Method for preparing cross-linking polymer clew with bimodal distribution grain diameter

A cross-linked polymer, bimodal distribution technology, applied in the petroleum industry, can solve problems such as the inability to meet the requirements of different oil reservoirs, and achieve the effects of improving the effect of heterogeneity, improving oil recovery, and effective mechanical retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

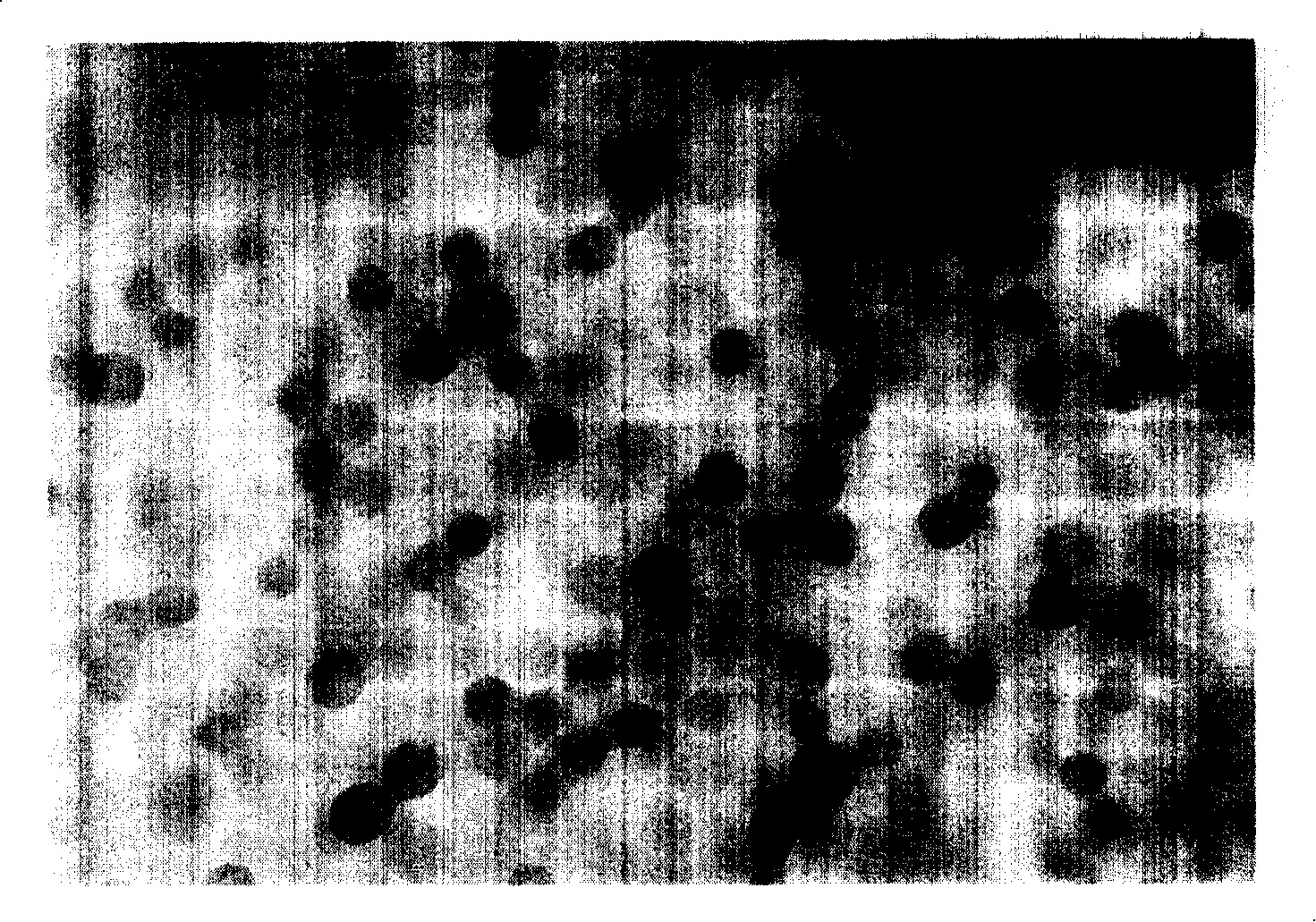

Image

Examples

Embodiment 1

[0063] Prepare the oil phase: take by weighing 50 grams of base oil isoparaffin (Daqing Refining and Chemical Company) (viscosity 10.85cP), join in the 250 milliliters three-necked flasks with stirring, add 9.8 grams of sorbitan monooleate ( Span-80) and 2.2 grams of polyoxyethylene (20) sorbitan monostearate (20) ether (Tween-60) two non-ionic surfactants, after mixing evenly, add the azobisiso Heptanonitrile as oil phase;

[0064] Prepare the water phase: Weigh 18.8 grams of conventional water-soluble monomer acrylamide and 6.2 grams of sodium acrylate, and the functional water-soluble monomer N,N-diallyl-N,N, N, N-tetramethylhexammonium dichloride 0.75 g, salt anhydrous sodium acetate 1.00 g, chelating agent edetate disodium 0.75 mg, cosolvent urea 1.0 mg, oxidizing initiator ammonium persulfate 0.13 mg , the above ingredients are dissolved in 31.25 grams of ultrapure water (conductivity ≤ 4μS / cm) as the water phase for later use;

[0065] Start stirring, slowly add the a...

Embodiment 2

[0070] Prepare the same cross-linked polymer coil powder as in Example 1.

[0071] Cross-linked polymer coils with a mass fraction of 600mg / kg were matured in simulated island water at 60°C for 96 hours to obtain an aqueous solution of cross-linked polymer coils, with a gas permeability of 1.5 μm 2 The simulated oil displacement experiment of the isolated island was carried out on artificial cores, and it was measured that the simulated oil recovery could be increased by 17.0% under the experimental conditions.

Embodiment 3

[0073] Prepare the same cross-linked polymer coil powder as in Example 1.

[0074] Cross-linked polymer coils with a mass fraction of 300 mg / kg were aged in simulated island water at 60°C for 96 hours to obtain an aqueous solution of cross-linked polymer coils, with a gas permeability of 4.5 μm 2 The simulated oil displacement experiment of the isolated island was carried out on artificial cores, and it was measured that the simulated oil recovery could be increased by 14.0% under the experimental conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com