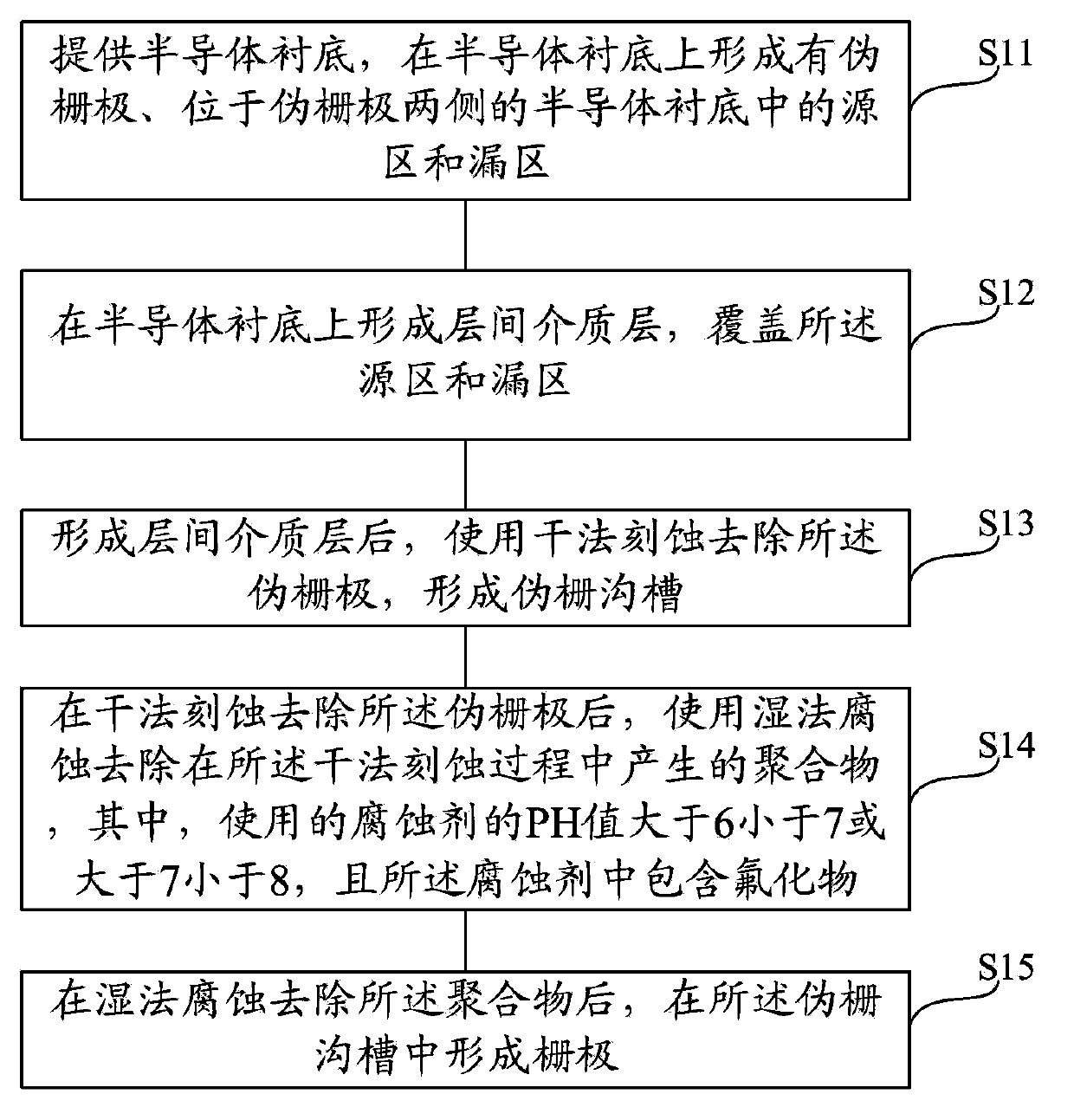

Forming method for transistor

A technology of transistors and semiconductors, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as poor performance of transistors, and achieve the effect of improving reliability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

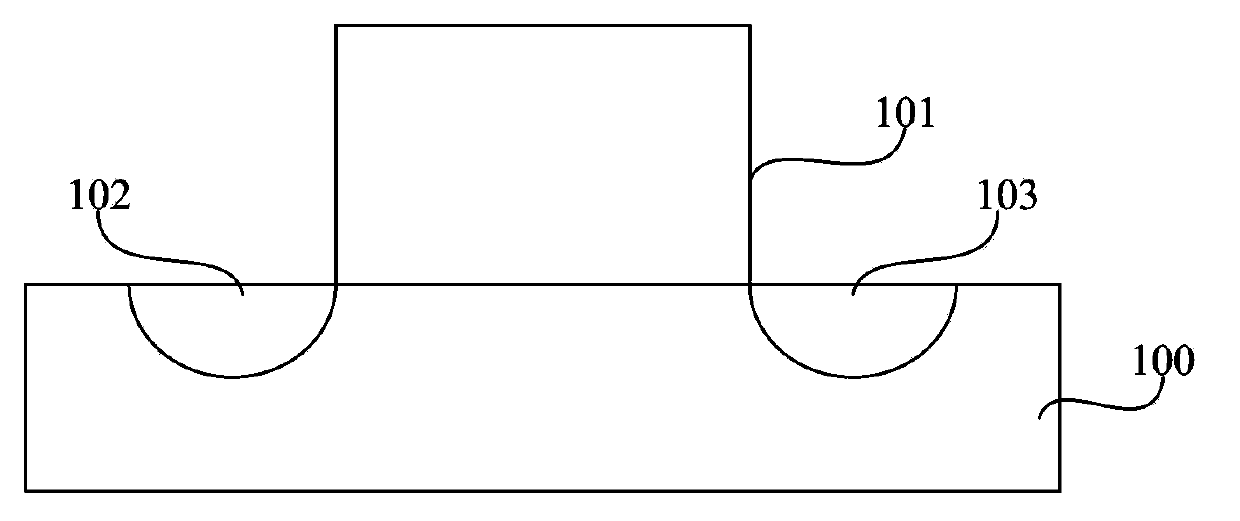

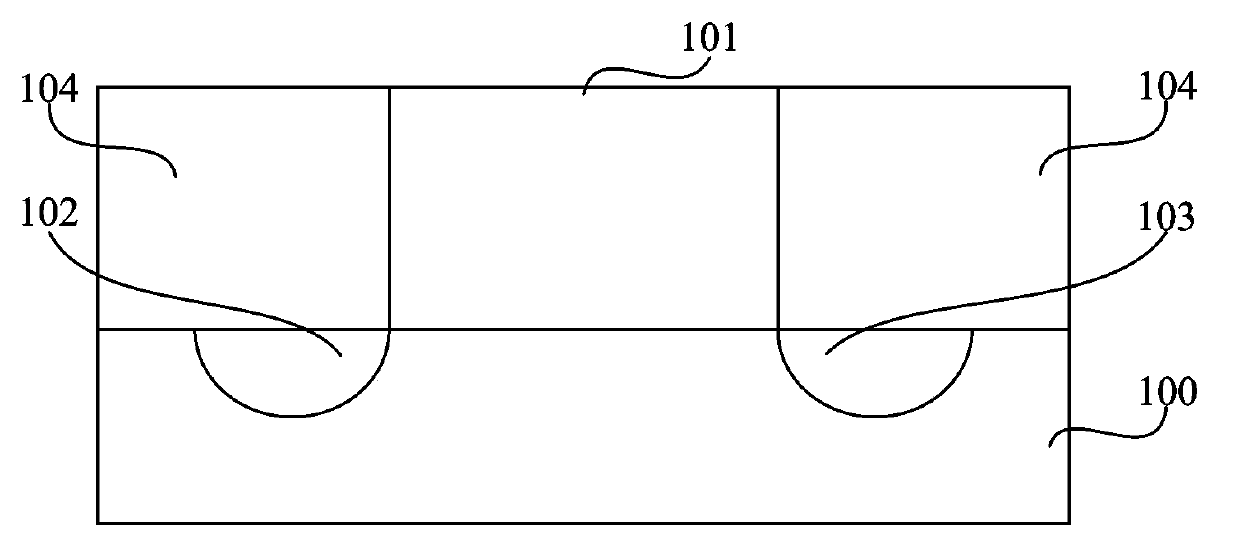

[0040] The inventors conducted research on the problems existing in the gate-last process of the prior art, and found that: in the process of removing the dummy gate by dry etching, polymers will be formed and adhere to the bottom and sidewalls of the dummy gate trench. For example, in the dry etching process, oxygen is usually introduced into the etching reaction chamber, and part of the oxygen will react with polysilicon or other substances in the etching reaction chamber to form oxides, which can be regarded as a kind of polymer Element. Although, subsequent wet etching is used to remove the polymer, the etchant commonly used in the prior art is N-methylpyrrolidone (NMP, N-methyl-2-pyrrolidone) solvent or EKC solvent (a product provided by DuPont EKC Technology Co., Ltd. an alkaline solution). Both NMP solvent and EKC solvent have strong alkalinity. While removing polymers, they also cause damage to adjacent semiconductor devices. The ability of NMP solvents or EKC solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com