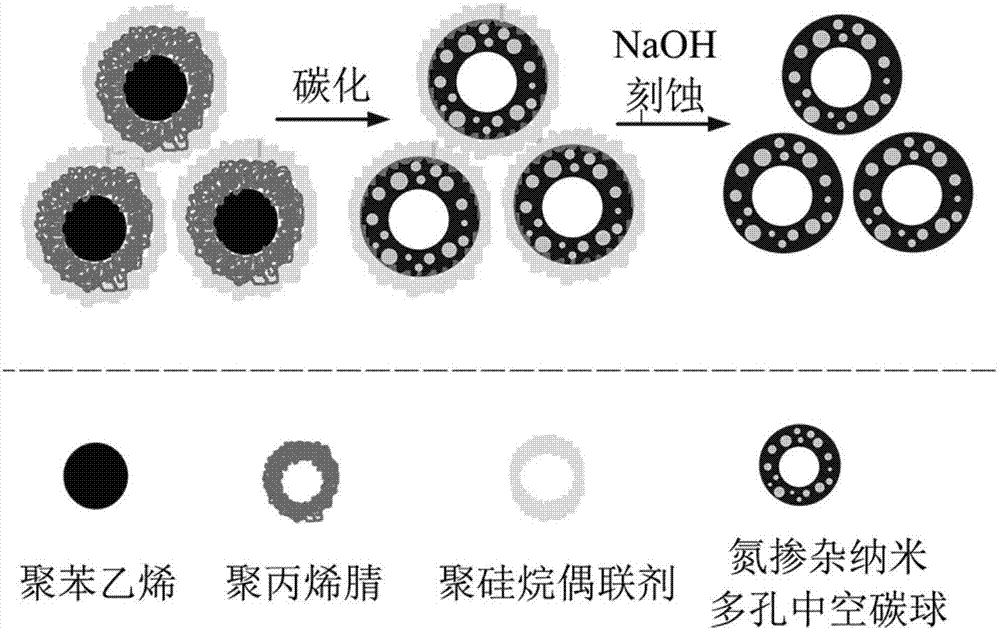

Preparation method of nitrogen-doped nano porous hollow carbon spheres

A nano-porous, nitrogen-doped technology, applied in nano-carbon, nanotechnology, chemical instruments and methods, etc., can solve the problems of toxicity, complex post-processing, high equipment requirements, etc., and achieve improved reactivity, narrow particle size distribution, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of carbon sphere precursor

[0032]Weigh 14.0g styrene, 0.2g polystyrene, 0.8g hexadecane and 0.2g azobisisoheptanonitrile and mix to form an oil phase; weigh 0.2g sodium lauryl sulfate and 0.2g sodium nitrite and dissolve in Form a water phase in 90.0g of water; slowly add the oil phase to the water phase and magnetically stir for 0.5h for pre-emulsification, and then homogeneously emulsify for 5min at a shear rate of 19000rpm in an ice-water bath to form a miniemulsion; transfer the miniemulsion to the container In a three-necked flask with a stirrer, a thermometer and a reflux condenser, pass nitrogen gas for 0.5h, and react at a constant temperature in a water bath at 50°C for 1.0h to obtain polystyrene microspheres; add 10.0g of acrylonitrile dropwise to the obtained polystyrene microspheres Mixture with 0.2g of divinylbenzene, continue to react at constant temperature for 0.5h, then drop 5.0ml of γ-methacryloxypropyl trimethoxysilane into the reacti...

Embodiment 2

[0046] The preparation process of this example is the same as that of Example 1, except that the amount of aqueous phase polymerization inhibitor sodium nitrite is 0.1 g.

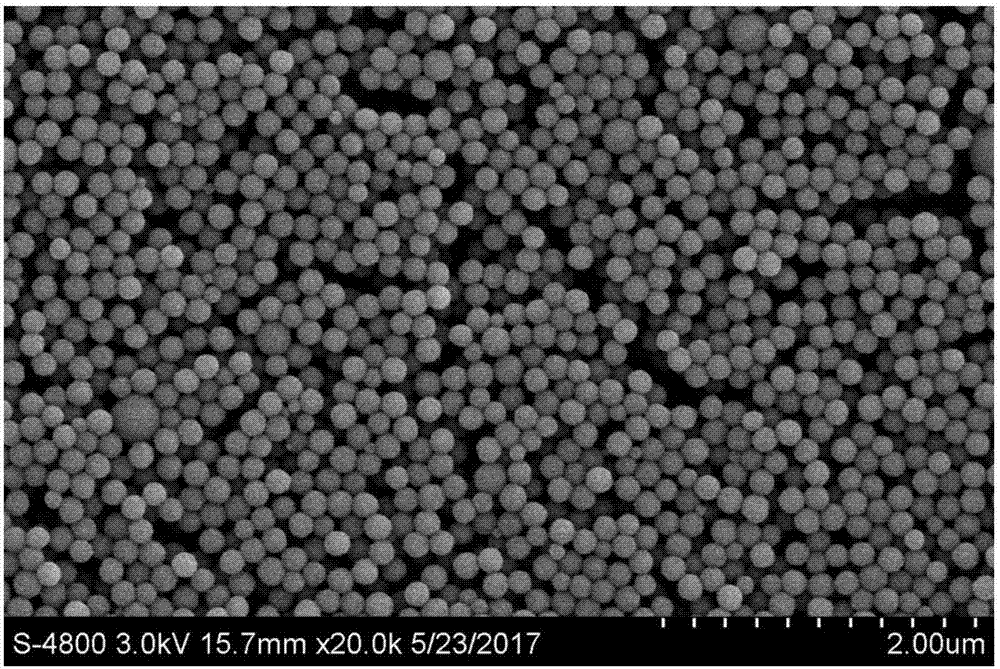

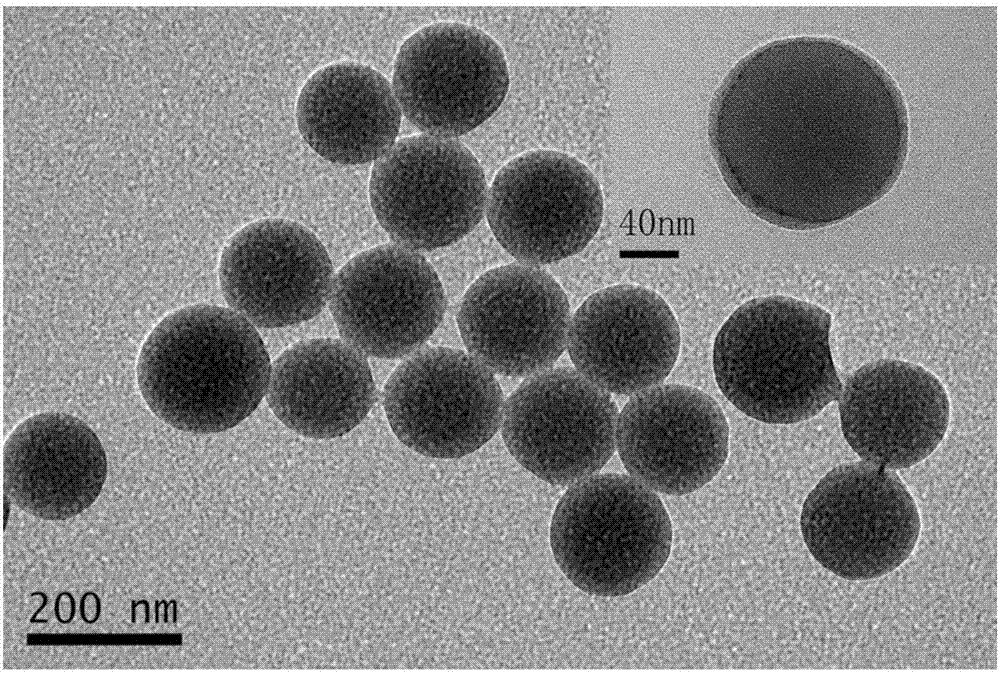

[0047] The nitrogen-doped nanoporous hollow carbon spheres obtained in this example have a particle size of about 100 nm and a specific surface area of 398 m 2 / g, the pore volume is 0.3cm 3 / g, the pore size is 3.1nm.

Embodiment 3

[0049] The preparation process of this example is the same as that of Example 1, except that the amount of aqueous phase polymerization inhibitor sodium nitrite is 0.05 g.

[0050] The nitrogen-doped nanoporous hollow carbon spheres obtained in this example have a particle size of about 100 nm and a specific surface area of 591 m 2 / g, the pore volume is 0.4cm 3 / g, the pore size is 2.9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com