LED epitaxial growth method for improvement of growth quality

A technology of epitaxial growth and quality, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of high chip grinding fragmentation rate, large warping of epitaxial wafers, and low product yield, so as to improve antistatic ability , improve crystal quality, improve the effect of lattice matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

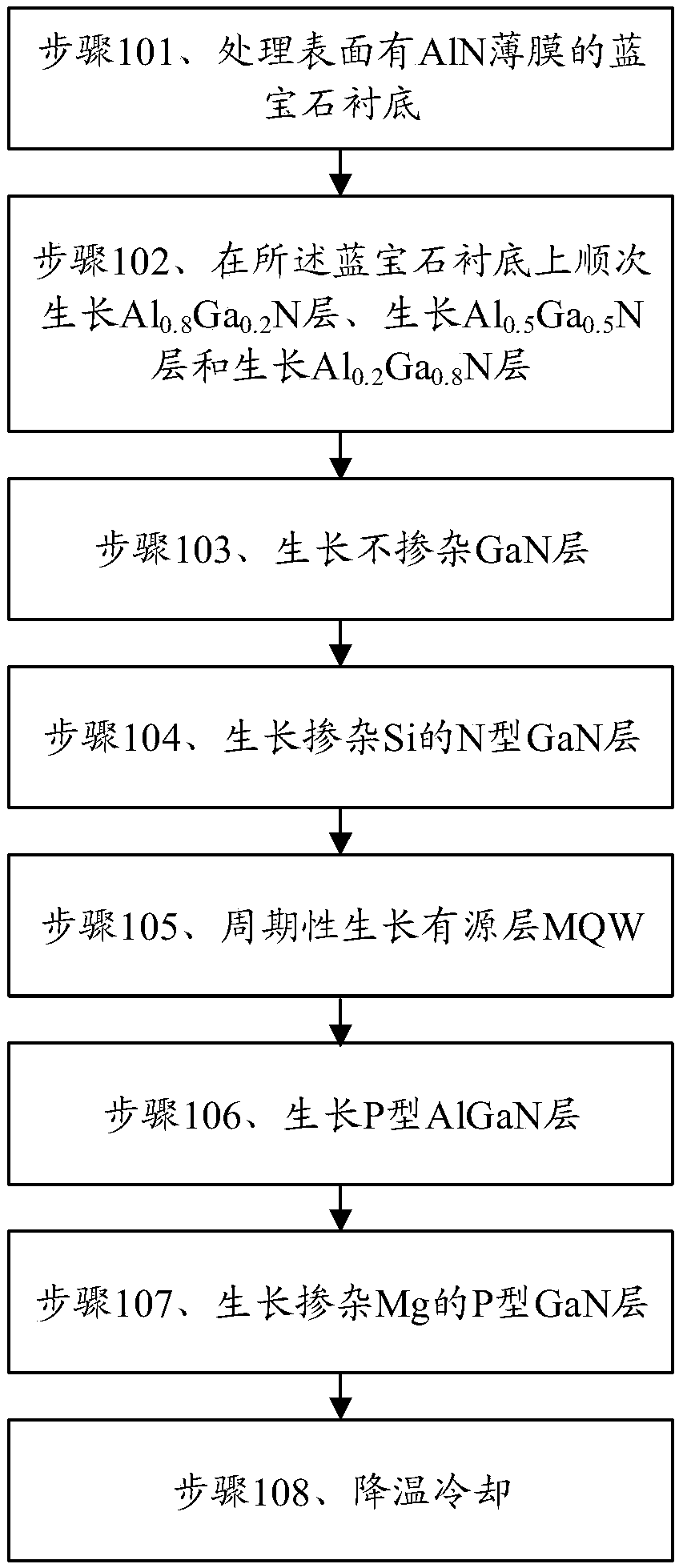

[0040] see figure 1 Shown is a specific embodiment of the LED epitaxial growth method for improving the growth quality described in this application, the method comprising:

[0041] Step 101, processing the sapphire substrate with the AlN thin film on the surface, specifically, treating the sapphire substrate with the AlN thin film on the surface at 1000° C. for 5 minutes under a hydrogen atmosphere with the reaction chamber pressure maintained at 100 mbar.

[0042] Step 102, sequentially growing Al on the sapphire substrate 0.8 Ga 0.2 N layer, grown Al 0.5 Ga 0.5 N layer and grown Al 0.2 Ga 0.8 N layer:

[0043] The grown Al 0.8 Ga 0.2 The N layer includes: control the reaction chamber pressure of 400mbar, and feed NH with a flow rate Q1 of 60L / min into the reaction chamber 3 , N with a flow rate of 90L / min 2 , TMGa of 100 sccm, TMAl source of 230 sccm, the growth temperature is gradually increased from 800 °C to 900 °C by increasing 0.4 °C per second during the gro...

Embodiment 2

[0059] This embodiment provides an LED epitaxial growth method for improving the growth quality, the method comprising:

[0060] Step 201, processing the sapphire substrate with the AlN thin film on the surface, specifically, treating the sapphire substrate with the AlN thin film on the surface at 1200° C. for 10 minutes under a hydrogen atmosphere with the reaction chamber pressure maintained at 150 mbar.

[0061] Step 202, sequentially growing Al on the sapphire substrate 0.8 Ga 0.2 N layer, grown Al 0.5 Ga 0.5 N layer and grown Al 0.2 Ga 0.8 N layer:

[0062] The grown Al 0.8 Ga0.2 The N layer includes: control the reaction chamber pressure of 600mbar, and feed NH with a flow rate Q1 of 70L / min into the reaction chamber 3 , the N flow rate is 95L / min 2 , TMGa of 110 sccm, TMAl source of 250 sccm, the growth temperature is gradually increased from 800 °C to 900 °C by increasing 0.4 °C per second during the growth process, and Al with a thickness D1 of 10 nm is grown ...

Embodiment 3

[0078] Step 301, processing the sapphire substrate with the AlN thin film on the surface, specifically, treating the sapphire substrate with the AlN thin film on the surface at 1100° C. for 7 minutes under a hydrogen atmosphere with the reaction chamber pressure maintained at 125 mbar.

[0079] Step 302, sequentially growing Al on the sapphire substrate 0.8 Ga 0.2 N layer, grown Al 0.5 Ga 0.5 N layer and grown Al 0.2 Ga 0.8 N layer:

[0080] The grown Al 0.8 Ga 0.2 The N layer includes: control the reaction chamber pressure of 500mbar, and feed NH with a flow rate Q1 of 65L / min into the reaction chamber 3 , N with a flow rate of 92.5L / min 2 , TMGa of 105 sccm, TMAl source of 240 sccm, the growth temperature is gradually increased from 800 °C to 900 °C by increasing 0.4 °C per second during the growth process, and Al with a thickness D1 of 9 nm is grown on the sapphire substrate 0.8 Ga 0.2 N layer;

[0081] Keep the reaction chamber pressure and growth temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com