Patents

Literature

75results about How to "Neat surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

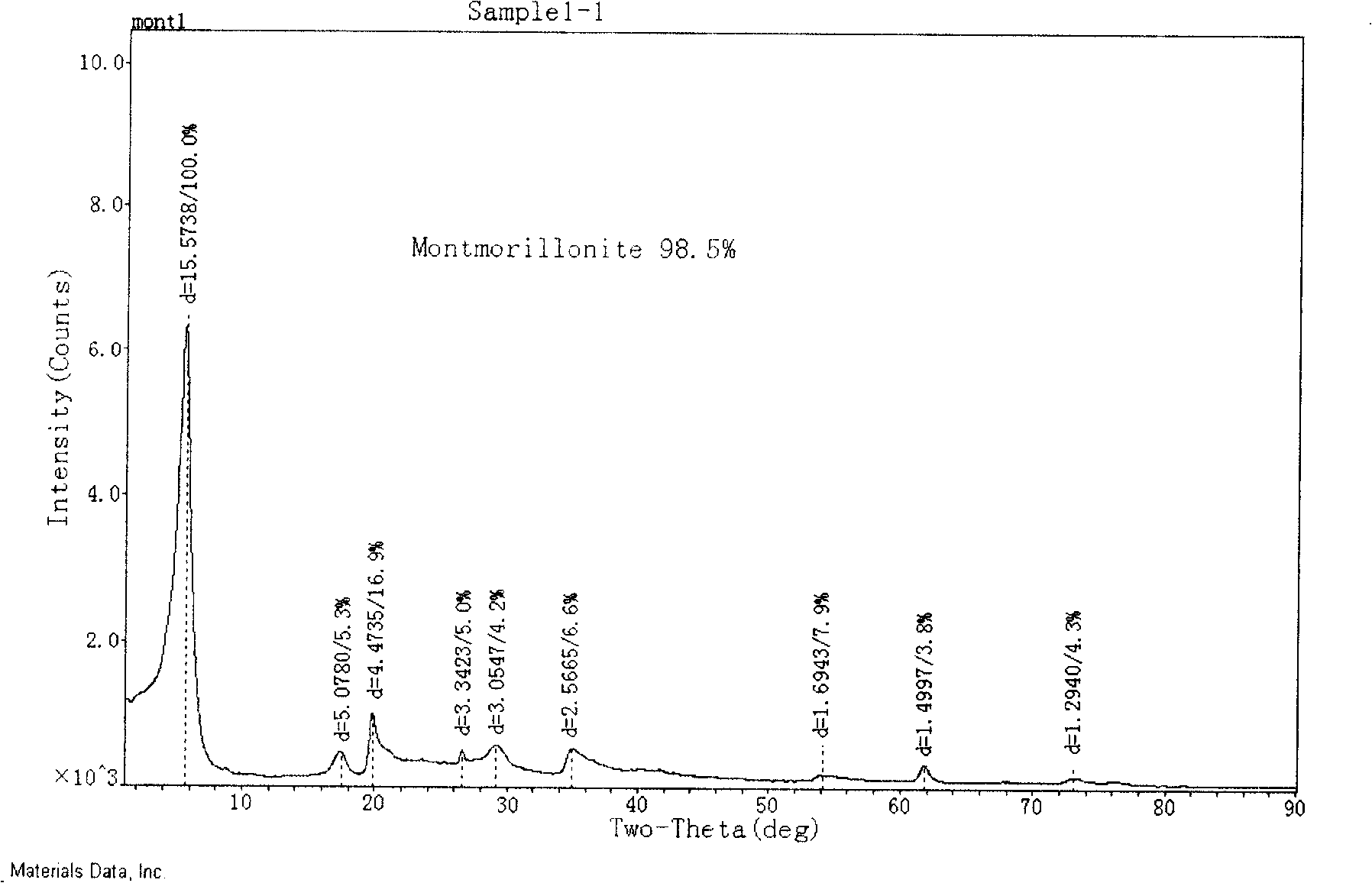

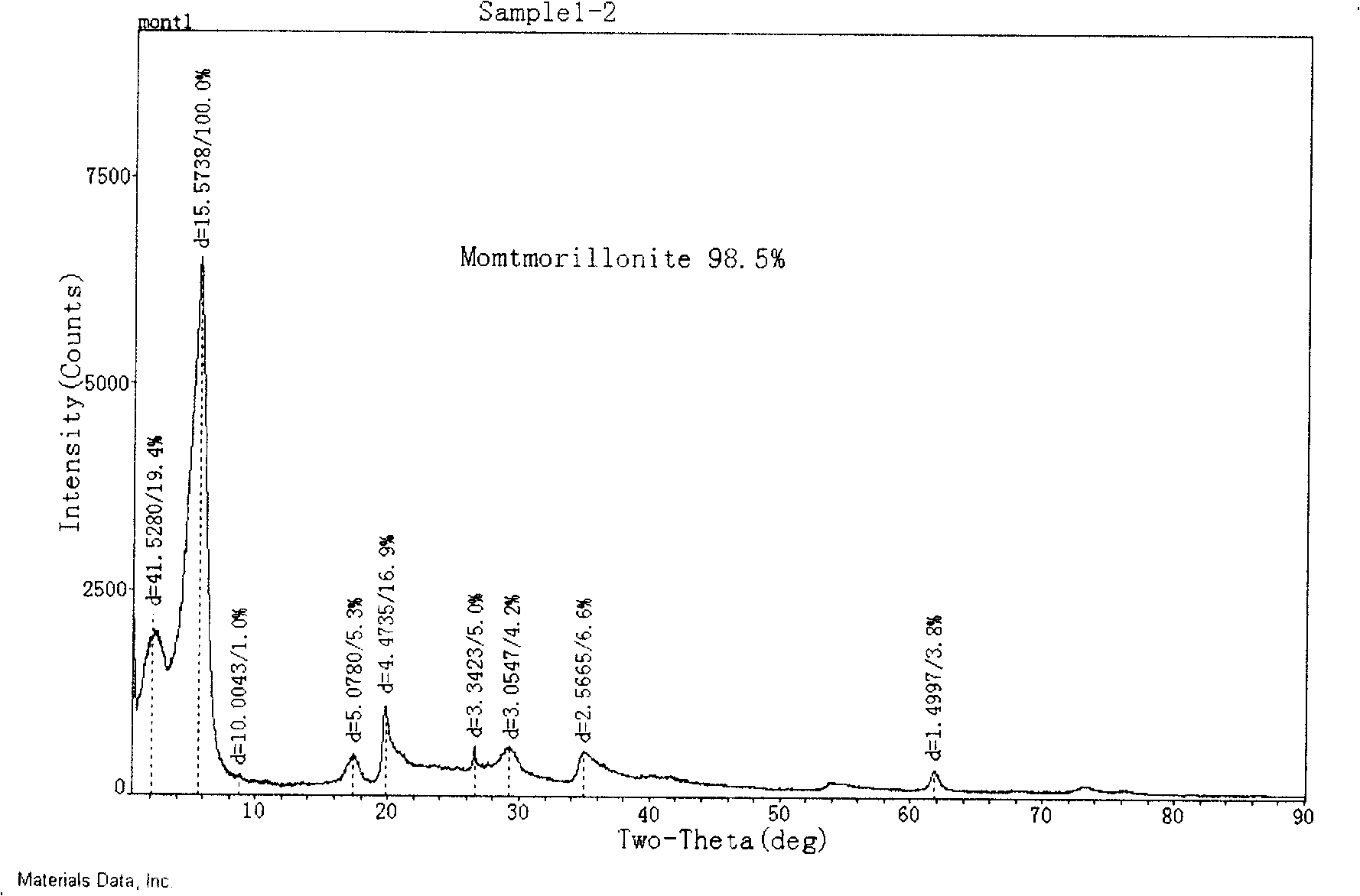

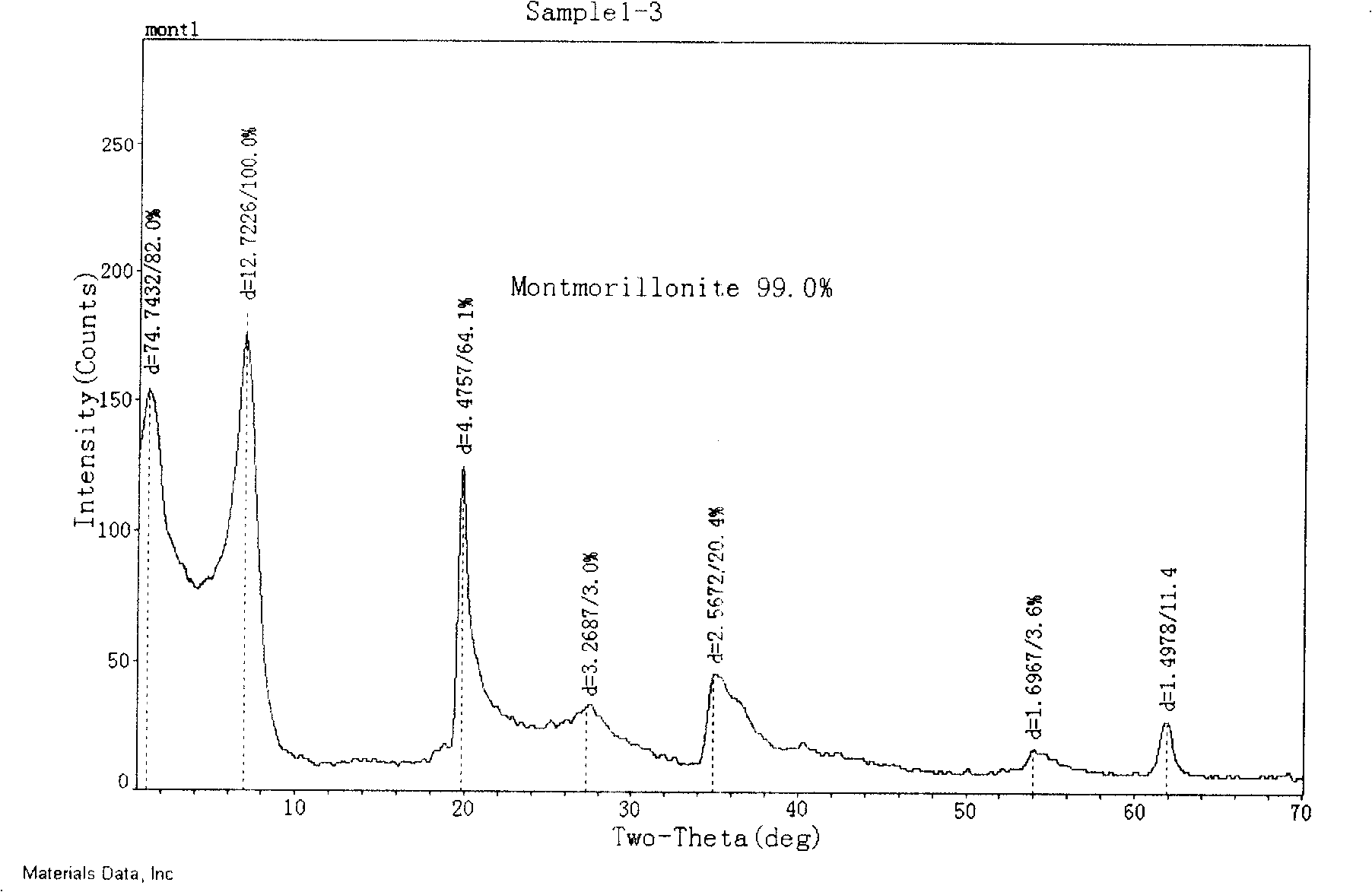

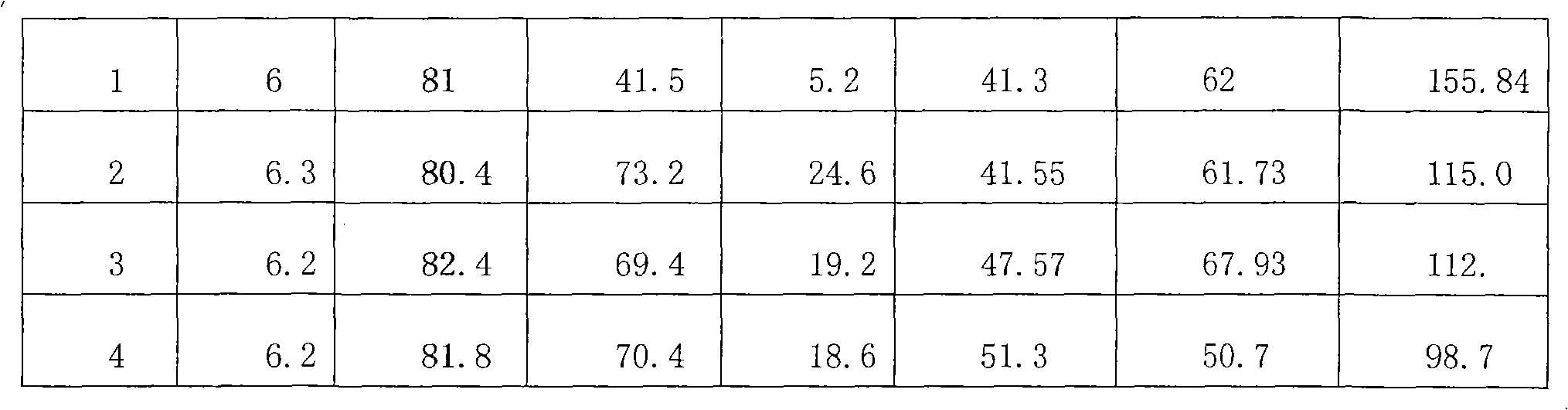

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

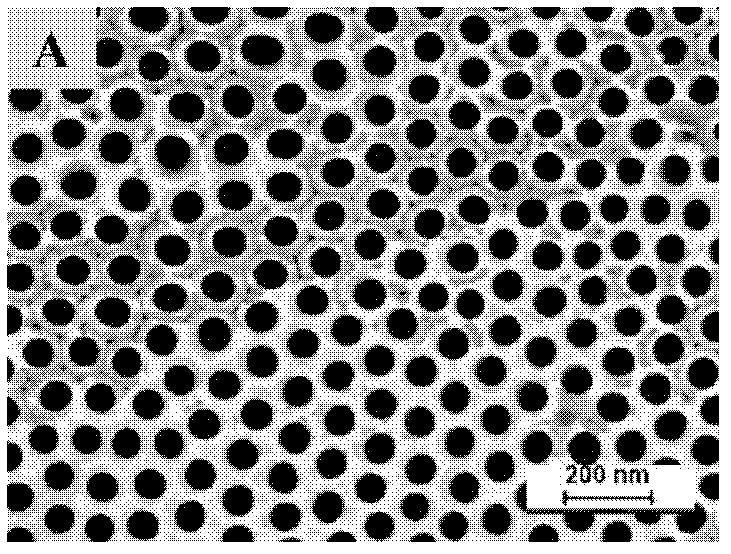

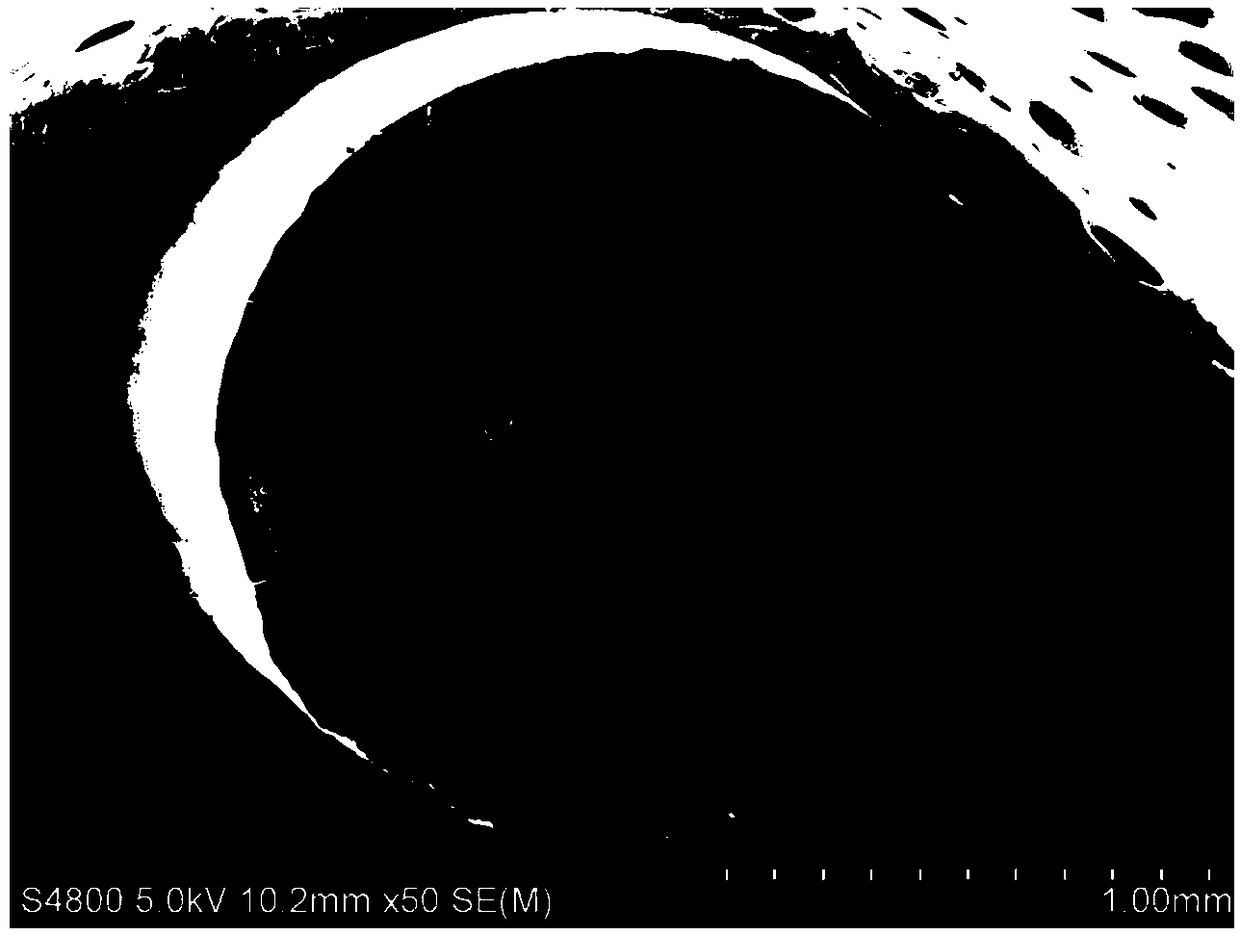

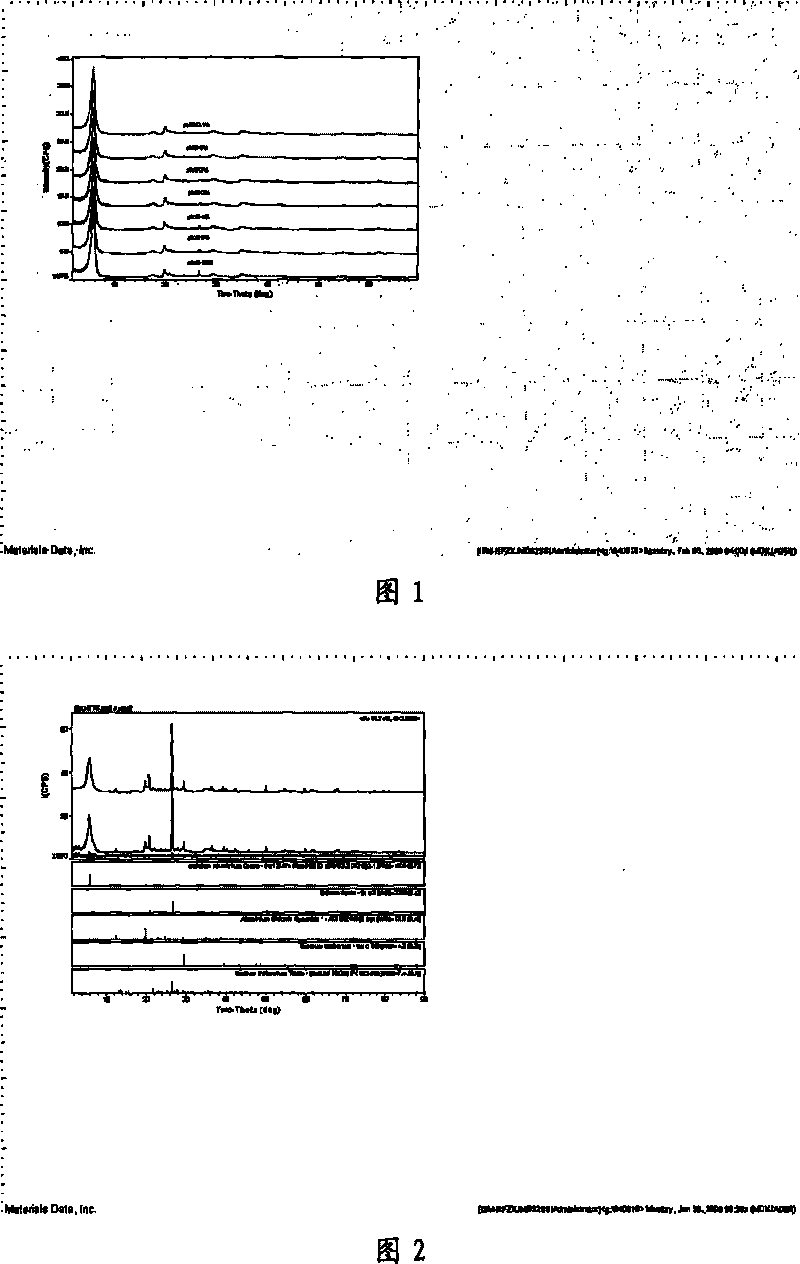

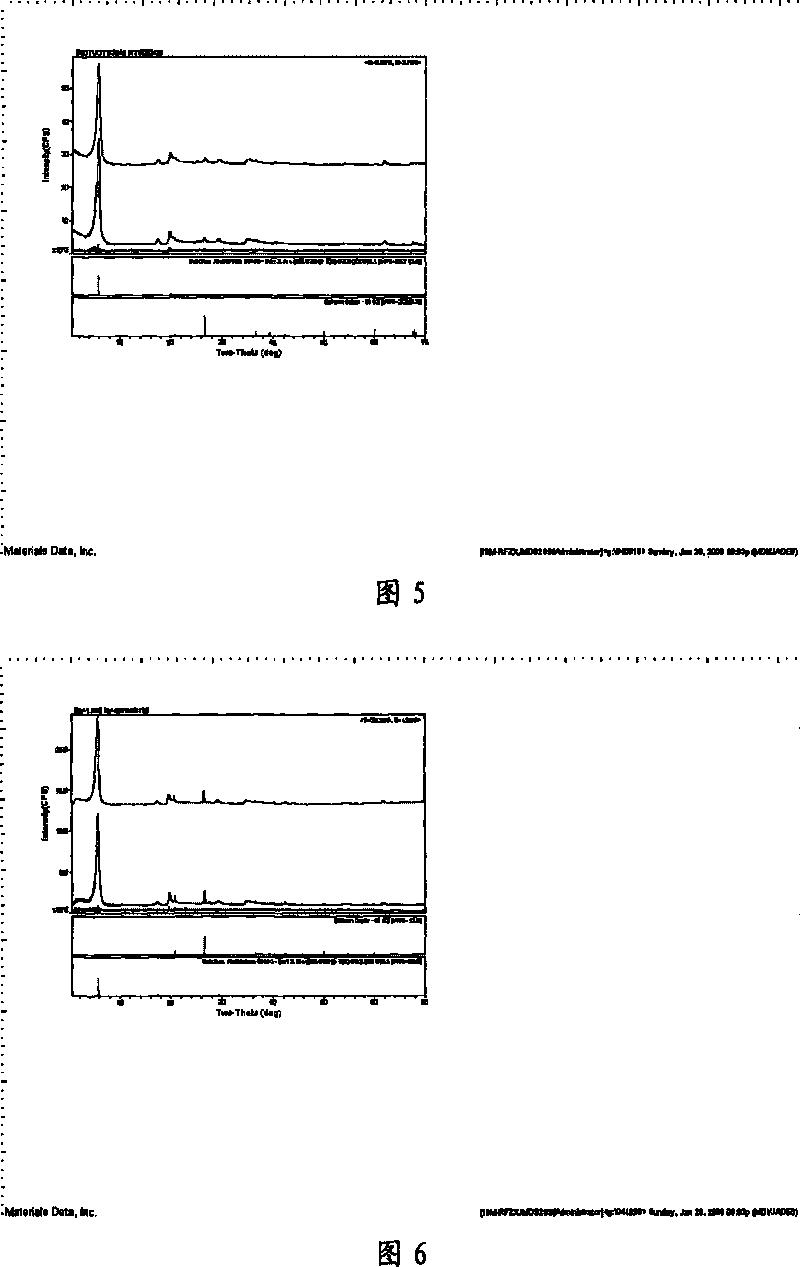

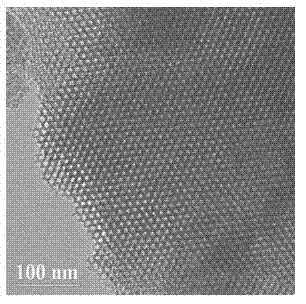

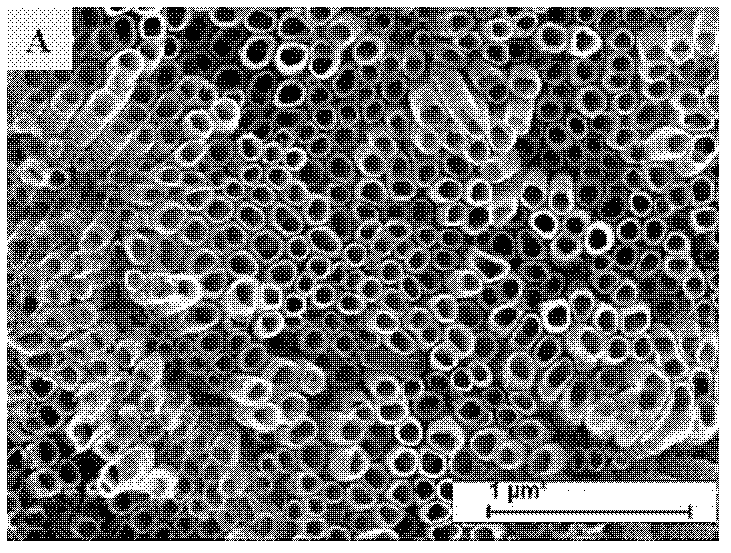

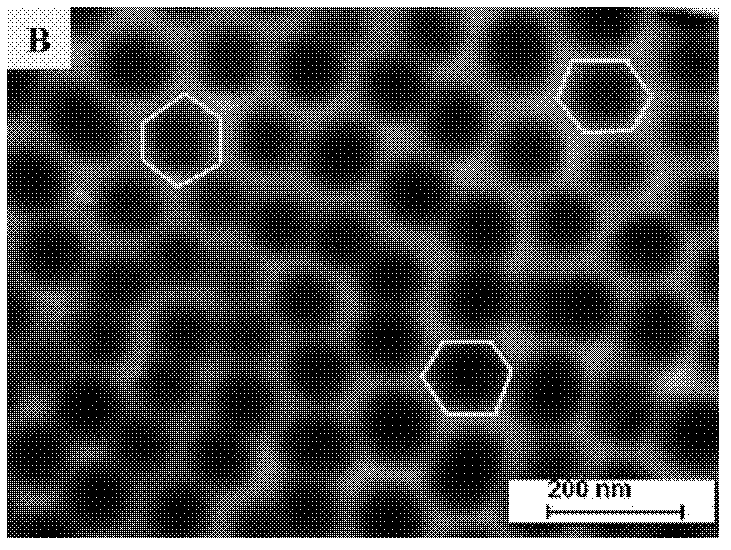

Method for preparing titanium dioxide nanotube array

InactiveCN102220616ANeat surfaceEvenly distributedSurface reaction electrolytic coatingSolventAnodic oxidation

The invention discloses a method for preparing a titanium dioxide nanotube array, which comprises the following steps: grinding the surface of a titanium sheet by using abrasive paper, polishing by using chemical polishing solution, and drying for later use; preparing electrolyte, wherein a fluoride is used as a solute, water is used as a solvent and an alcohol additive is added; preparing an electrolytic cell having two electrode systems, wherein a titanium sheet is used as an anode, a platinum sheet is used as a counter electrode, and a layer of TiO2 nanotube array can be formed on the surface of the titanium sheet by electrochemical anodic oxidation; subjecting the anodically oxidized titanium sheet to ultrasonic cleaning in acidic solution and drying; and performing anodic oxidation again by using the titanium sheet as the anode, and thus, forming the TiO2 nanotube array with uniform pipe diameter and flat surface on the surface of the titanium sheet. In the method, the problems of non-uniform tube diameter, uneven nantube surface and irregular array of two-step anodic oxidization are solved, and the titanium dioxide nanotube array with more regular shape is formed.

Owner:SOUTHEAST UNIV

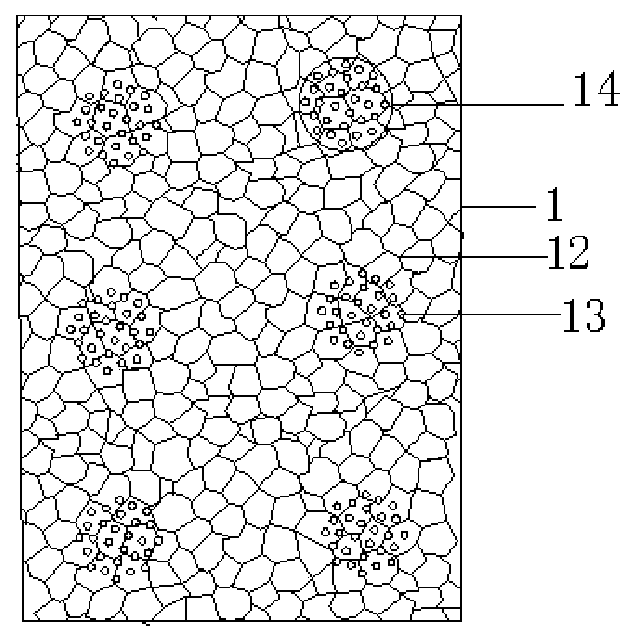

Biodegradable hard tissue repair composite scaffold prepared by 3D printing technology and preparation method thereof

PendingCN109260522AEvenly dispersedGood dispersionAdditive manufacturing apparatus3D object support structuresMelt extrusionHard tissue

The invention discloses a biodegradable hard tissue repair composite scaffold prepared by 3D printing technology and a preparation method thereof, belonging to the field of biomedical materials. The composite scaffold combines degradable high molecular polymer and biologically active calcium phosphate together through a wet composite method, complements each other in advantages, and obtains a hardtissue repair scaffold material with excellent mechanical properties and biologically active through a 3D printing technology of melt extrusion (FDM). Silane coupling agent was used to modify the surface of calcium phosphate nano-powder, which enhanced the combination of calcium phosphate and polymer, and improved the fluidity and integrity of outgoing wire in the preparation of FDM standard wire.

Owner:SICHUAN UNIV

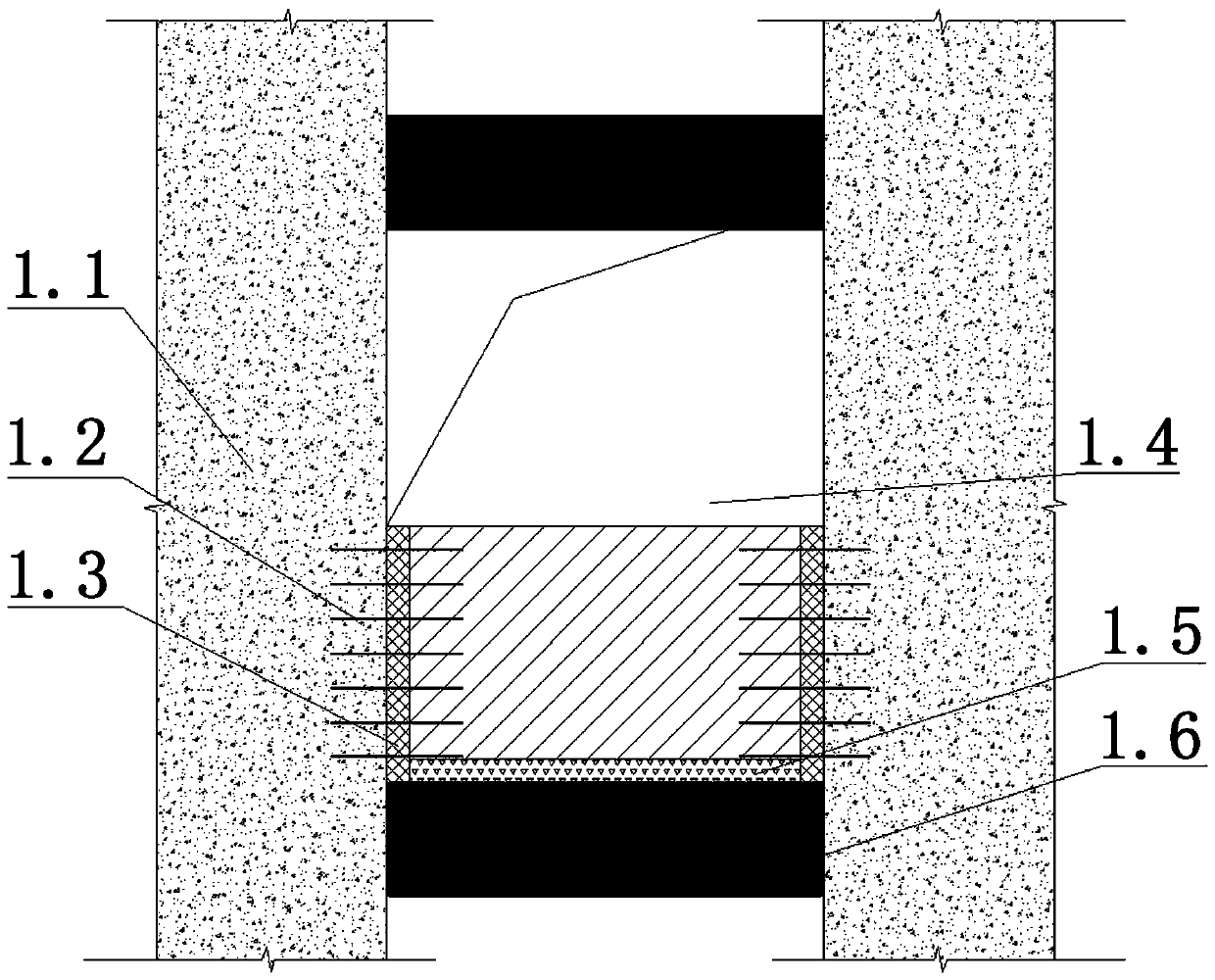

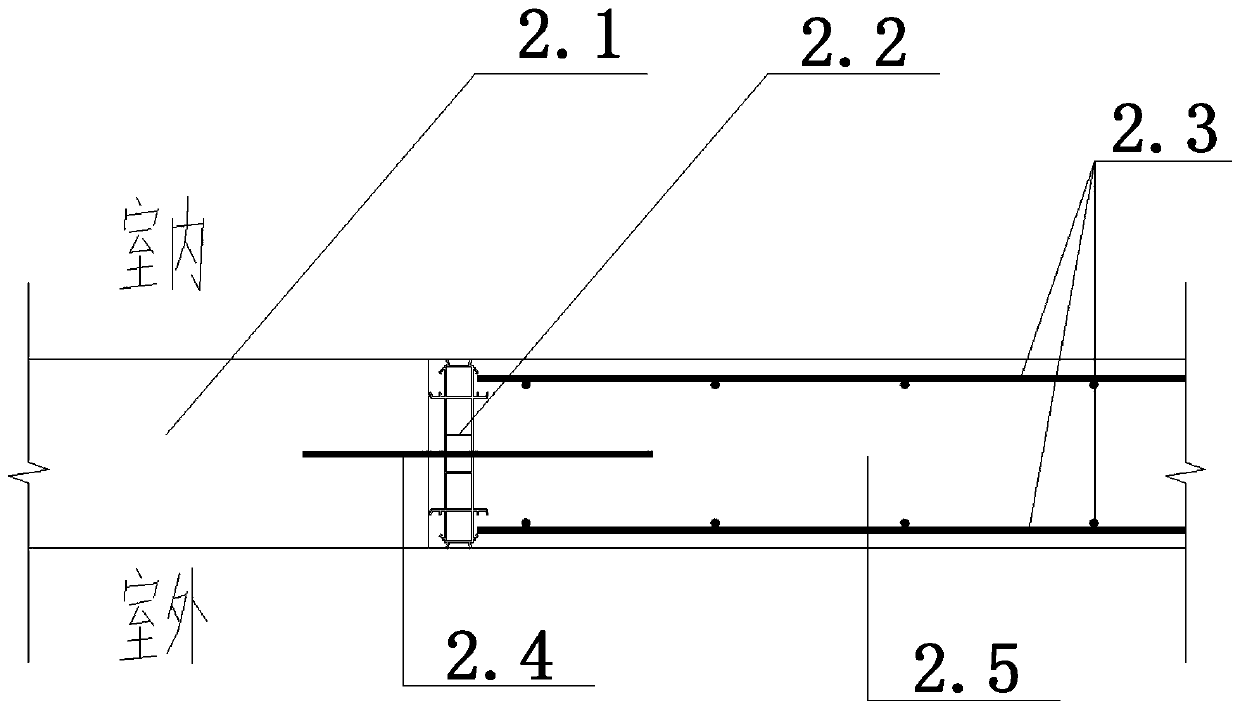

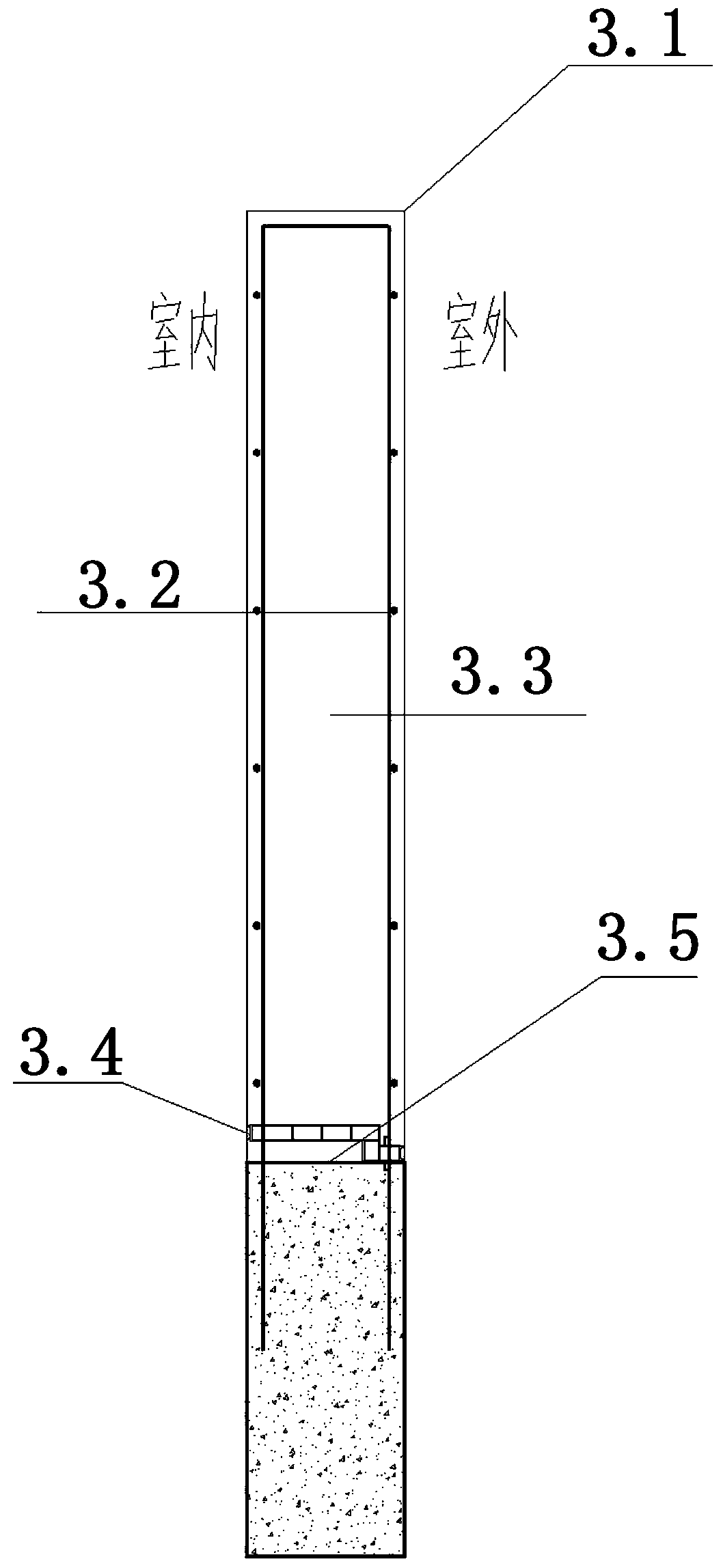

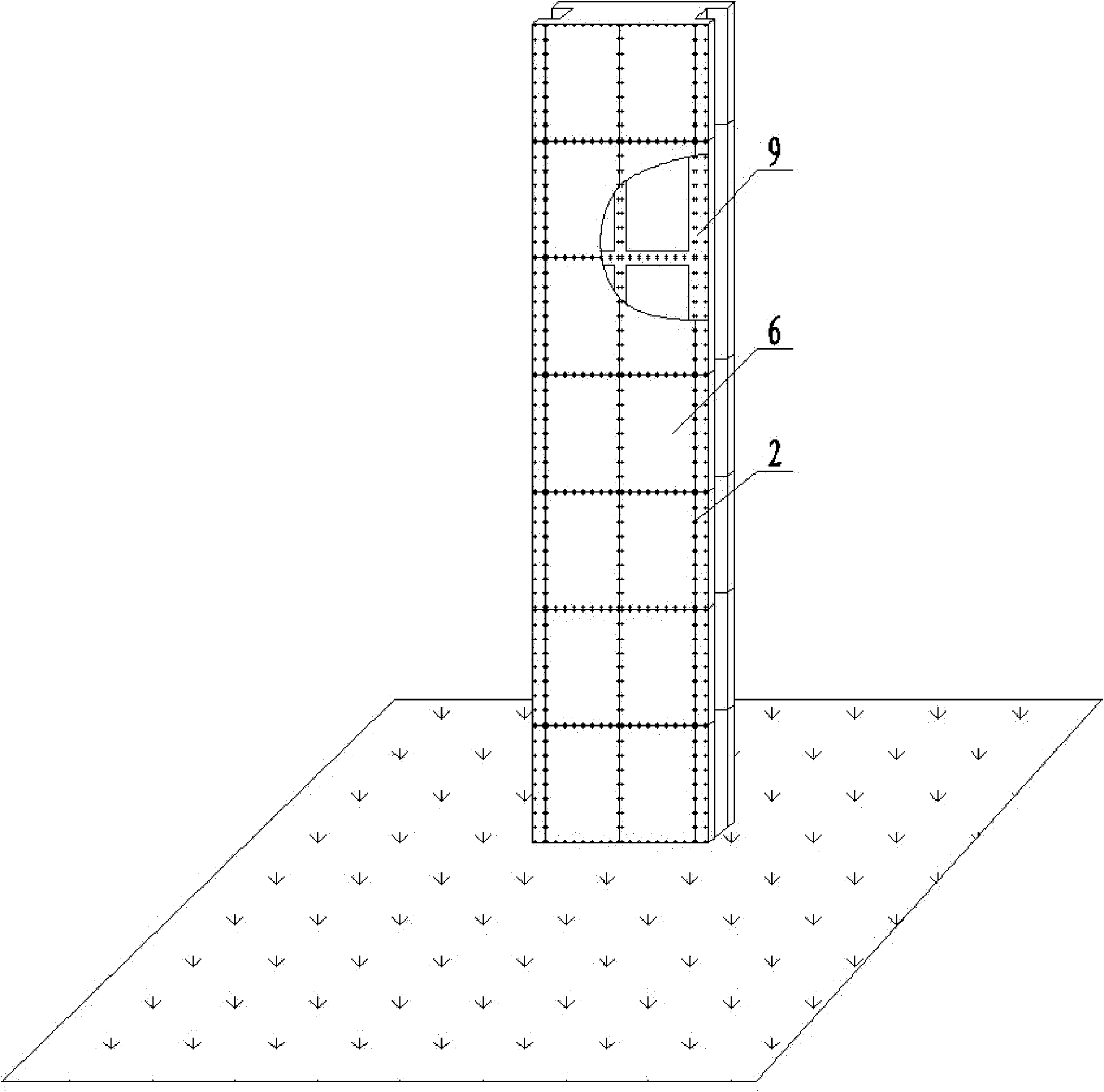

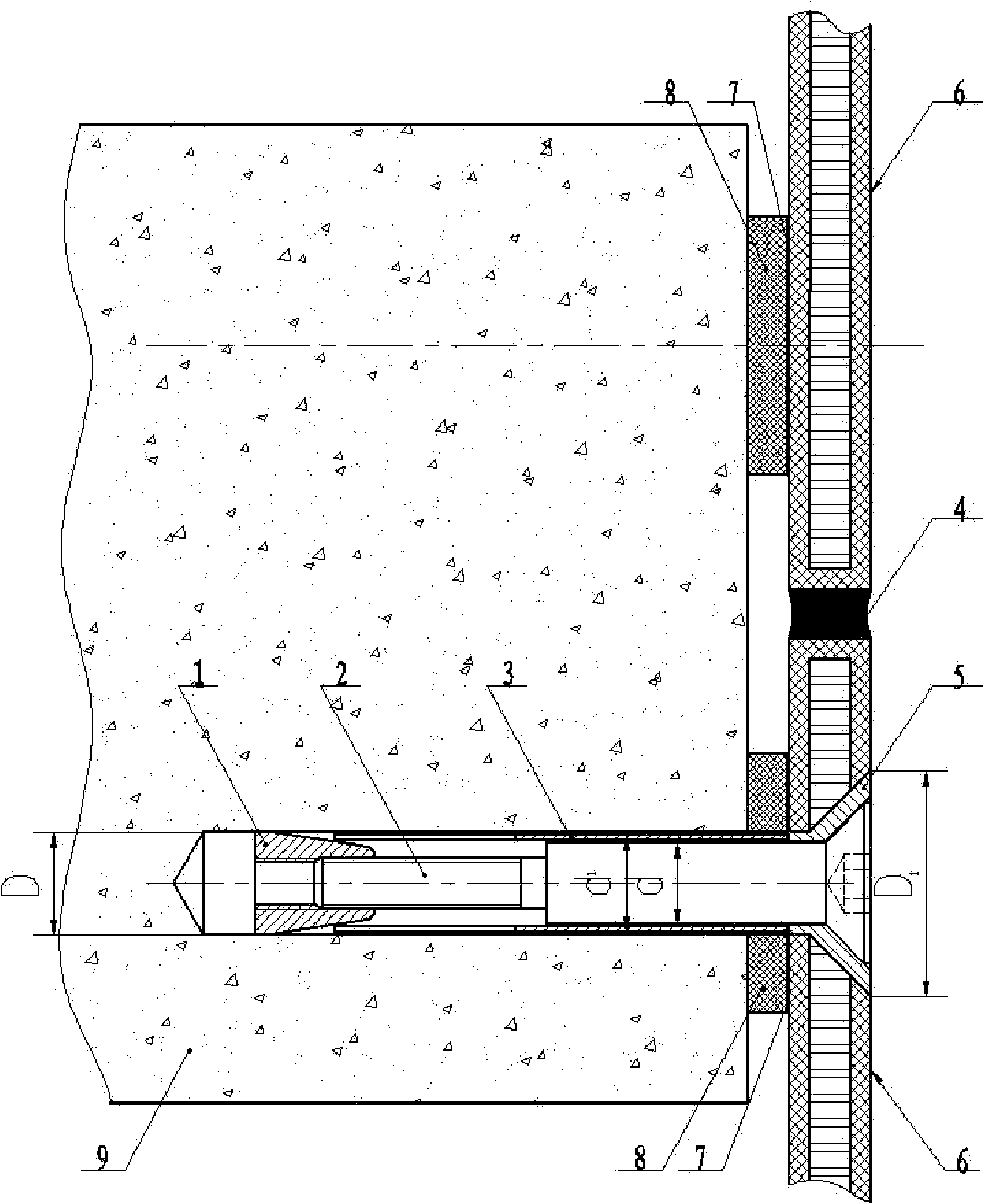

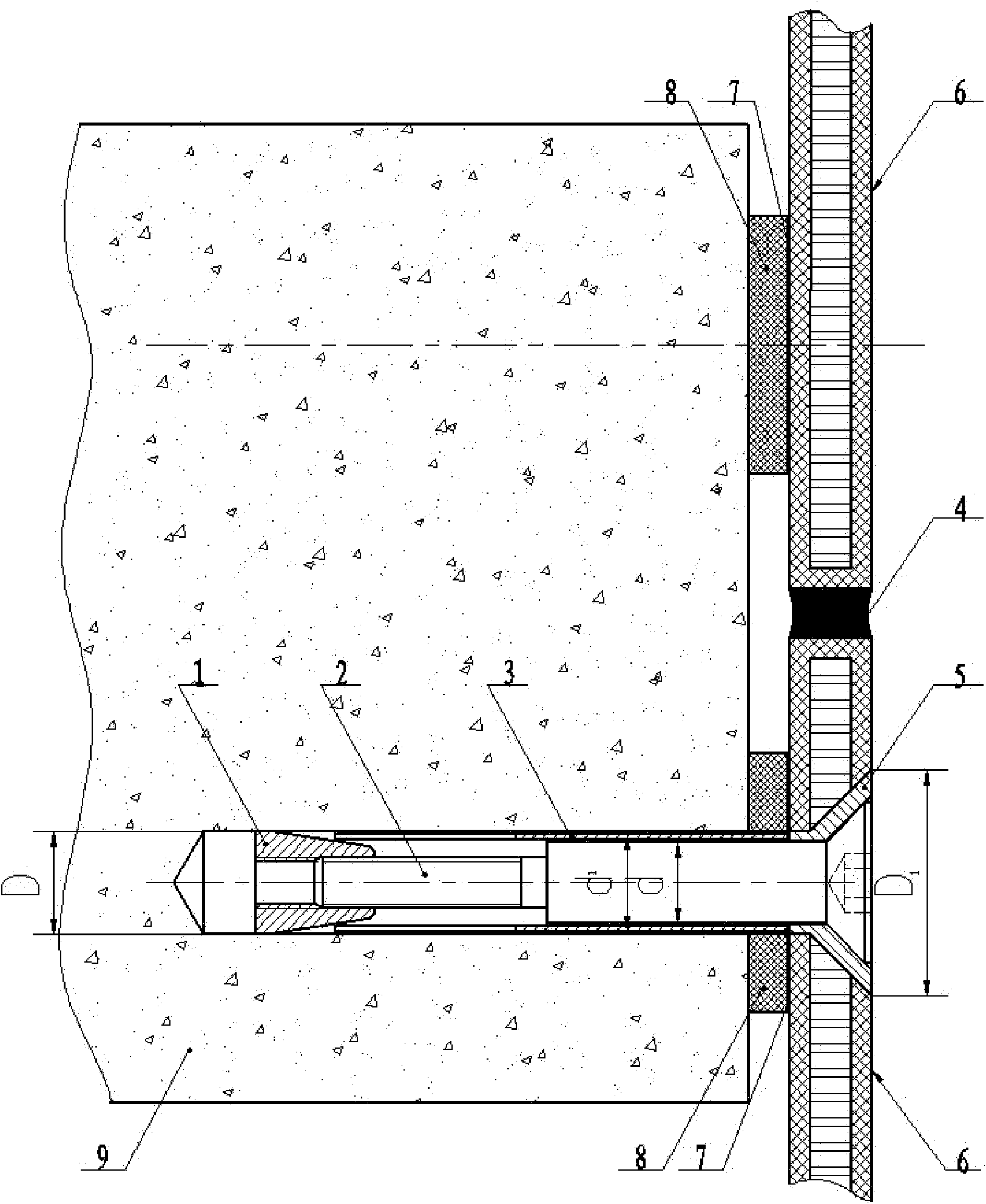

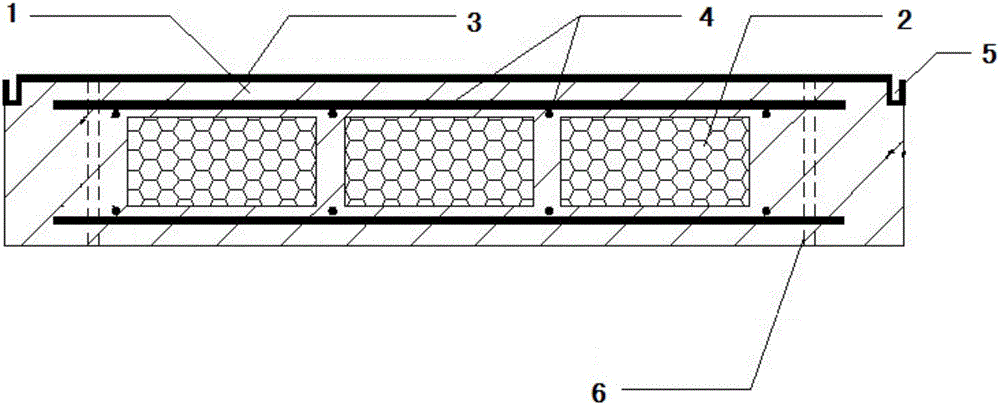

Anti-cracking structure for joint of full-concrete outer wall under-window filling wall and shear wall and construction method thereof

InactiveCN111335490AReduce wasteReduce the risk of water leakageWallsForms/shuttering/falseworksWater leakageFloor slab

The invention belongs to the technical field of concrete outer wall construction, and provides an anti-cracking structure for a joint of a full-concrete outer wall under-window filling wall and a shear wall and a construction method thereof in order to prevent the problem that cracks are generated at the positions such as the under-window wall due to concrete shrinkage. Anti-cracking steel bars and joint pulling plates are arranged in a concrete pouring layer at intervals, wherein the joint pulling plates comprise horizontal structure joint pulling plates and vertical structure joint pulling plates; the horizontal structure joint pulling plates are arranged between floors or beams of all layers and the under-window filling wall; and the vertical structure joint pulling plates are arrangedbetween the shear wall and the under-window filling wall; transverse anti-cracking steel bars are arranged at the joint of the shear wall and the under-window filling wall, and the transverse anti-cracking steel bars penetrate through the vertical structure joint pulling plates to be bound and overlapped with wall body steel bars of the shear wall and the under-window filling wall on the two sides. The anti-cracking structure is convenient to assemble and disassemble, construction joints are avoided, the hidden danger of water leakage of the structure is reduced, and the applicability is improved. The operation is convenient, the construction quality and effect are good, the change of the overall rigidity is avoided, the construction period is shortened, and the structural safety is guaranteed.

Owner:CHINA SHANXI SIJIAN GRP

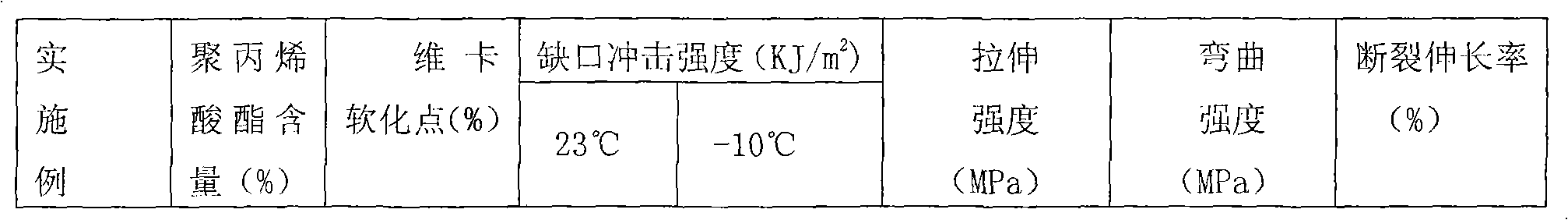

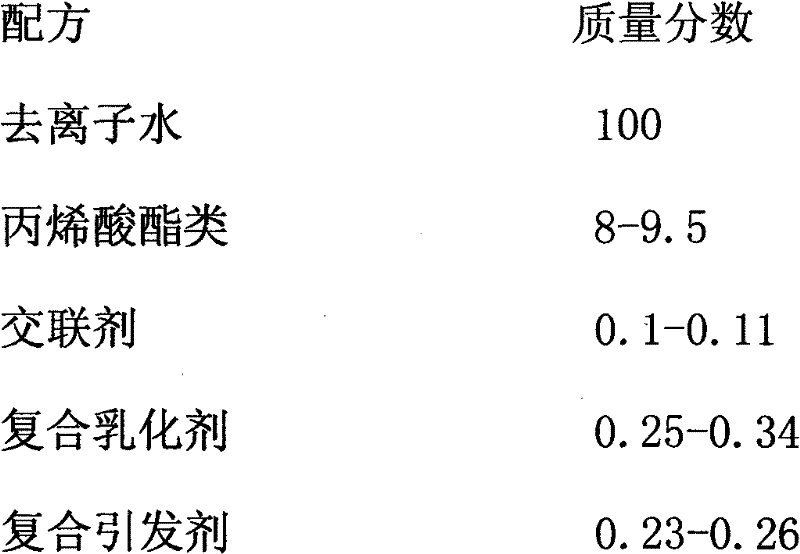

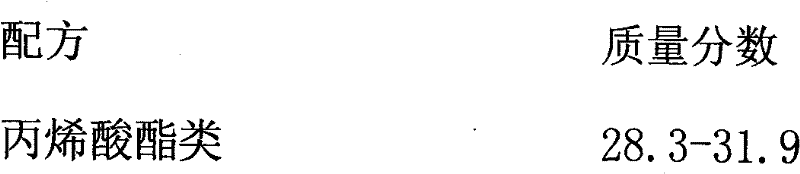

Preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin

The invention relates to the technical field of vinyl chloride resin, in particular to a preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin. A single emulsifier and a single initiator are adopted by the original synthesis process, and tests proof that the single emulsifier can enable polymer latex not to be stable, and therefore, a stable polymerization product can not be obtained; the single initiator enables a polymerization system not to be stable, and reaction is difficult to control; freezing demulsification, filtering, washing, drying and the like are adopted as treatment processes of a vinyl chloride grafting copolymer emulsion to form a thick and big aggregated particle structure, and the product performance is low; moreover, much wastewater and many waste residues are generated in the process. In the invention, the stability of the latex is ensured by adopting a compound emulsifier and a compound initiator, which ensures that the latex has better average particle diameter, the polymerization system is stable and the reaction is easy to control; centrifugal spray drying is adopted to treat emulsion resin, and thereby, a good resin product with even particle size distribution and good processing performance can be obtained; and the wastewater and the waste residues are not generated, the process flow is short and the energy can be saved and the consumption can be lowered.

Owner:河北盛华化工有限公司

Method for purifying montmorillonite, purified montmorillonite and combination thereof

ActiveCN101340979BReduce moisture contentAvoid cakingWet separationClaywaresPhysical chemistryMontmorillonite

A method for purification and separation of inorganic mineral, especially for purification and separation of montmorillonite from natural bentonite is provided. The said method is simple, and uses high-speed centrifugal device to well solve the problems present in purification of montmorillonite that a-quartz and cristobalite are difficult to be separated and removed and purified slurry is difficult to be concentrated and dehydrated. The purity of montmorillonite thus obtained is not less than 95%.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

Pre-stress galvanizing steel strand manufacture method

The invention relates to a pre-stress galvanizing steel strand manufacture method; the pre-stress galvanizing steel strand comprises a heart wire, inner wires and outer wires; the inner wires are wrapped outside the heart wire in an anticlockwise manner; the outer wires are wrapped outside the inner wires in an anticlockwise manner; the inner wires and outer wires are synchronically wrapped on the heart wire with same lay length, and the strand is formed in one time stranding moulding; the inner wires comprise 9 galvanizing steel wires, and the outer wires comprise 9 galvanizing steel wires. A drawing die angle and calibration bench parameters are finely designed in galvanizing drawing; most proper temperature and clamp tension parameters are selected in laying length and stabilization treatment under tension tempering after laying, so the prepared strand is uniform and compact; the galvanizing layer is strong in clunging and smooth in surface; the steel strand is tidy in wiring, compact, high in tension strength, high in breaking force, high in ductility, low in loosening property, strong in corrosion resistance, and long in life.

Owner:天津市新天钢中兴盛达有限公司

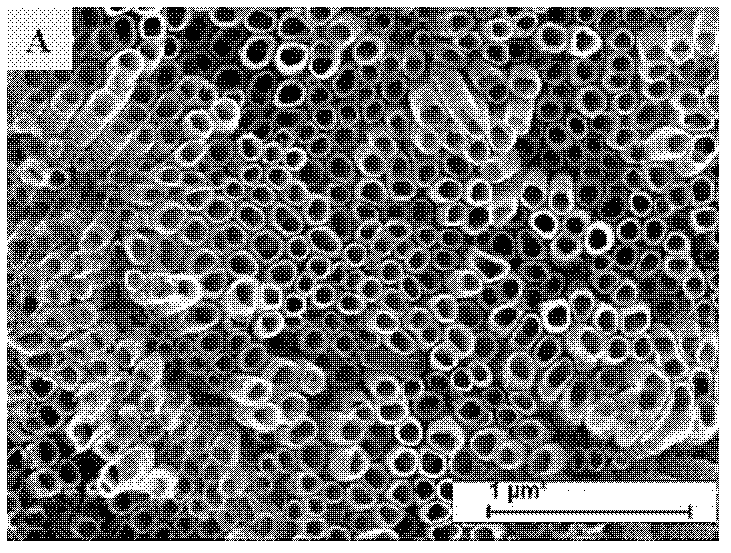

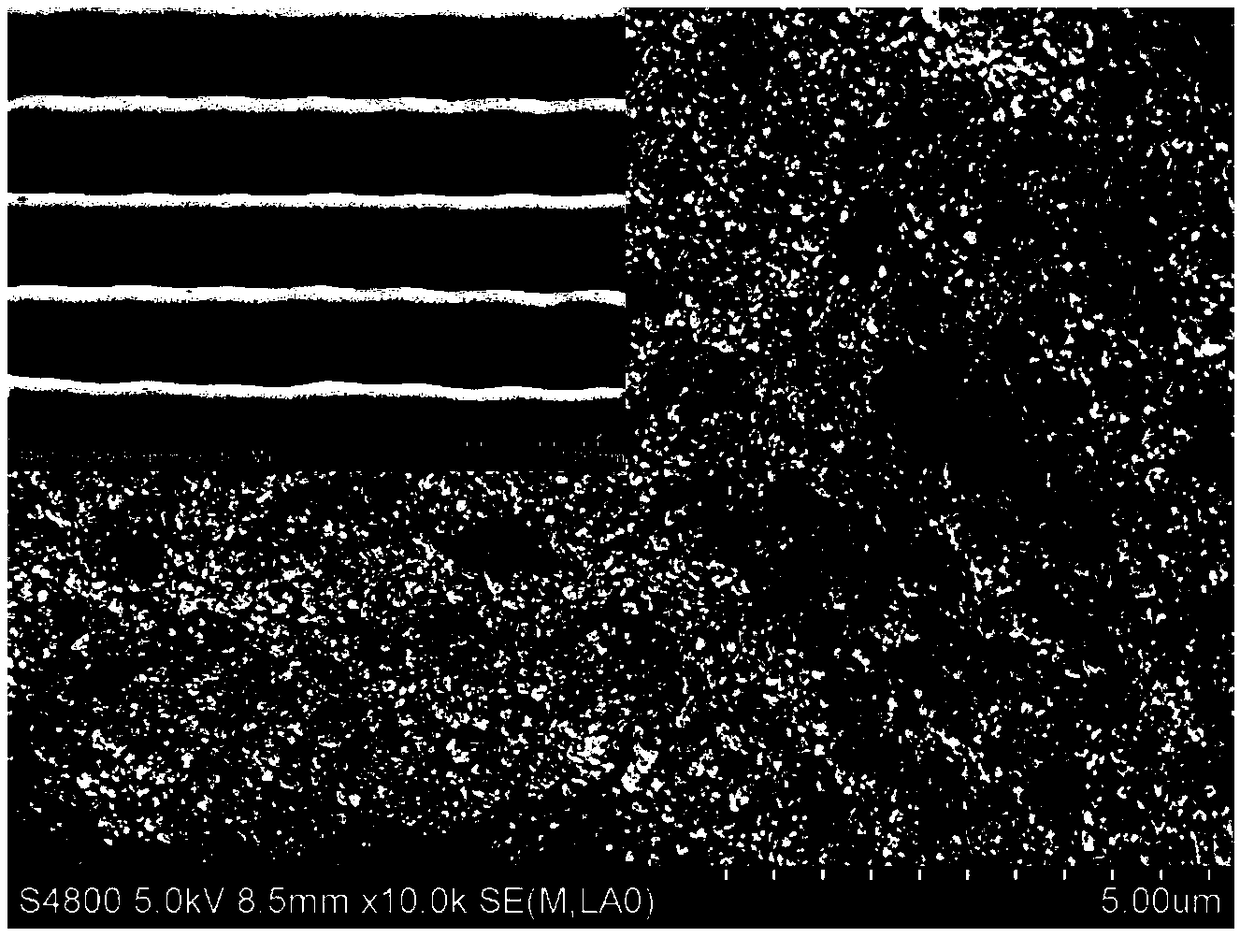

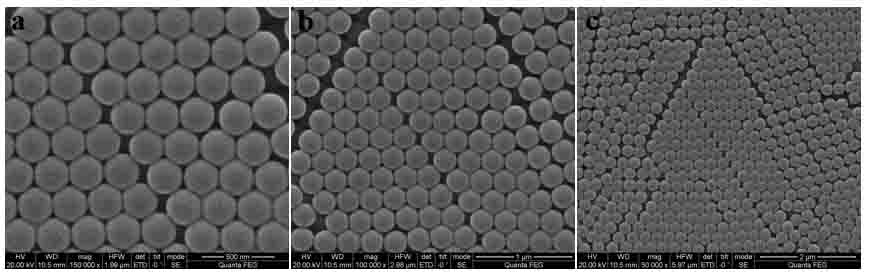

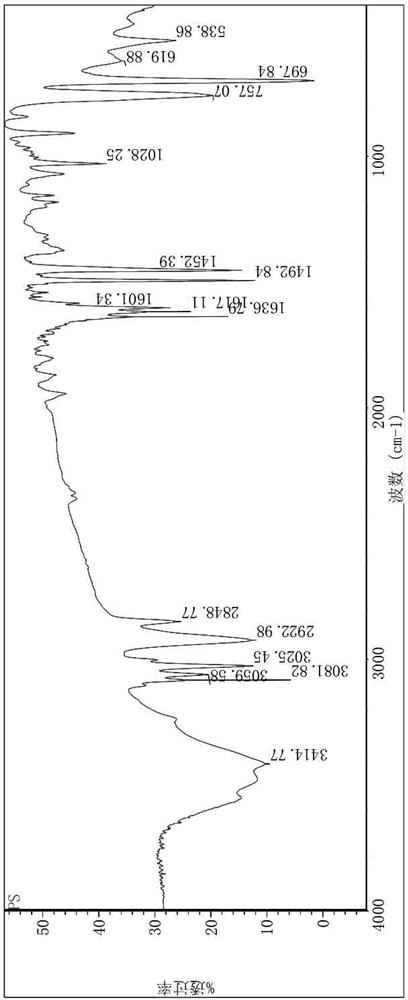

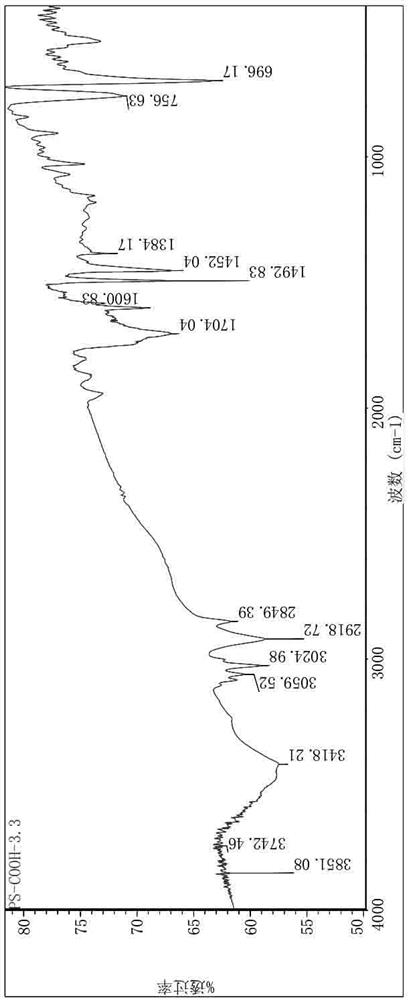

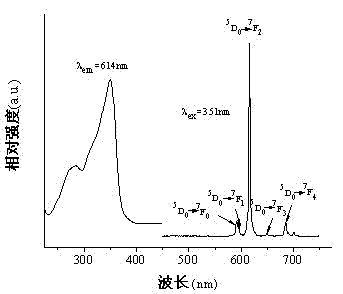

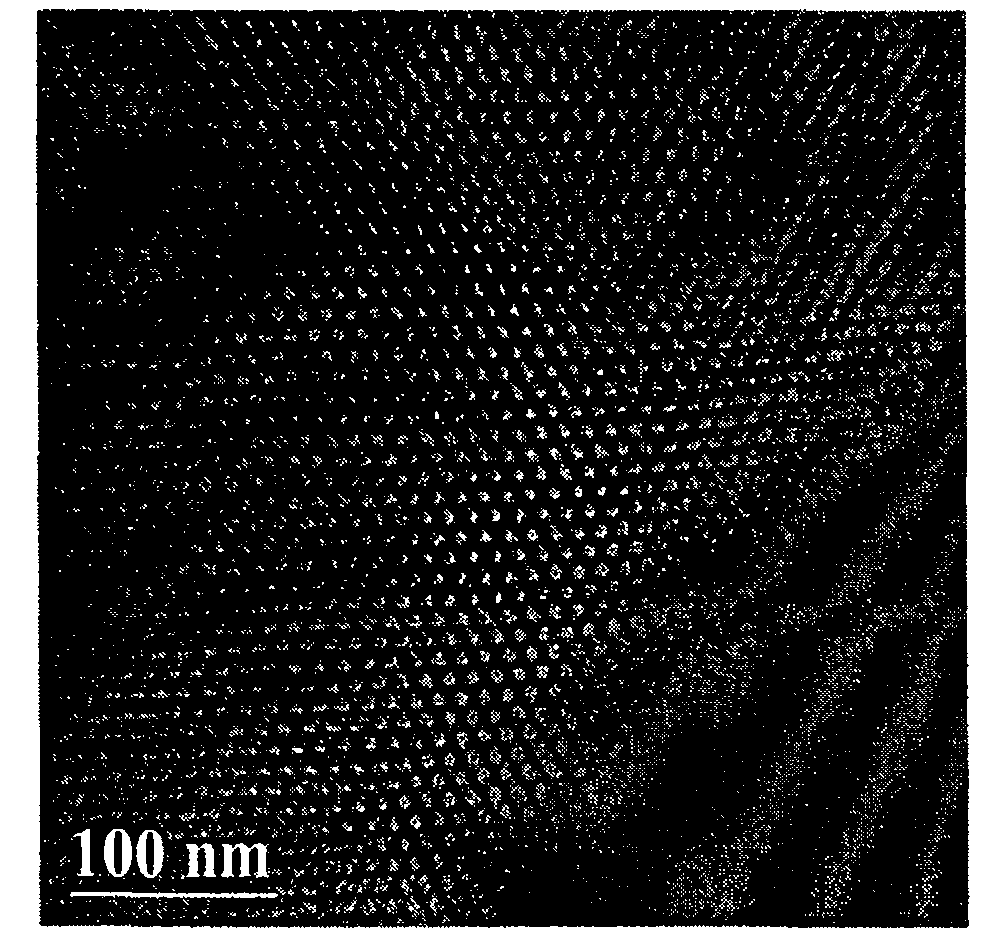

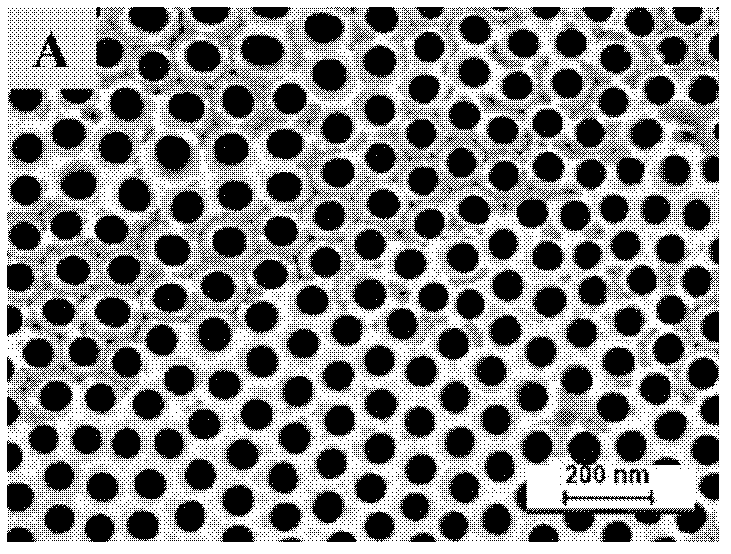

Preparation method of monodisperse polymer fluorescent microspheres

PendingCN112342014AUniform and controllable sizeNeat surfaceBiological testingLuminescent compositionsTernary complexPolystyrene microsphere

The invention discloses a preparation method of monodisperse polymer fluorescent microspheres. The preparation method comprises the following steps: (1) synthesizing a europium-containing ternary complex by adopting a coordination reaction; (2) preparing carboxyl polystyrene microspheres by adopting a soap-free emulsion polymerization method; and (3) permeating the europium complex into the functional microspheres by a one-step seed swelling method to obtain the fluorescent carboxyl polystyrene microspheres with fluorescent substances wrapped in the microspheres. Fluorescent functional microspheres are obtained through a one-step swelling method, seed microspheres used for swelling come from carboxyl latex microspheres obtained in a soap-free emulsion polymerization mode, operation is easy, and the obtained microspheres are uniform and controllable in size and regular in surface.

Owner:ANHUI WEIZHEN BIOLOGICAL ENG TECH CO LTD

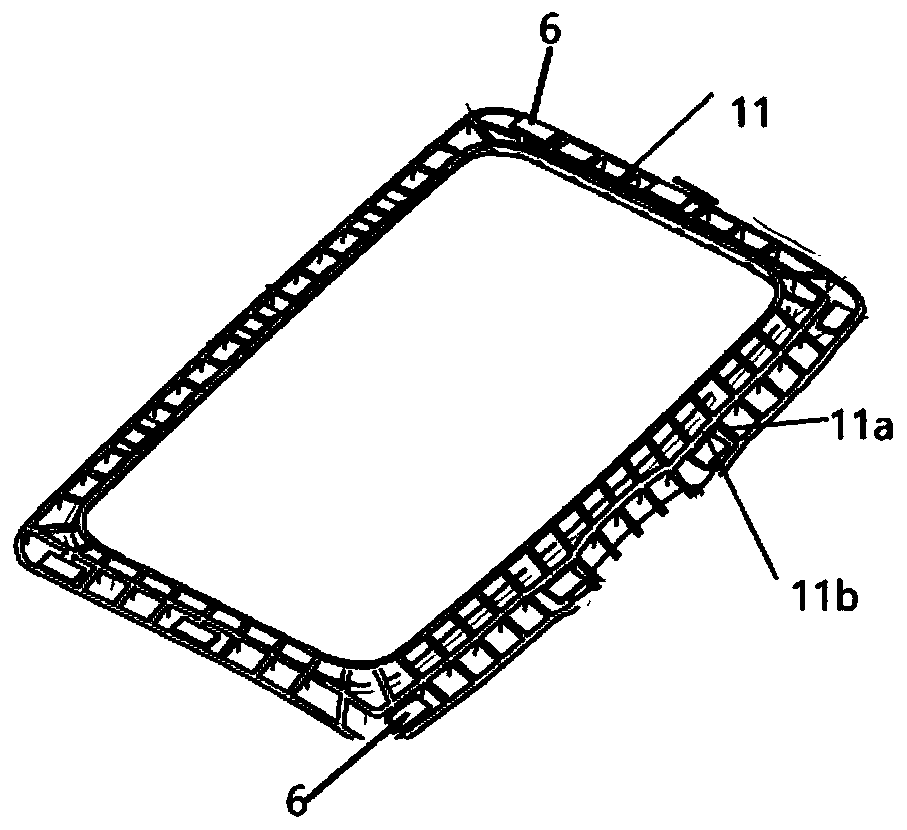

Invisible connected composite plate curtain wall

InactiveCN102121287ALightweight and high strengthImpact resistantWallsBuilding material handlingSingle plateLandscape structure

The invention belongs to a building enclosure, and particularly relates to an invisible connected composite plate curtain wall. The composite plate can be manufactured into an oversized unit plate with the same size as a building framework structure, mounting holes are uniformly distributed on the periphery of the plate, and a main body structure is also provided with holes matched with the mounting holes; by adopting a specially designed countersunk head expansion bolt group, the installation operations are all finished on the outer side, and invisibility of curtain wall connectors is realized; and an elastic adjusting shim plate (adjusting shim plate) between the composite plate and the main body structure can make certain adjusting compensation for unevenness of the main body structure. Compared with a glass curtain wall, the invisible connected composite plate curtain wall has the predominant advantages of light weight, high strength, impact resistance, large single plate area, connecting assembly invisibility, regular surface, bright color, safety, reliability, long service life, convenience in construction, high cost performance and the like. The curtain wall and the connecting structure thereof can be applied in the fields of landscape structures, curtain walls of framework structural buildings, enclosures and other similar decorations, and have broad application prospect.

Owner:秦皇岛耀华装备集团股份有限公司

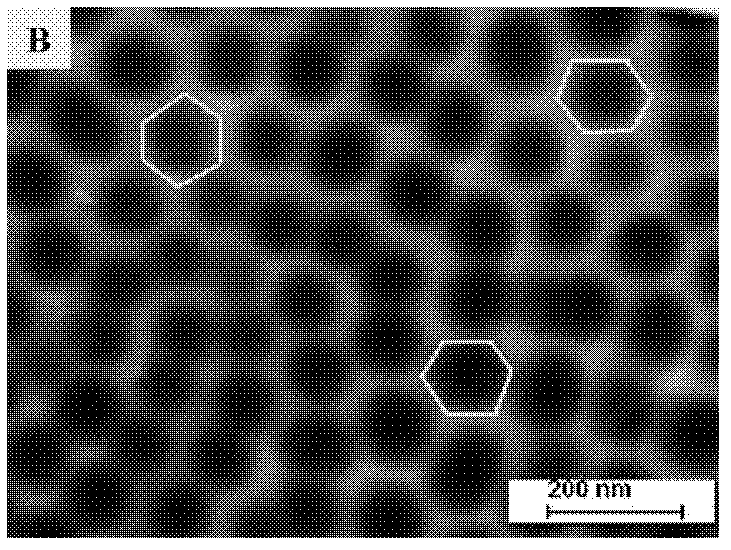

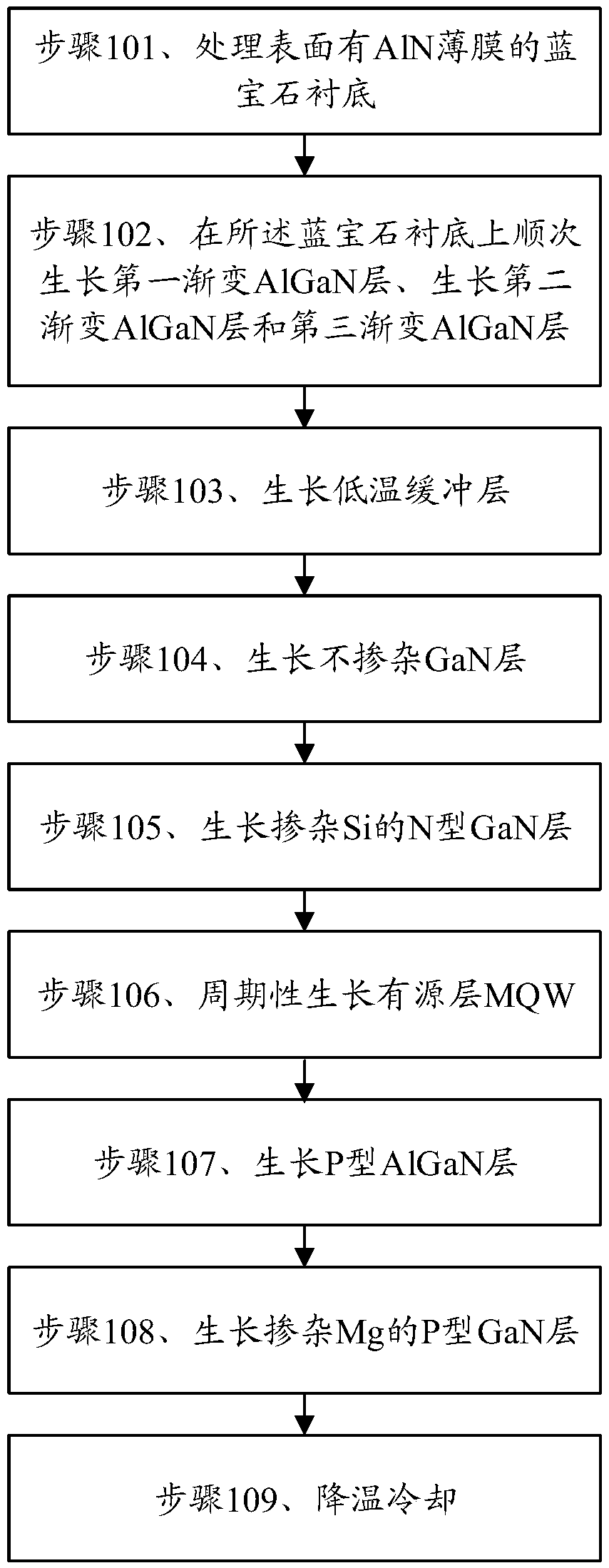

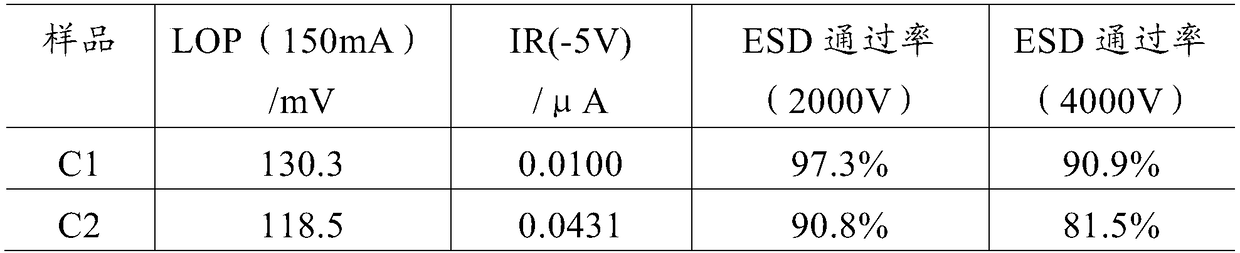

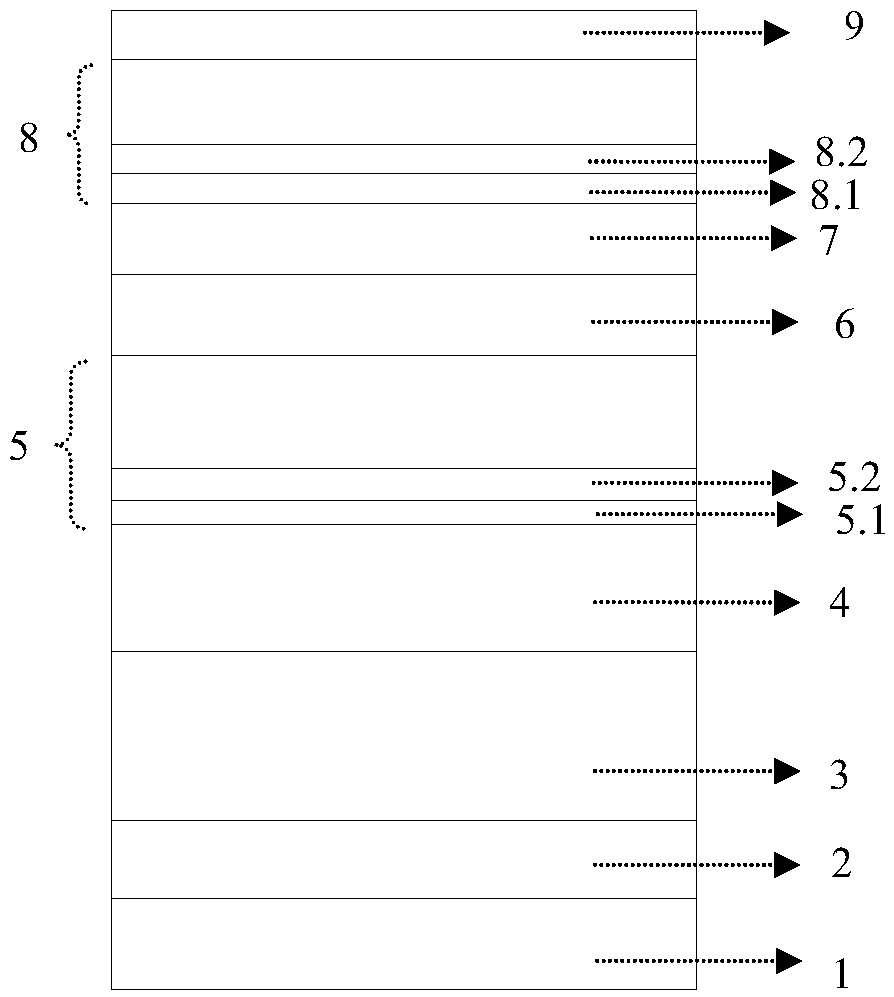

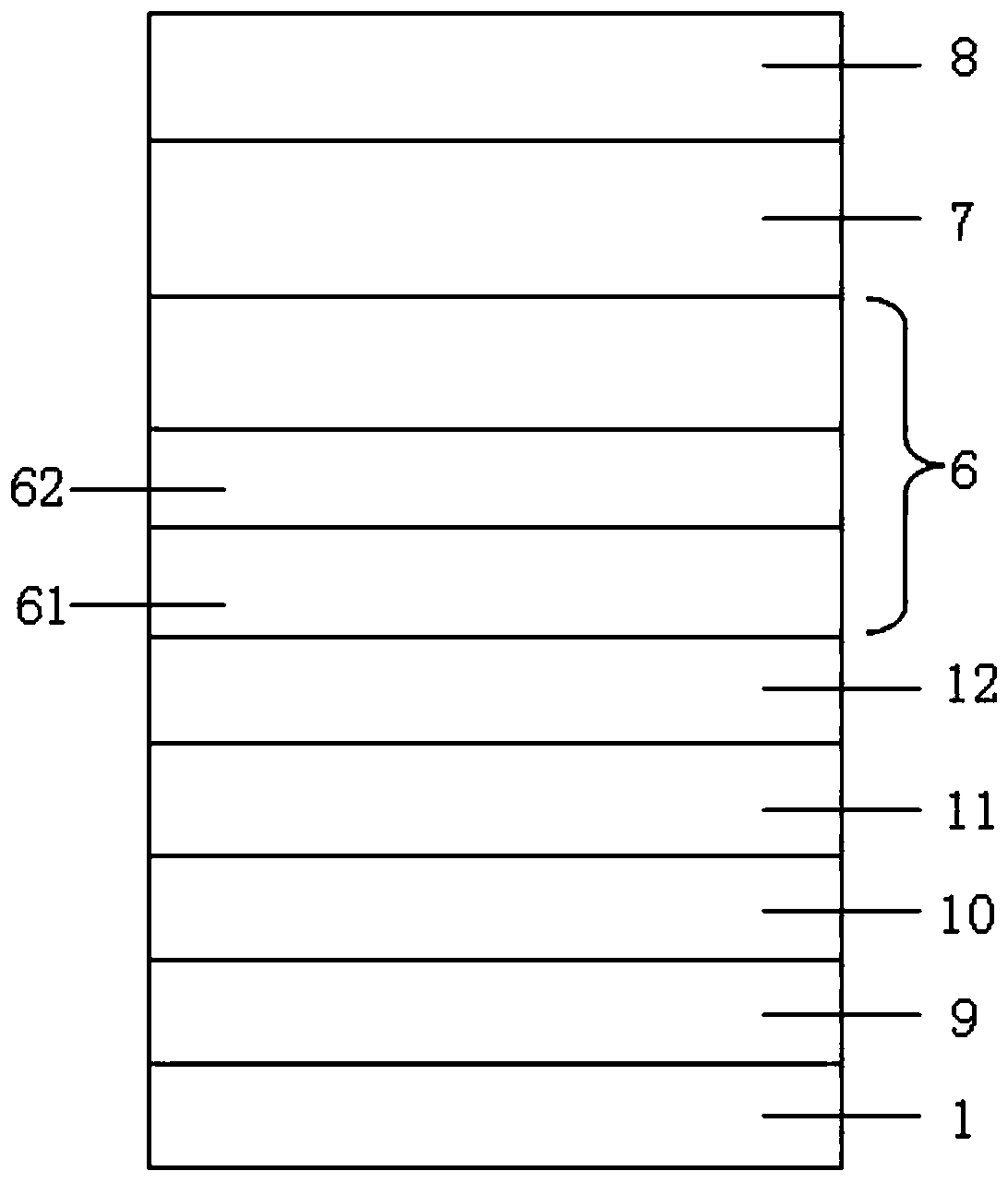

LED epitaxial wafer growth method

ActiveCN109300854AEvenly filledImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsActive layer

The present invention discloses an LED epitaxial wafer growth method. The method comprises the steps of: arranging a sapphire substrate of an AlN film at a processing surface, growing a first gradualchange AlGaN layer, a second gradual change AlGaN layer and a third gradual change AlGaN layer in order on the sapphire substrate, growing a low-temperature buffer layer, an un-doped GaN layer and a Si-doped N-type GaN layer, periodically growing an active layer MQW, growing a P-type AlGaN layer, growing a Mg-doped P-type GaN layer, and performing cooling. The first gradual change AlGaN layer, thesecond gradual change AlGaN layer and the third gradual change AlGaN layer are grown to reduce the dislocation density, improve the crystalline quality, reduce the warping of an epitaxial wafer, improve the percent of pass of the GaN epitaxial wafer and improve the LED luminous efficiency. The gradual change AlGaN layers are subjected to annealing processing to allow the whole surface of the epitaxial wafer to be smoother, allow the surface hexagonal defects and the hollow pits to be fewer and allow the whole appearance to be better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

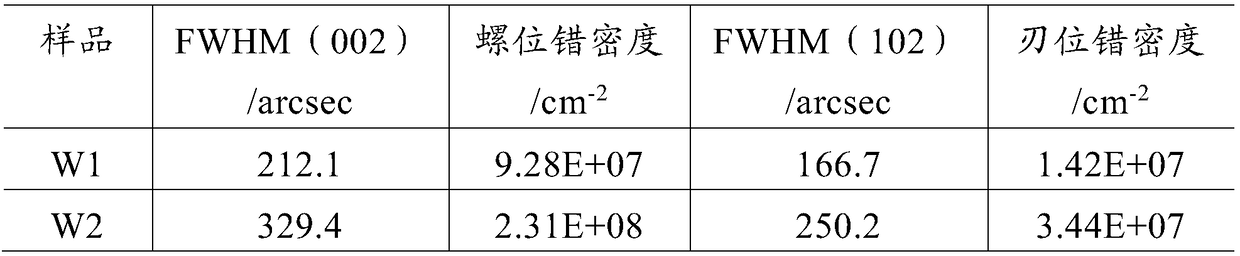

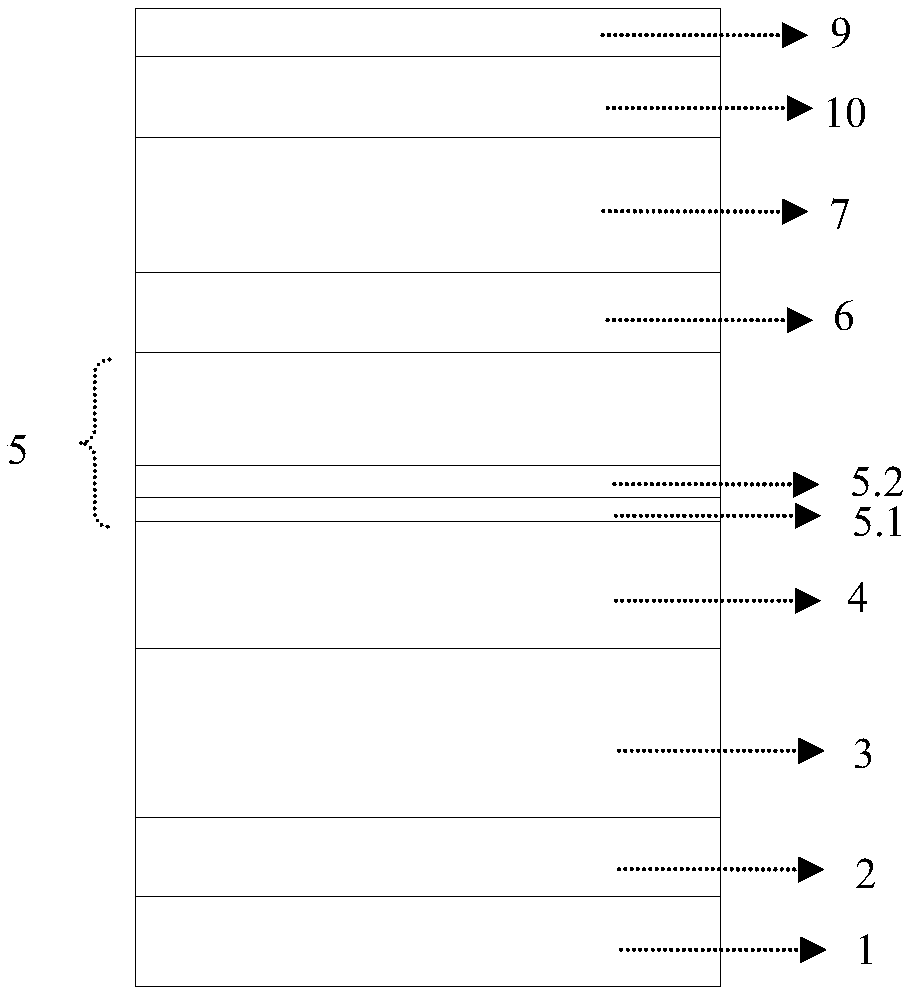

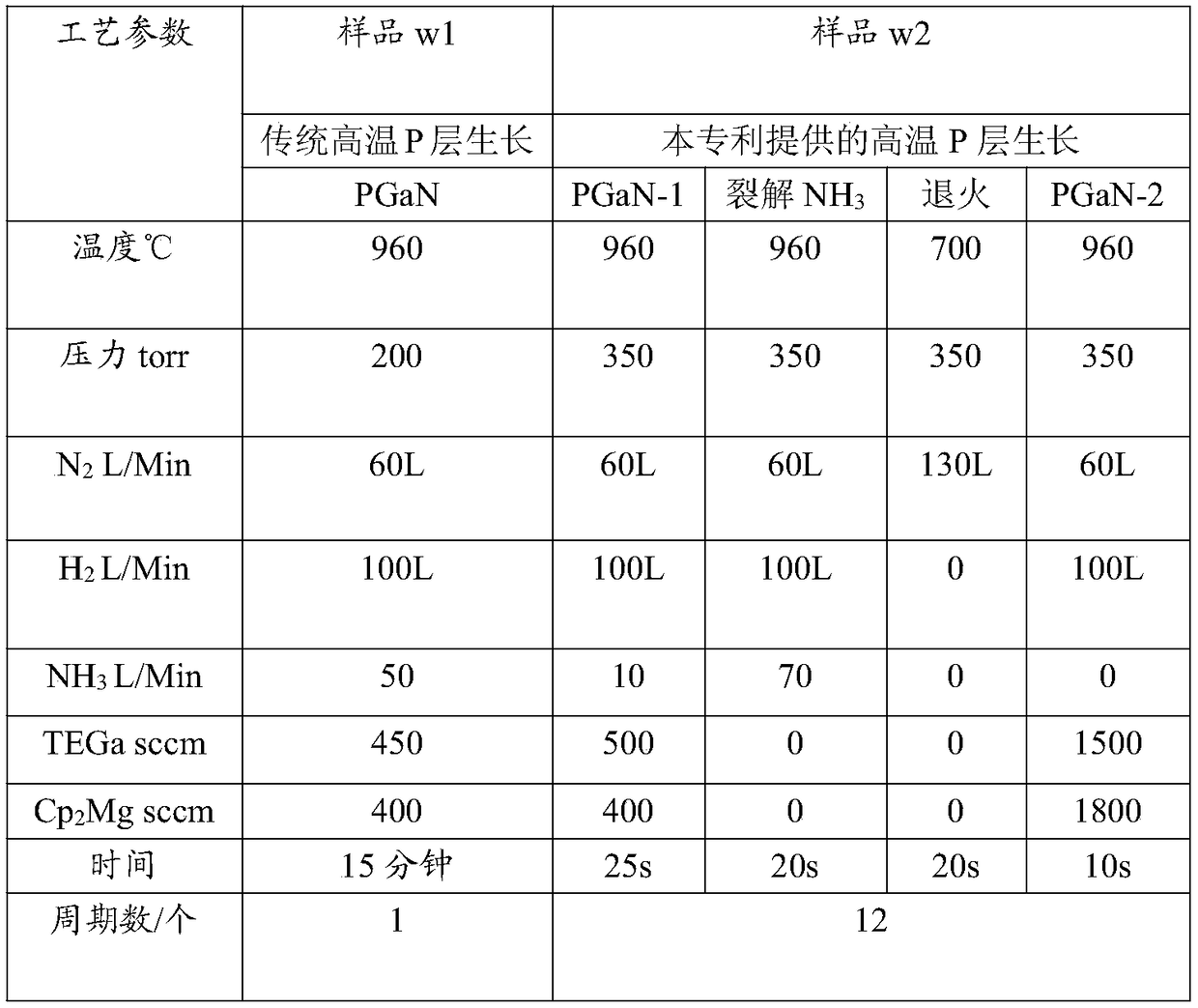

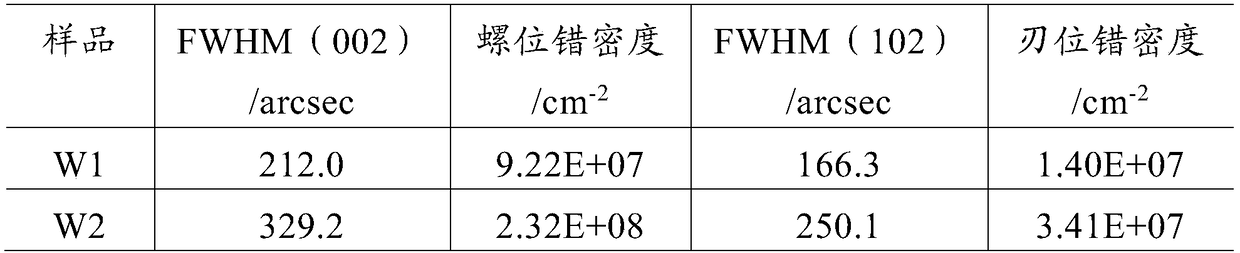

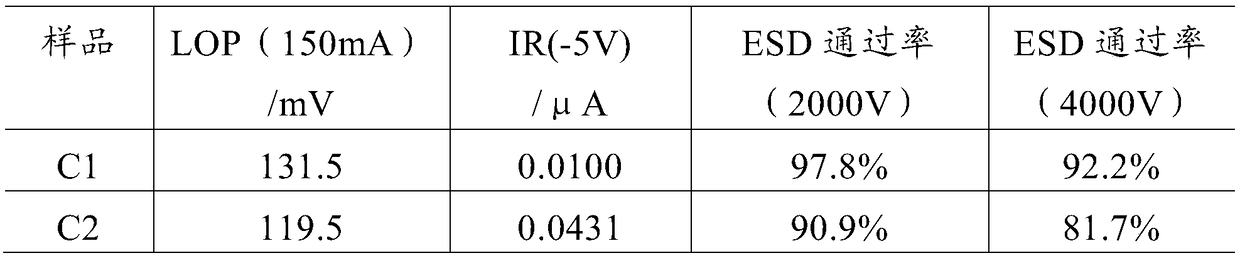

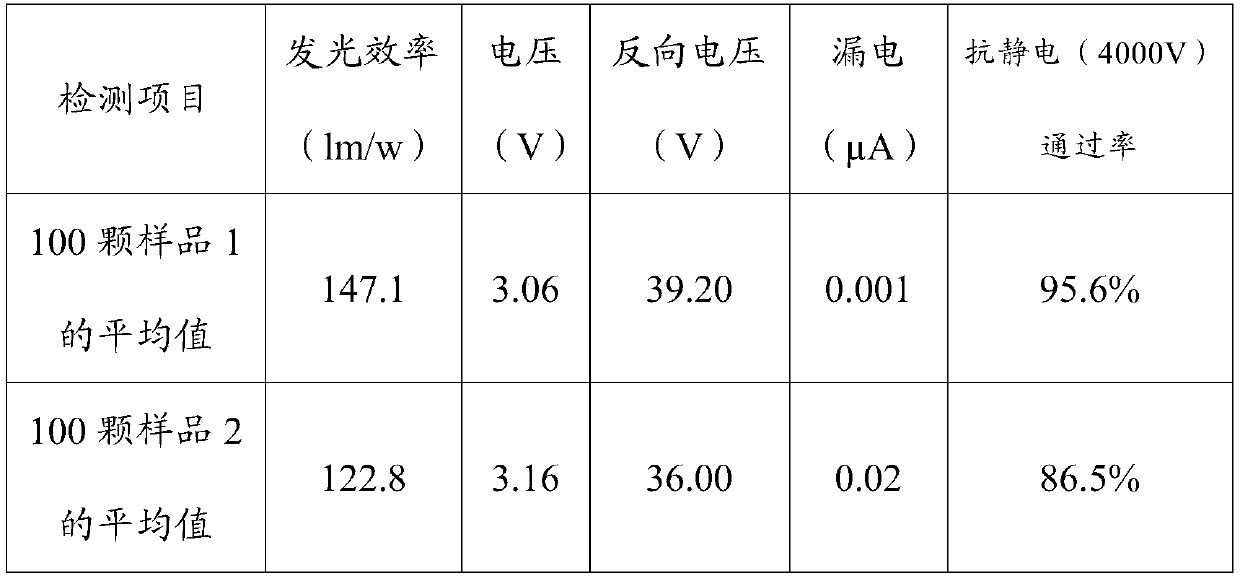

An epitaxial growth method for improving the luminous efficiency of a GaN-based LED chip

ActiveCN109004073AImprove luminous efficiencyIncrease ionization concentrationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingContact layerIonization

The invention discloses an epitaxial growth method for improving the luminous efficiency of a GaN-based LED chip, and includes growing an undoped GaN layer, growing a Si-doped n-type GaN layer, growing a lightly Si-doped n-type GaN layer, growing a luminescent layer, growing a low-temperature p-type GaN layer, growing a p-type AlGaN layer, growing a new p-type GaN layer, growing a high-temperaturep-type GaN contact layer, and cooling, wherein growing the new p-type GaN layer sequentially comprises the steps of growing a high-temperature P-type GaN-1 layer, performing NH3 pyrolysis, performingannealing treatment, and growing a high-temperature P-type GaN-2 layer. Through introduction of the new p-type GaN lay, the n-vacancy of a P structure can be reduced, and Mg-H bonds can be reduced, the ionization rate of Mg of the P structure is increased, the hole concentration of the P structure is increased, and the luminous efficiency of the LED chip is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

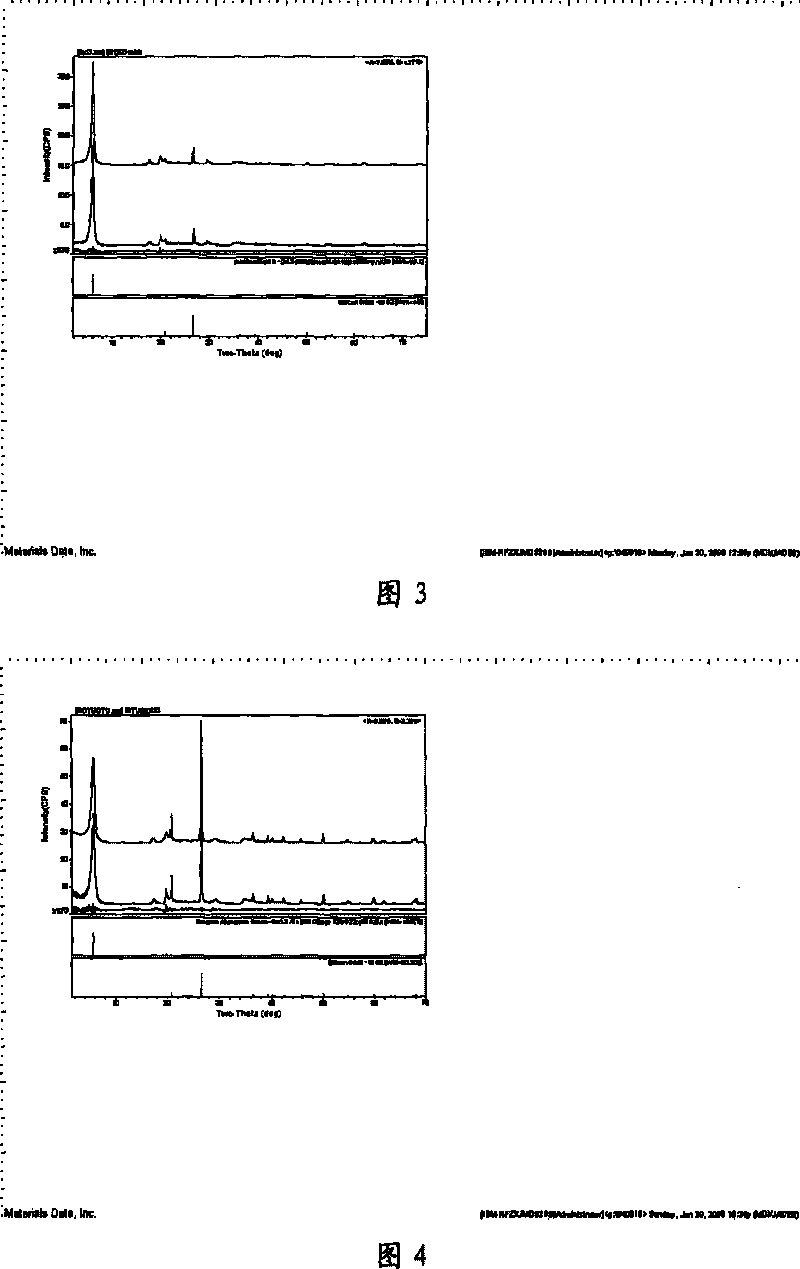

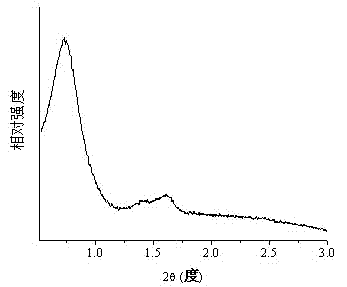

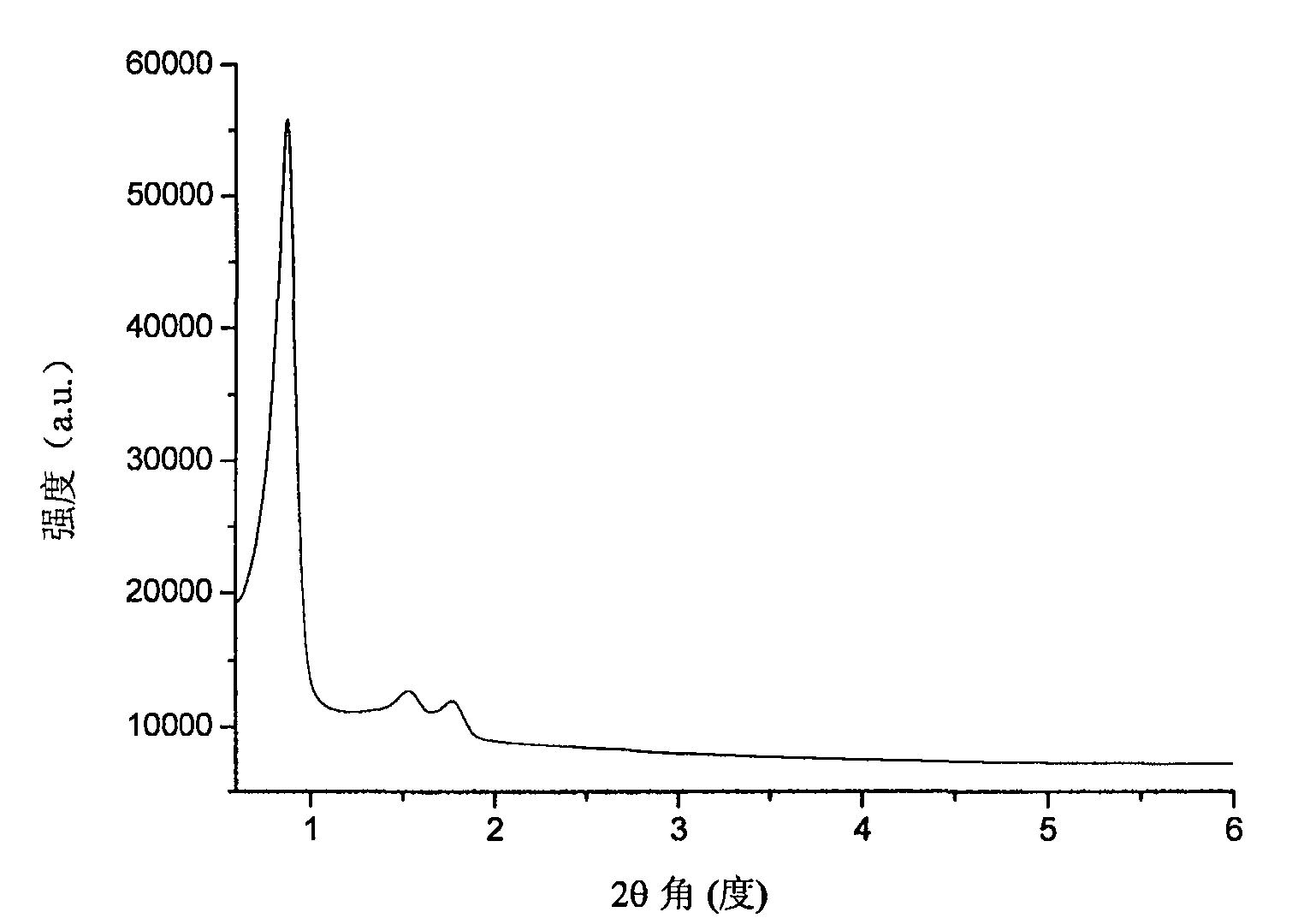

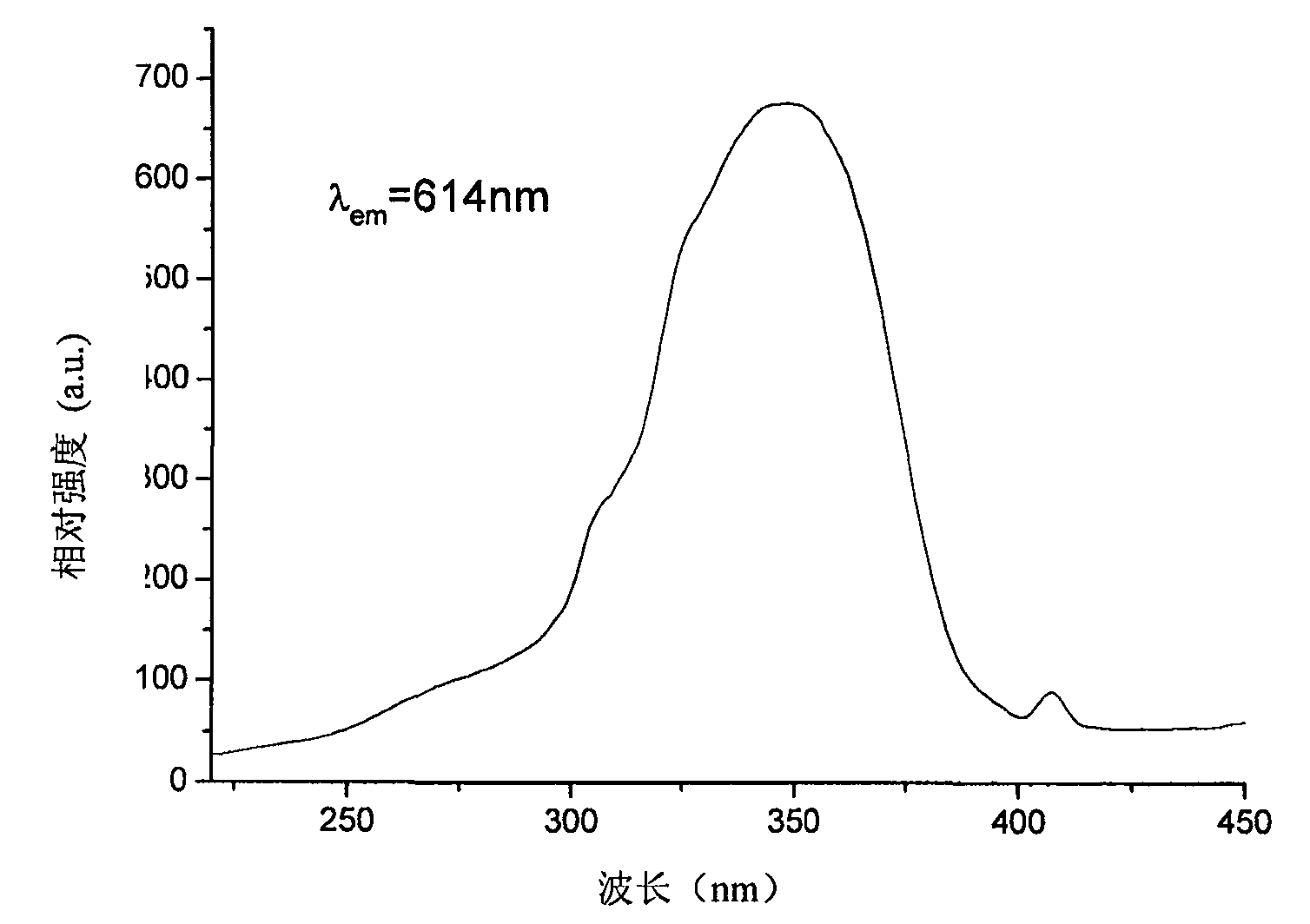

Preparation method of high molecule functionalized rare earth/mesoporous fluorescent nano-material

InactiveCN102775982AImprove stabilityOvercome mechanical propertiesLuminescent compositionsMolecular functionEuropium ion

The invention discloses a preparation method of a high molecule functionalized rare earth / mesoporous fluorescent nano-material. The preparation method comprises the following steps of: functionalizing organic high molecules with active functional groups by using a chemical modification and synthesis method at first; grafting to an inorganic and ordered mesoporous body SBA-15 or SBA-16 framework through a covalent bond; and then introducing rare earth europium ions to synthesize to obtain the highly ordered high molecule functionalized rare earth / mesoporous fluorescent nano-material with stable chemical and thermodynamic properties. The preparation method of the high molecule functionalized rare earth / mesoporous fluorescent nano-material is mild in experiment conditions that are easily controlled, an overall preparation system is easy to construct, is simple and convenient to operate, the obtained product has the advantages of stable quality, strong practicability and good repeatability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

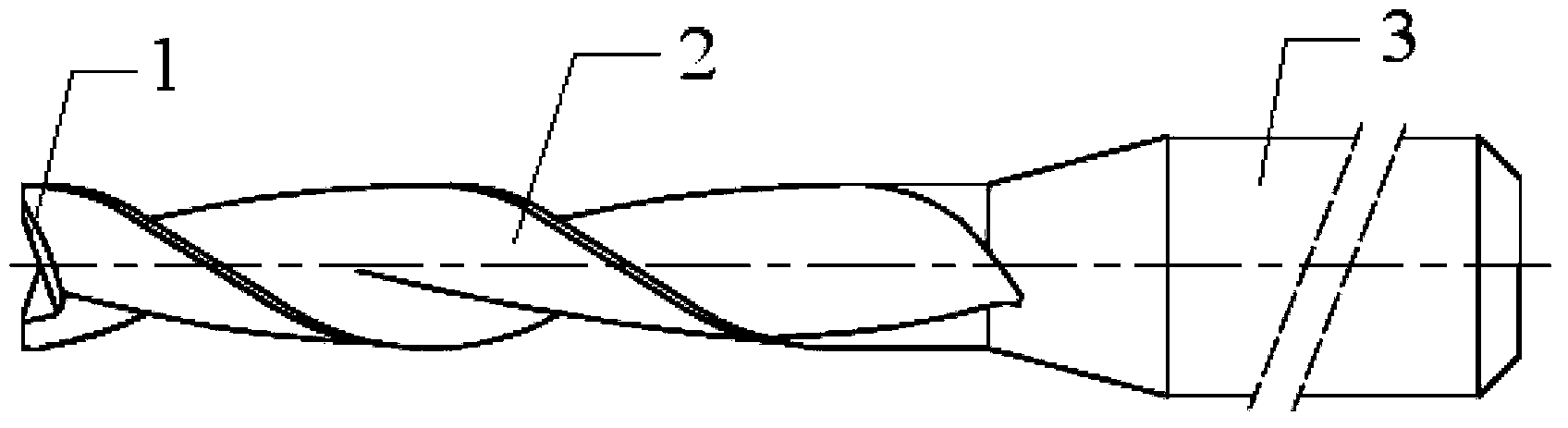

Blind groove diamond coating milling cutter

InactiveCN103567520AImprove high temperature resistanceImprove wear resistanceMilling cuttersChemical vapor deposition coatingMilling cutterEngineering

The invention relates to a blind groove diamond coating milling cutter. The milling cutter has a fishtail-shaped structure, and comprises a milling cutter head, a scrap discharging groove and a handle, wherein the head cutting edge of the milling cutter head is inclined to the center; the scrap discharging groove is integrally formed in the back cutter surface of the milling cutter; a helical angle is formed outside the scrap discharging groove; the handle is arranged on the back part of the scrap discharging groove and is connected with the main shaft of a PCB (printed circuit board) drilling and milling machine; an HFCVD (hot filament chemical vapor deposition) diamond coating is deposed on the surface of the milling cutter. Compared with the prior art, the blind groove diamond coating milling cutter has the advantages of wide machining range, high production efficiency, long service life and the like.

Owner:SHANGHAI UNIV OF ENG SCI +1

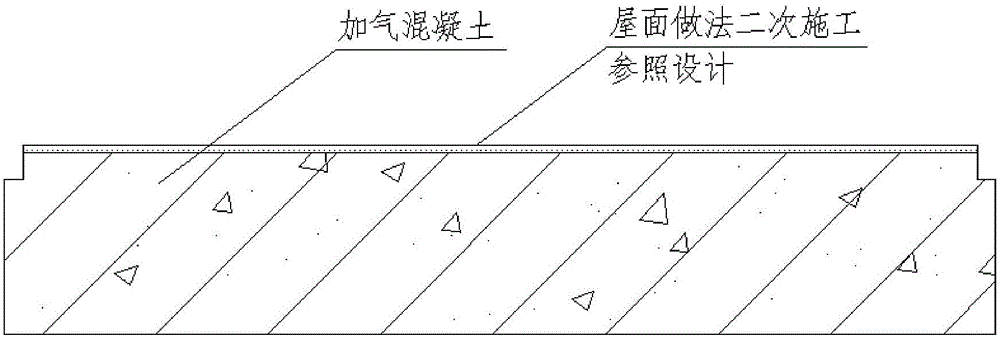

Light concrete precast compound roof board

InactiveCN106223547AImprove integrityBeautiful surfaceRoof covering using slabs/sheetsInsulation layerSurface layer

The invention relates to the technical field of building precast roof boards, and provides a light concrete precast compound roof board which comprises a waterproof reinforced layer and a heat insulation layer. The waterproof reinforced layer is arranged on the heat insulation layer, reinforcing meshes are arranged on the upper portion and the lower portion of the heat insulation layer, reinforcing ribs are arranged on the lower portion of the waterproof reinforced layer, and the waterproof reinforced layer, the heat insulation layer and the reinforcing meshes are cast into a whole through light concrete. Mounting parts connected with adjacent compound roof boards are arranged at two ends of the compound roof board, a decorative surface layer can be arranged on the waterproof reinforced layer, the mounting parts include upward opening grooved profiles or corresponding press strips, and the gap between the adjacent compound roof boards is sealed by the mounting parts and weather proofing sealants. The light concrete precast compound roof board has the advantages that the decorative surface layer, the waterproof reinforced layer, the heat insulation layer and the reinforcing meshes are integrated to form the compound roof board, the compound roof board is good in integrality, waterproof, resistant to aging, long in service life, high in strength, not easy to damage in transportation, high in construction efficiency and suitable for popularization and application, and ready-made secondary holes are decreased.

Owner:李予新

Preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin

The invention relates to the technical field of vinyl chloride resin, in particular to a preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin. A single emulsifier and a single initiator are adopted by the original synthesis process, and tests proof that the single emulsifier can enable polymer latex not to be stable, and therefore, a stable polymerization product can not be obtained; the single initiator enables a polymerization system not to be stable, and reaction is difficult to control; freezing demulsification, filtering, washing, drying and thelike are adopted as treatment processes of a vinyl chloride grafting copolymer emulsion to form a thick and big aggregated particle structure, and the product performance is low; moreover, much wastewater and many waste residues are generated in the process. In the invention, the stability of the latex is ensured by adopting a compound emulsifier and a compound initiator, which ensures that the latex has better average particle diameter, the polymerization system is stable and the reaction is easy to control; centrifugal spray drying is adopted to treat emulsion resin, and thereby, a good resin product with even particle size distribution and good processing performance can be obtained; and the wastewater and the waste residues are not generated, the process flow is short and the energy can be saved and the consumption can be lowered.

Owner:河北盛华化工有限公司

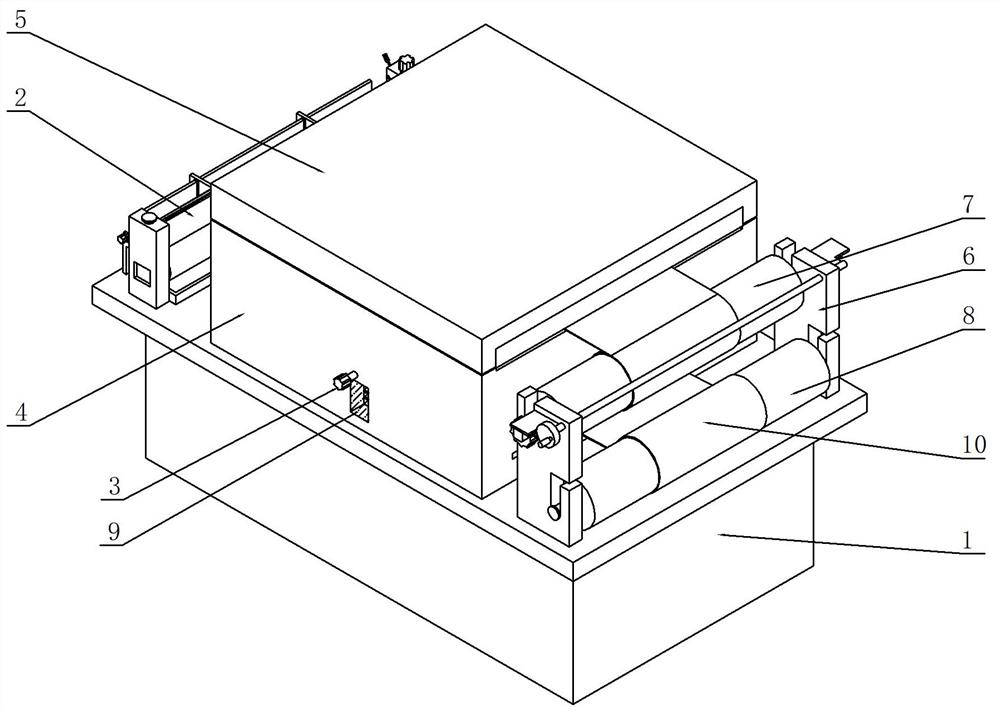

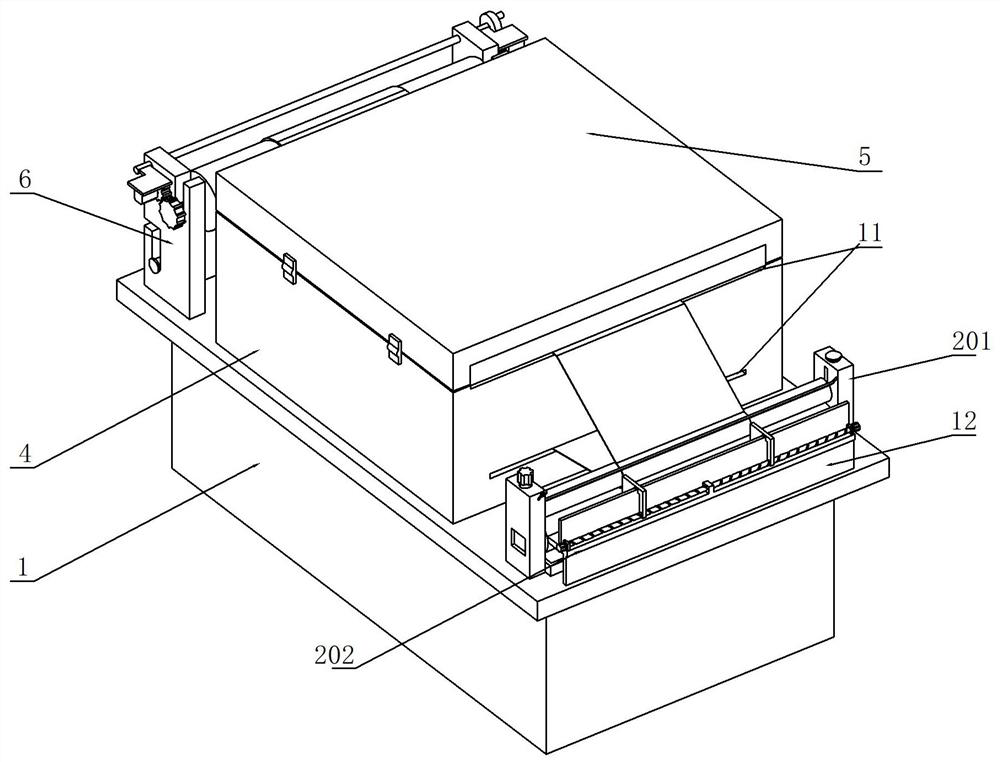

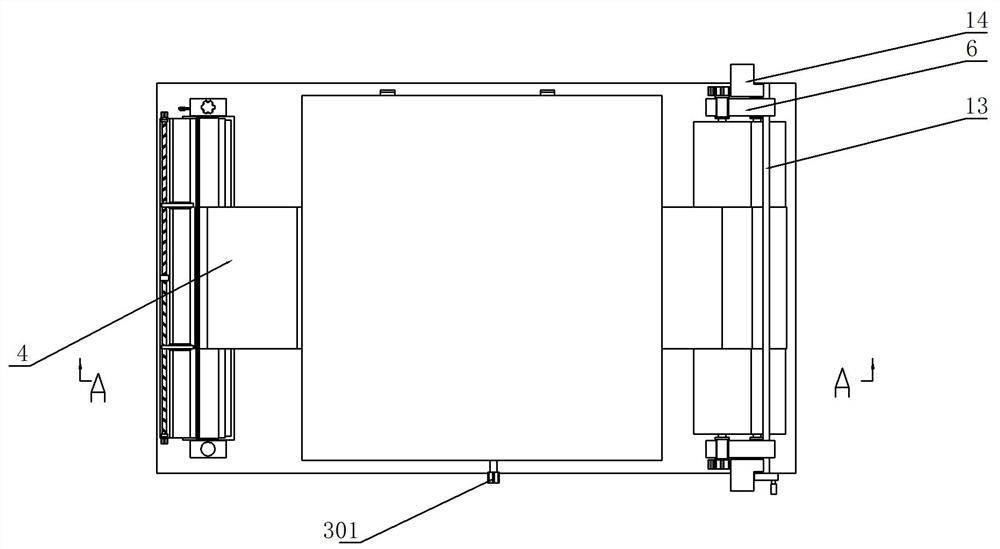

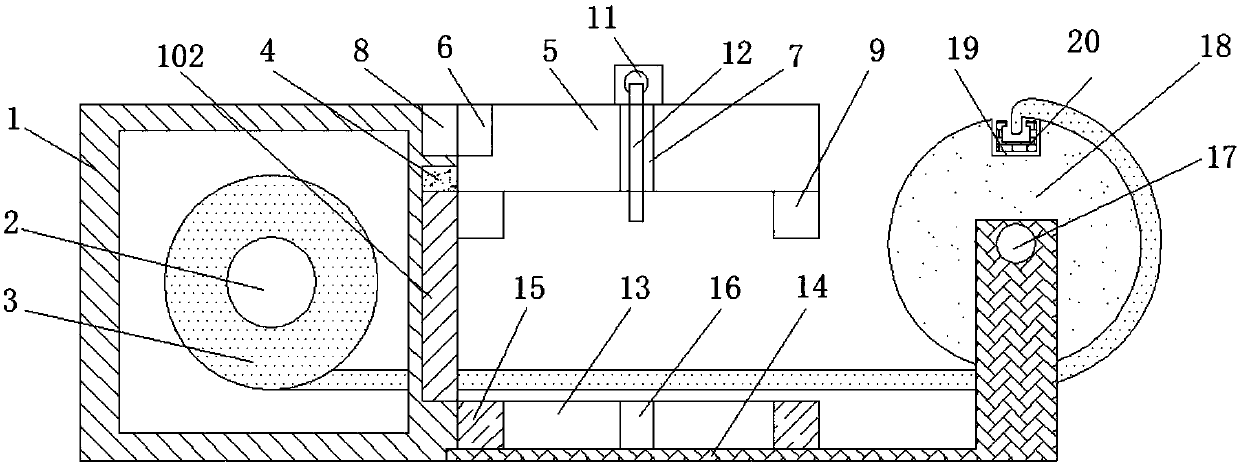

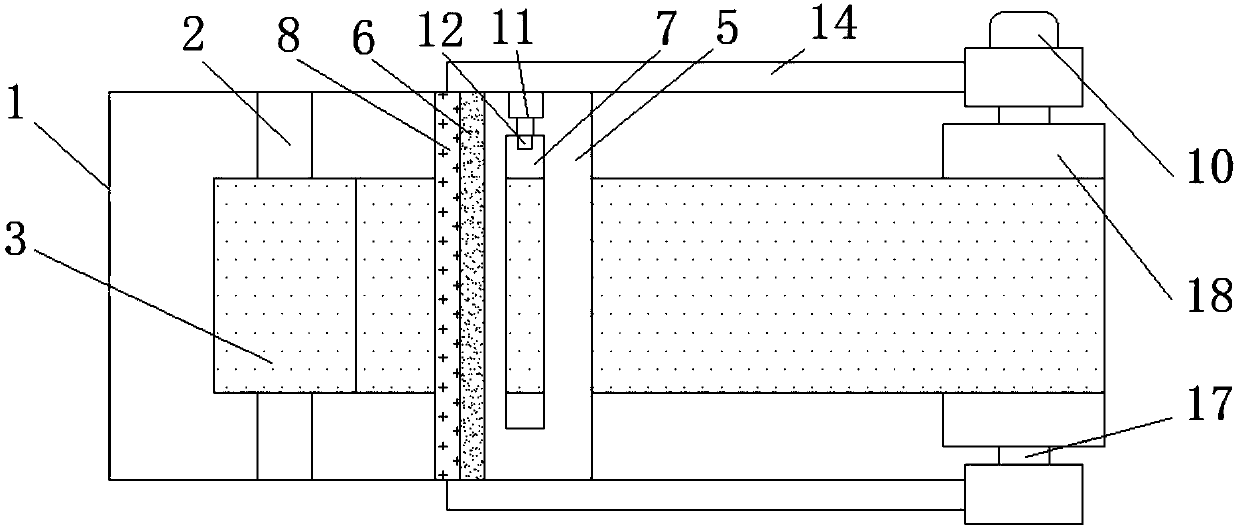

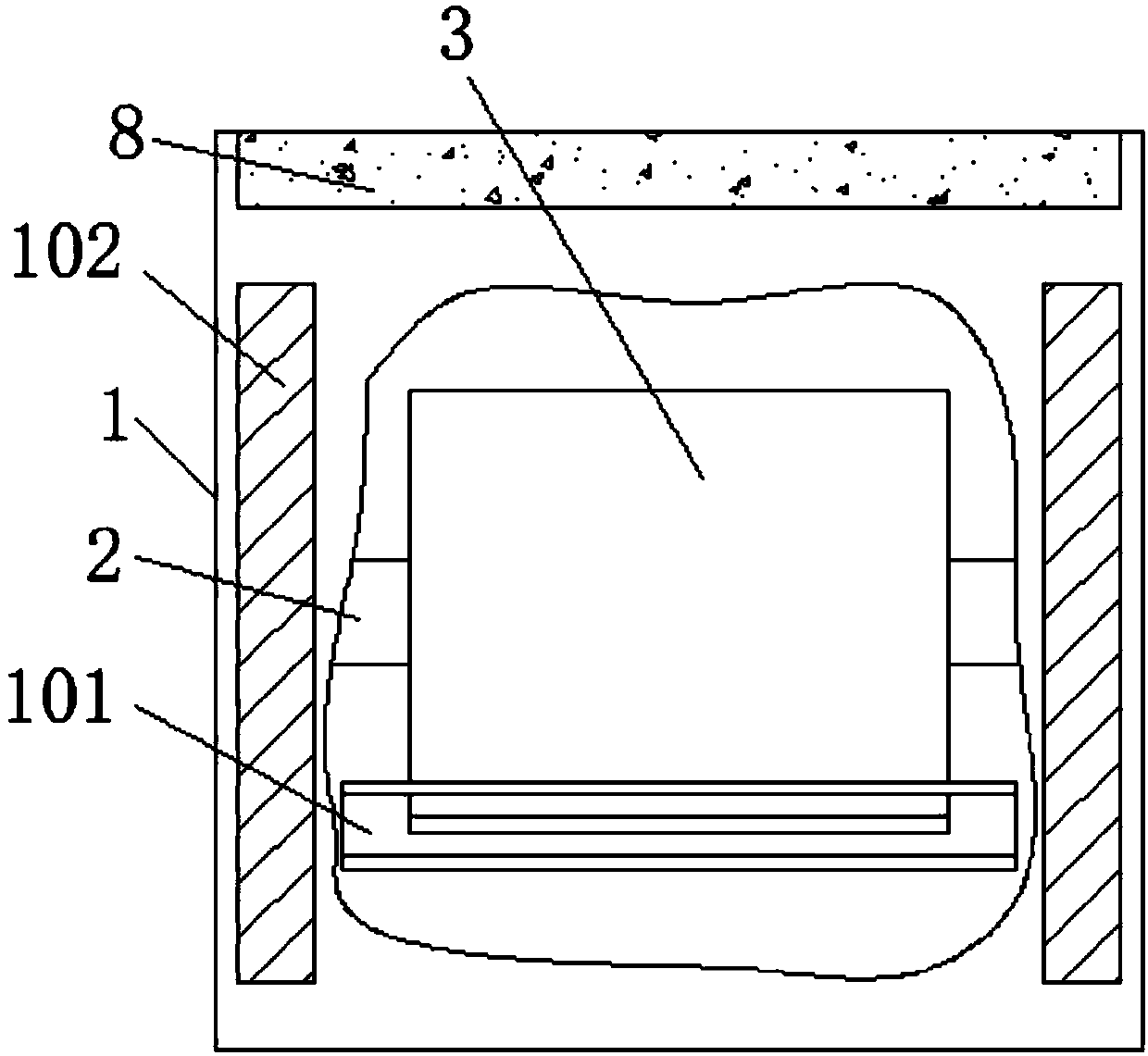

Macromolecular adhesive coating device for waterproof coiled material processing

ActiveCN113877761ARealize coating functionImprove adaptabilityPretreated surfacesCoatingsAdhesiveMaterials processing

The invention provides a macromolecular adhesive coating device for waterproof coiled material processing, and relates to the technical field of waterproof coiled material processing. The macromolecular adhesive coating device comprises a workbench, a heating shell is fixedly installed in the middle of the upper surface of the workbench, and penetrating through holes are formed in the surfaces of the two sides of the heating shell in a penetrating mode correspondingly; and an overturning upper cover is rotationally mounted at the upper end of the heating shell through a hinge. According to the device, the position of a second coating roller can be adjusted through a first coating assembly, and meanwhile, the contact area between coiled material bodies and an adhesive can be adjusted; so that compared with the prior art, the problems that different sizes of waterproof coiled materials need to be produced during production, the adhesive cannot be matched with the waterproof coiled materials during coating operation, the range of the adhesive cannot be controlled during coating, the problems that materials are wasted and follow-up machining is affected are solved, waste of the materials is greatly reduced, and the strength of later cleaning is reduced are solved.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

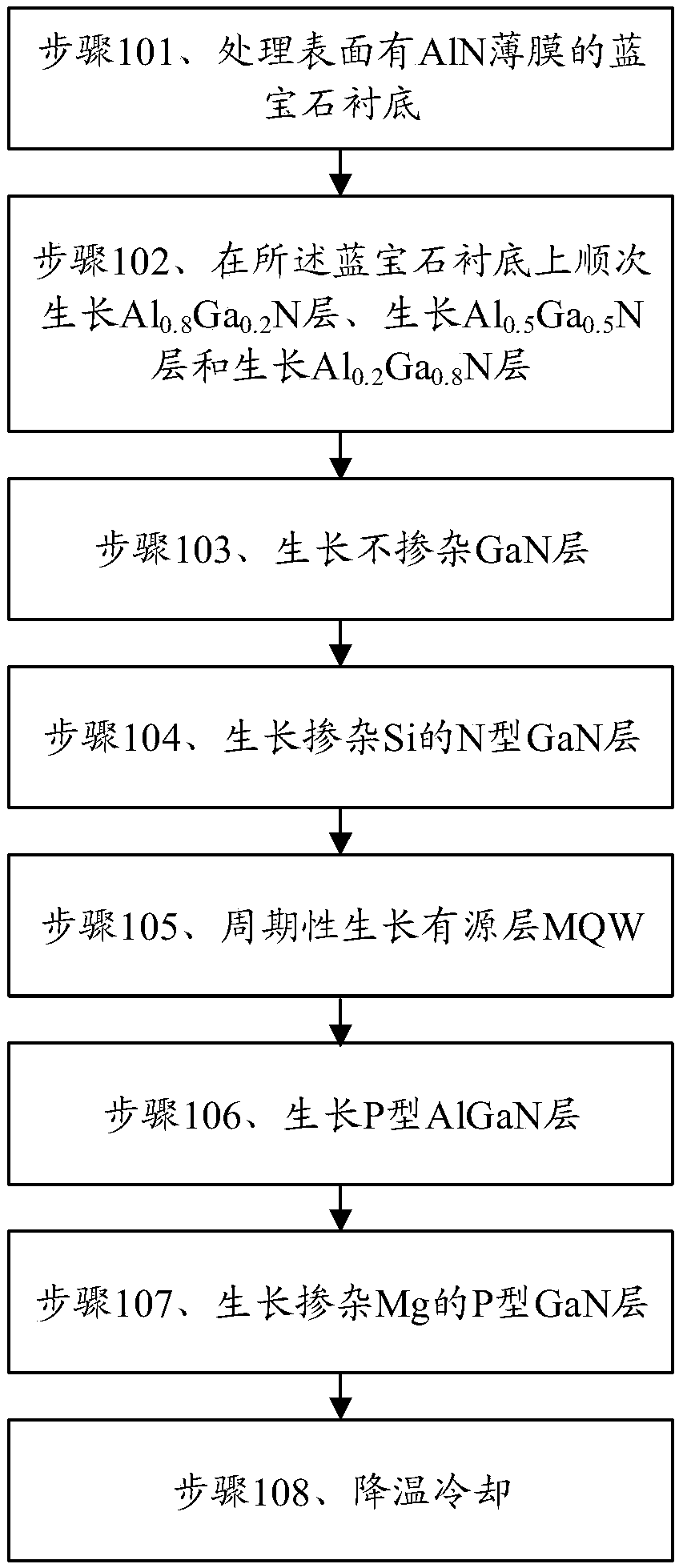

LED epitaxial growth method for improvement of growth quality

InactiveCN109300855AImprove growth qualityImprove doping efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesActive layerBiology

The present invention discloses a LED epitaxial growth method for improvement of growth quality. The method comprises the steps of: processing a sapphire substrate of an AlN film at a surface, growingan Al0.8Ga0.2N layer, an Al0.5Ga0.5N layer and an Al0.2Ga0.8N layer in order on the sapphire substrate, growing an un-doped GaN layer and a Si-doped N-type GaN layer, periodically growing an active layer MQW, growing a P-type AlGaN layer, growing a Mg-doped P-type GaN layer, and performing cooling. The method increases the defect blocking and isolation mechanisms when the epitaxial crystal is grown to improve the lattice matching, reduce the dislocation density, reduce the defect proportion and improve the crystalline quality so as to improve the LED light-emitting efficiency, improve the antistatic capacity and improve the epitaxial wafer surface appearance condition. The LED epitaxial growth method for improvement of growth quality is convenient to eliminate the stress accumulative effect of the sapphire substrate on the GaN film so as to reduce the warping of the epitaxial wafer and improve the product yield.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Process for producing beta-diketone functionalization rare earth mesoporous hybridisation luminescent material

InactiveCN100558853CLong fluorescence lifetimeHigh Luminous Quantum EfficiencyLuminescent compositionsDiketoneRare earth

The invention belongs to the technical field of preparation of nano mesoporous materials, and in particular relates to a synthesis technology of a novel β-diketone functionalized rare earth mesoporous hybrid luminescent material. In the present invention, organic ligand molecules with β-diketone structure are covalently grafted into the inorganic mesoporous main frame by the method of organic modification synthesis, and then the rare earth europium or terbium ions are introduced to obtain stable chemical and thermodynamic properties and a high degree of order. mesoporous hybrid luminescent materials. The method of the invention has mild experimental conditions, easy construction of the whole preparation system, simple and convenient operation, easy control of conditions, and stable product quality.

Owner:TONGJI UNIV

Aluminum foil coiled material protection mechanism capable of drawing materials conveniently

PendingCN107934640AWill not wrinkle and deformReasonable structureArticle deliveryWebs handlingProtection mechanismEngineering

The invention discloses an aluminum foil coil protection mechanism which is convenient for material acquisition, which comprises a main casing, an aluminum foil outlet, a chute, a rotating shaft, an aluminum foil coil, a slider, an upper pressing plate, a first magnet, a sliding seam, a second magnet, a card blocks, motors, electric push rods, aluminum foil cutters, lower pressure plates, fixed frames, card slots, sliding chambers, output shafts, rollers, grooves and clamping blocks. This kind of aluminum foil coil protection mechanism that is easy to obtain materials has a reasonable structure. Through the set main shell, the aluminum foil coil is protected from the influence of external factors when placed, and the surface of the aluminum foil coil is also guaranteed to be clean; through the set upper platen , clamping block, electric push rod, aluminum foil cutting knife, sliding seam, slider, lower platen, card slot and sliding cavity are used in conjunction with each other. When the aluminum foil is cut, it is not easy to wear and tear, ensuring that the aluminum foil will not wrinkle and deform, so that the aluminum foil The surface is neat during cutting, the use efficiency is improved, the practical value is high, and it is suitable for popularization and use.

Owner:JIANGSU FUWEI ENERGY CO LTD

Glue scraping device for flat piece and with controllable gluing shape

PendingCN111842023AEasy to operateImprove efficiencyLiquid surface applicatorsCoatingsAdhesiveBonding process

The invention discloses a glue scraping device for a flat piece and with a controllable gluing shape. The device comprises an inverted U-shaped base and a glue scraping plate, a height difference exists between the lower edges of vertical walls on the two sides of the U-shaped base, a short vertical wall and a long vertical wall are formed, a glue injection hole is formed in the top wall, and theglue scraping plate is located in the U-shaped base and connected with the top wall; and the bonding face of the flat piece faces upwards and abuts against the lower edge of the short vertical wall, one side face of the flat piece abuts against the inner wall face of the long vertical wall, and a gap is formed between the lower edge of the glue scraping plate and the bonding face of the flat platepiece. The glue scraping device disclosed by the invention is convenient to operate, high in efficiency, uniform in thickness and shape of an adhesive after gluing, neat in surface and free of excessive glue overflow, the gluing is integrally formed, the device can be used for directly bonding a metal part or a nonmetal part, and the controllability of a bonding process is improved; and the device has certain universality and is suitable for flat pieces and glue injection guns of different specifications.

Owner:FESHER AVIATION COMPONENTS ZHENJIANG

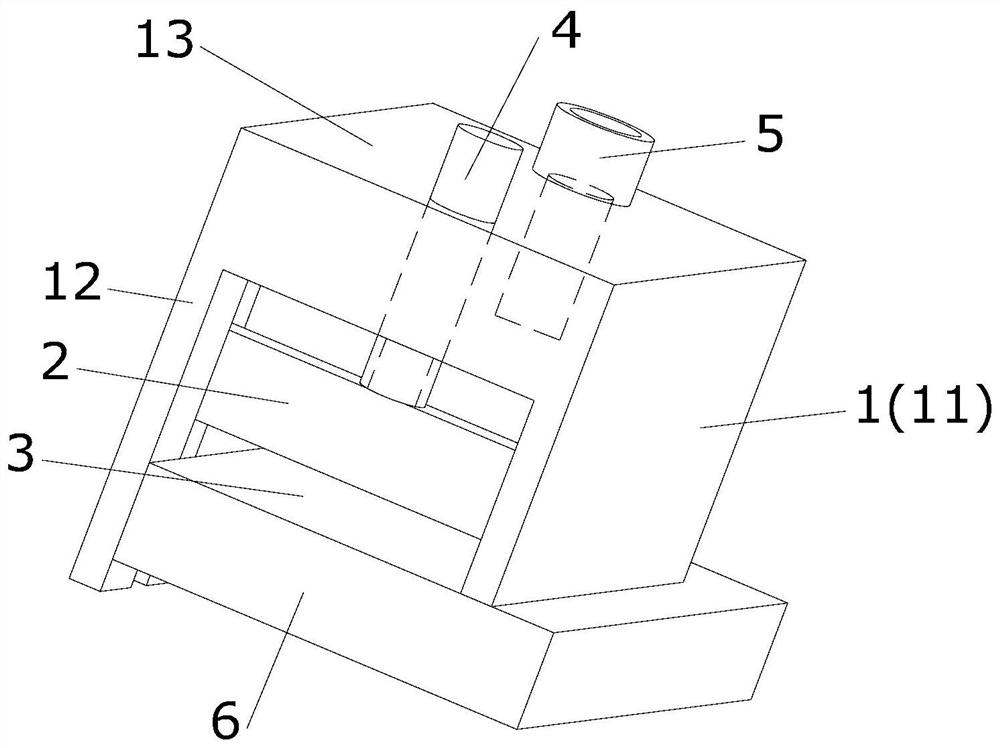

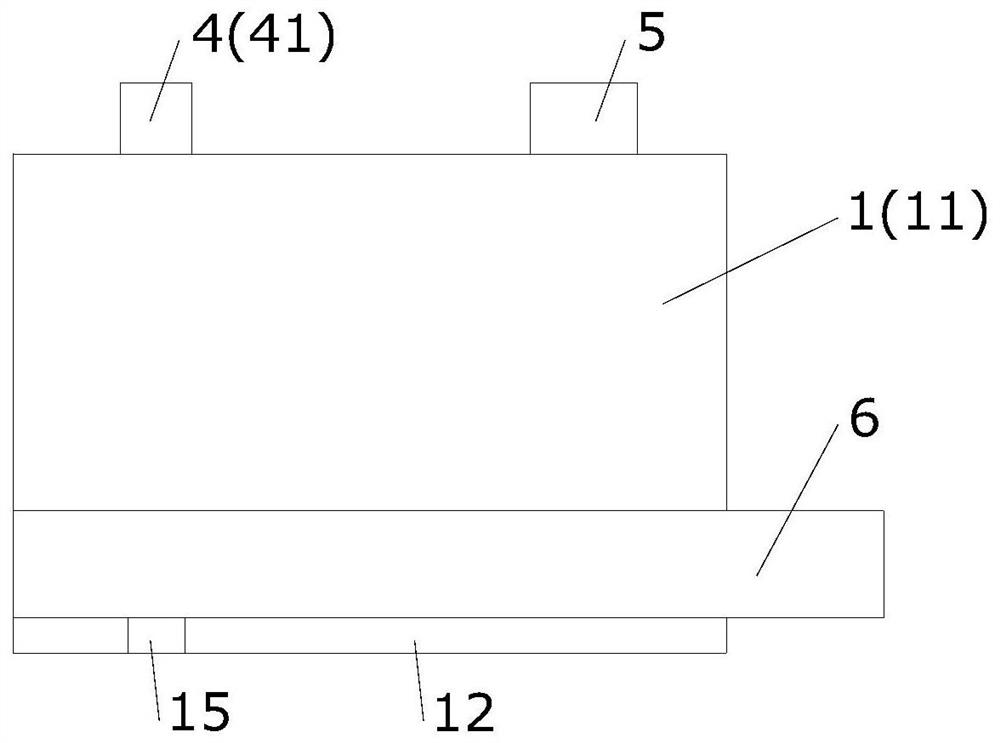

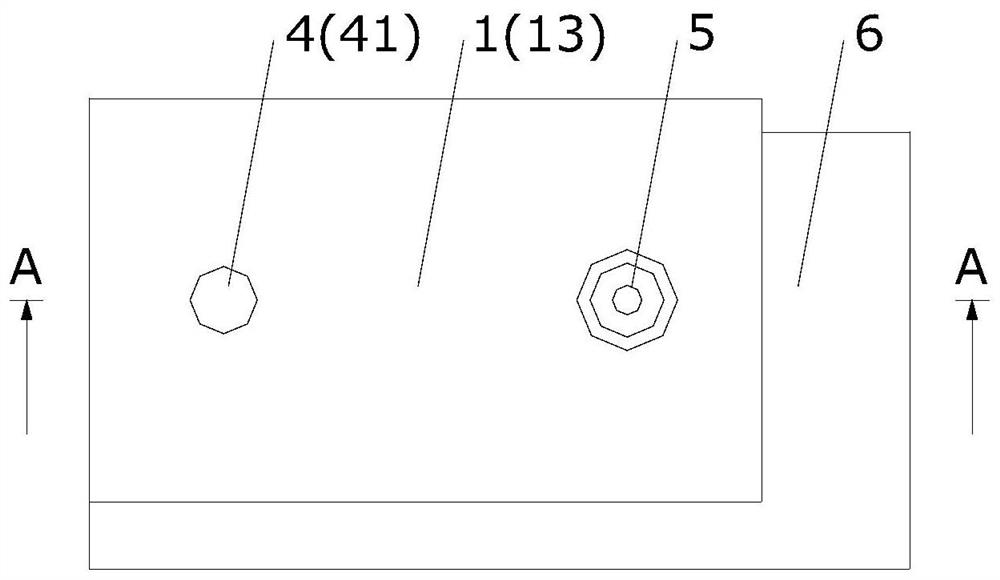

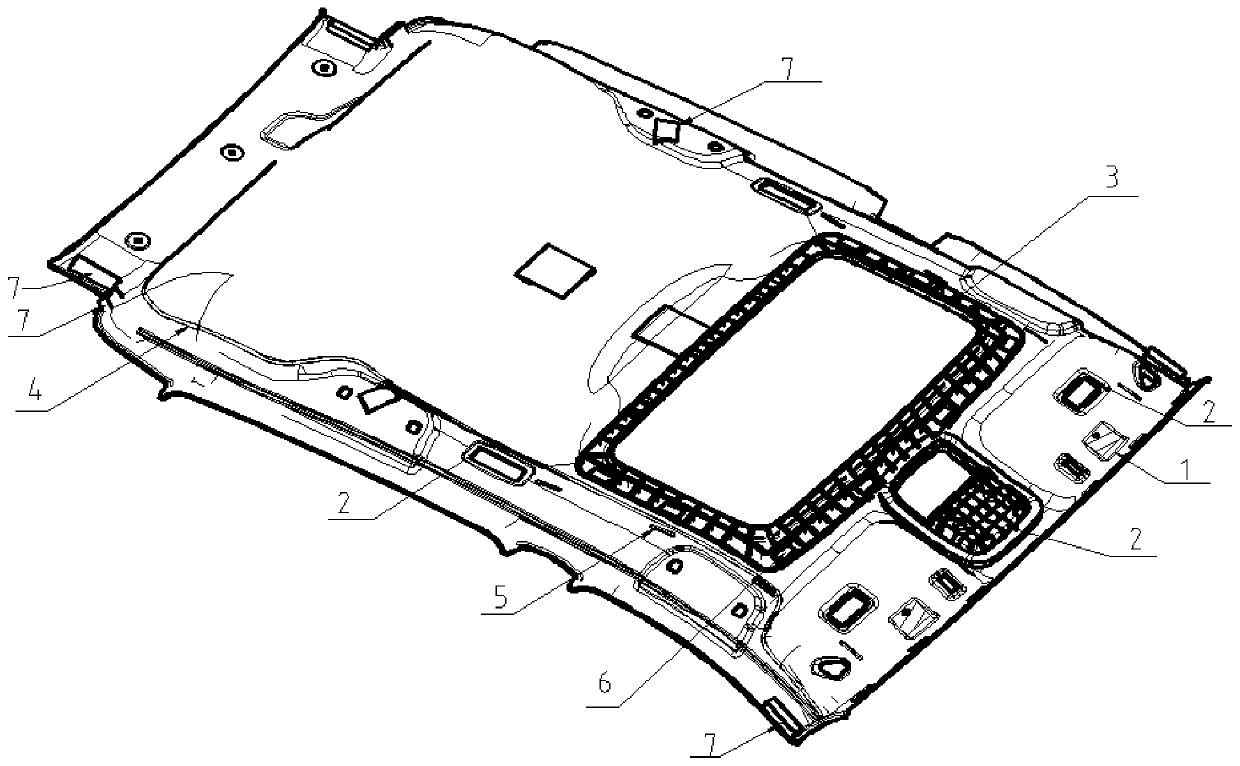

Integrally-formed automobile EPP ceiling and preparation method thereof

ActiveCN111204294AReduce generationImprove thickness uniformitySuperstructure subunitsElectric/fluid circuitUltimate tensile strengthOil consumption

The invention discloses an integrally-formed automobile EPP ceiling. The EPP ceiling is integrally formed by an EPP material and has the characteristics of light weight, good heat insulation property,low odor and low VOC generation; the formed ceiling is good in thickness uniformity; the bending boundary strength of the ceiling is high; the overall strength of ceiling is high, the EPP ceiling hasexcellent mechanical properties and long service life, can be well assembled and contacted with automobile body roof metal parts, does not produce abnormal sound in the driving process, has a more regular surface after being assembled, can be more fitted with coated woven cloth and the like, reduces wrinkles, has good smoothness, can save oil consumption, can improve the driving safety coefficient and can enhance the riding comfort. The forming process is easy to operate and can be completed only through one set of forming die and supporting facilities of the forming die, the production costis reduced, and the high-quality product rate is increased in a one-time forming mode.

Owner:四川诺阳汽车部件有限公司

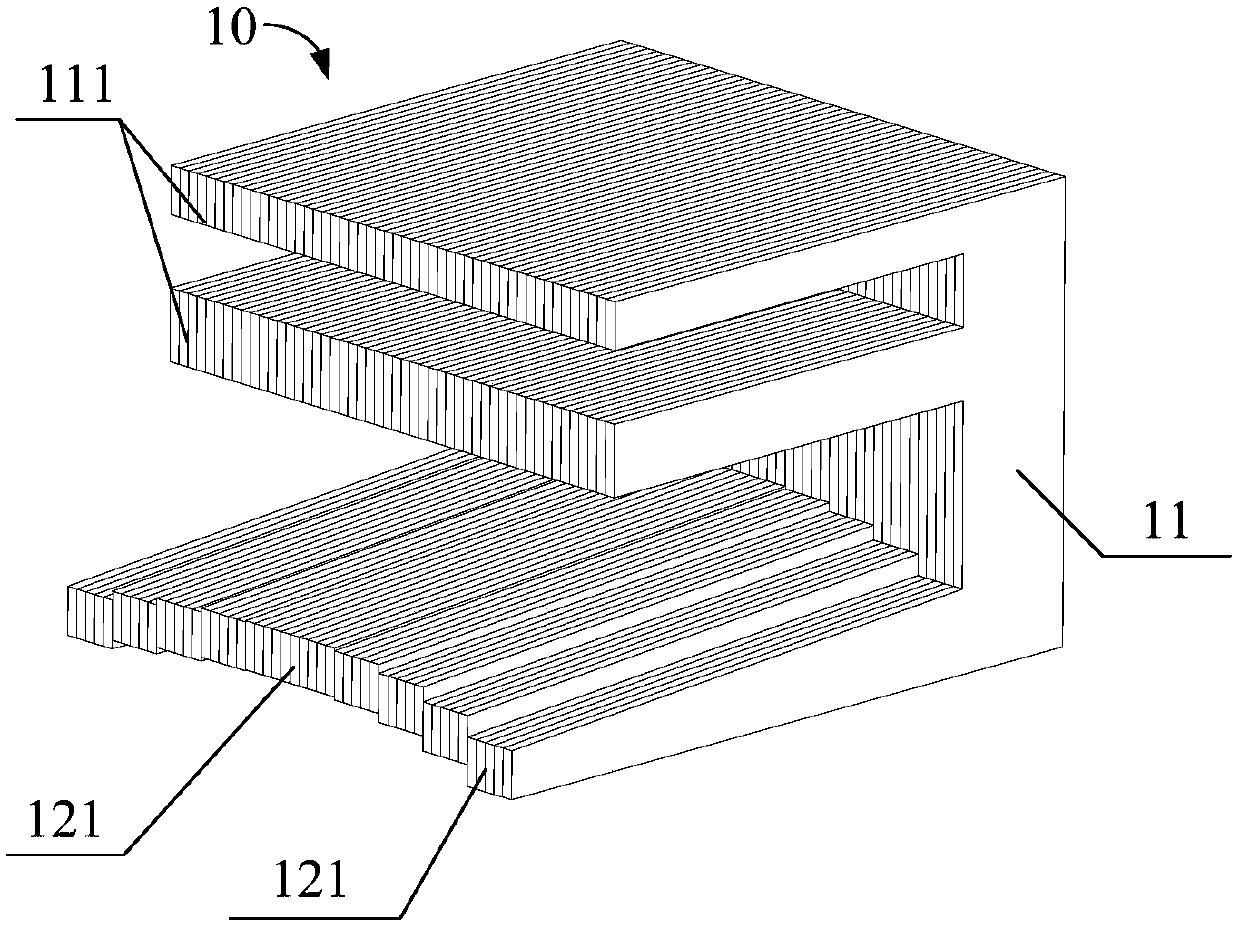

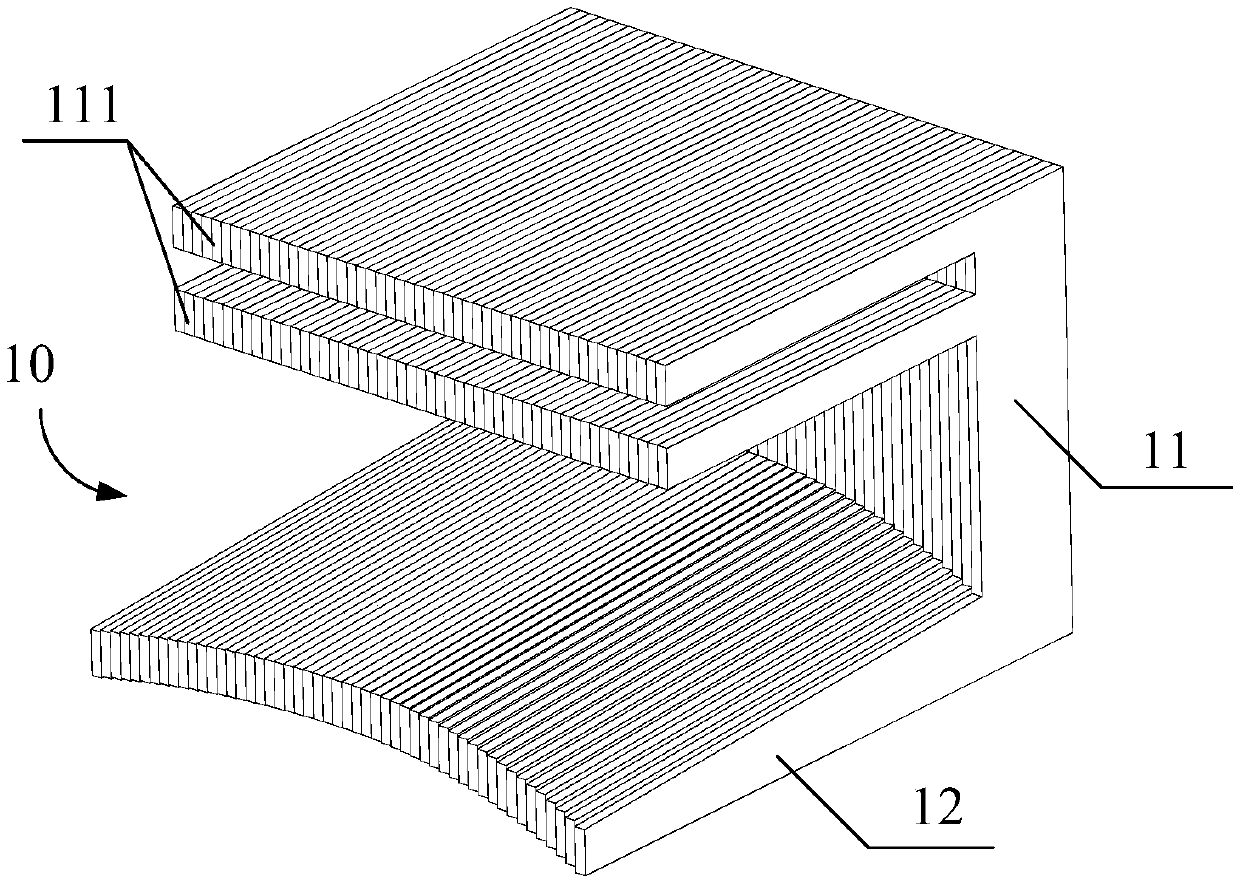

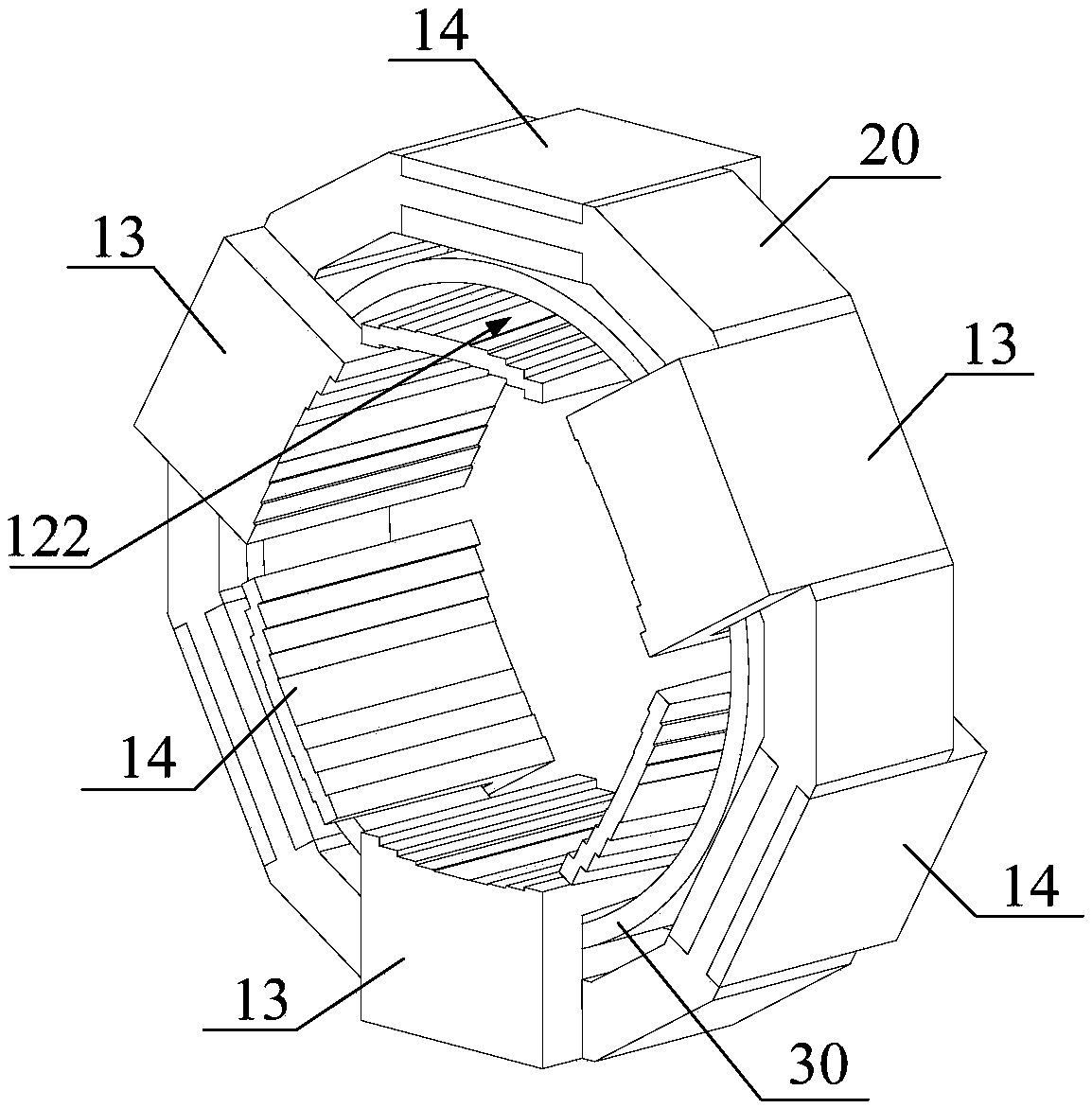

Stator tooth, stator and motor

PendingCN111293794AReduce processing difficultyReduce typesMagnetic circuit stationary partsPermanent magnet rotorElectric machinery

The invention provides a stator tooth, a stator and a motor. The stator tooth comprises a tooth body and a wire winding part; the tooth body is provided with a connecting part connected with the stator yoke of a stator; the wire winding part is connected with the tooth body and can be inserted into the inner side of the stator yoke, so that a wire winding groove for an annular winding to pass through can be defined between the winding part and the stator yoke; and in the circumferential direction of the stator, the wire winding parts gradually bends and extends towards a direction close to thecentral axis of the stator from the middle to the two sides. According to the stator tooth of the invention, the structure of the stator tooth is improved, and therefore, on one hand, an air gap between a rotor and a tooth part can be effectively reduced, so that the acting force between the stator and the permanent magnet rotor is enhanced; the rotor is driven to rotate, so that the performanceof a motor is effectively improved; and on the other hand, the volume of an accommodating cavity can be increased, a larger wire winding space is provided, and therefore, more windings can be wound, and the performance of the motor is improved.

Owner:WELLING WUHU MOTOR MFG +1

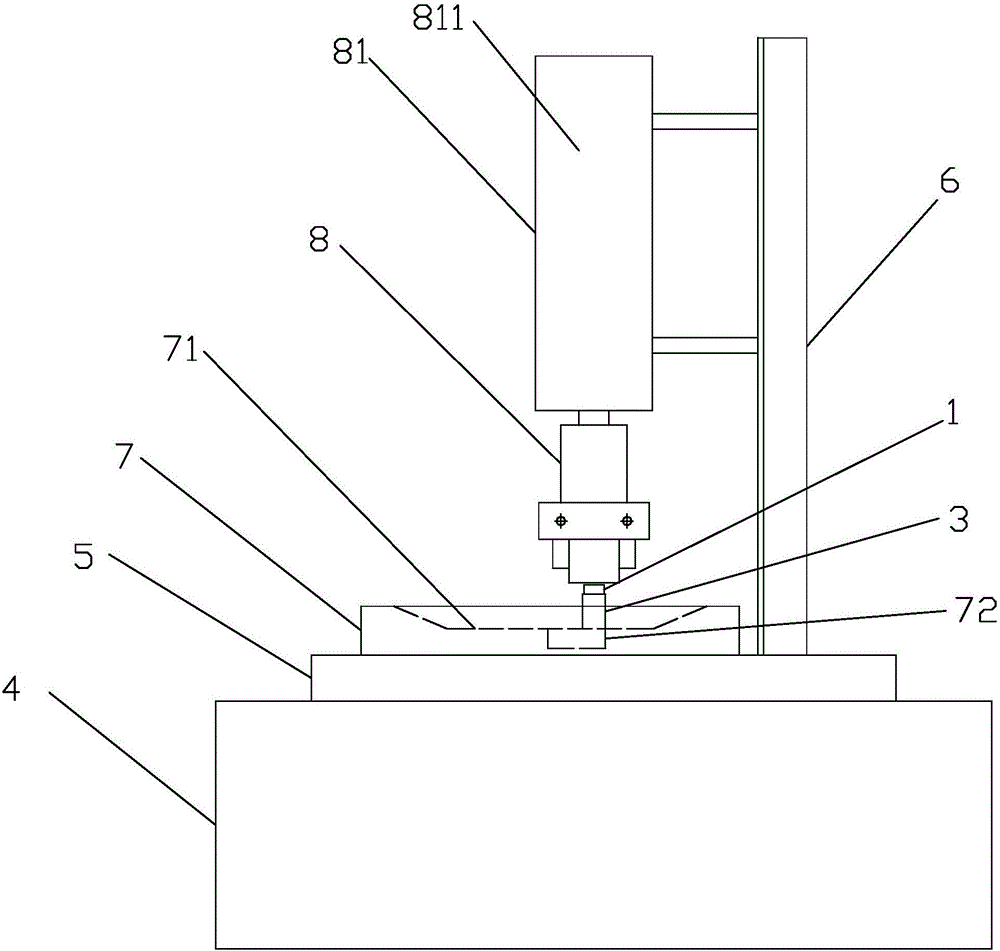

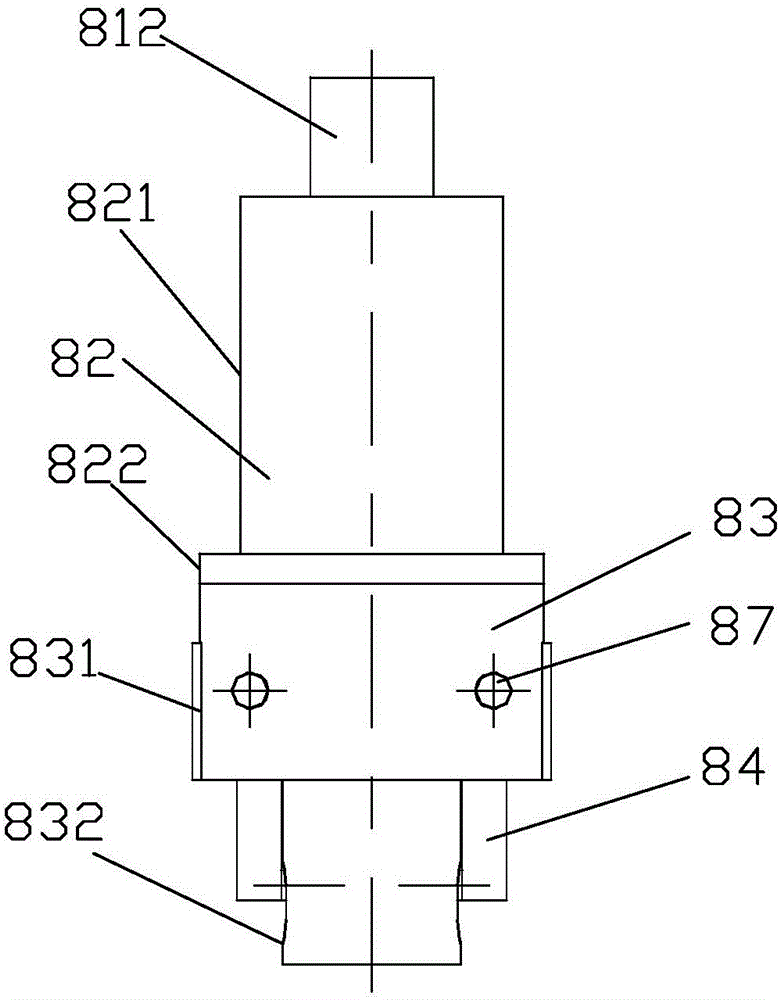

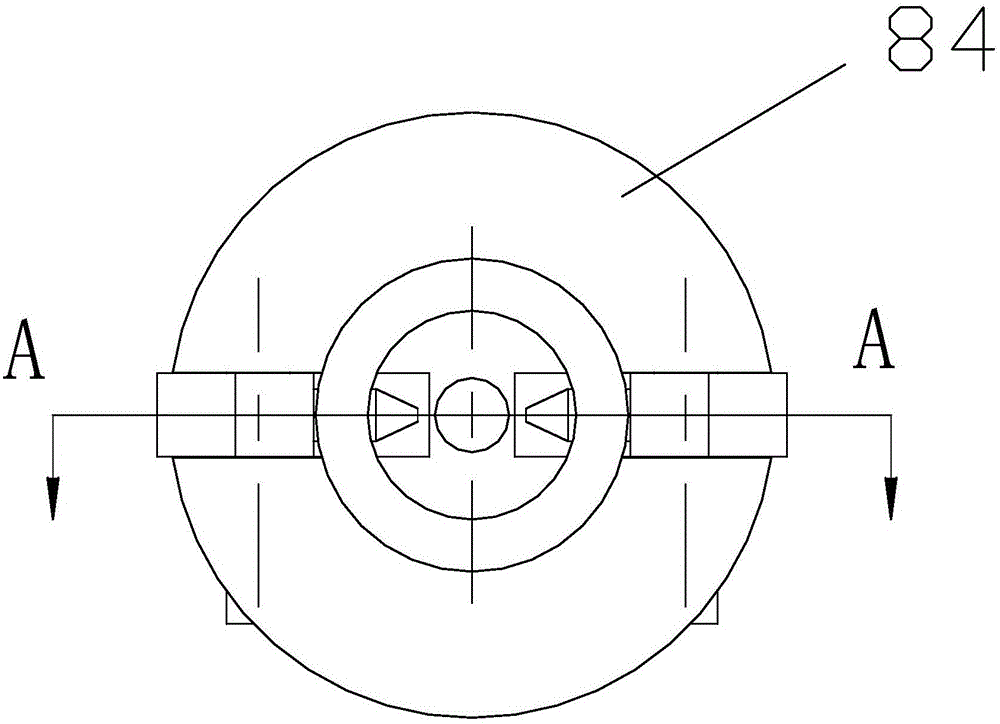

Withhold tooling for automobile wire harness plug

ActiveCN105742938AEasy to processImprove connection qualityContact member assembly/disassemblyEngineeringMechanical engineering

The invention provides a withhold tooling for an automobile wire harness plug and provides the withhold tooling for the automobile wire harness plug, which is simple in structure and convenient to process and improves the connection reliability of the wire harness plug. The withhold tooling comprises an air cylinder, a guide cylinder, a withhold cylinder and a pair of withhold blocks, wherein the air cylinder comprises a cylinder body and a piston rod; the cylinder body is connected to a slide base; a slide hole is formed in the piston rod; a tapered end is arranged at the bottom part of the piston rod; the withhold cylinder comprises a pressure cylinder I and a pressure cylinder II, which are integrally molded and are large in upper parts and small in lower parts; swing holes are symmetrically formed in two sides of the pressure cylinder I; pressure holes are symmetrically formed in two sides of the pressure cylinder II; the diameter of the pressure cylinder II is consistent with that of a cylinder; the swing holes correspond to the pressure holes one by one; the withhold blocks are C-shaped; the inner side of the top end of each withhold block is an inclined plane; a pressure tip is arranged at the inner side of the bottom end of each withhold block; the inclined planes of the pair of withhold blocks are in contact with the tapered end of the piston rod; and the withhold blocks are located in the swing holes and the pressure holes. The withhold tooling is convenient to process; and the reliability of the product connection quality is improved.

Owner:YANGZHOU LIANGCHENG AUTO PARTS

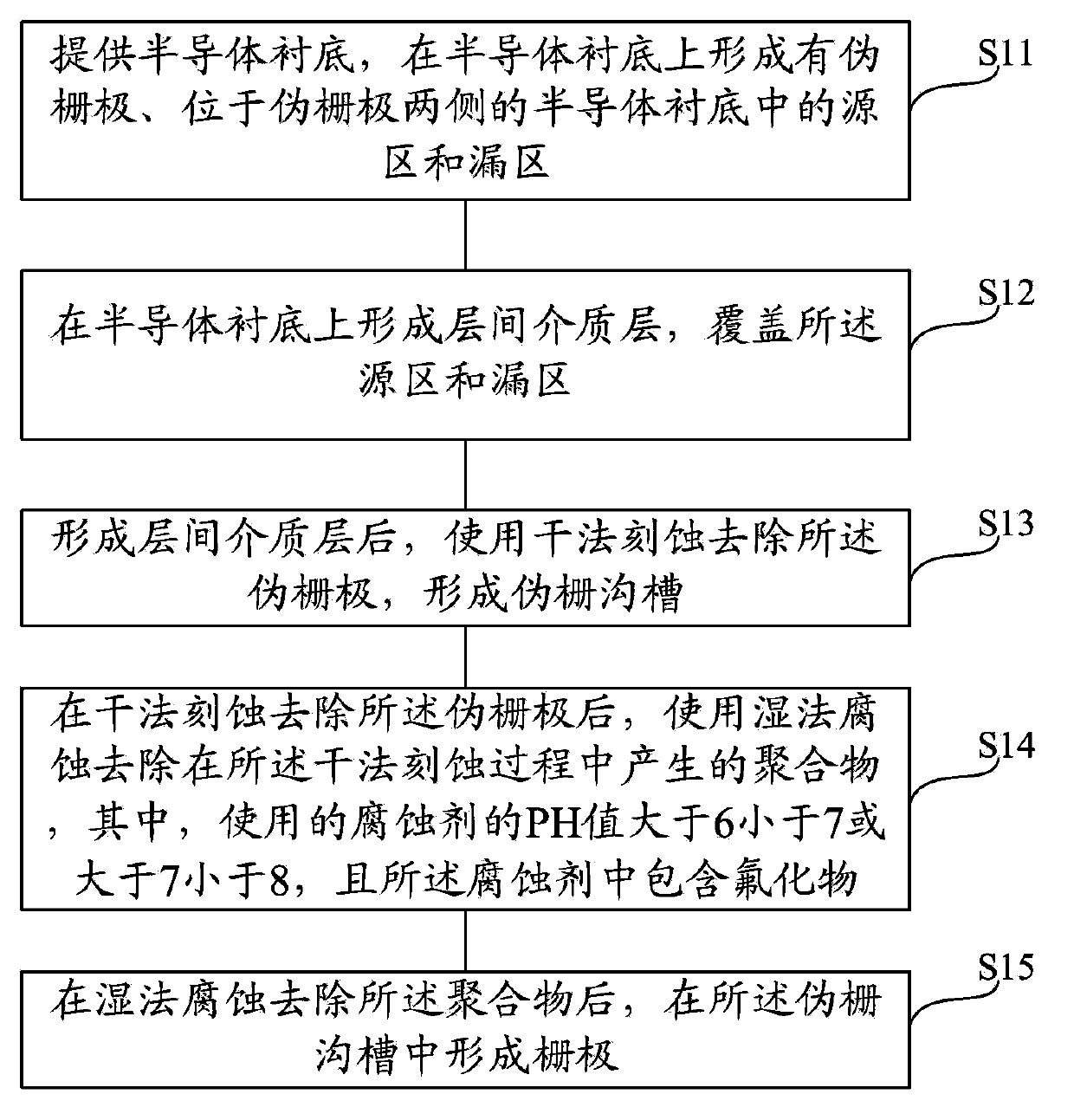

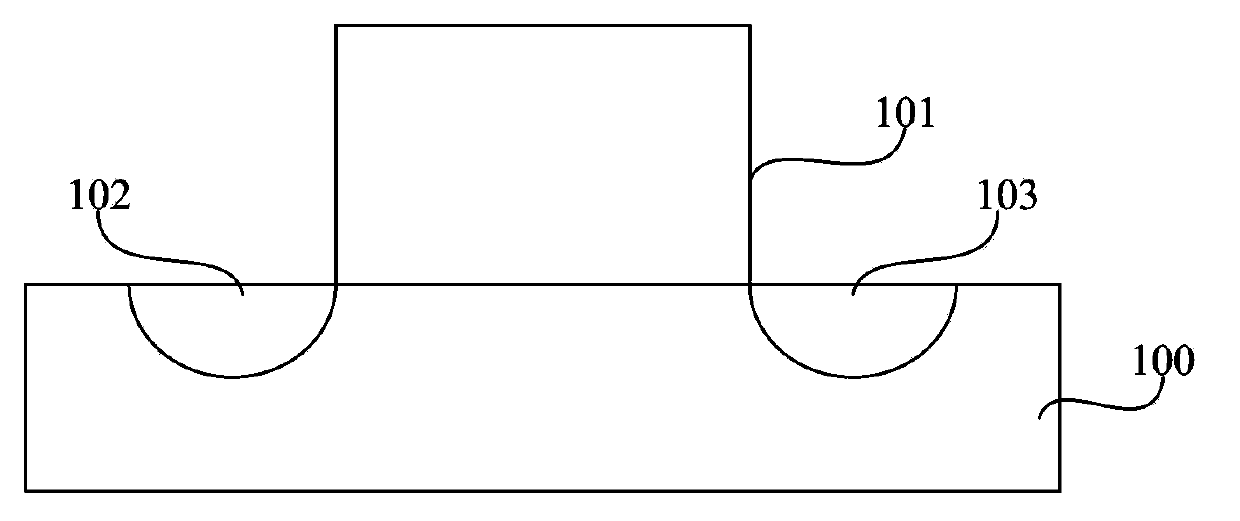

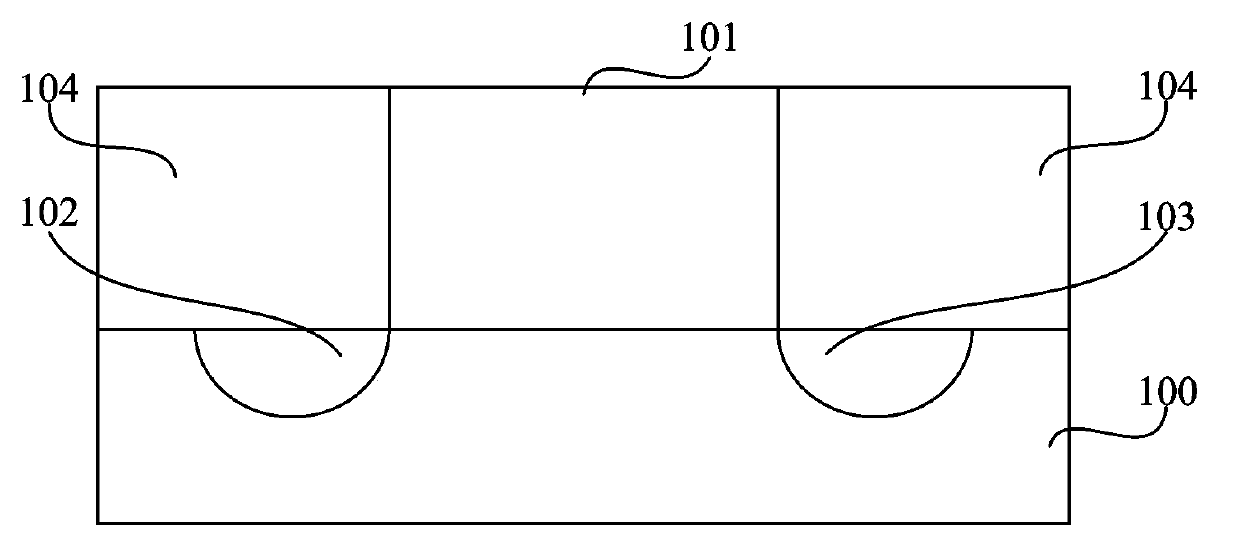

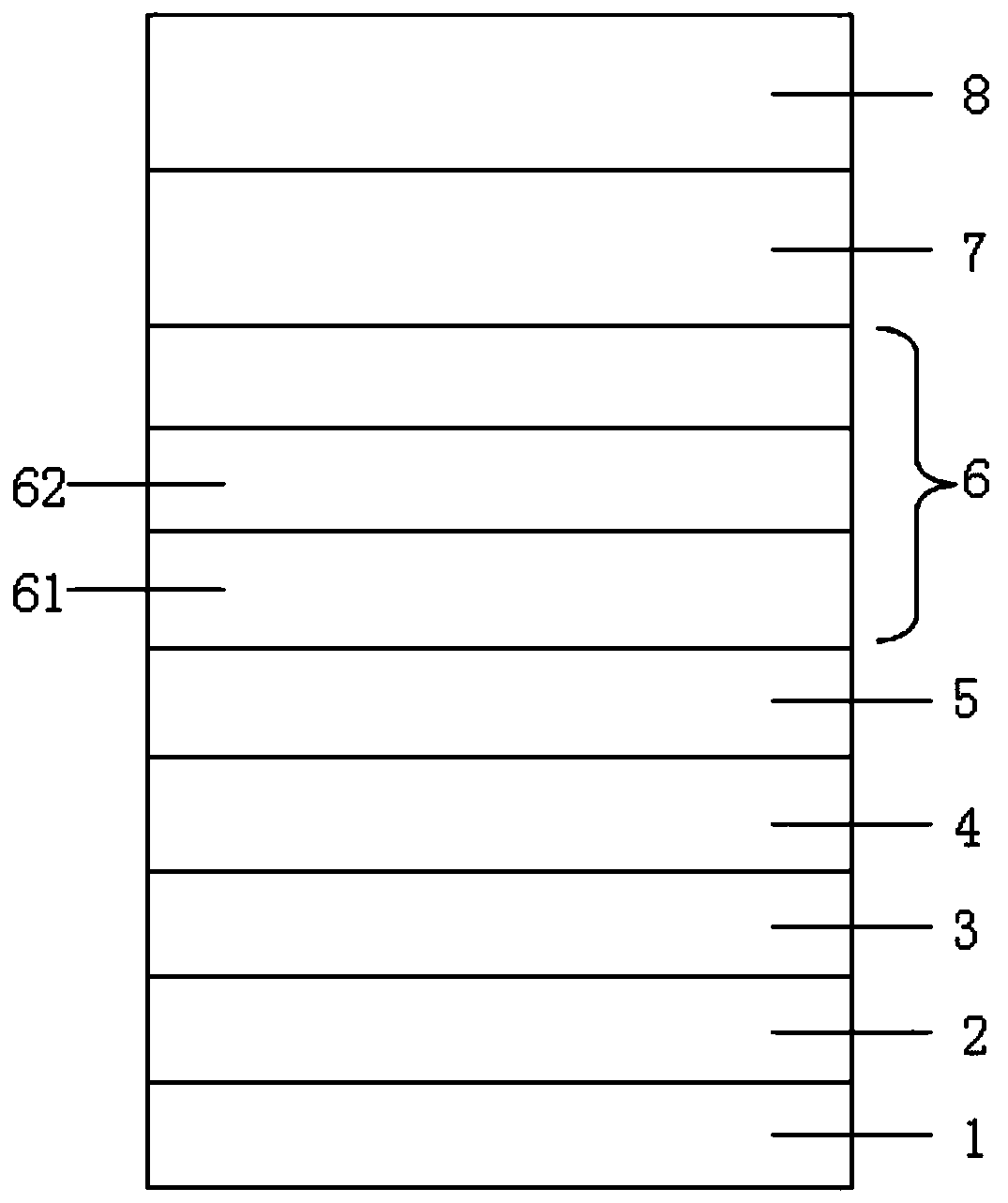

Forming method for transistor

ActiveCN103871886AImprove performanceImprove reliabilityTransistorSemiconductor/solid-state device manufacturingCorrosionSource area

The invention discloses a forming method for a transistor. The forming method comprises the following steps of providing a semiconductor substrate, and forming a pseudo gate, and a source area and a drain area, which are positioned in the semiconductor substrate on the two sides of the pseudo gate, on the semiconductor substrate; forming an interlayer dielectric layer on the semiconductor substrate to cover the source area and the drain area; after the interlayer dielectric layer is formed, removing the pseudo gate to form a pseudo gate trench in a dry etching way; after the pseudo gate is removed in the dry etching way, removing a polymer generated in a dry etching process in a wet corrosion way, wherein the PH value of a corrosive agent is greater than 6 and smaller than 7 or greater than 7 and smaller than 8, and the corrosive agent contains fluoride; after the polymer is removed in the wet corrosion way, forming a gate in the pseudo gate trench. According to the forming method, the corrosive agent is used for substantially removing the polymer on the sidewalls and the bottom of the pseudo gate trench, and the gate can form barrier-free contact with the dielectric layer of the gate or the gate on the sidewalls of the pseudo gate trench; the performance of the transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

LED epitaxial growth method for reducing warping

ActiveCN109980055AEliminates stress build-up effectsIncrease windowSemiconductor/solid-state device manufacturingSemiconductor devicesMagnesiumOptoelectronics

The invention discloses an LED epitaxial growth method for reducing warping. The method comprises the following steps of processing a substrate; growing an AlzGa1-zN layer, an AlN layer, a MgAlyGa1-yNlayer, a Si-doped N-type GaN layer, an InxGa(1-x)N / GaN light-emitting layer, a P-type AlGaN layer and a magnesium-doped P-type GaN layer; and performing temperature reduction and cooling, wherein x is equal to 0.20-0.25. The LED epitaxial growth method solves the technical problem in the prior art that the LED epitaxial wafer has large warpage and high fragmentation rate, and makes the surface appearance of the epitaxial wafer better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

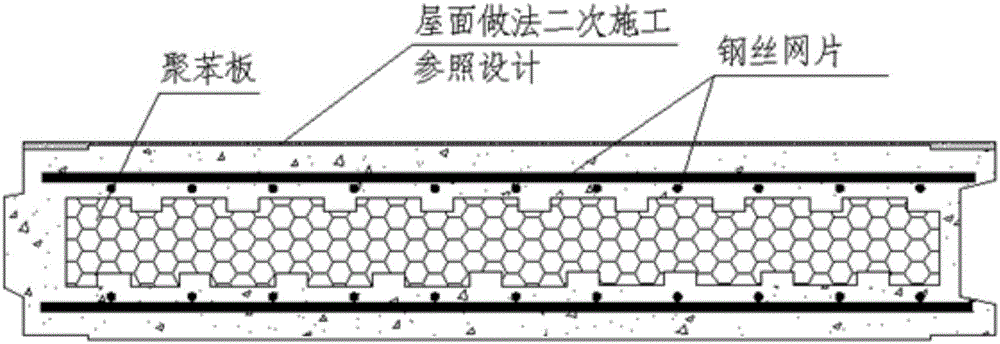

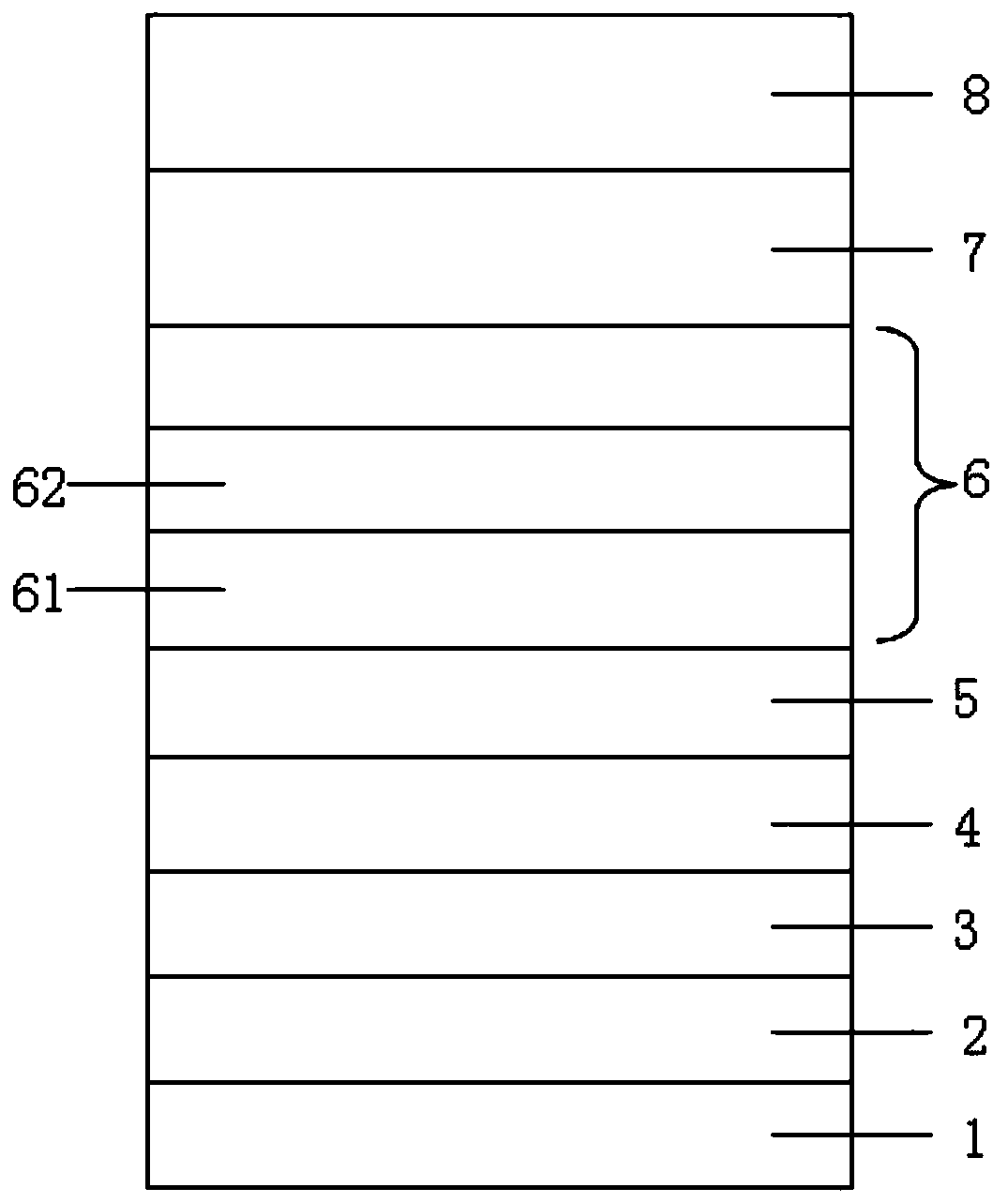

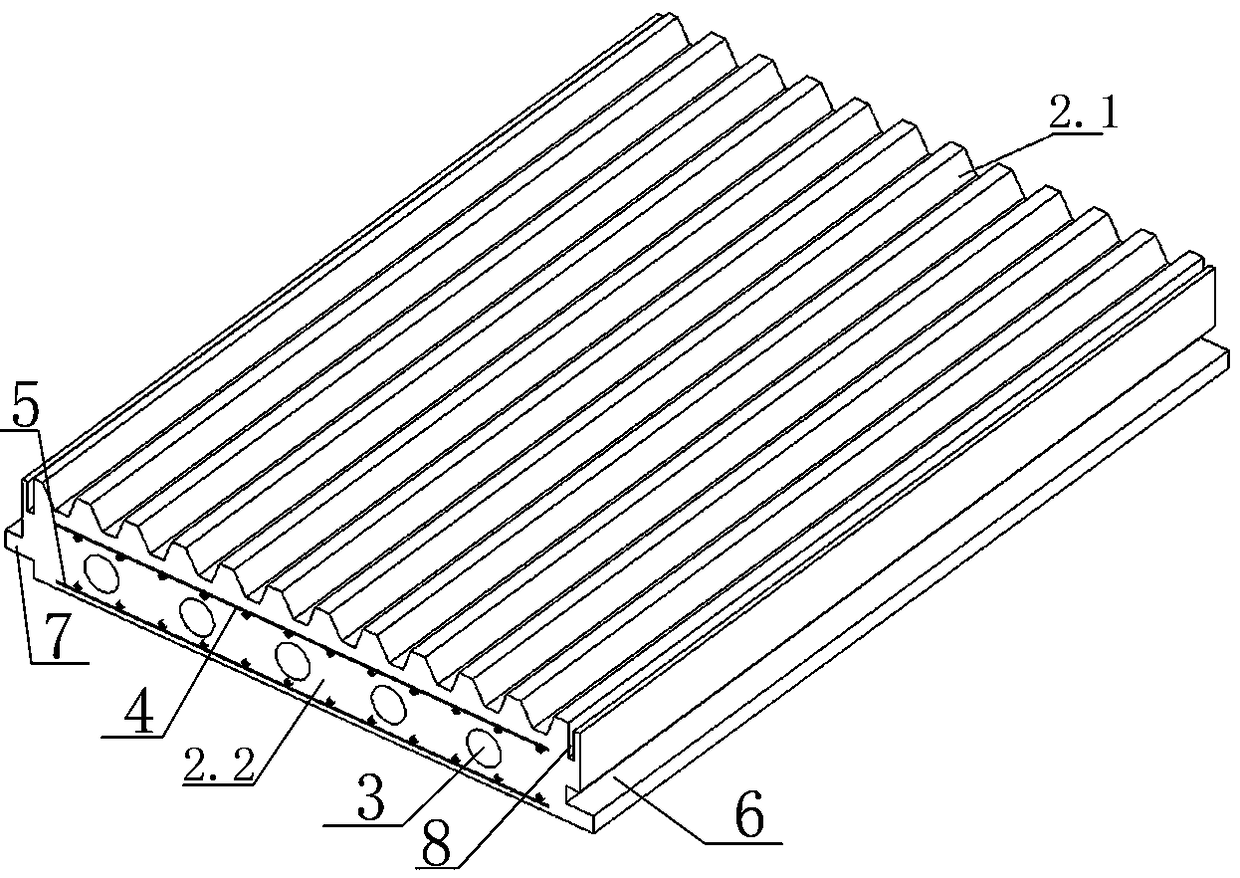

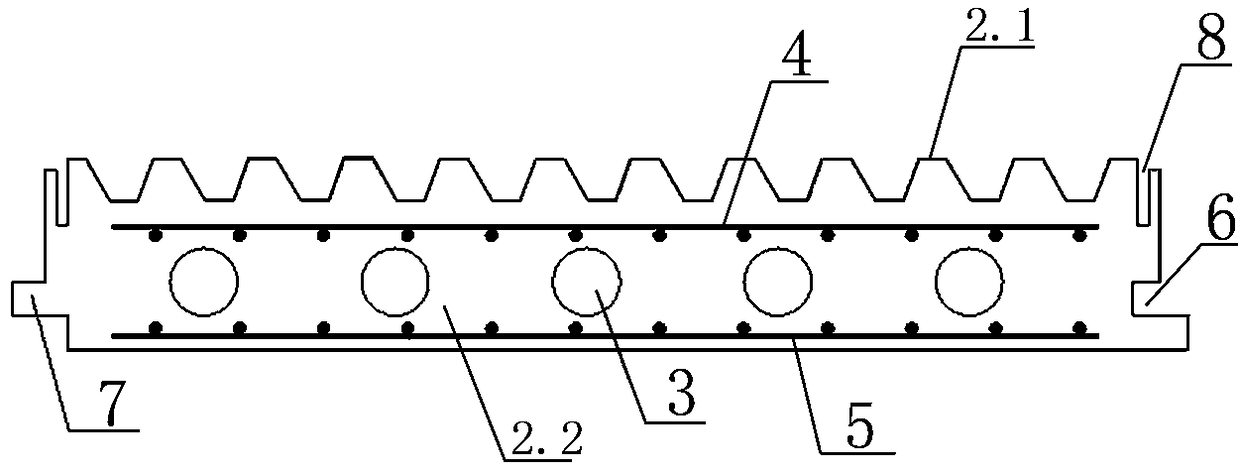

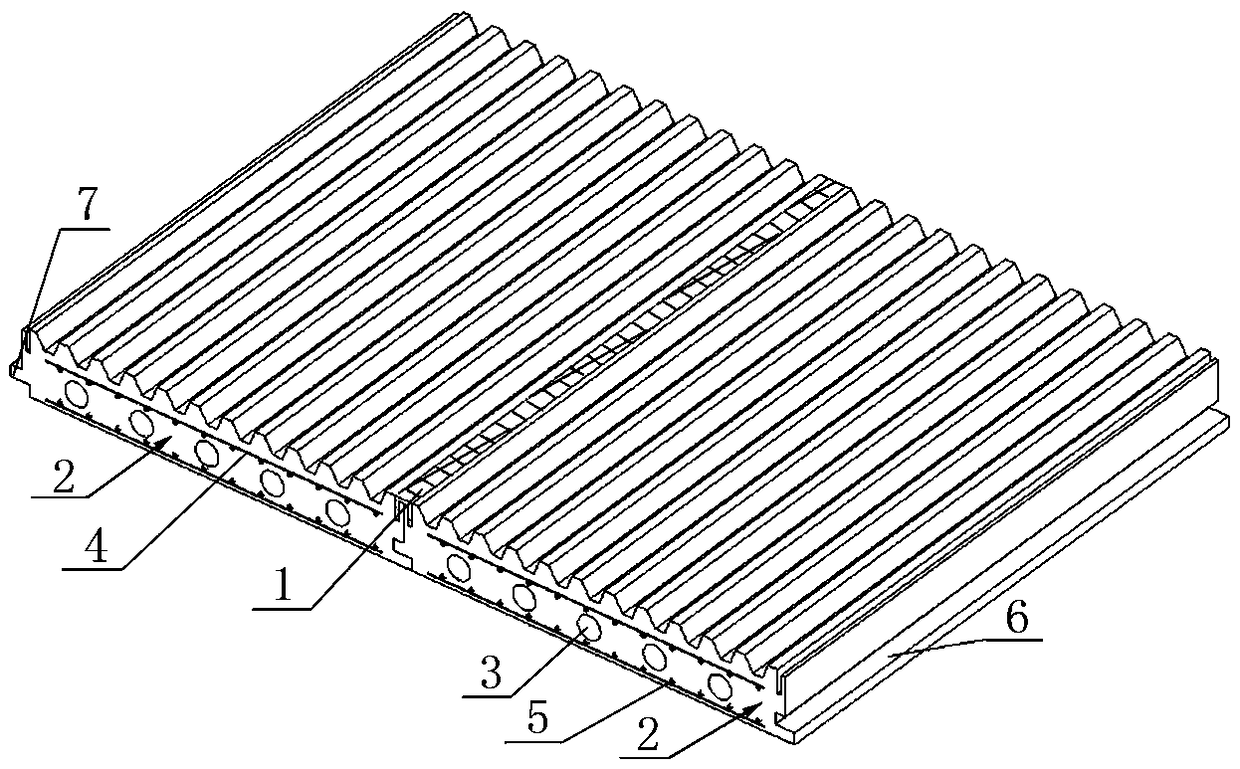

Prefabricated color steel tile-lightweight concrete composite roof board and construction method thereof

PendingCN108979015AEasy to prepare in large batchesSimple structureRoof covering using slabs/sheetsLong axisRebar

Provided are a prefabricated color steel tile-lightweight concrete composite roof board and a construction method thereof. The composite roof board is formed by splicing of a group of composite roof board units. The composite roof board units comprise color steel tiles and lightweight concrete layers poured at bottoms of the color steel tiles. A group of hole passages is arranged at intervals along the transverse direction in each lightweight concrete layer. Each hole passage penetrates each lightweight concrete layer along the vertical direction. An upper-layer reinforcing mesh sheet is arranged at the position above each group of hole passages and close to the top surface of each lightweight concrete layer. A lower-layer reinforcing mesh sheet is arranged at the position below each groupof hole passages and close to the bottom surface of each lightweight concrete layer. An elongated groove is formed on the vertical side surface on one side of each lightweight concrete layer along the long-axis direction. A protrusion matching each groove is arranged on the vertical side surface on the other side of each lightweight concrete layer along the long-axis direction. Technical problemsof a conventional roof board such as low strength, poor waterproof and heat-preservation effect and difficulty in connection are resolved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

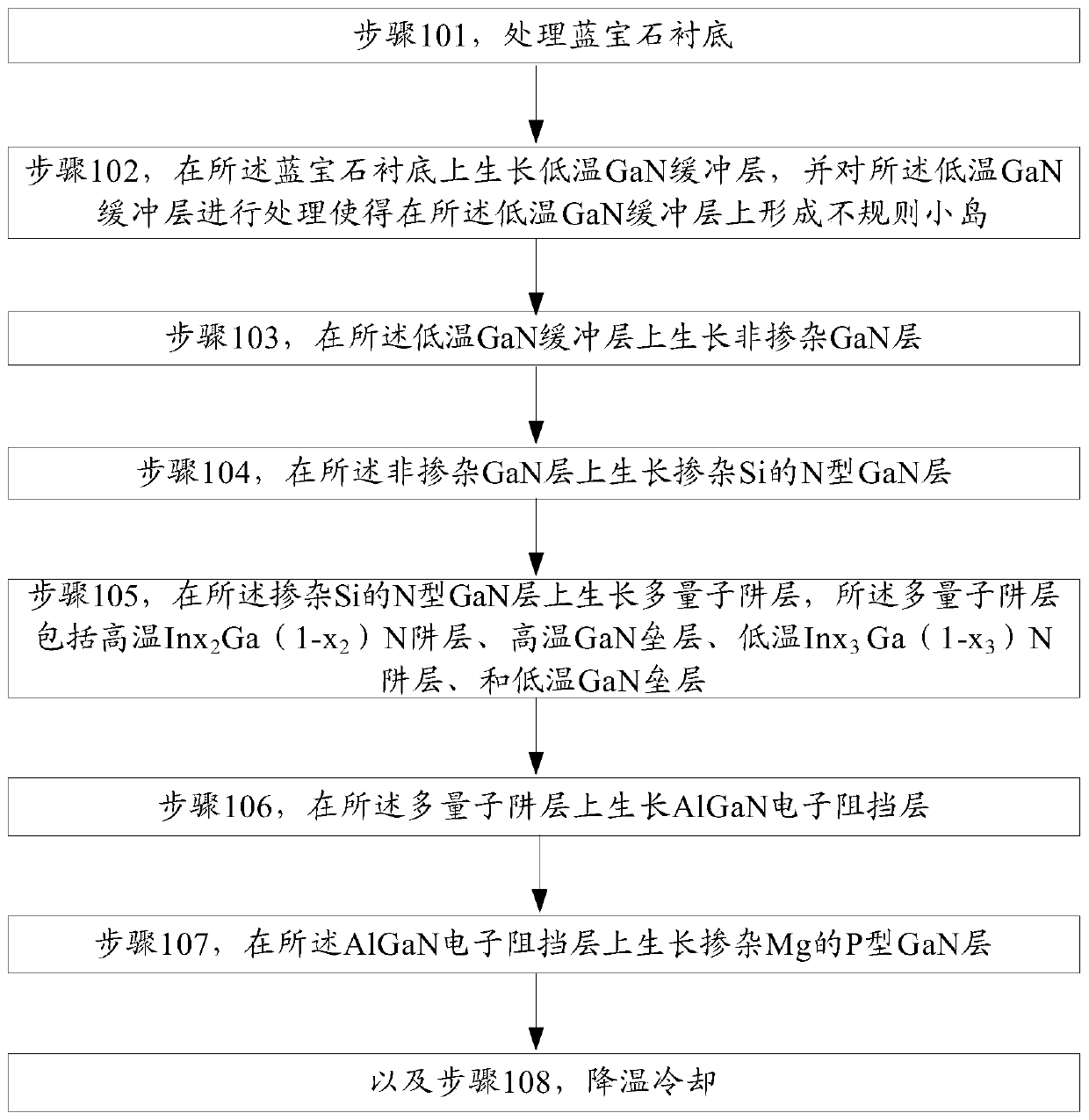

LED epitaxial quantum well growth method

ActiveCN109860344AQuality improvementIncrease brightnessSemiconductor devicesQuantum wellOptoelectronics

The invention discloses an LED epitaxial quantum well growth method. The method comprises steps: a sapphire substrate is processed; a low-temperature GaN buffer layer grows on the sapphire substrate,the low-temperature GaN buffer layer is processed, and an irregular island is formed on the low-temperature GaN buffer layer; an undoped GaN layer grows on the low-temperature GaN buffer layer; a Si-doped N-type GaN layer grows on the undoped GaN layer; a multi-quantum well layer grows on the Si-doped N-type GaN layer; an AlGaN electron blocking layer grows on the multi-quantum well layer; a Mg-doped P-type GaN layer grows on the AlGaN electron blocking layer; and temperature reduction and cooling are carried out. According to the growth method disclosed in the invention, the light emitting efficiency of the LED can be effectively enhanced, warpage of the epitaxial wafer can be reduced, the qualified rate of the GaN epitaxial wafer is improved, the surface of the epitaxial layer becomes flat, and the appearance is better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

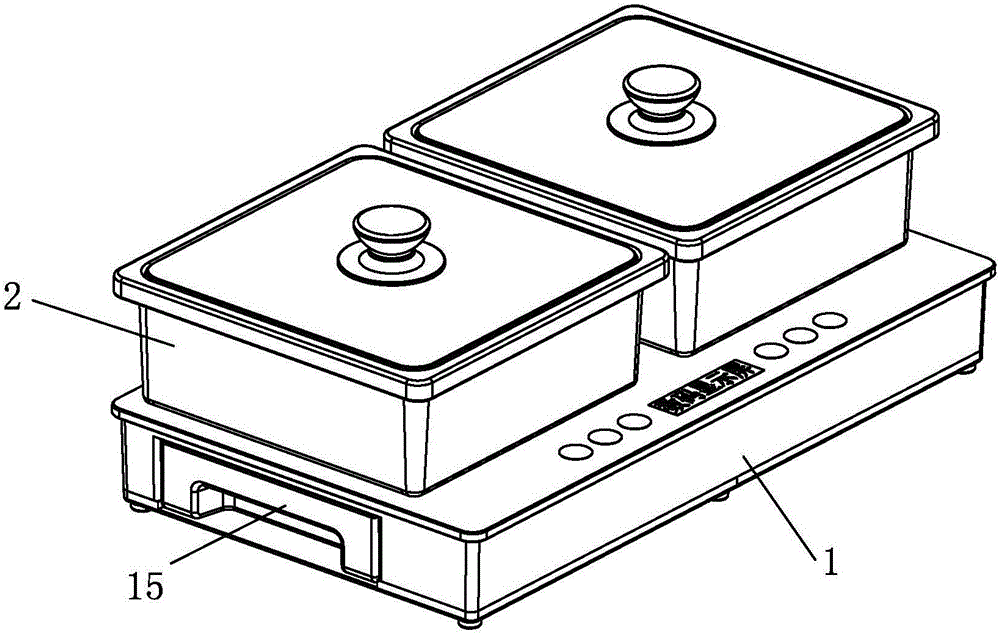

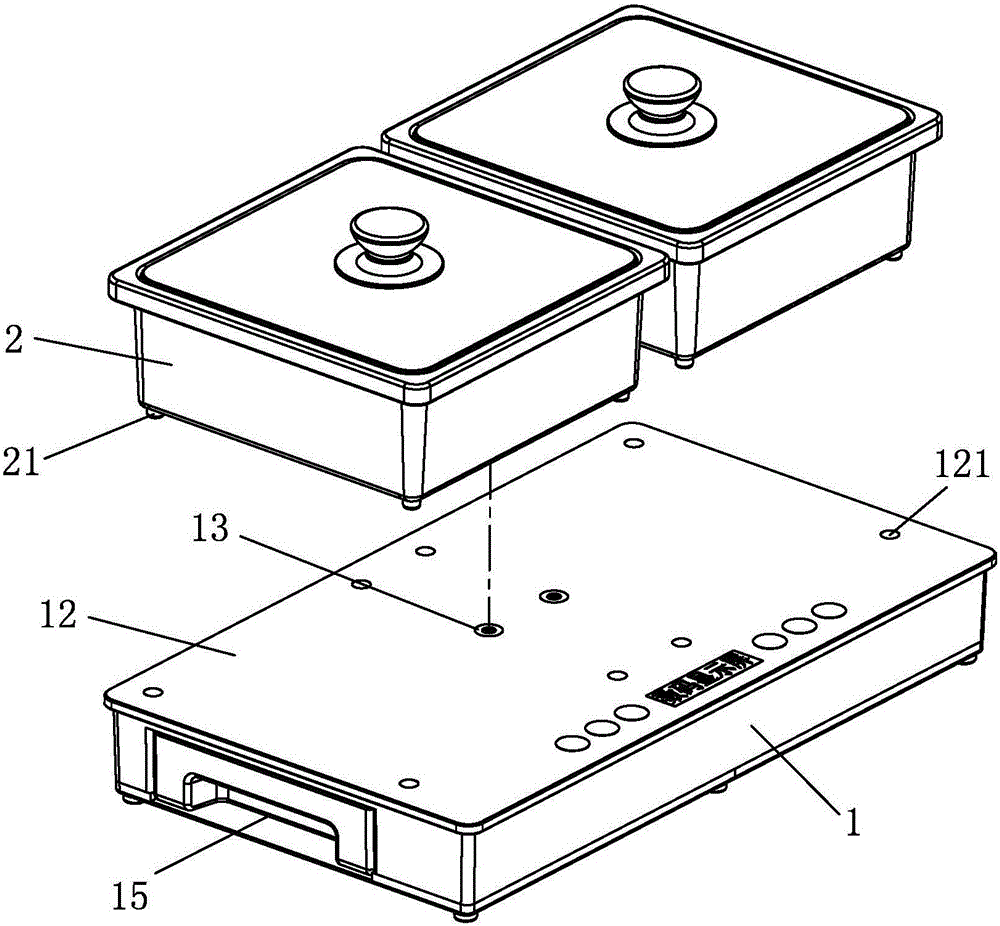

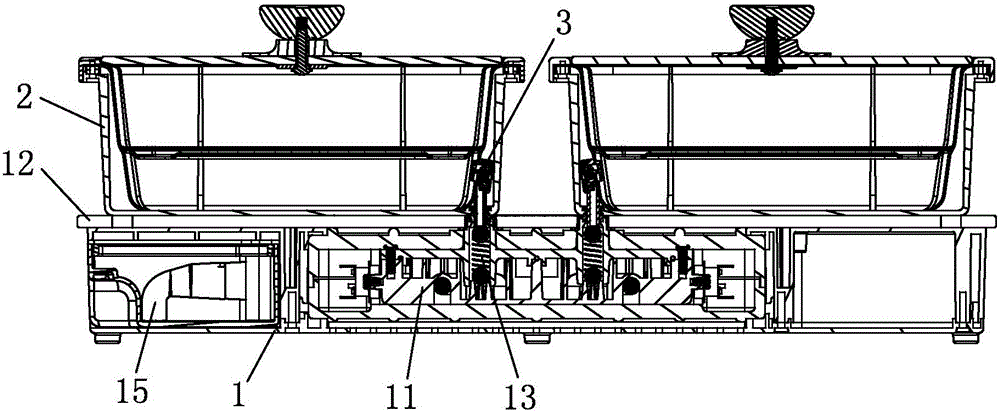

Desk type steam cooker

InactiveCN105996746ARegular structureNeat surfaceMultiple-unit cooking vesselsSteam cooking vesselsEngineeringControl circuit

The invention relates to a desktop steam pot, which comprises a base provided with a steam generator and a cooking pot provided with a steam spray head, the upper surface of the base is provided with a plane plate, and the cooking pot can be placed on the plane board separately; the cooking pot When placed on the flat plate, the steam spray head communicates with the steam generator, and when the cooking pot is separated from the flat plate, the steam spray head is separated from the steam generator. In the present invention, by optimizing the structure of the base, a flat plate is arranged on the surface of the base to become a platform for installing and placing a cooking pot. The steam generator and control circuit are still built in the base, so that the overall structure of the base is table-top. The whole machine is small and light, easy to store and store, and the surface of the base is regular and easy to clean, especially suitable for home use.

Owner:FOSHAN CITY SHUNDE DISTRICT SHUNJIALI ELECTRICAL APPLIANCE

Method for preparing titanium dioxide nanotube array

InactiveCN102220616BNeat surfaceEvenly distributedSurface reaction electrolytic coatingTio2 nanotubeElectrochemical anodization

Owner:SOUTHEAST UNIV

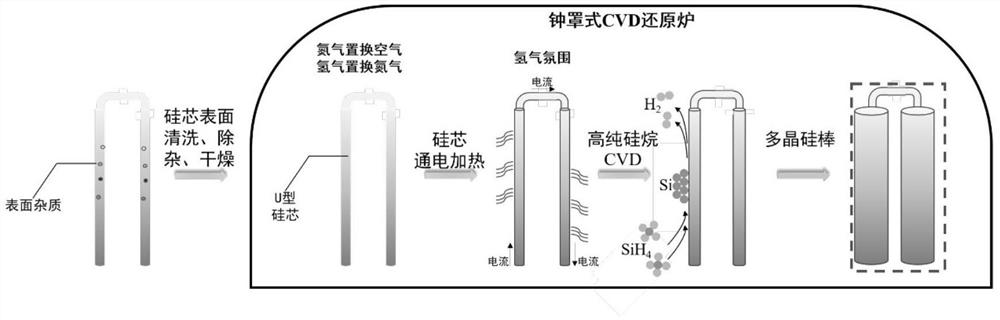

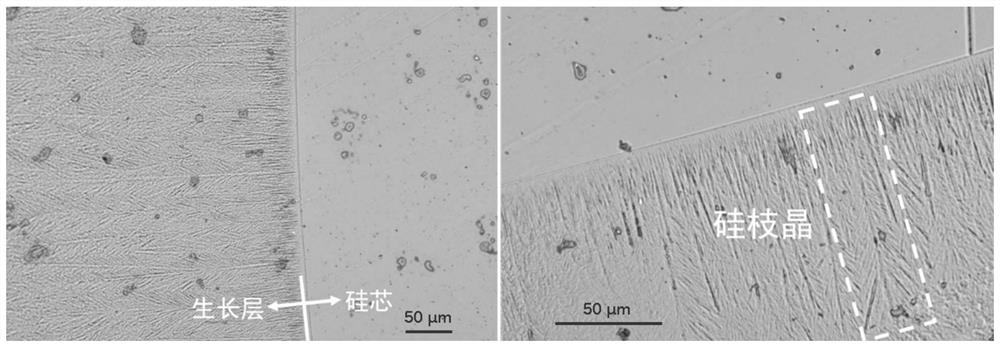

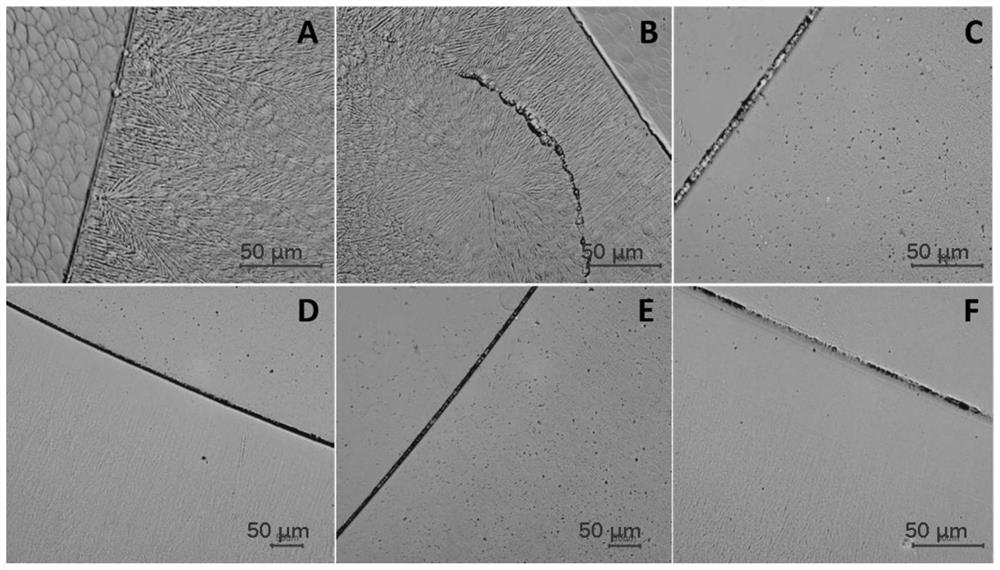

Interface wettability regulation and control method for inhibiting growth of silicon dendrites in CVD process of zone-melting-grade polycrystalline silicon

PendingCN113387360AEffectively stainEffectively removes stainsSilicon compoundsSurface oxidationSilanes

The invention discloses an interface wettability regulation and control method for inhibiting growth of silicon dendrites in a CVD process of zone-melting-grade polycrystalline silicon, and relates to the field of zone-melting-grade polycrystalline silicon. The method comprises the steps of removing surface impurities on the surface of a U-shaped silicon core; placing in a thermal cracking furnace reactor, and replacing air with nitrogen; replacing nitrogen with hydrogen; continuously introducing hydrogen, loading current to the silicon core in the reactor so as to enable an oxide layer on the surface of the silicon core to be reduced, regulating and controlling the wettability of the silicon core, and constructing a super-hydrophilic silicon surface; and regulating the current to control the silicon core to reach the reaction temperature, introducing mixed gas of high-purity silane and high-purity hydrogen, enabling the silane to be subjected to high-temperature cracking on the surface of the silicon core, enabling the product silicon to be subjected to uniform nucleation and layered growth on the surface of the super-hydrophilic silicon core, and finally obtaining a compact polycrystalline silicon rod . According to the method, the problems of 'island growth' and silicon dendrites in the silicon deposition process can be effectively inhibited by regulating and controlling the surface interface and reducing the nucleation barrier, so that the product meeting the mechanical property of the zone-melting-grade polycrystalline silicon is obtained, and the method is reasonable in design, convenient to operate and high in practicability.

Owner:河南硅烷科技发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com