of 350rpm and heat up;

[0050] ③Wh...

Embodiment 2

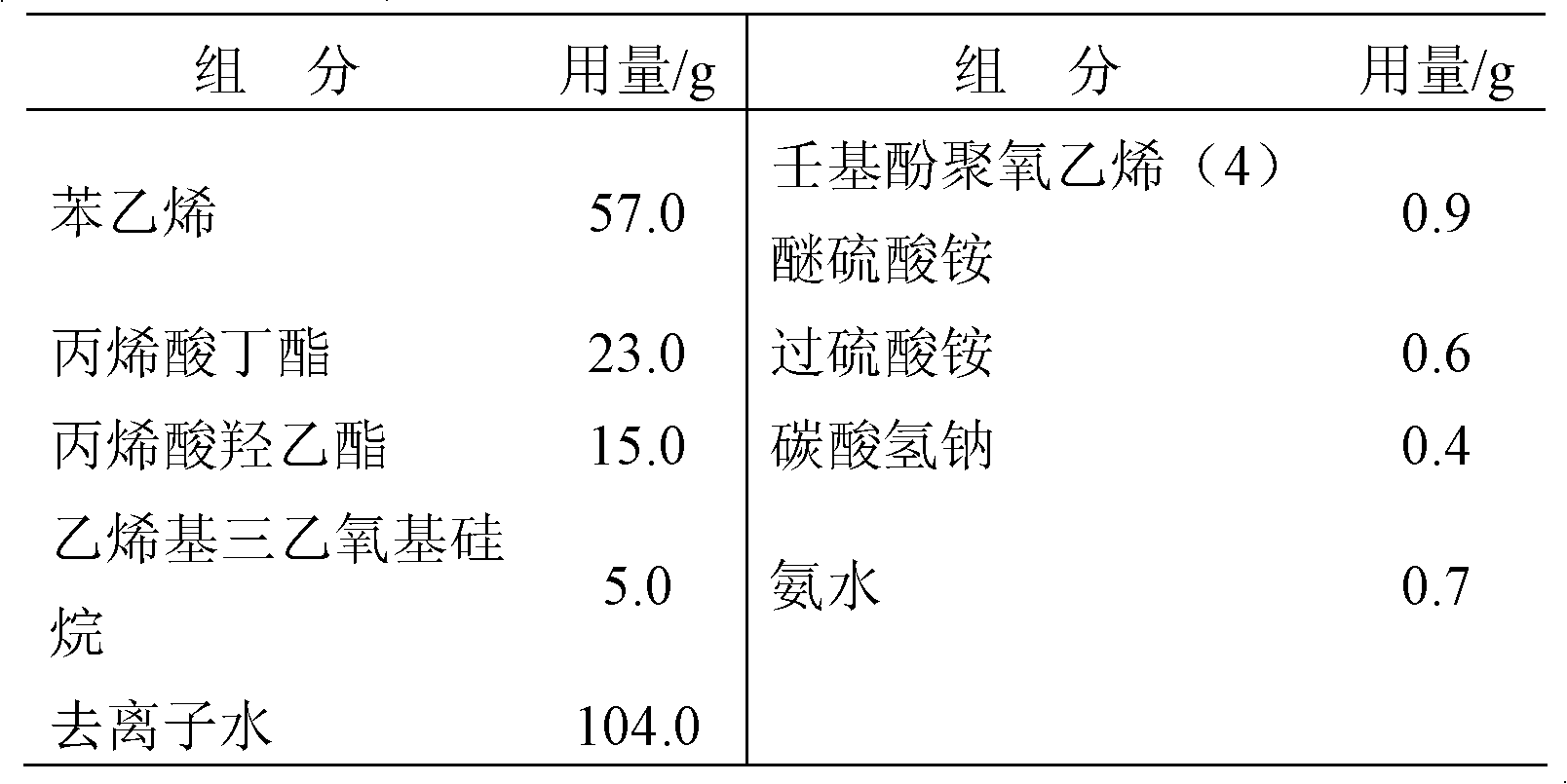

[0055] The raw material formula of high hydroxyl silicon-containing acrylate water-based glass coating emulsion is shown in Table 2:

[0056] Table 2 Formula of silanol-containing acrylate emulsion

[0057]

[0058] Its synthesis method is:

[0059] ①Add 0.6g of emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate, 34g of deionized water, 15g of hydroxyethyl acrylate, 57g of styrene, 23g of butyl acrylate, and 5g of vinyl triethoxysilane to the pre- In the emulsification kettle, it was pre-emulsified at room temperature at a stirring rate of 500 rpm for 15 minutes to obtain a pre-emulsion;

[0060] ② Add emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate 0.3g, sodium bicarbonate 0.4g and deionized water in sequence in the reaction kettle equipped with thermometer, constant pressure dropping funnel, reflux condenser and stirrer 40g, put into a water bath, mix evenly at a stirring rate of 350rpm and heat up;

[0061] ③When the reaction temperatu...

Embodiment 3

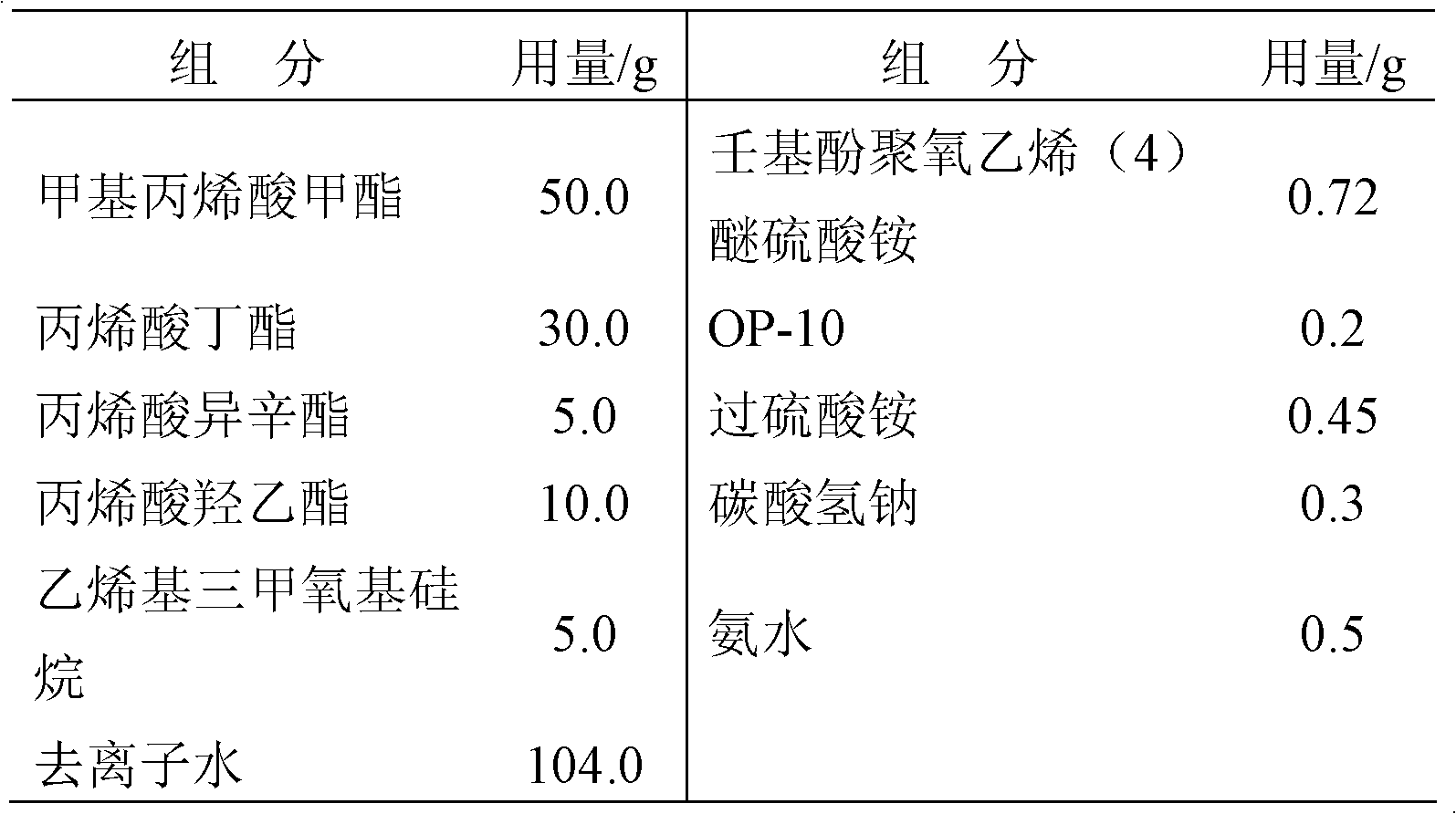

[0066] The raw material formula of high hydroxyl silicon-containing acrylate water-based glass coating emulsion is shown in Table 3:

[0067] Table 3 Formula of Silicone Hydroxyl Acrylate Emulsion

[0068]

[0069] Its synthesis method is:

[0070] ①The emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate 0.48g, OP-100.1g, deionized water 34g and hydroxyethyl acrylate 10g, methyl methacrylate 50g, butyl acrylate 30g, isooctyl acrylate Add 5 g of ester and 5 g of vinyltriethoxysilane into the pre-emulsification tank in sequence, and continue stirring at room temperature at a stirring rate of 500 rpm for 15 minutes to pre-emulsify it to obtain a pre-emulsion;

[0071] ② Add emulsifier nonylphenol polyoxyethylene (4) ether ammonium sulfate 0.24g, OP-100.1g, sodium bicarbonate 0.3 g and 40g of deionized water, put into a water bath and mix evenly at a stirring rate of 350rpm and heat up;

[0072] ③ When the reaction temperature rises to 60°C, the stirring rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com