Preparation method of quantum dot membrane light-guide component and corresponding backlight module

A technology of quantum dot film and light guide components, which is applied in the direction of optical components, light guides, optics, etc., to achieve the effects of light and thin appearance, protection stability, and improvement of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

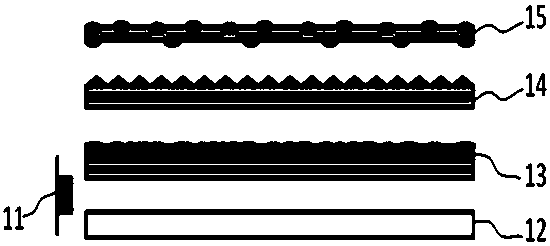

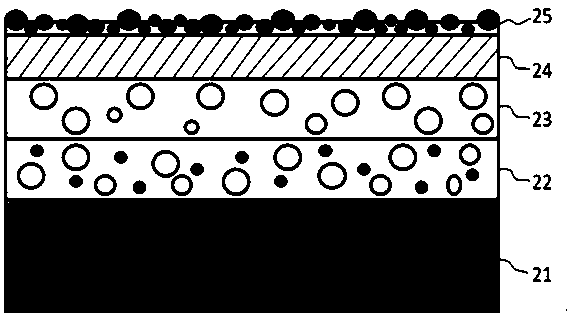

[0026] see Figure 1~2 , the present invention provides a technical solution: a method for preparing a quantum dot film light guide assembly, the quantum dot film light guide assembly 13 includes a glass light guide plate 21, a red quantum dot layer 22, a green quantum dot layer arranged in sequence from bottom to top Dot layer 23 and substrate layer 24; described red quantum dot layer 22, green quantum dot layer 23 and substrate layer 24 form the quantum dot film of pressure-sensitive adhesive type, and the specific preparation of described quantum dot film light guide assembly 13 includes Follow the steps below:

[0027] 1) Evenly disperse 0.2% by mass of red quantum dot powder and 1-3% by mass of diffusion particles in 10% by mass of monomer to form a red quantum dot stock solution; then, mix the red quantum dot stock solution with 85- 90% by mass of the UV-curable acrylic pressure-sensitive glue is mixed evenly to form a red quantum dot glue, and the mass part is the rati...

Embodiment 1

[0045] A method for preparing a quantum dot film light guide assembly, the specific steps are:

[0046] 1) Disperse 0.2% by mass of red quantum dot powder and 1-3% by mass of ZnO diffusion particles in 10% by mass of monomer to form a red quantum dot stock solution; then, mix the red quantum dot stock solution with 85 ~90% by mass of the UV-curable acrylic pressure-sensitive adhesive is mixed evenly to form a red quantum dot glue, and the mass part is the ratio of the total mass of the red quantum dot glue;

[0047] 2) Evenly disperse 0.8% by mass of green quantum dot powder and 1-3% by mass of ZnO diffusion particles in 10% by mass of monomer to form a green quantum dot stock solution; then, mix the green quantum dot stock solution with 20 ~30% by mass of monomer, 45~60% by mass of acrylic resin and 1~3% by mass of photoinitiator (Irgacure819 or TPO) are mixed uniformly to form green quantum dot glue, and the mass part is mixed with green quantum dot glue The ratio of the to...

Embodiment 2

[0052] A method for preparing a quantum dot film light guide assembly, the difference from Example 1 is that after the quantum dot film and the glass light guide plate are bonded to form the quantum dot film light guide assembly, the four side end faces of the quantum dot film light guide assembly An organic coating with water-blocking and oxygen-blocking functions and good light transmittance is applied on the seal coat. In this embodiment, the water-blocking organic coating is preferably polyvinylidene chloride, and the oxygen-blocking organic coating is preferably polyvinyl alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com