Interface wettability regulation and control method for inhibiting growth of silicon dendrites in CVD process of zone-melting-grade polycrystalline silicon

A polysilicon and inhibition zone technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems that the mechanical properties of products are difficult to meet the processing and production of molten grade polysilicon, and the growth of silicon dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

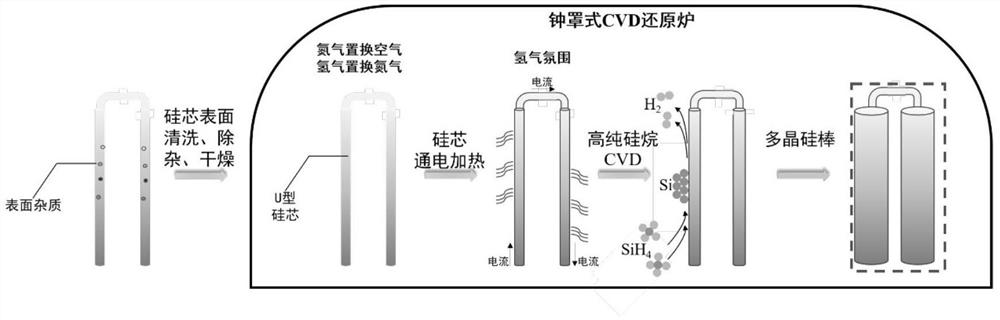

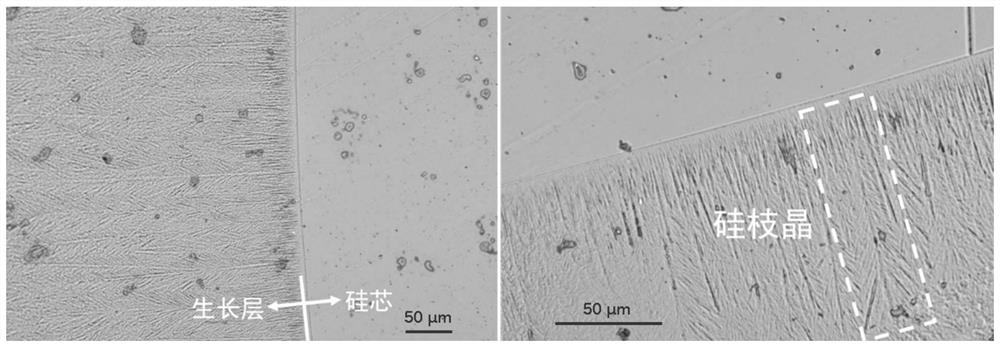

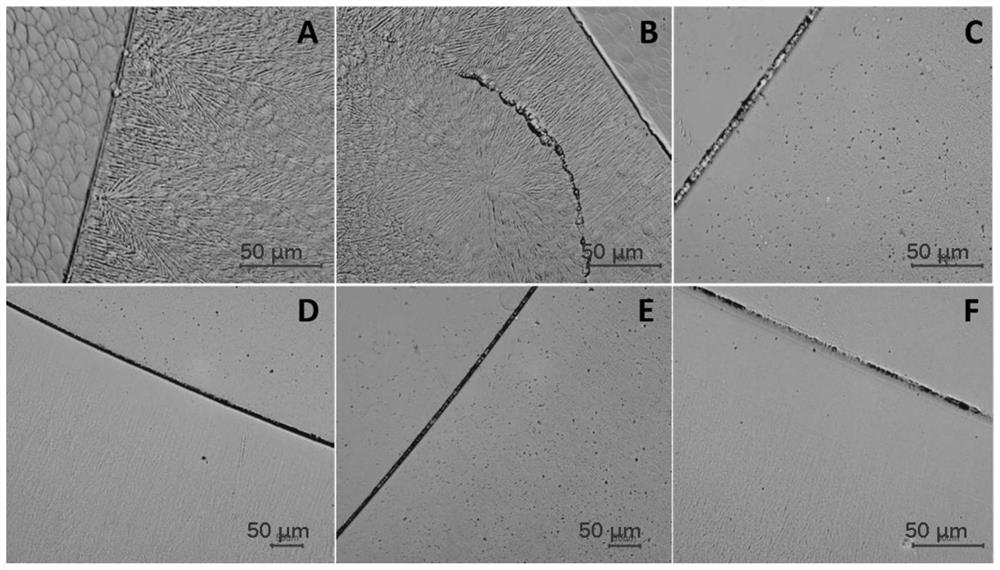

[0036] A method for inhibiting the growth of silicon dendrites and promoting uniform deposition in the process of preparing molten-grade polysilicon by silane method CVD, such as figure 1 As shown, including the steps of surface treatment of U-shaped silicon core to remove surface impurities, including: cleaning, wiping and drying; the treated U-shaped silicon core is placed inside the thermal cracking furnace reactor, and nitrogen is introduced to replace the air inside the reactor ; Introduce hydrogen to replace nitrogen in the reactor; continue to inject hydrogen, and apply current to the silicon core in the reactor for a certain period of time to reduce the oxide layer on the surface of the silicon core, regulate its wettability and build a "super-silicon-philic" Surface; adjust the current to control the silicon core to reach a suitable reaction temperature, and introduce a mixture of high-purity silane and high-purity hydrogen. layered growth”, resulting in dense polycry...

Embodiment 2

[0045] (1) The U silicon core was rinsed with ultrapure water (≥15MΩ*cm, 25°C) for 3 times, and then wiped with absolute ethanol and ethyl acetate for 3 times;

[0046] (2) The cleaned and wiped silicon cores are stored in a vacuum drying oven in a clean workshop (≥100,000 grades) for drying, and the temperature is set to 100°C;

[0047] (3) The silicon core is placed inside the reactor, and nitrogen (O 2 ≤0.001%) replace the air inside the reactor for 3 times;

[0048] (4) Use hydrogen (≥99.99%) to replace the nitrogen inside the reaction furnace for 3 times;

[0049] (5) Continue to feed hydrogen for 20m 3 / h, load current on the silicon core in the reactor, set the current to 80A, keep it for 2 hours, adjust its wettability and build a "super-siliconophilic" surface;

[0050] (6) Adjust the current and control the reaction temperature of the silicon core to be 900-950 ° C, the initial molar ratio of silane to hydrogen is 0.12, and the initial mixed gas flow rate is 600 m...

Embodiment 3

[0053] (1) The U silicon core is rinsed with ultrapure water (≥15MΩ*cm, 25°C) for 5 times, and then wiped with a mixed solution of absolute ethanol, ethyl acetate and acetone for 3 times;

[0054] (2) The cleaned and wiped silicon cores are stored in a vacuum drying oven in a clean workshop (≥100,000 grades) for drying, and the temperature is set to 80°C;

[0055] (3) The silicon core is placed inside the reactor, and nitrogen (O 2 ≤0.001%) replace the air inside the reactor for 5 times;

[0056] (4) Use hydrogen (≥99.99%) to replace the nitrogen inside the reaction furnace for 5 times;

[0057] (5) Continue to feed hydrogen for 30m 3 / h, load current on the silicon core in the reactor, set the current to 50A, keep it for 4 hours, adjust its wettability and build a "super-silicon-philic" surface;

[0058] (6) Adjust the current and control the reaction temperature of the silicon core to be 1000-1050°C, the initial molar ratio of silane to hydrogen is 0.08, and the initial m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com