Prefabricated color steel tile-lightweight concrete composite roof board and construction method thereof

A technology of lightweight concrete and construction method, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problems of poor waterproof and thermal insulation effect, difficult connection, low strength of roof panel, etc., to achieve beautiful surface , The process is simple and convenient, and the construction efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

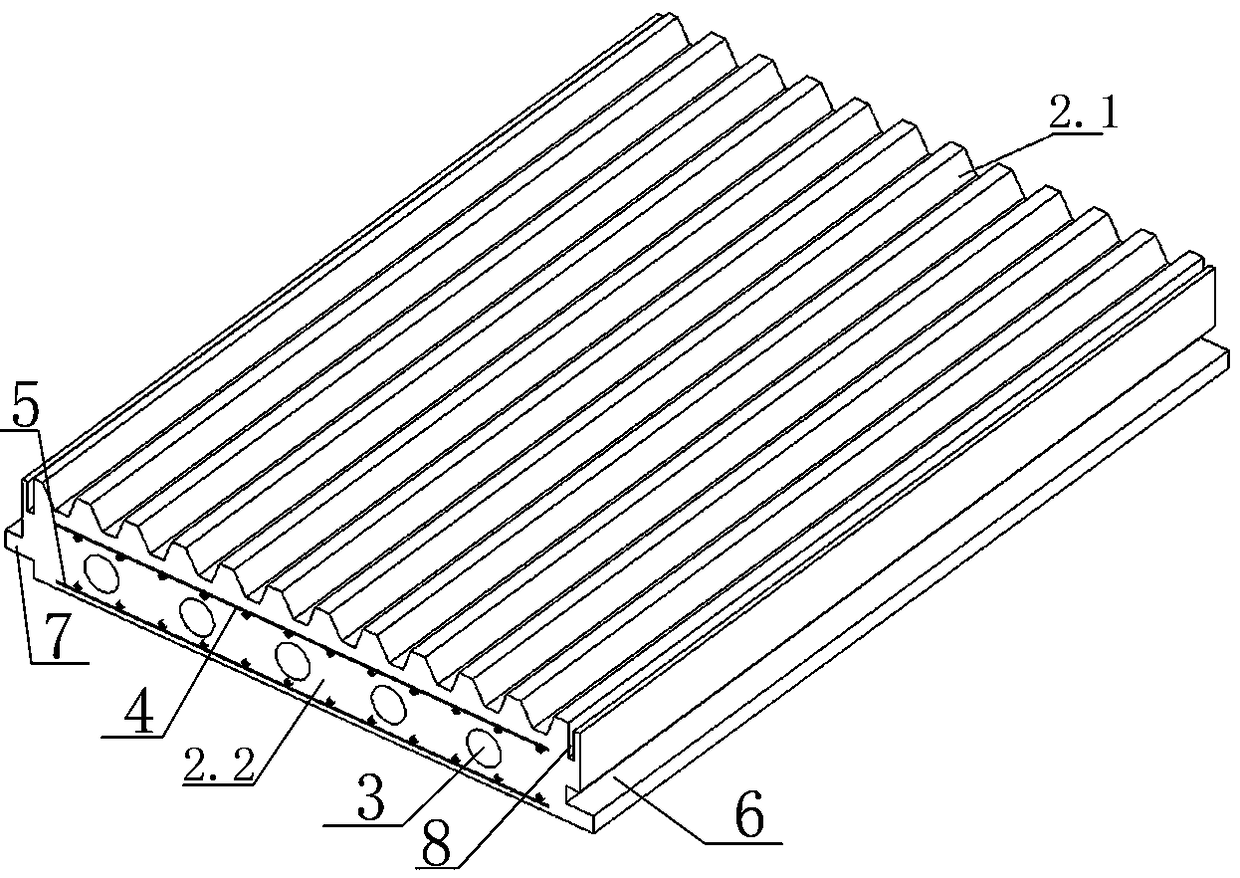

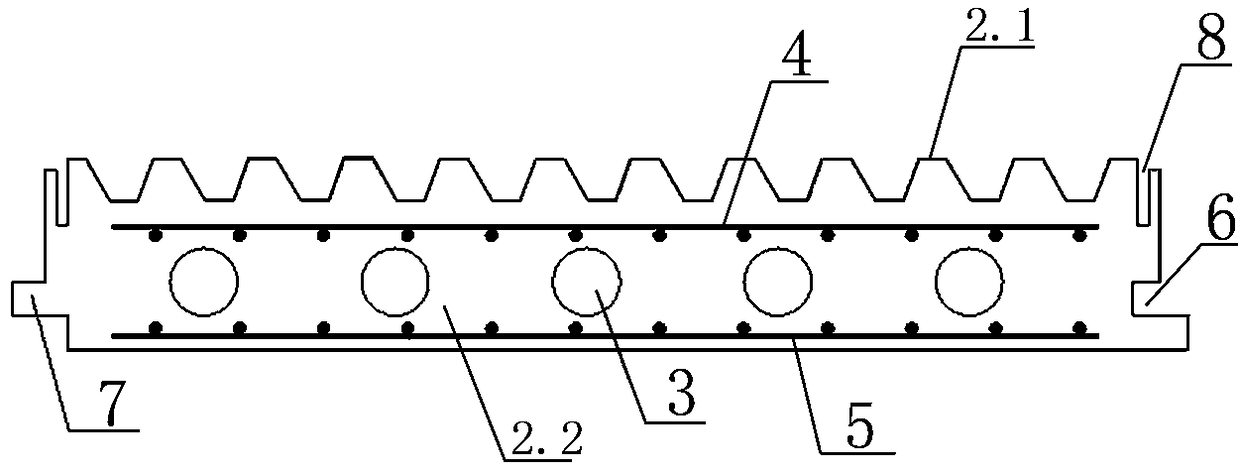

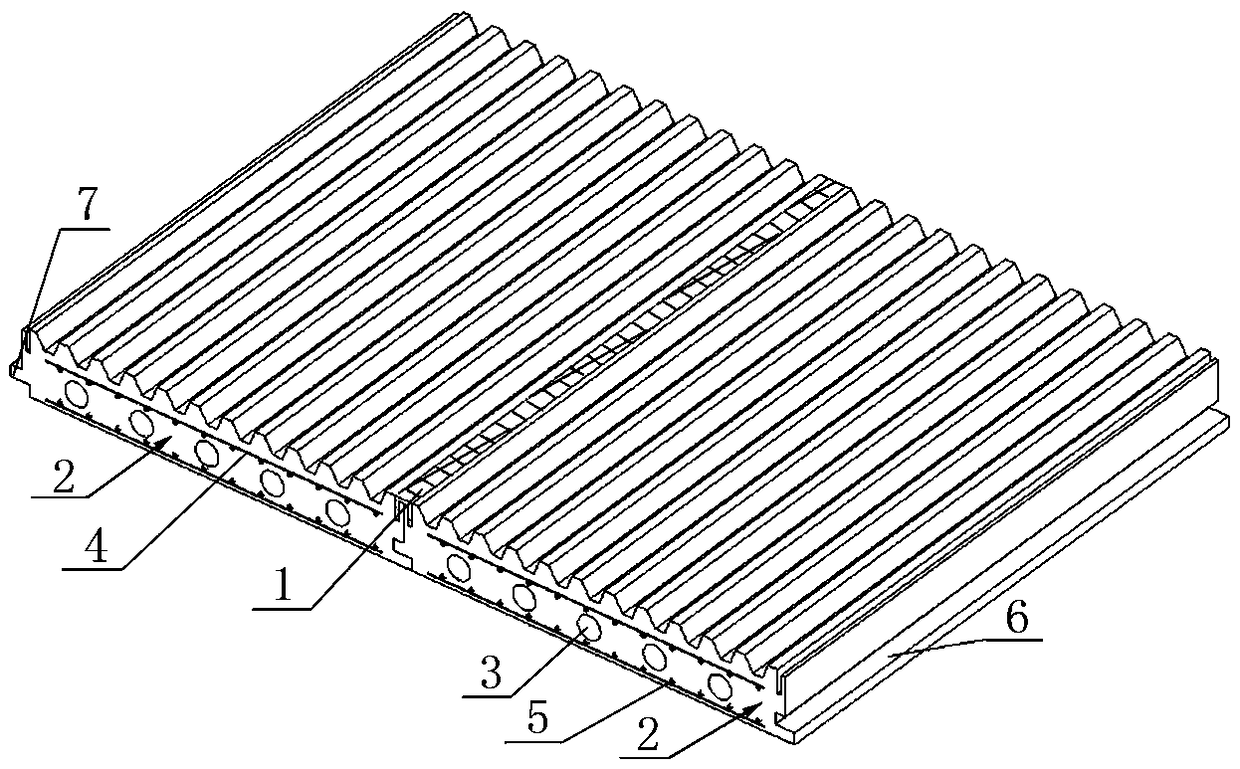

[0031] Such as Figure 1-4 As shown, this prefabricated color steel tile-lightweight concrete composite roof panel is spliced by a group of composite roof panel units 2; The lightweight concrete layer 2.2; in the lightweight concrete layer 2.2, a group of tunnels 3 are arranged at parallel intervals along the transverse direction; wherein, each tunnel 3 runs through the lightweight concrete layer 2.2 along the longitudinal direction; above a group of tunnels 3, The upper steel mesh sheet 4 is arranged near the top surface of the lightweight concrete layer 2.2; the lower layer steel mesh sheet 5 is arranged below a group of channels 3 and near the bottom surface of the lightweight concrete layer 2.2; 2.2 On the longitudinal side of one side, there is a long groove 6 along the direction of its long axis, and on the longitudinal side of the other side of the lightweight concrete layer 2.2, there is a groove 6 adapted to Raised 7.

[0032] In this embodiment, the color steel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com