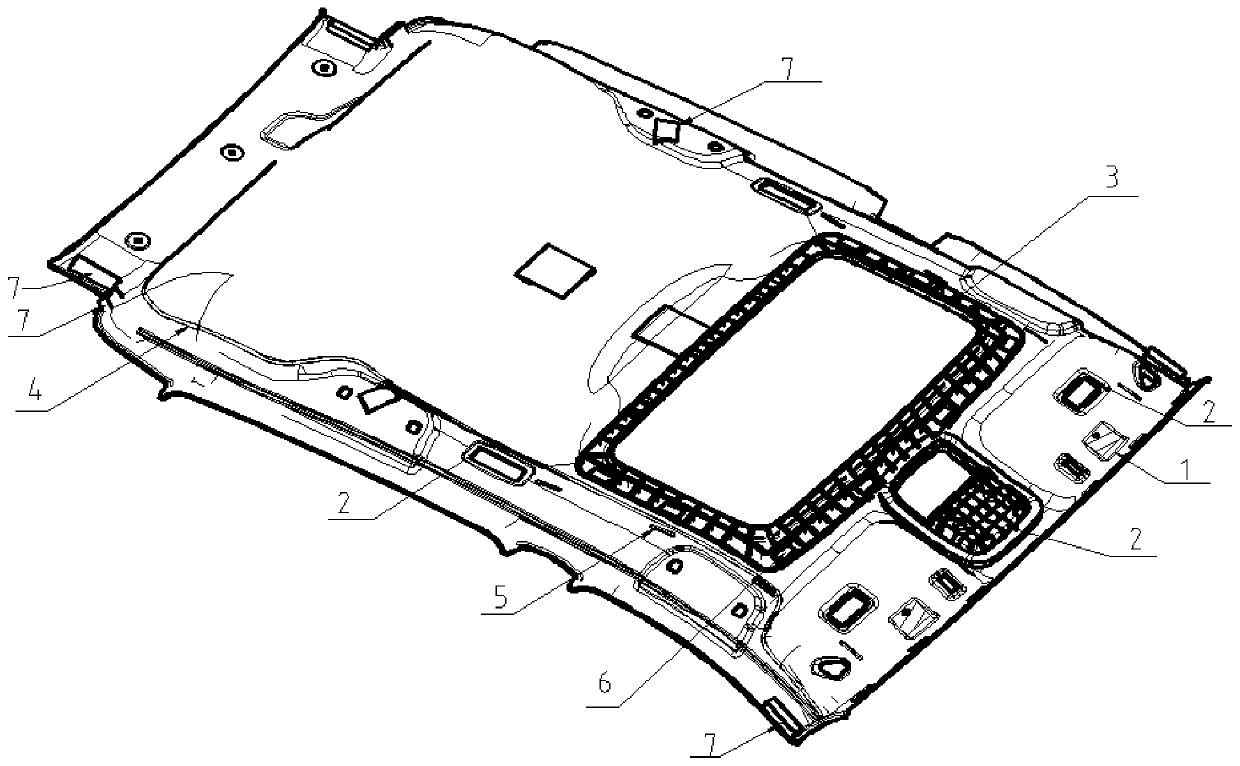

Integrally-formed automobile EPP ceiling and preparation method thereof

A roof and integrated technology, applied in the field of automotive EPP roof and its preparation, can solve the problems of bad influence of strength, influence of fabric covering fit, and decrease of bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

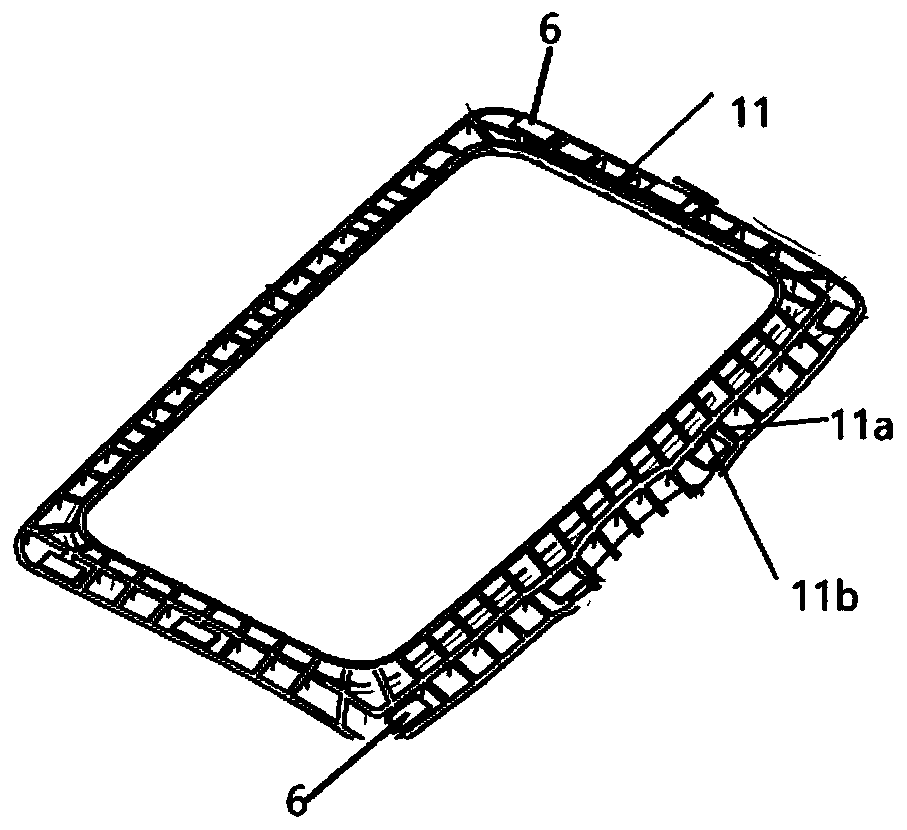

Examples

preparation example Construction

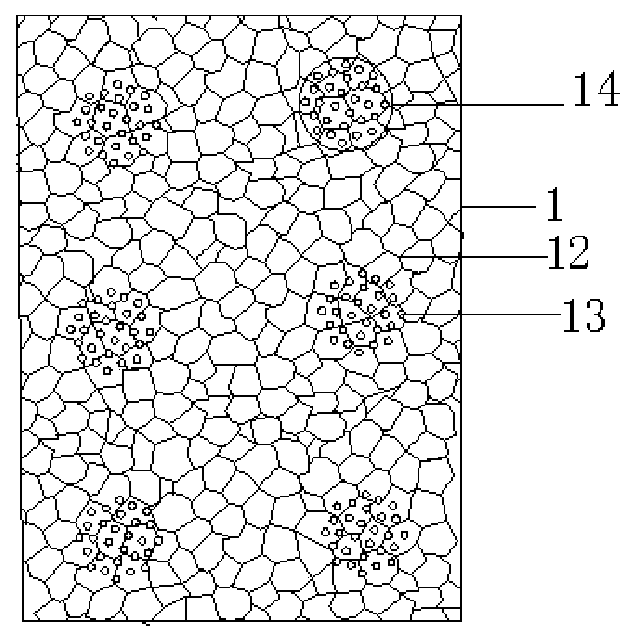

[0034] A kind of preparation method of the integrated automobile EPP ceiling of the present embodiment, comprises the following steps:

[0035] a. Preloading: The EPP raw material particles are prepressed by means of staged pressurization to generate internal stress inside the particles. The six-stage staged pressurization method is adopted, respectively: preloading process 0, pressure 0.2-0.4 bar, the time is 25-35min; pre-pressing process 1, the pressure is 3.5-4.5bar, the time is 7-9h; pre-pressing process 2, the pressure is 3.5-4.5bar, the time is 25-35min; pre-pressing process 3, the pressure The pressure is 2.5~3.5bar, the time is 25~35min; the prepressing process 4, the pressure is 1.5~2.0bar, the time is 25~35min; the prepressing process 5, the pressure is 1.5~2.0bar, the time is 80~100h; The setting of the stage pressure and the setting of the pressing time corresponding to each stage of pressure enable the EPP particles to fully expand and foam in the particle pre-pr...

Embodiment 1

[0043] The method for preparing the car roof by EPP surface overmolding of the present embodiment may further comprise the steps:

[0044] a. Pre-pressing: Pre-pressing the EPP raw material particles by means of staged pressurization; pre-pressing process 0, the pressure is 0.2bar, and the time is 25min; pre-pressing process 1, the pressure is 3.5bar, and the time is 7h; Pressing process 2, the pressure is 3.5bar, the time is 25min; pre-pressing process 3, the pressure is 2.5bar, the time is 25-35min; pre-pressing process 4, the pressure is 1.5bar, the time is 25min; pre-pressing process 5, the pressure is 1.5bar, the time is 80h;

[0045] b. Lock and fix the solid mold and the moving mold of the mold, then inject steam into the mold cavity to preheat the mold cavity, and then send the EPP raw material particles from the barrel through the pressurized feeding air Enter the mold cavity, and pass the flowing air with pressure into the mold cavity so that the EPP raw material pa...

Embodiment 2

[0050] The method for preparing the car roof by EPP surface overmolding of the present embodiment may further comprise the steps:

[0051] a. Pre-pressing: Pre-pressing the EPP raw material particles by means of staged pressurization; pre-pressing process 0, pressure 0.4bar, time 35min; pre-pressing process 1, pressure 4.5bar, time 9h; pre-pressing process Pressing process 2, the pressure is 4.5bar, the time is 35min; pre-pressing process 3, the pressure is 3.5bar, the time is 35min; pre-pressing process 4, the pressure is 2.0bar, the time is 35min; pre-pressing process 5, the pressure is 2.0bar , the time is 100h;

[0052] b. Lock and fix the solid mold and the moving mold of the mold, then inject steam into the mold cavity to preheat the mold cavity, and then send the EPP raw material particles from the barrel through the pressurized feeding air Enter the mold cavity, and pass the flowing wind with pressure into the mold cavity so that the EPP raw material particles are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com