Glue scraping device for flat piece and with controllable gluing shape

A squeegee device, flat plate technology, applied in the direction of surface coating device, coating, etc., can solve the problems of high cost, long operation time, inconvenient production and operation, achieve consistent thickness and shape, improve controllability, Surface neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

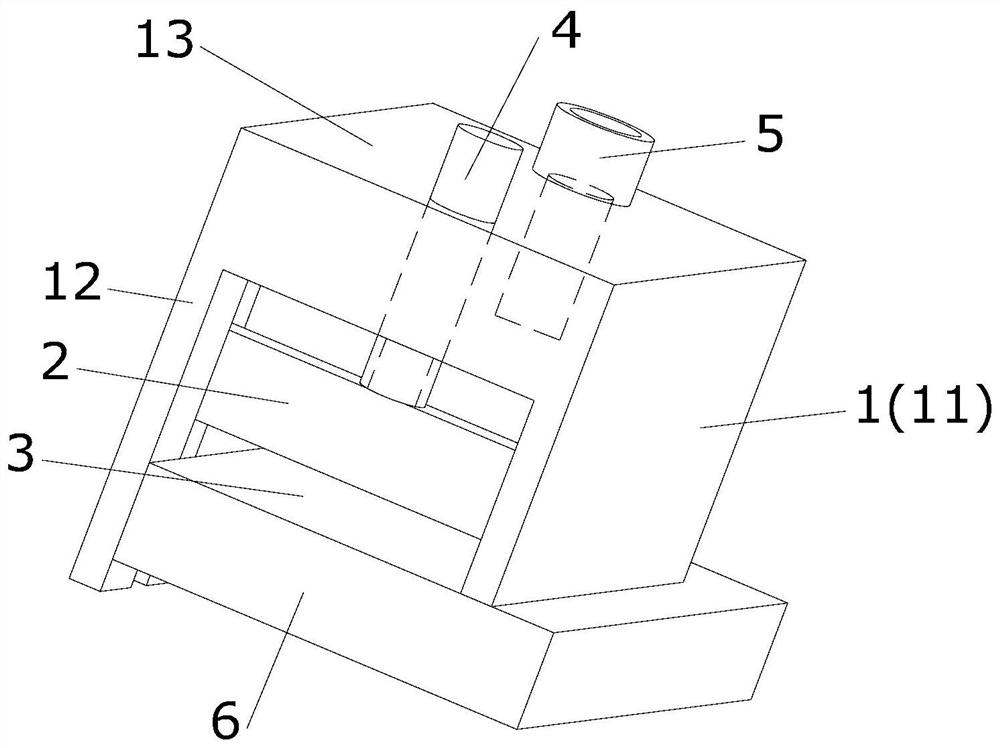

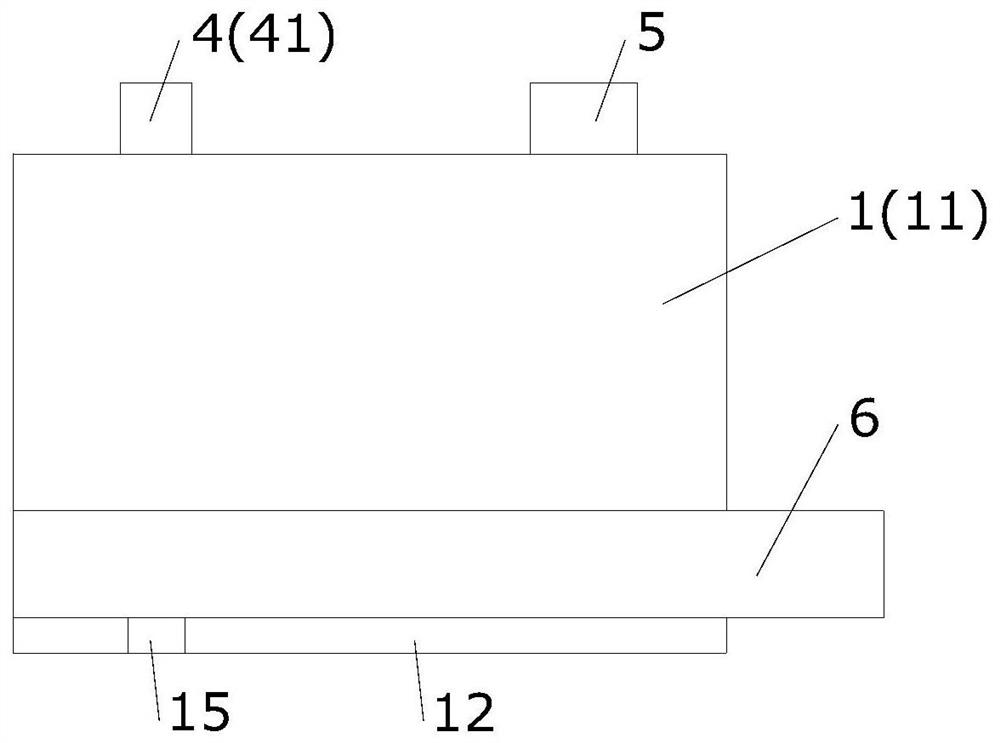

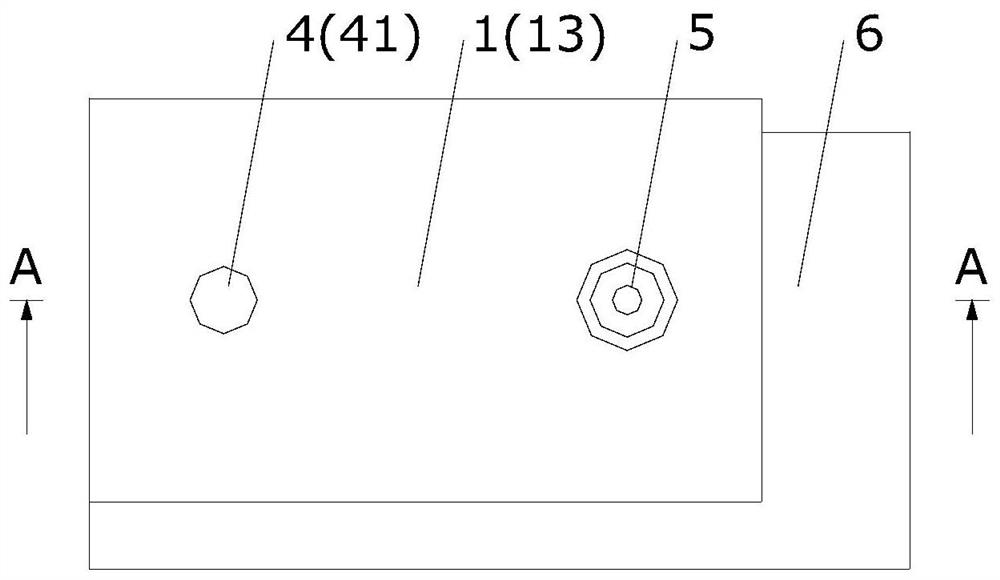

[0021] A squeegee device with controllable gluing form for flat parts, as attached Figure 1~6 As shown, it includes a U-shaped base 1, a rubber scraper 2, a lifting mechanism 4, and a glue injection adapter 5.

[0022] The U-shaped base 1 is inverted, the opening is downward, and the lower edges of the vertical walls on both sides have a height difference, forming a short vertical wall 11 and a long vertical wall 12. The top wall 13 is provided with a glue injection hole 14, and the glue injection adapter 5 passes through it. The glue injection hole 14 is provided to connect with the top wall 13 .

[0023] The elevating mechanism 4 is a guide post 41, and the guide post 41 penetrates the top wall 13, and the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com