Process for producing beta-diketone functionalization rare earth mesoporous hybridisation luminescent material

A technology of luminescent materials and functionalization, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low doping amount of rare earth complexes, uneven distribution, instability of rare earth complexes, etc., to overcome mechanical and Insufficient stability, simple process, regular and orderly microscopic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of Dibenzoylmethane Intermediate

[0027] Dissolve 1mmol of dibenzoylmethane in 20mL of anhydrous tetrahydrofuran and add 2mmol of NaH to the solution system. The reaction solution bubbled vigorously. After one and a half hours, add 2.2mmol of propyltriethoxysilyl group to the above reflux solution. The tetrahydrofuran solution of propyl isocyanate was reacted at 65°C for 12 hours, and the solvent was removed by rotary evaporation to obtain an abnormally viscous yellow oil drop product.

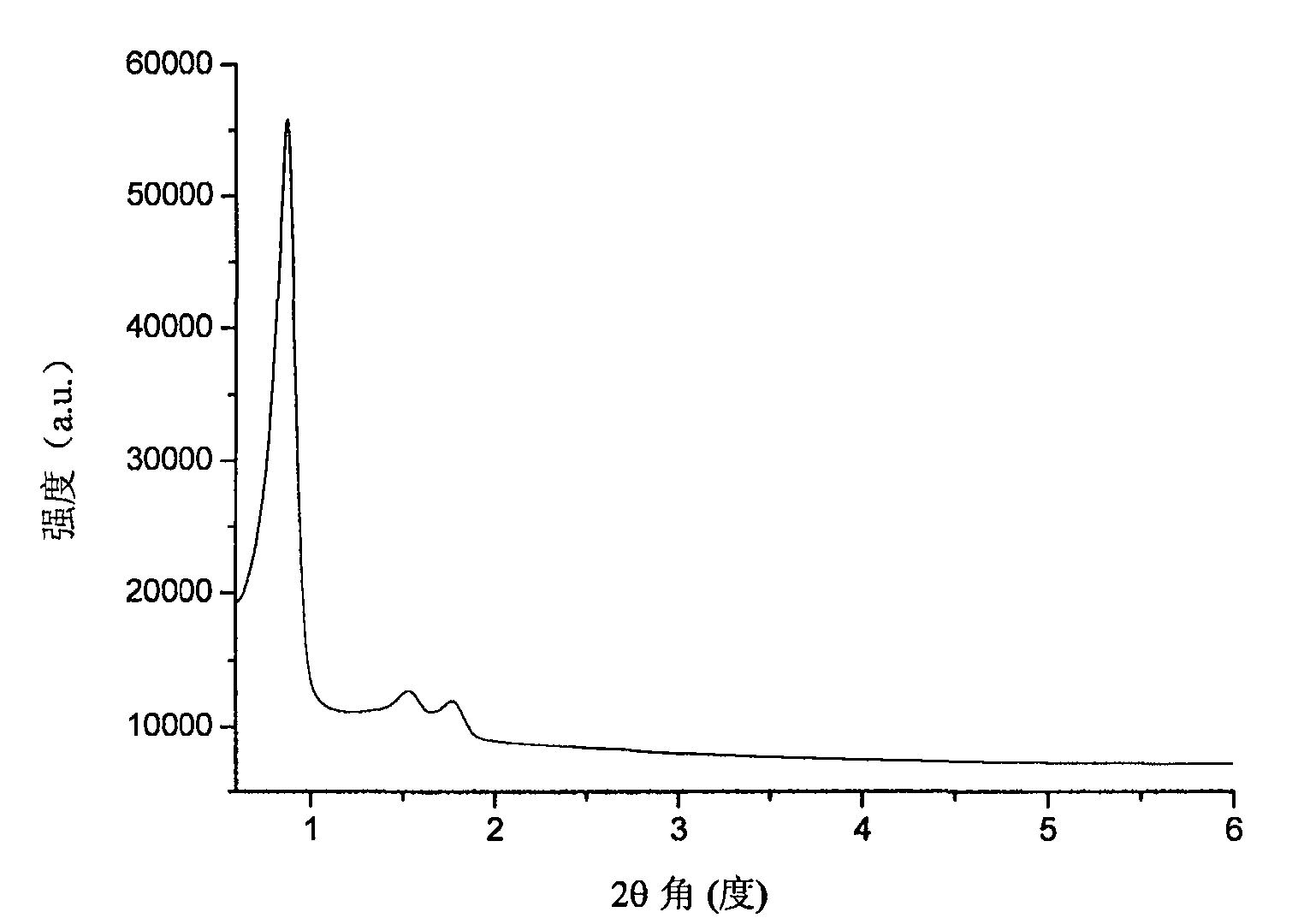

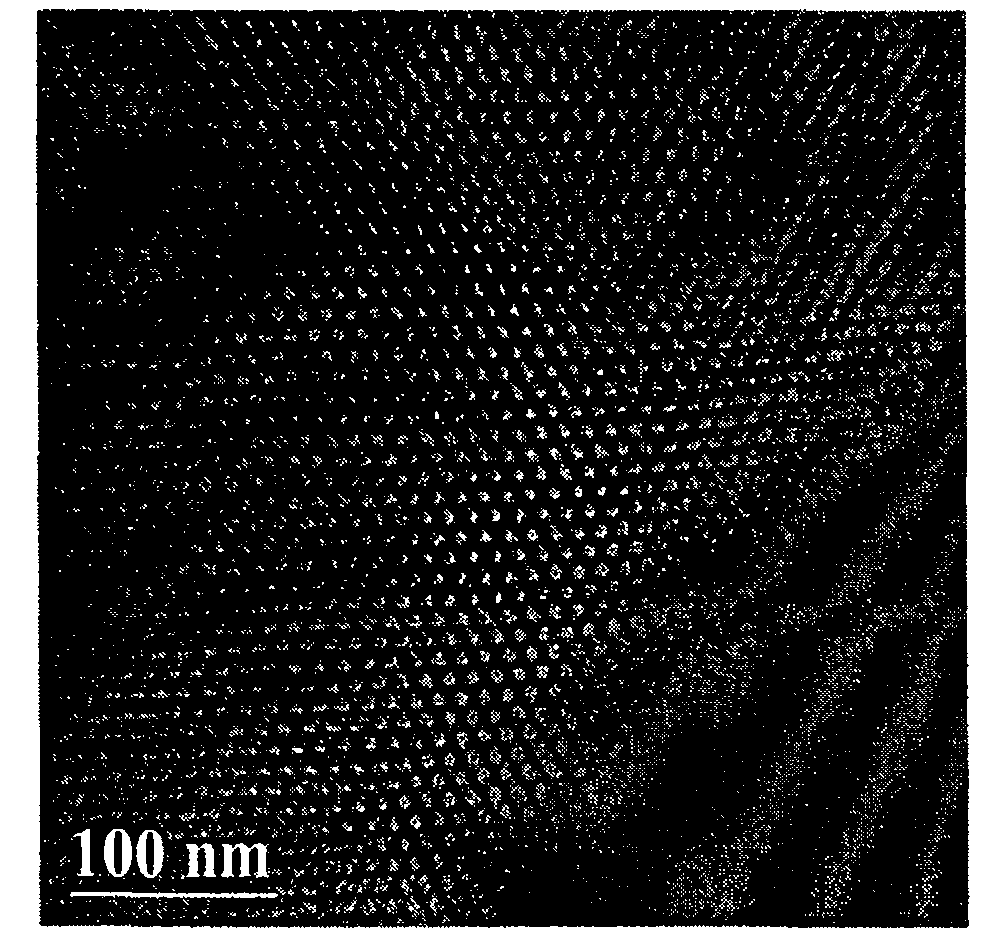

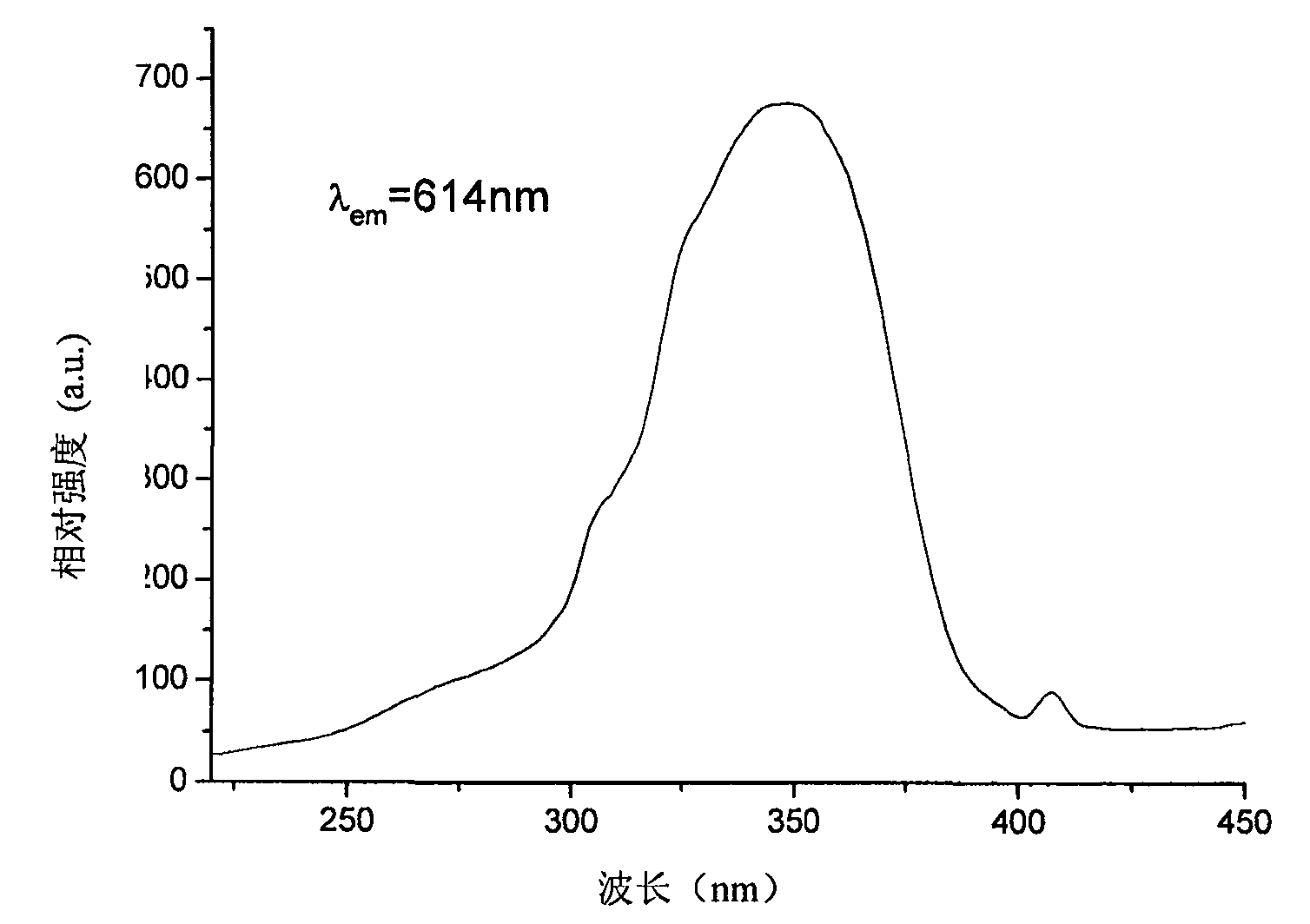

[0028] (2) Synthesis of dibenzoylmethane functionalized binary mesoporous hybrid luminescent material

[0029] First, weigh 1.0 g of Pluronic P123 surfactant, add 7.5 g of deionized water and 30 g of 2 mol / L hydrochloric acid, and heat and stir to dissolve it. At room temperature, slowly add dropwise the mixed solution of TEOS and dibenzoylmethane intermediate at a molar ratio of 0.94:0.06, and stir for 24 hours. Then it was put into a stainless steel reaction kettle lined wi...

Embodiment 2

[0031] (1) Synthesis of Dibenzoylmethane Intermediate

[0032] Dissolve 1.5mmol of dibenzoylmethane in 25mL of anhydrous tetrahydrofuran and add 3mmol of NaH to the solution system. The reaction solution bubbled vigorously. After about one and a half hours, add 3.3mmol of propyltriethoxy to the reflux solution. The tetrahydrofuran solution of silyl propyl isocyanate was reacted at 70° C. for 12 hours, and the solvent was removed by rotary evaporation to obtain an abnormally viscous yellow oil drop product.

[0033] (2) Synthesis of dibenzoylmethane functionalized ternary mesoporous hybrid luminescent material

[0034] Weigh 1.5g of PluronicPl23 surfactant, add 11g of deionized water and 45g of 2mol / L hydrochloric acid, heat and stir to dissolve it. At room temperature, slowly add dropwise the mixed solution of TEOS and dibenzoylmethane intermediate at a molar ratio of 0.96:0.04, and stir for 24 hours. Then put it into a stainless steel reaction kettle lined with polytetrafluoroeth...

Embodiment 3

[0036] (1) Synthesis of acetylacetone intermediate

[0037] Dissolve 1mmol of acetylacetone in 15mL of anhydrous pyridine and add 2mmol of NaH to the solution system. The reaction solution bubbled vigorously. After about one and a half hours, add 2.2mmol of propyltriethoxysilyl isocyanide to the above reflux solution. The tetrahydrofuran solution of propyl acid was reacted at 65°C for 12 hours, and the solvent was removed by rotary evaporation to obtain an abnormally viscous yellow oily product.

[0038] (2) Synthesis of acetylacetone functionalized mesoporous hybrid luminescent material

[0039]Weigh 1.2 g of Pluronic P123 surfactant, add 9.0 g of deionized water and 36 g of 2 mol / L hydrochloric acid, and heat and stir to dissolve it. At room temperature, slowly add the TEOS and acetylacetone intermediate mixture dropwise with a molar ratio of 0.94:0.06, and stir for 24 hours. Then it was put into a stainless steel reaction kettle lined with polytetrafluoroethylene and crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com