Preparation method for mesoporous silicon oxide hollow microspheres with magnetic nanoparticles embedded in shell layers

A technology of magnetic nanoparticles and mesoporous silica, which is applied in the preparation of microspheres, silica and microcapsules, etc., can solve the problems of limited content of magnetic nanoparticles, uneven distribution, difficult operation, etc., and achieve a narrow particle size distribution. , low cost of raw materials, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

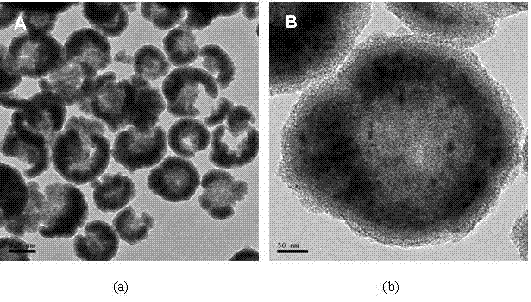

[0029] Example 1. 24 g FeCl 3 ·6H 2 O and 9.82 g FeCl 2 ·7H 2 Dissolve O in an appropriate amount of water, add an appropriate amount of ammonia water, pass N 2 Gas, heated at 80°C for 30min, then added 3.86 g of oleic acid, continued to heat and stir for 1h, then stopped passing through N 2 , volatilize ammonia water until a large amount of black precipitate appears after stopping stirring, then the reaction can be stopped. Under magnetic separation, the precipitate is washed with deionized water to neutrality, and then washed with deionized water and ethanol three times respectively, and the obtained magnetic Nanoparticles, ultrasonically disperse the magnetic particles in an appropriate amount of n-octane, then evaporate the n-octane to dryness by rotary evaporation, and set aside; dissolve 0.104 g of SDS in 40 g of deionized water, dissolve 9 g of styrene monomer, 0.4 g of sixteen The dispersion of alkane, 1 g TEOS, and 55 mg magnetic particles was mixed and ultras...

Embodiment 2

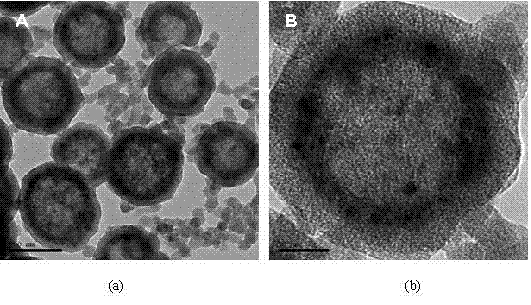

[0030] Example 2. The co-precipitation method was used to prepare the oleic acid-modified magnetic nano-particles, and the magnetic particles dispersed by n-octane and then evaporated to dryness were prepared. Dissolve 0.12 g SDBS in 40 g deionized water, mix 8 g styrene monomer, 0.4 g hexadecane, 2 g orthomethyl orthosilicate, and 80 mg magnetic particles into a homogeneous oil phase , and then mixed with an aqueous solution of surfactant, and ultrasonically finely emulsified at 500 W for 10 min. Add 1.0% potassium persulfate relative to styrene monomer, stir at room temperature and pass N 2 After 30 min, the reaction system was transferred to a water bath at a temperature range of 70 °C to initiate polymerization. After the polymerization was carried out for 90 min, 0.1 mL of ammonia water was added, and the reaction was carried out at 70 °C for 6 h; the product was used under the assistance of magnetic separation. Wash with deionized water repeatedly 2-3 times. Dispers...

Embodiment 3

[0031] Example 3. The co-precipitation method was used to prepare the oleic acid-modified magnetic nano-particles, and the magnetic particles dispersed by n-octane and then evaporated to dryness were prepared. Dissolve 0.23 g of SDS in 40 g of deionized water, mix 8 g of styrene monomer, 0.4 g of cetyl alcohol, 1 g of TEOS, and 55 mg of magnetic particles into a homogeneous oil phase, and then mix with the surface The aqueous solutions of the active agents were mixed and ultrasonically finely emulsified at 500 W for 10 min. Add 1.0% AIBN relative to styrene monomer, stir at room temperature and pass N 2 After 30 min, the reaction system was transferred to a water bath at a temperature range of 70 °C to initiate polymerization. After the polymerization was carried out for 60 min, 0.05 mL of 1% sodium hydroxide aqueous solution was added, and the reaction was carried out at 70 °C for 6 h; Wash with deionized water repeatedly 2-3 times with assistance. Disperse the template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com