A two-dimensional semiconductor conjugated polymer material and its preparation and application in ultrafast laser protection

A conjugated polymer and two-dimensional semiconductor technology, applied in the field of two-dimensional materials, can solve the problems of hindering electron transport, π-π stacking hindering electron transport, poor response, etc., and achieve excellent broadband absorption, good optical properties, and high thermal stability Effects on sexuality and environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

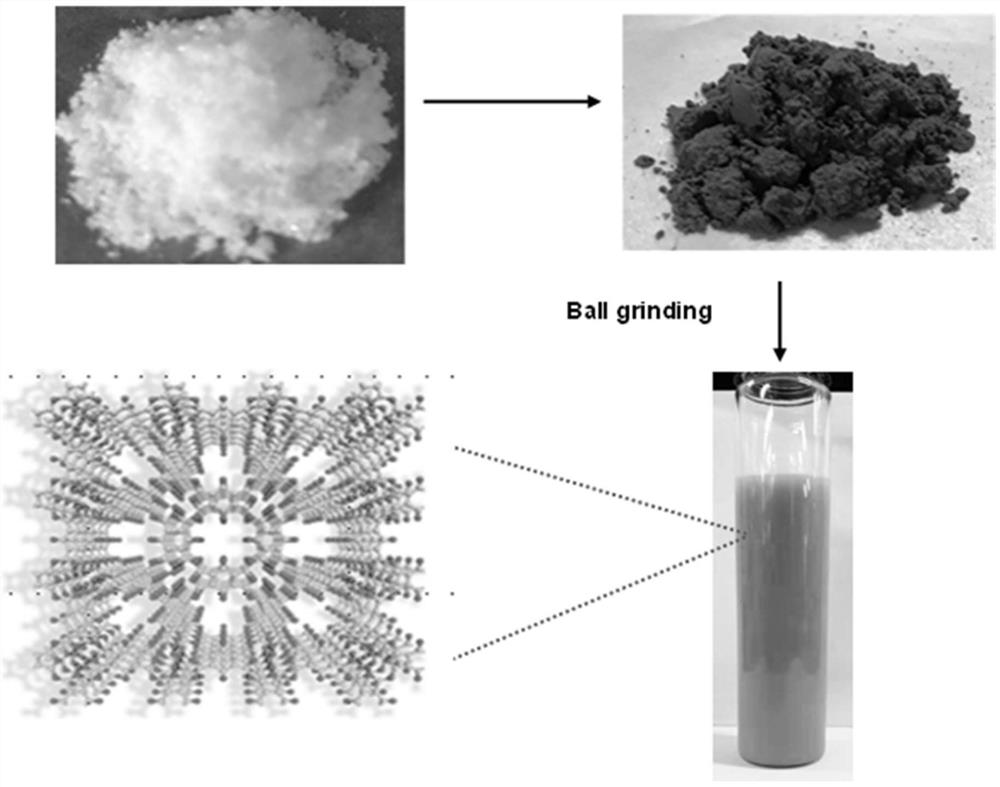

[0035] A method for preparing a two-dimensional semiconductor conjugated polymer material, specifically comprising the following steps:

[0036] (1) Take 10 g of urea, 2.5 g of ammonium chloride, 3 g of pyromellitic dianhydride, 0.5 g of ammonium molybdate, and 1.5 g of phthalic anhydride, grind for about 20 minutes, and mix well to obtain a raw material mixture;

[0037] (2) Add the above-mentioned raw material mixture into the crucible, and then place it in a muffle furnace, and the muffle furnace raises the temperature from room temperature to about 350°C at a rate of 10°C / min, and calcines for 2.5 hours to obtain a crude product;

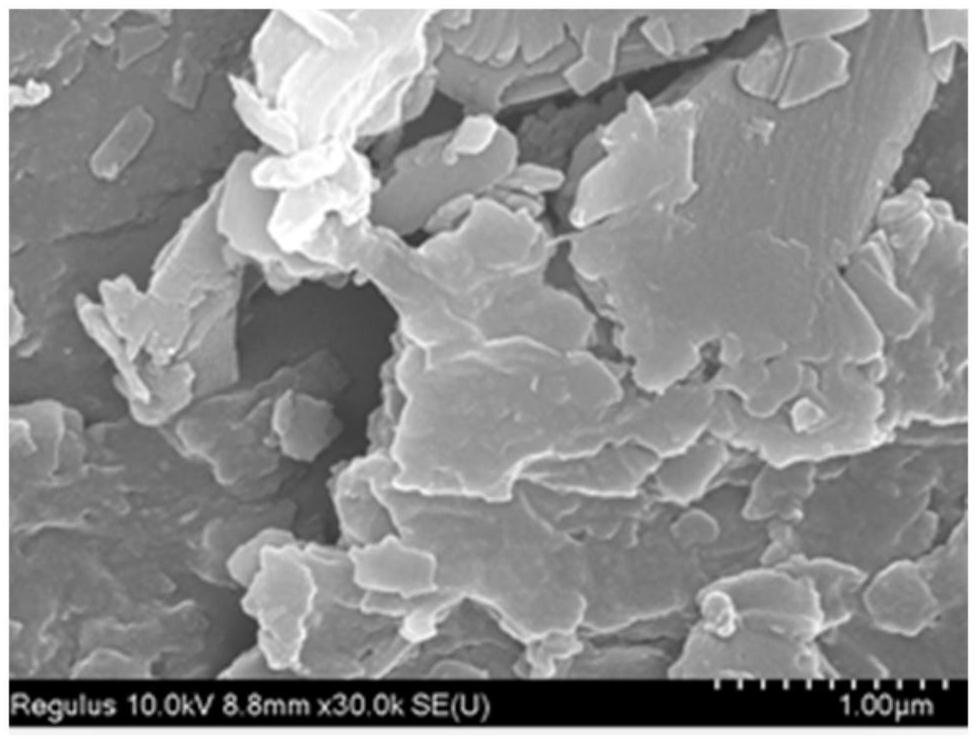

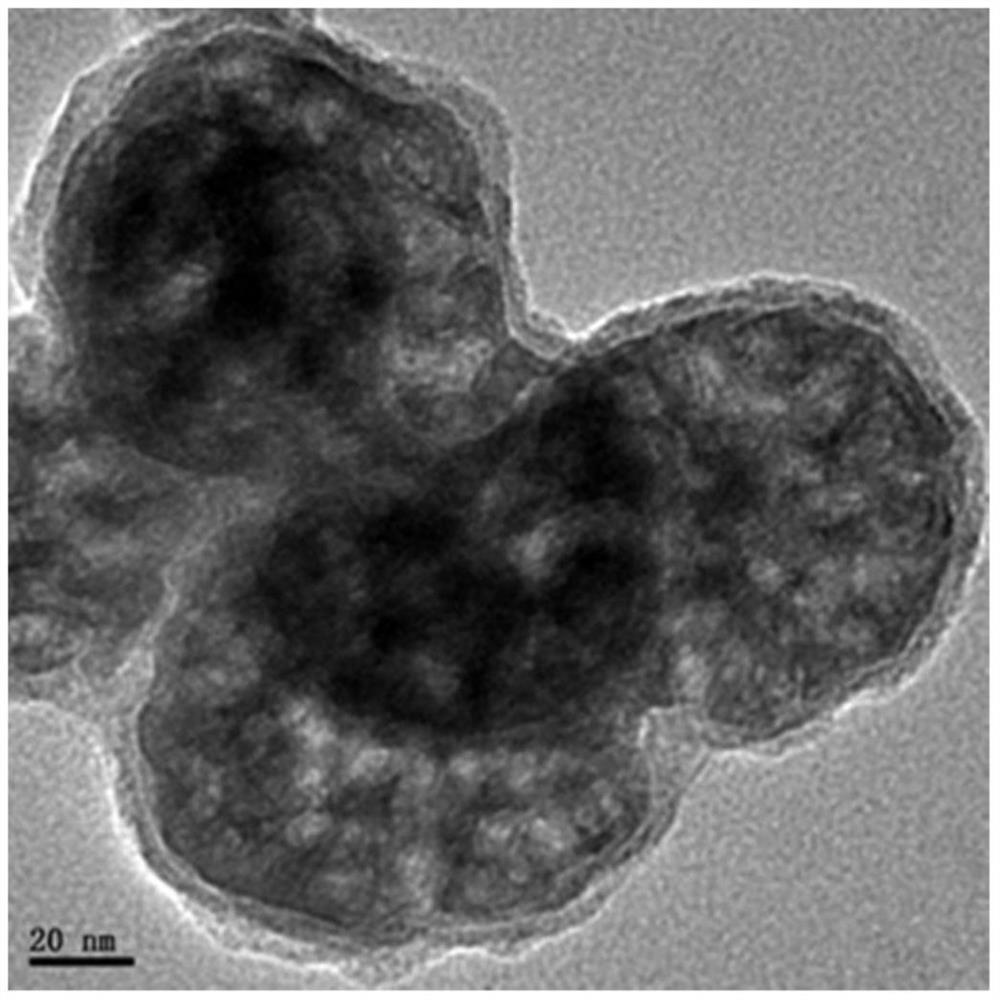

[0038] (3) Wash and filter the crude product repeatedly with methanol and distilled water until the filtrate is colorless, then disperse the filtered solid phase product in distilled water, place the resulting dispersion in a grinding bowl made of zirconia, add The zirconium pellets were ball milled for 4 hours at a rotational speed of 2500 rpm,...

Embodiment 2

[0042] A method for preparing a two-dimensional semiconductor conjugated polymer material, specifically comprising the following steps:

[0043] (1) Take 10 g of urea, 2.5 g of ammonium chloride, 6 g of pyromellitic dianhydride, 0.5 g of ammonium molybdate, and 1.5 g of phthalic anhydride, grind for about 20 minutes, and mix well to obtain a raw material mixture;

[0044] (2) The crucible is placed in a muffle furnace, and the temperature of the muffle furnace is raised from room temperature to about 350° C. at a rate of 10° C. / min, and calcined for 2.5 hours to obtain a crude product.

[0045] (3) The crude product was repeatedly washed and filtered with methanol until the filtrate was colorless, and then filtered to obtain a powder product.

[0046] (4) Disperse the powder product in ethanol, place the dispersion in a grinding bowl made of zirconia, add zirconia balls, and ball mill for 4 hours at a speed of 2500.

[0047] Take the two-dimensional semiconductor conjugated pol...

Embodiment 3

[0050] A method for preparing a two-dimensional semiconductor conjugated polymer material and its ultrafast laser test, specifically including the following steps:

[0051] (1) Take 10g of urea, 2.5g of ammonium chloride, 6g of pyromellitic dianhydride, 0.5g of ammonium molybdate, and 1.5g of phthalic anhydride, grind for about 20min, and mix well to obtain the raw material mixture and add it to the crucible;

[0052] (2) The crucible is placed in a muffle furnace, and the temperature of the muffle furnace is raised from room temperature to about 350° C. at a rate of 10° C. / min, and calcined for 2.5 hours to obtain a crude product.

[0053] (3) The crude product is washed and filtered repeatedly in an organic solvent until the filtrate is colorless. The organic solvent is dichloromethane and dimethyl sulfoxide, and a filtered powder product is obtained.

[0054] (4) Disperse the filtered powder product in ethanol, place the dispersion in a grinding bowl made of zirconia, add z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com