Stator tooth, stator and motor

A stator tooth and stator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low motor manufacturing efficiency, achieve the effects of reducing material costs, simple manufacturing, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

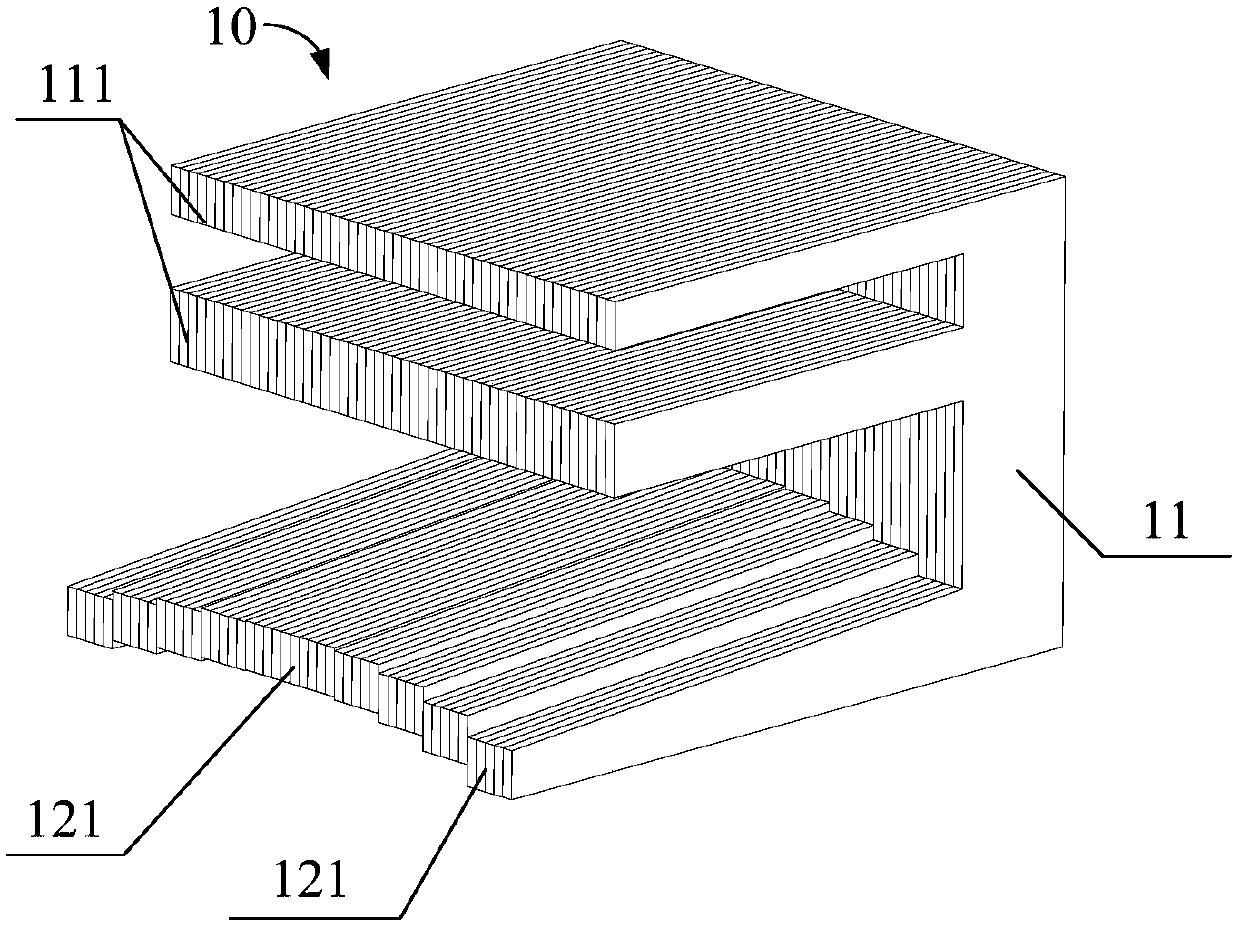

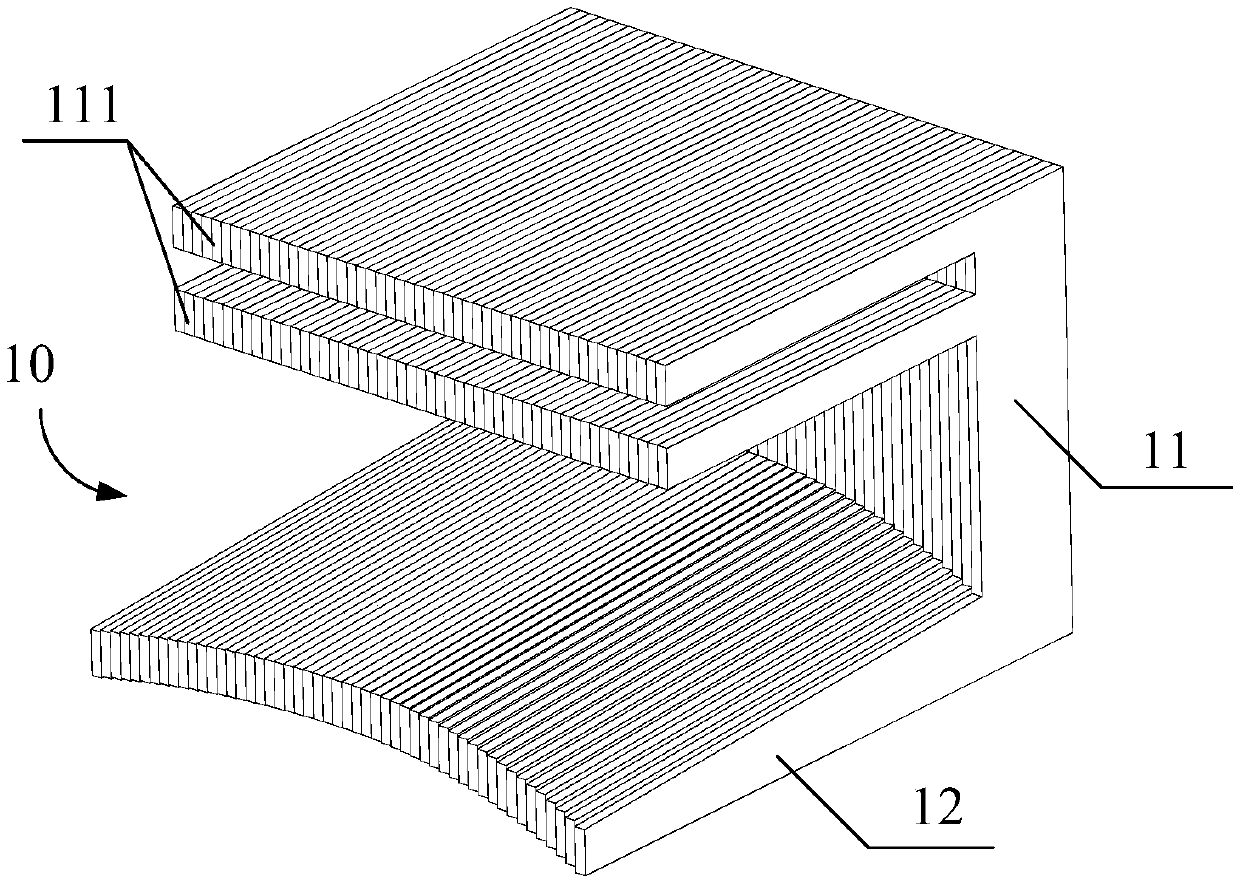

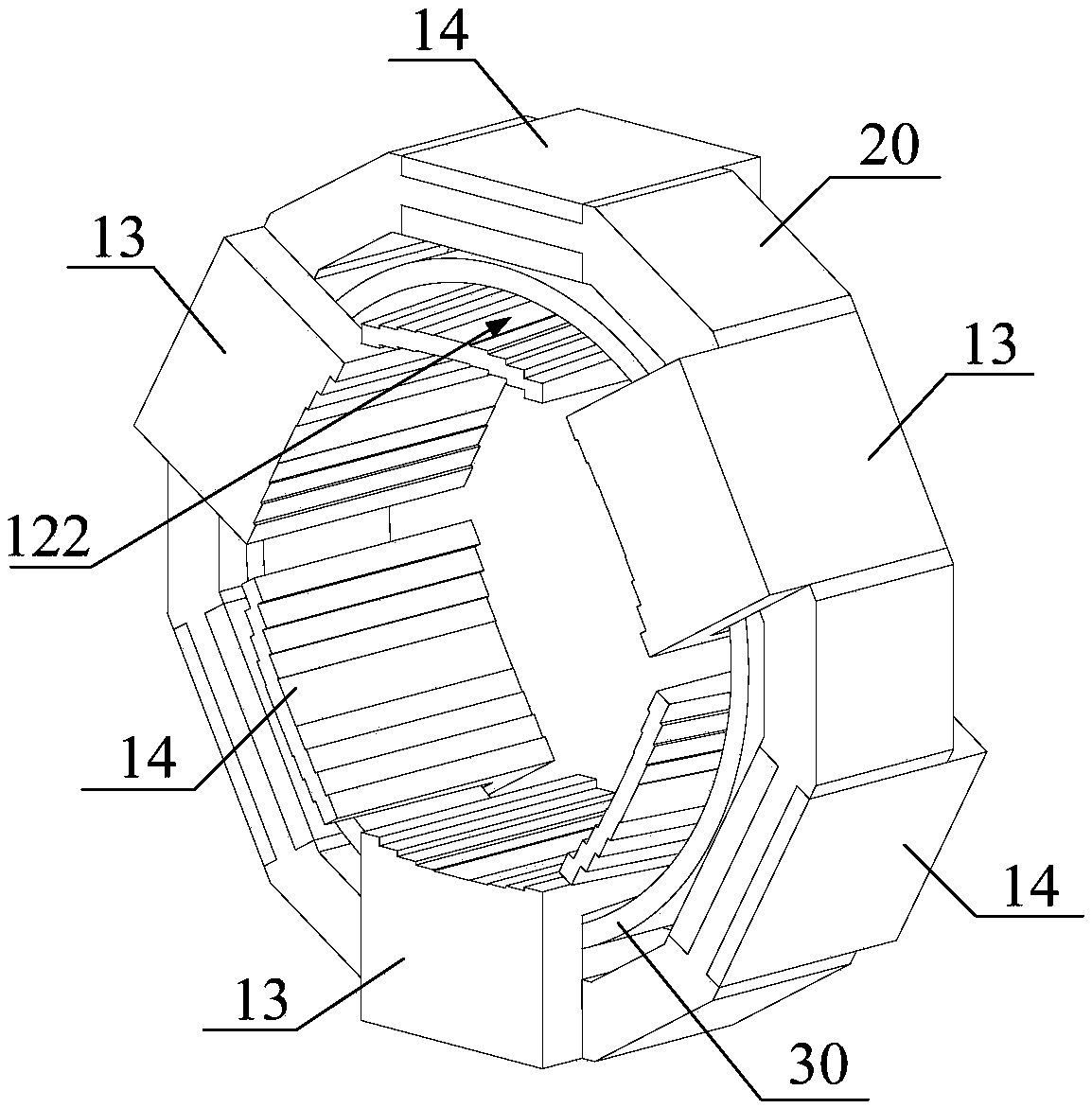

[0067] The winding portion 12 includes a plurality of stepped portions 121 arranged along the circumferential direction of the stator, such as figure 1 and figure 2 As shown, a plurality of stepped parts 121 are connected in sequence and staggered from each other to construct the winding part 12 into a stepped structure, so that the winding part 12 gradually bends and extends in a step-like manner from the middle to both sides in a direction close to the central axis of the stator, as shown in image 3 and Figure 9 shown.

[0068] Since the stator teeth 10 are generally prepared by laminating and forming multiple stator punches, the winding part 12 is constructed into a stepped structure, and the desired shape of the winding part can be assembled by reasonably arranging the dimensions of each stator punch. 12. The structure and principle are relatively simple, easy to process and shape, and suitable for mass production.

[0069] Specifically, the stepped portion 121 is fo...

Embodiment 2

[0078] The difference from Embodiment 1 is that the stepped portion 121 is formed by a sheet structure, such as figure 2 shown.

[0079]Alternatively, the step portion 121 can also be formed by a sheet structure, and the width of each step portion 121 is small, so that the entire winding portion 12 can be as close as possible to a circular arc shape, thereby significantly improving the structural regularity of the product. Further improve motor performance.

Embodiment 3

[0081] The difference from Embodiment 1 or Embodiment 2 is that: both the tooth body 11 and the winding portion 12 have symmetrical structures, and are symmetrical about the same plane passing through the central axis of the stator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com