Preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

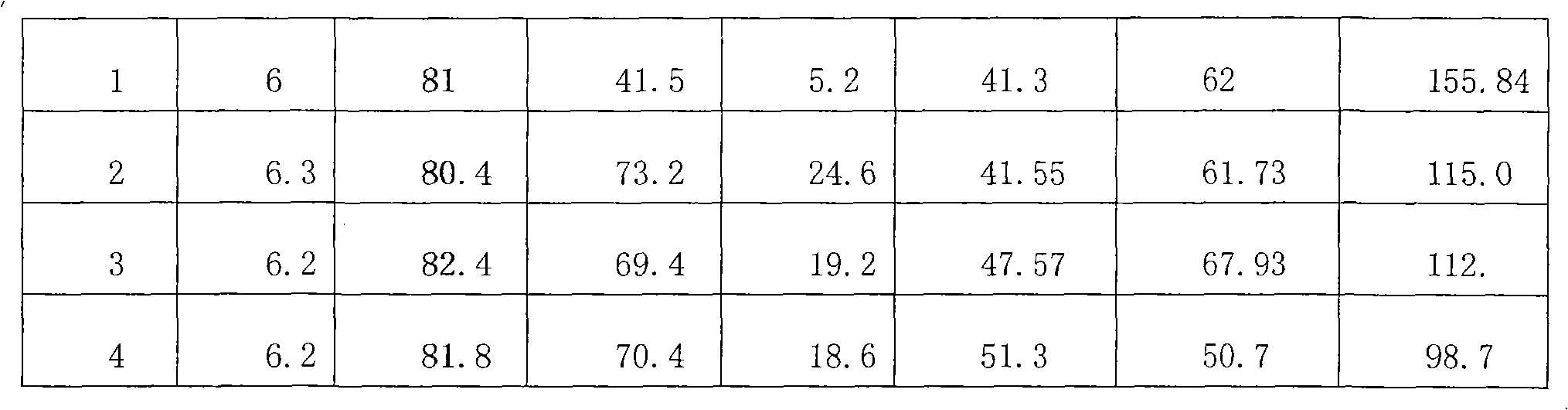

Examples

preparation example Construction

[0034] (1) Preparation of seed emulsion core layer

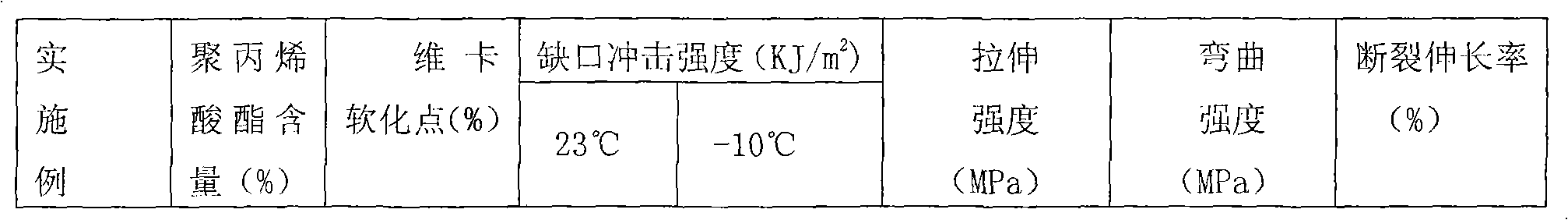

[0035] Table 1. The formulation and control temperature of the preparation of the seed emulsion core layer

[0036] implement

example

Deionized water

kg

Acrylic

Monomer Kg

crosslinking agent

kg

Composite emulsifier Kg

Composite initiator Kg

Control temperature ℃

1

350

28

0.35

0.88

0.81

70

2

350

33.25

0.385

1.2

0.91

71

3

350

29

0.36

1.1

0.85

72

4

350

31

0.37

0.95

0.89

69

[0037] in

[0038] Composite emulsifier ratio is sodium lauryl sulfate in each embodiment: alkylphenol polyoxyethylene ether=2: 1

[0039] The ratio of composite initiator is potassium persulfate: sodium bisulfite=3.5:1

Embodiment 2

[0040] Composite initiator ratio is potassium persulfate in embodiment 2: sodium bisulfite=3.7: 1

Embodiment 3

[0041] Composite initiator ratio is potassium persulfate in embodiment 3: sodium bisulfite=3.7: 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com