Hydrophobic association crosslinked polymer coil and preparation method thereof

A cross-linked polymer, associative technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as reducing the economy of injection systems, and achieve the effect of improving the effect of heterogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

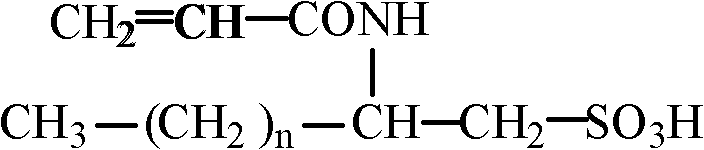

[0043] Embodiment 1, the preparation of hydrophobic association type cross-linked polymer coil

[0044] (1) Preparation of the oil phase: Weigh 110.0 grams of base oil isoparaffins (produced by the isomerization dewaxing unit of Daqing Refining and Chemical Company) (viscosity 10.85cP, flash point 178°C), and add it to a stirring 250 In the milliliter three-necked flask, add 57.4 gram sorbitan monooleate (Span-80, HLB value 4.3) and 32.6 gram sorbitan monostearate polyoxyethylene (20) ethers (Tween-60, The HLB value is 14.9) two kinds of non-ionic surfactants, mixed uniformly as the oil phase;

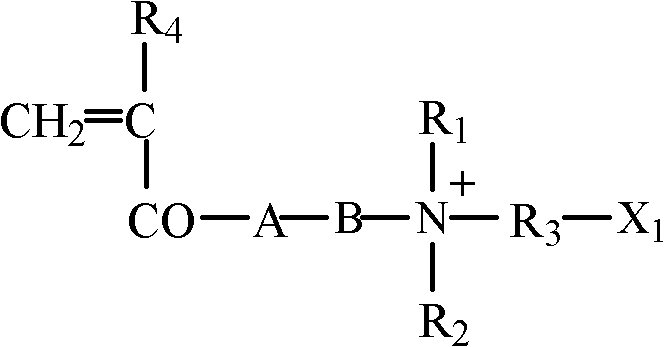

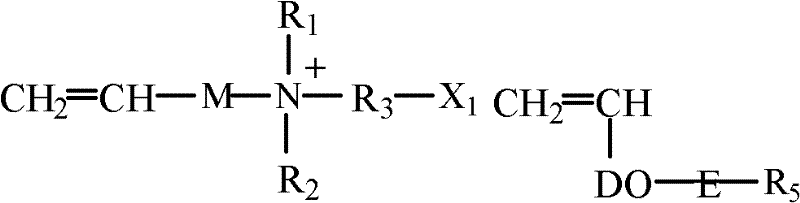

[0045] (2) Prepare the water phase: Weigh 58.9 grams of conventional water-soluble monomer acrylamide, 33.8 grams of sodium acrylate, water-soluble cross-linking monomer N, N'-diallyl-N, N, N', N' -Tetramethylhexammonium chloride 6.8 grams, its molecular structure contains two double bonds, hydrophobic monomer N, N '-dimethyl-N-p-vinyl benzyl octadecyl ammonium chloride 5.4 grams, It...

Embodiment 2

[0050] Embodiment 2, preparation of hydrophobic association type cross-linked polymer coils

[0051] (1) Preparation of the oil phase: Weigh 110.0 grams of base oil isoparaffins (produced by the isomerization dewaxing unit of Daqing Refining and Chemical Company) (viscosity 10.85cP, flash point 178°C), and add it to a stirring 250 In the milliliter three-necked flask, add 57.4 gram sorbitan monooleate (Span-80, HLB value 4.3) and 32.6 gram sorbitan monostearate polyoxyethylene (20) ethers (Tween-60, HLB value is 14.9) two kinds of nonionic surfactants, 12.5 milligrams of pyrolysis type initiator azobisisoheptanonitrile, after mixing homogeneously as oil phase;

[0052] (2) Prepare the water phase: Weigh 58.9 grams of conventional water-soluble monomer acrylamide, 33.3 grams of sodium acrylate, water-soluble cross-linking monomer N, N'-diallyl-N, N, N', N' -Tetramethylhexammonium chloride 6.8 grams, its molecular structure contains two double bonds, hydrophobic monomer N, N '-...

Embodiment 3

[0057] Embodiment 3, the preparation of hydrophobic association type cross-linked polymer coil

[0058] (1) Preparation of the oil phase: Weigh 110.0 grams of base oil isoparaffins (produced by the isomerization dewaxing unit of Daqing Refining and Chemical Company) (viscosity 10.85cP, flash point 178°C), and add it to a stirring 250 In the milliliter three-necked flask, add 57.4 gram sorbitan monooleate (Span-80, HLB value 4.3) and 32.6 gram sorbitan monostearate polyoxyethylene (20) ethers (Tween-60, The HLB value is 14.9) two kinds of non-ionic surfactants, mixed uniformly as the oil phase;

[0059] (2) Prepare the water phase: Weigh 58.9 grams of conventional water-soluble monomer acrylamide, 33.8 grams of sodium acrylate, water-soluble cross-linking monomer N, N'-diallyl-N, N, N', N' - 6.8 grams of tetramethylhexammonium chloride, its molecular structure contains two double bonds, 4.8 grams of hydrophobic monomer 2-acrylamido hexadecyl sodium sulfonate, its molecular str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com