Withhold tooling for automobile wire harness plug

An automobile wiring harness and tooling technology, which is applied in the field of crimping devices, can solve problems such as increasing the difficulty of work, and achieve the effects of convenient processing and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

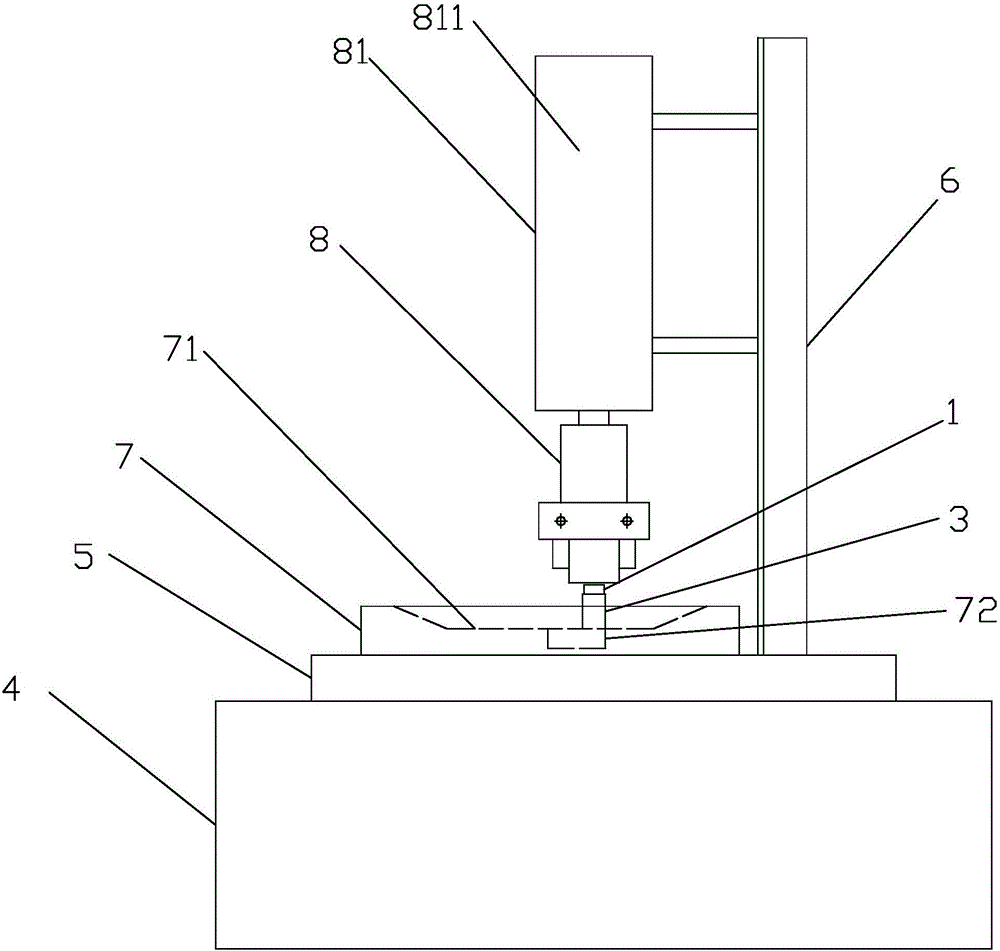

[0037] The present invention as Figure 1-11 As shown, the wire harness plug 1 is connected to the metal flange 2, the metal flange 2 is provided with a mounting hole 20, and the mounting hole is provided with a cylinder 3, and the wire harness plug is located in the cylinder ;

[0038] The crimping tool 8 is located above the workbench 4, the workbench 4 is provided with a base 5, the base 5 is provided with a sliding seat 6 and a support seat 7, and the crimping tooling 8 is movably connected to the sliding seat , and perform lifting movement (lifting movement can be performed in various forms, such as manual, chain drive, hydraulic cylinder action, etc.), the crimping tool is located directly above the support seat,

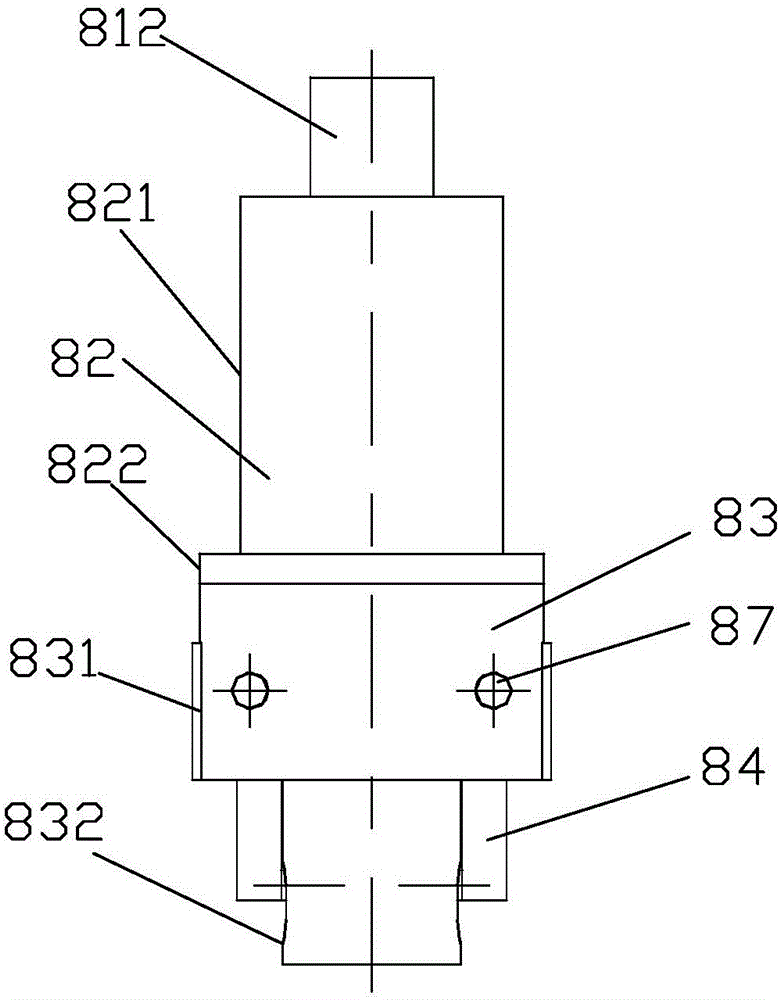

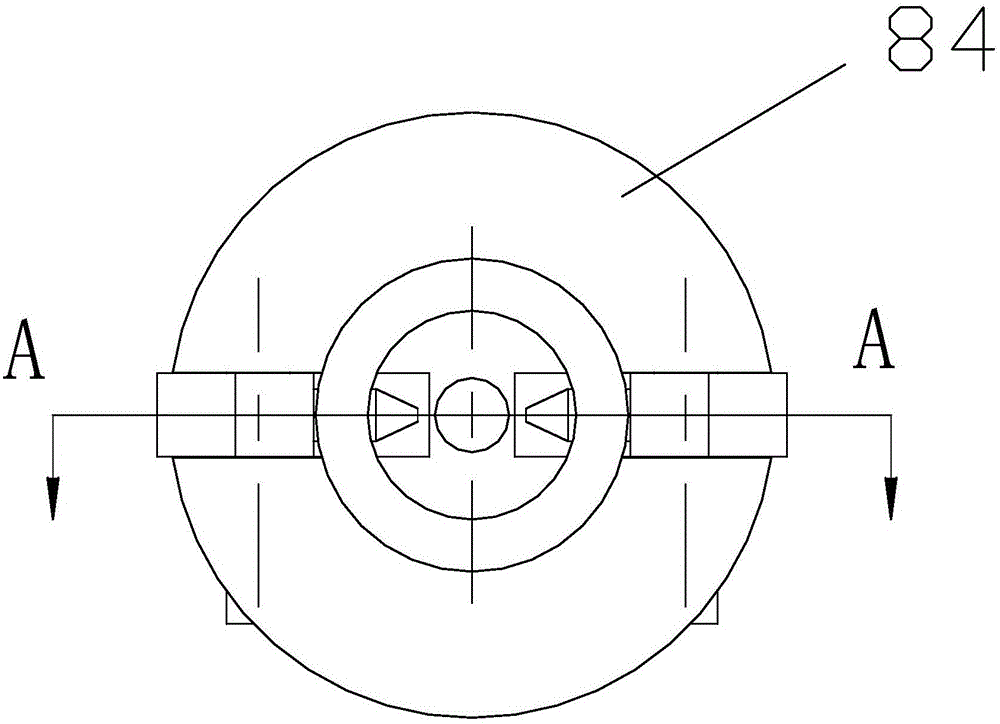

[0039] The crimping tool 8 includes a cylinder 81, a guide cylinder 82, a crimping cylinder 83 and a pair of crimping blocks 84. The cylinder includes a cylinder body 811 and a piston rod 812. A sliding hole 8121 is provided, and a tapered end 8122 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com