Invisible connected composite plate curtain wall

A composite panel, curtain wall technology, applied in the direction of walls, building components, buildings, etc., can solve structural design, manufacturing standard connection methods, installation components and construction methods system problems are not solved, affect the scope of application and service life, brittle and High density and other problems, to achieve the effect of bright appearance, long service life and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

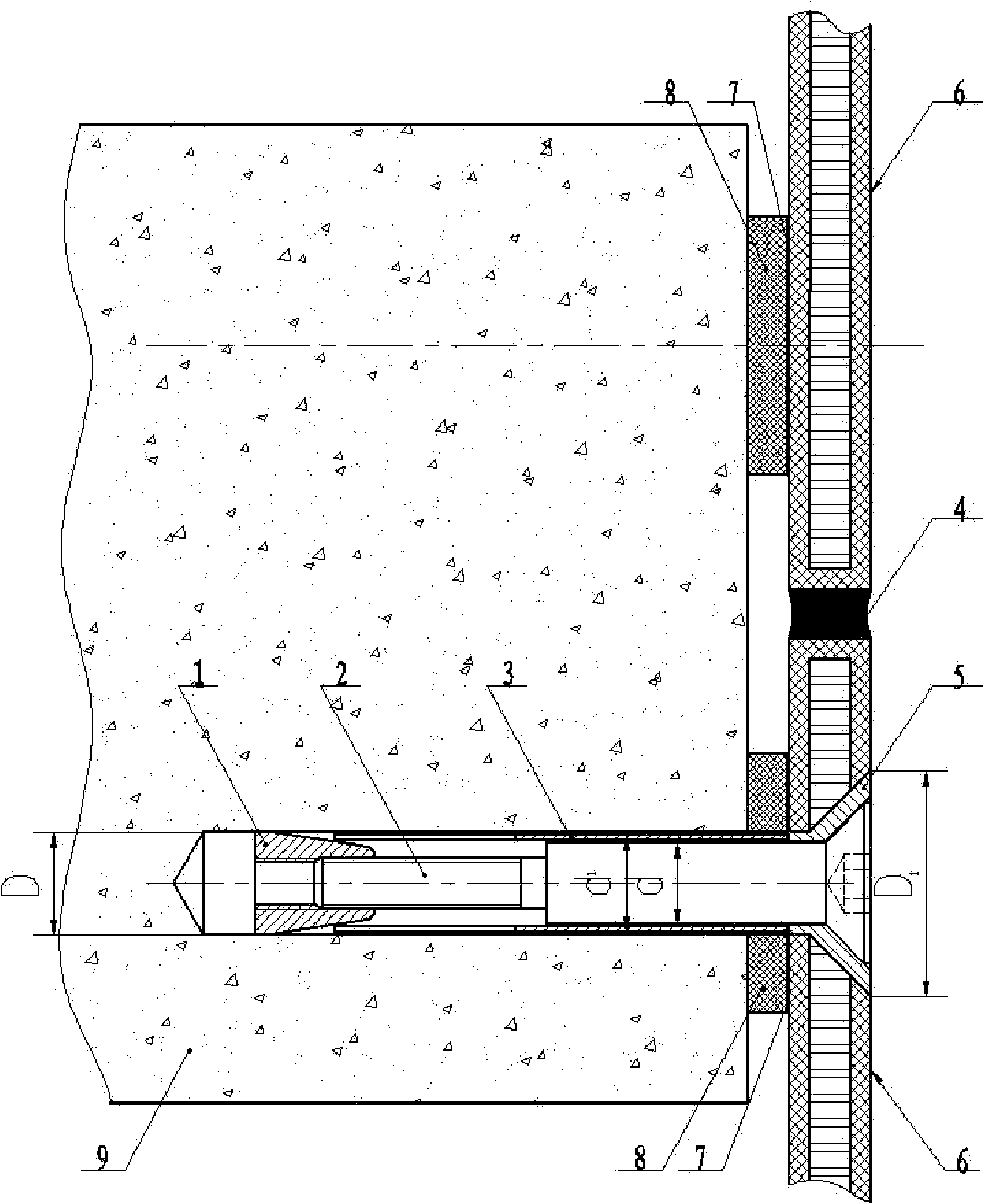

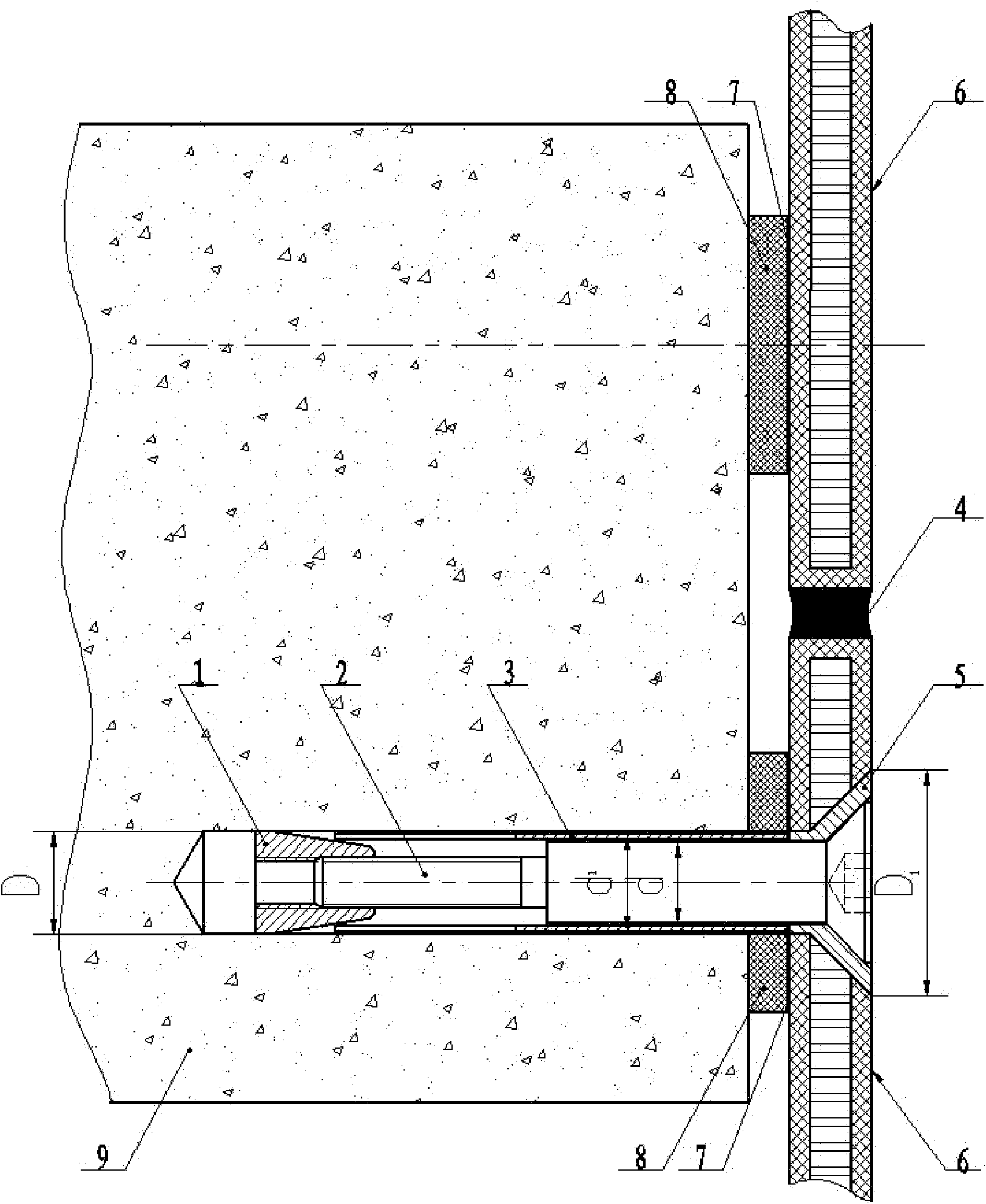

[0028] The specific embodiment 1 of the present invention will be further described below in conjunction with the accompanying drawings.

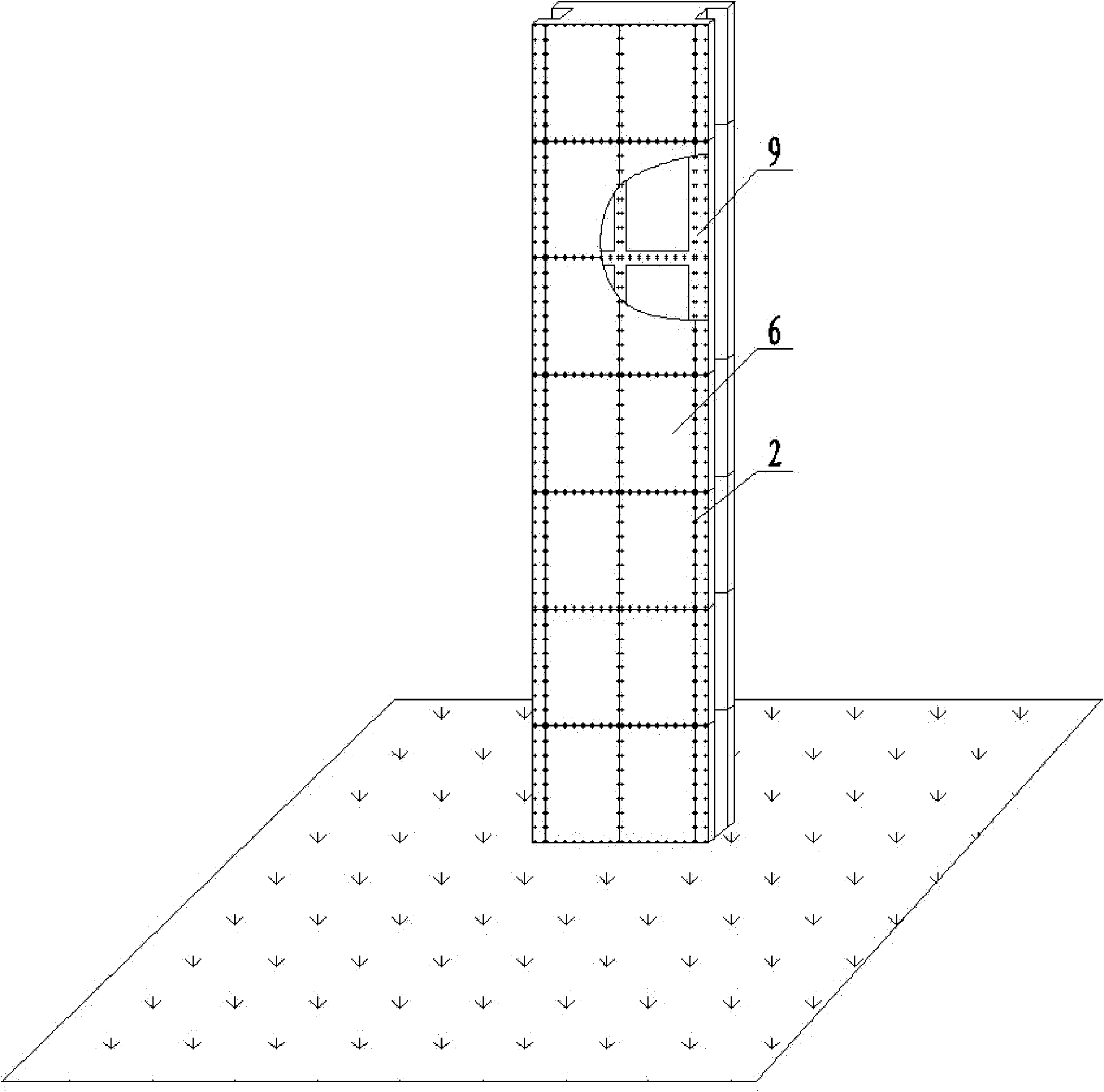

[0029] Such as figure 1 As shown, the invisible connection composite panel curtain wall provided in this embodiment can be used for a group of tower-shaped welcome landscapes. The landscape has a total of 7 monomers. , green, blue, blue, and purple, meaning "rainbow welcome". The main body size of a single landscape is: 6×1.5×28m (length×width×height), the horizontal section is rectangular as a whole, and the center of the two sides is truncated to a square of 0.6×0.6m, showing a "concave shape", and the main body of the structure is reinforced Concrete frame structure with a total of seven floors, and the shape design requires that all exterior facades adopt invisible joint composite panel curtain wall structure.

[0030] The front and back main facades of the tower-shaped welcome landscape are designed as seven composite panels 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com