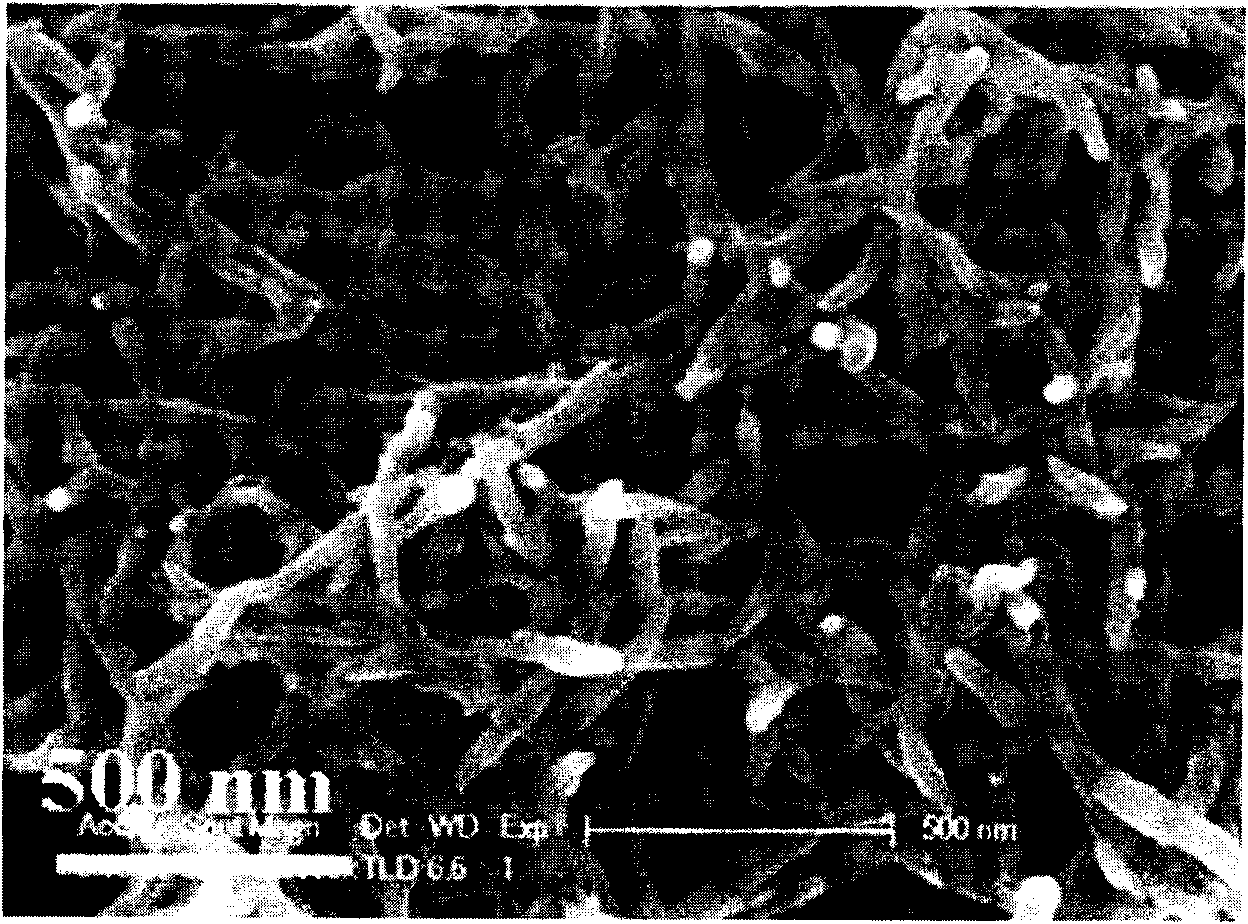

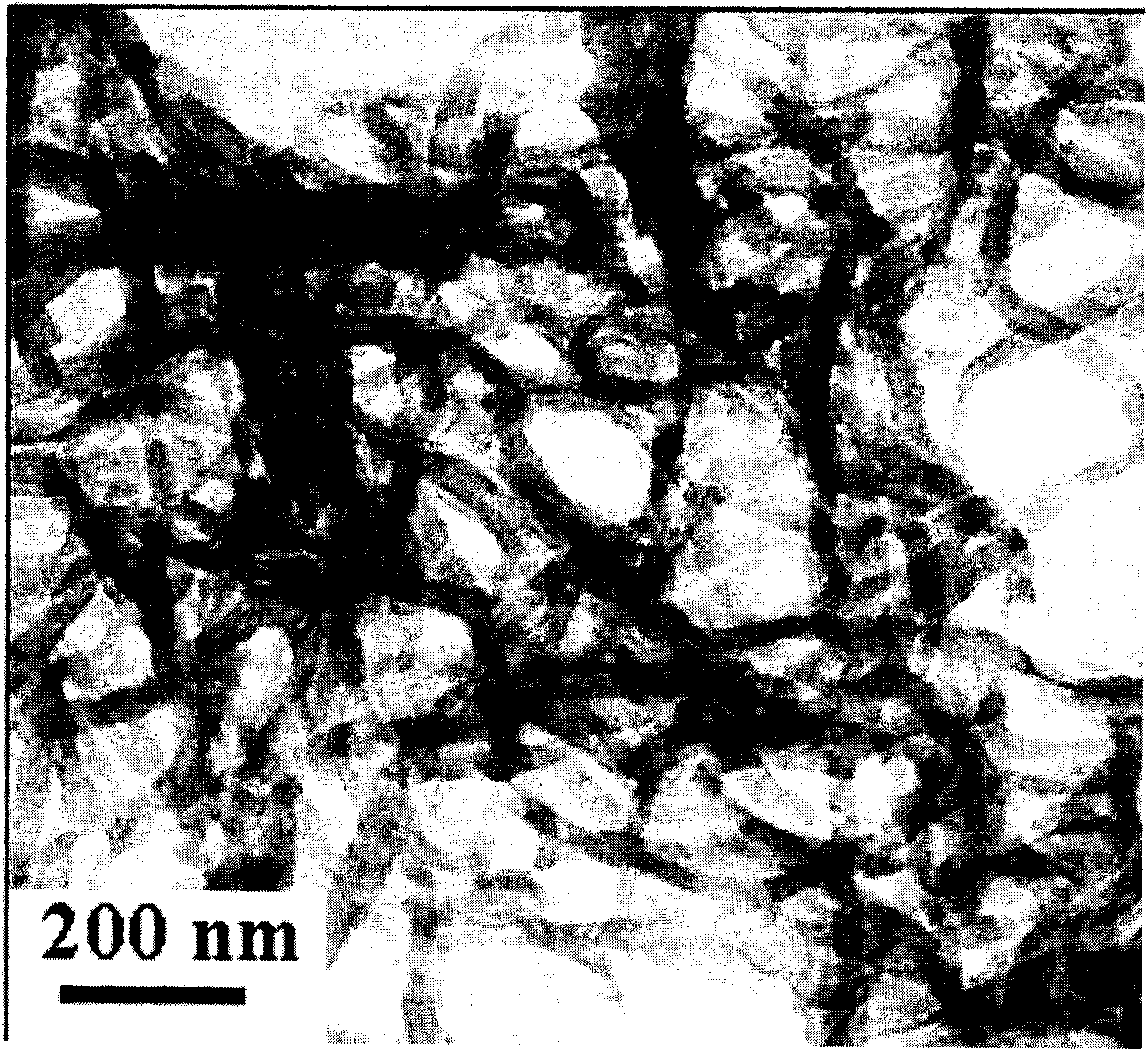

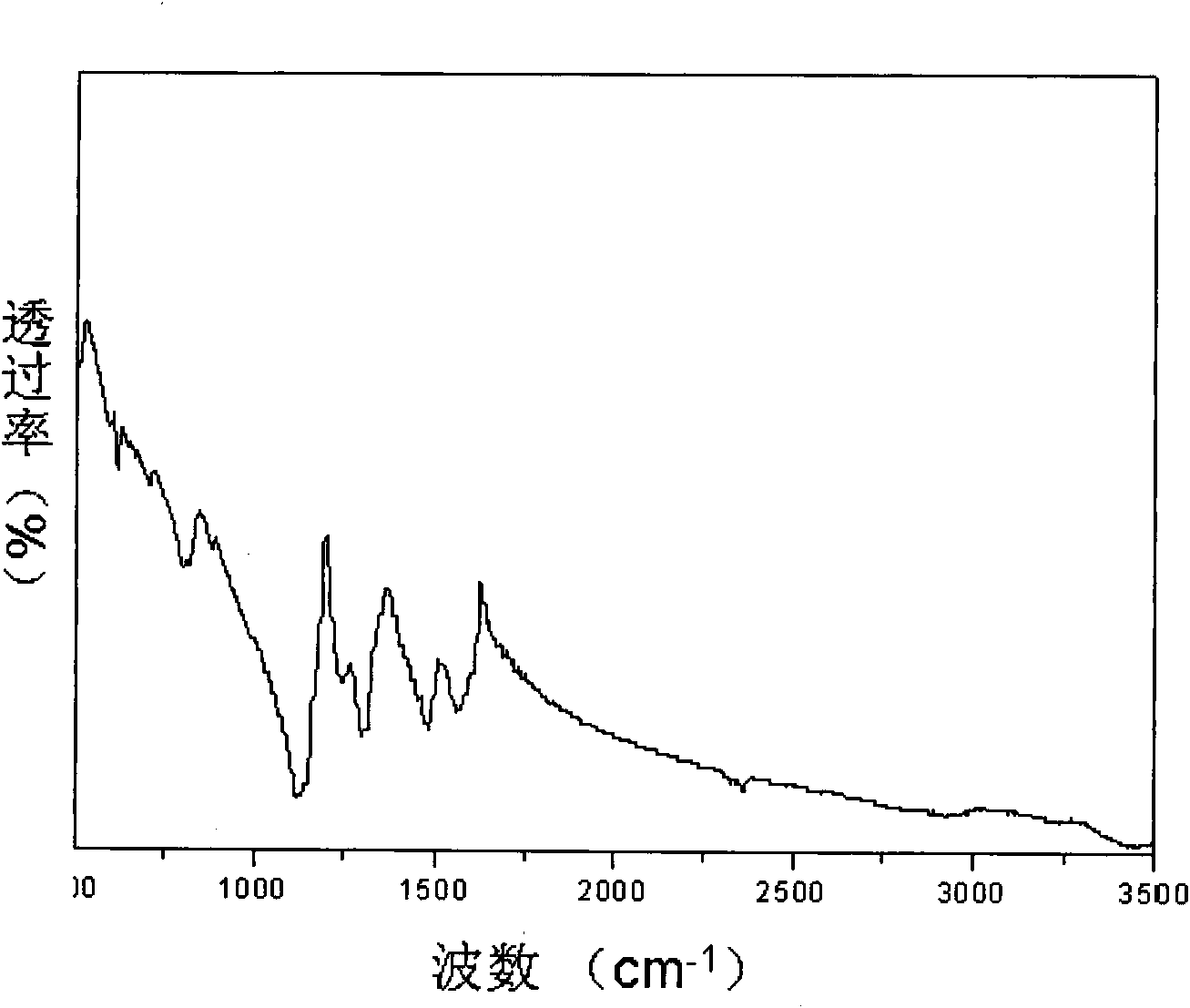

Soluble polyaniline conductive nanofiber and preparation method thereof

A technology of conductive nanometer and polyaniline, which is applied in the field of soluble polyaniline conductive nanofiber and its preparation, can solve the problems of not forming a three-dimensional network structure, poor repeatability of the preparation method, limited application scope, etc., achieving regular size and reducing the possibility of , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The concrete steps of preparation are:

[0024] Step 1: firstly mix aniline and co-stabilizer in a weight ratio of 48:1.2 and then stir for 15 minutes; wherein the co-stabilizer is hexadecane to obtain an oil phase liquid. Then, the emulsifier and water were mixed according to the weight ratio of 1.2:430 and then stirred for 15 minutes; wherein, the emulsifier was cetyl sodium sulfate to obtain an aqueous phase liquid. Next, first mix the oil phase liquid and the water phase liquid and then stir for 15 minutes; wherein, the weight ratio between the aniline in the oil phase liquid and the emulsifier in the water phase liquid is 48:1.2. Then place it in an ultrasonic wave and homogenize it for 10 minutes to obtain a miniemulsion.

[0025]Step 2, first add protonic acid solution to the miniemulsion and then stir for 10 minutes; wherein, the weight ratio between aniline and protonic acid in the miniemulsion is 2.2:1, the protonic acid is hydrochloric acid, and its concentr...

Embodiment 2

[0028] The concrete steps of preparation are:

[0029] Step 1: firstly mix aniline and co-stabilizer in a weight ratio of 49:1.1 and then stir for 17 minutes; wherein the co-stabilizer is hexadecane to obtain an oil phase liquid. Then the emulsifier and water were mixed according to the weight ratio of 1.1:440 and then stirred for 17 minutes; wherein, the emulsifier was cetyl sodium sulfate to obtain an aqueous phase liquid. Next, first mix the oil phase liquid and the water phase liquid and then stir for 17 minutes; wherein, the weight ratio between the aniline in the oil phase liquid and the emulsifier in the water phase liquid is 49:1.1. Then place it in an ultrasonic wave and homogenize it for 11 minutes to obtain a miniemulsion.

[0030] Step 2, first add protonic acid solution to the miniemulsion and then stir for 11 minutes; wherein, the weight ratio between aniline and protonic acid in the miniemulsion is 2.3:1, the protonic acid is hydrochloric acid, and its concentr...

Embodiment 3

[0033] The concrete steps of preparation are:

[0034] Step 1, first mix aniline and co-stabilizer in a weight ratio of 50:1 and then stir for 20 minutes; wherein the co-stabilizer is hexadecane to obtain an oil phase liquid. Then, the emulsifier and water were mixed according to the weight ratio of 1:450 and then stirred for 20 minutes; wherein, the emulsifier was cetyl sodium sulfate to obtain an aqueous phase liquid. Next, first mix the oil phase liquid and the water phase liquid and then stir for 20 minutes; wherein, the weight ratio between the aniline in the oil phase liquid and the emulsifier in the water phase liquid is 50:1. Then place it in an ultrasonic wave and homogenize it for 13 minutes to obtain a miniemulsion.

[0035] Step 2, first add protonic acid solution to the miniemulsion and then stir for 13 minutes; wherein, the weight ratio between aniline and protonic acid in the miniemulsion is 2.3:1, the protonic acid is hydrochloric acid, and its concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com