Patents

Literature

40results about How to "Prevent downgrade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

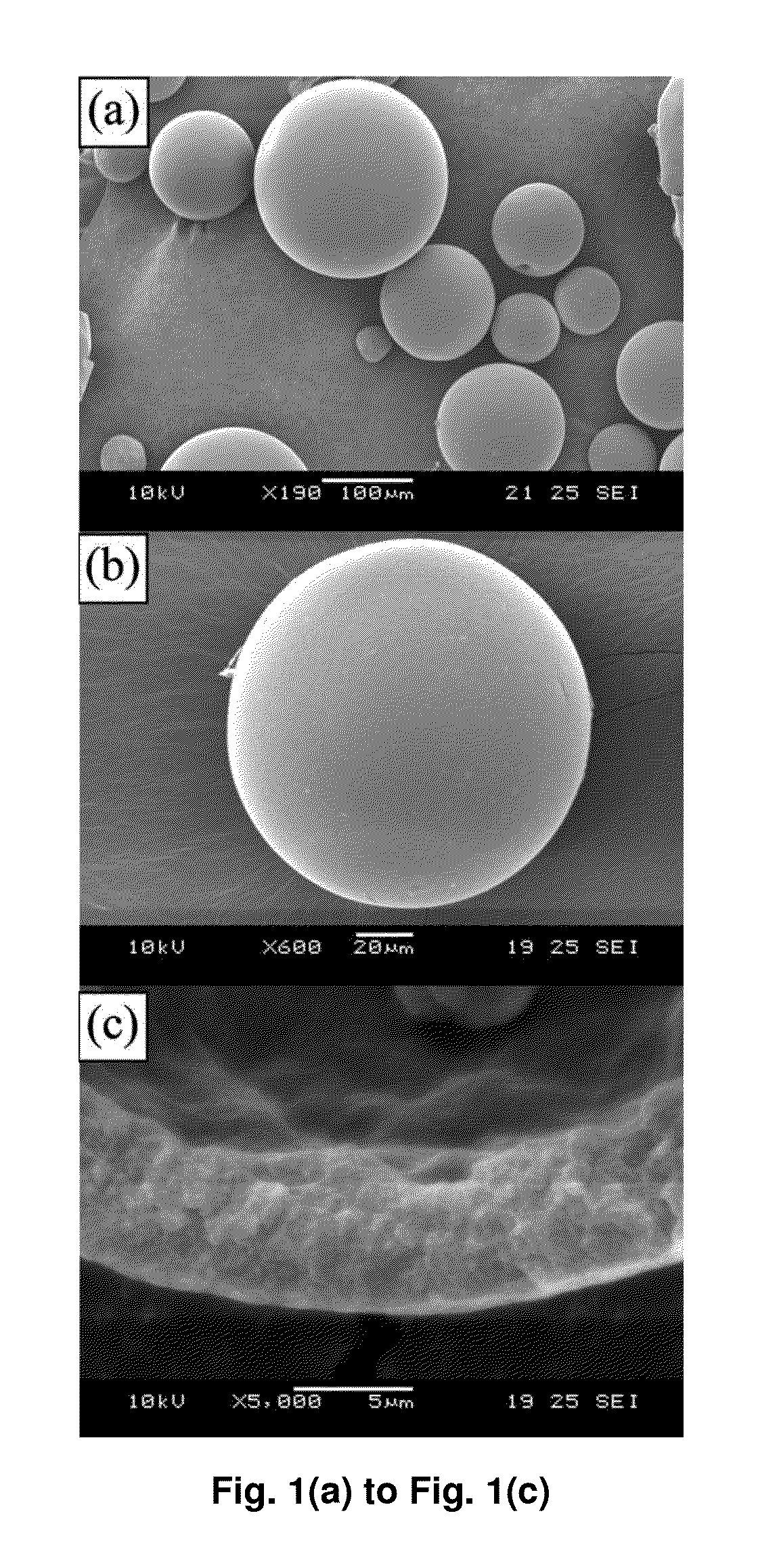

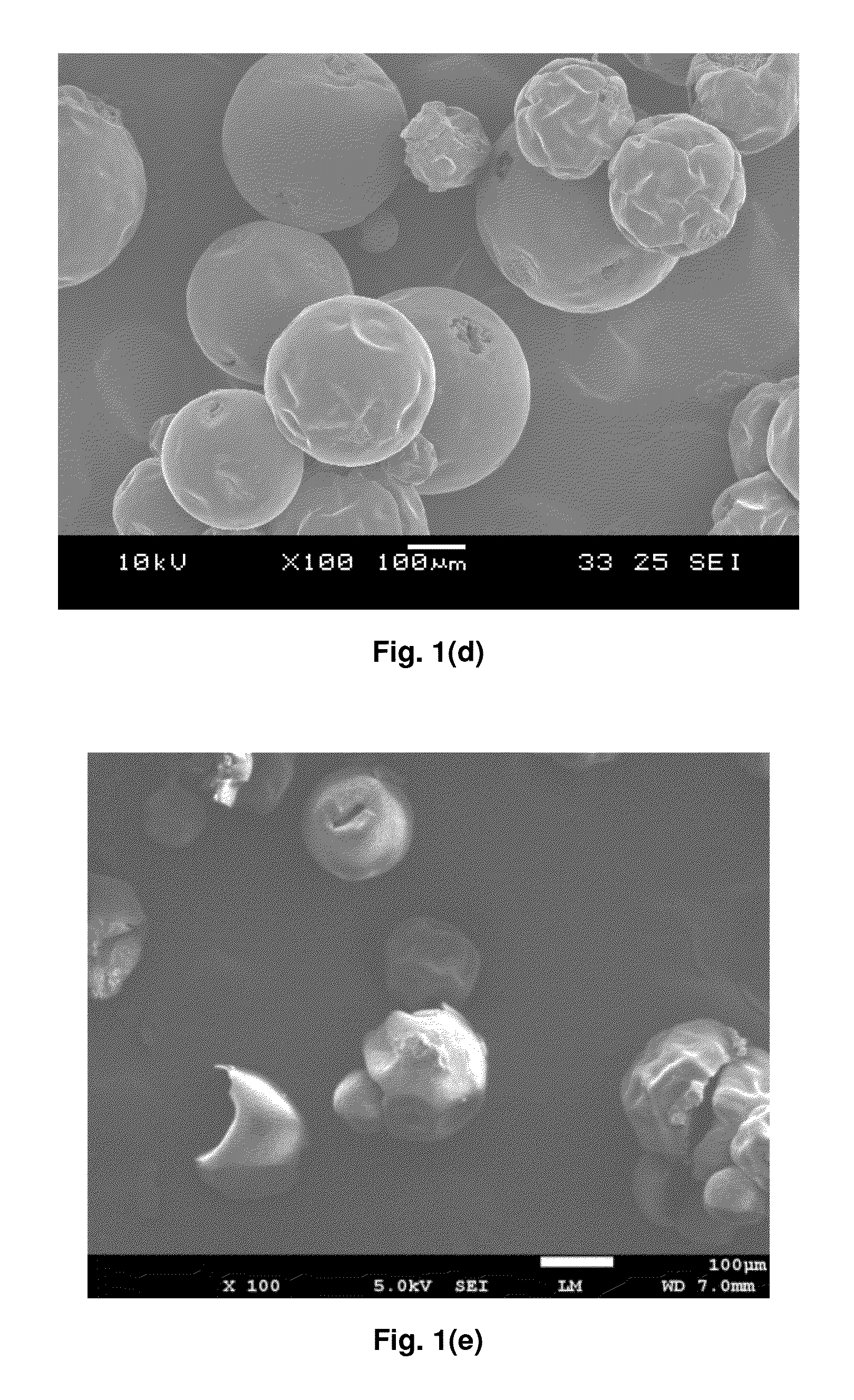

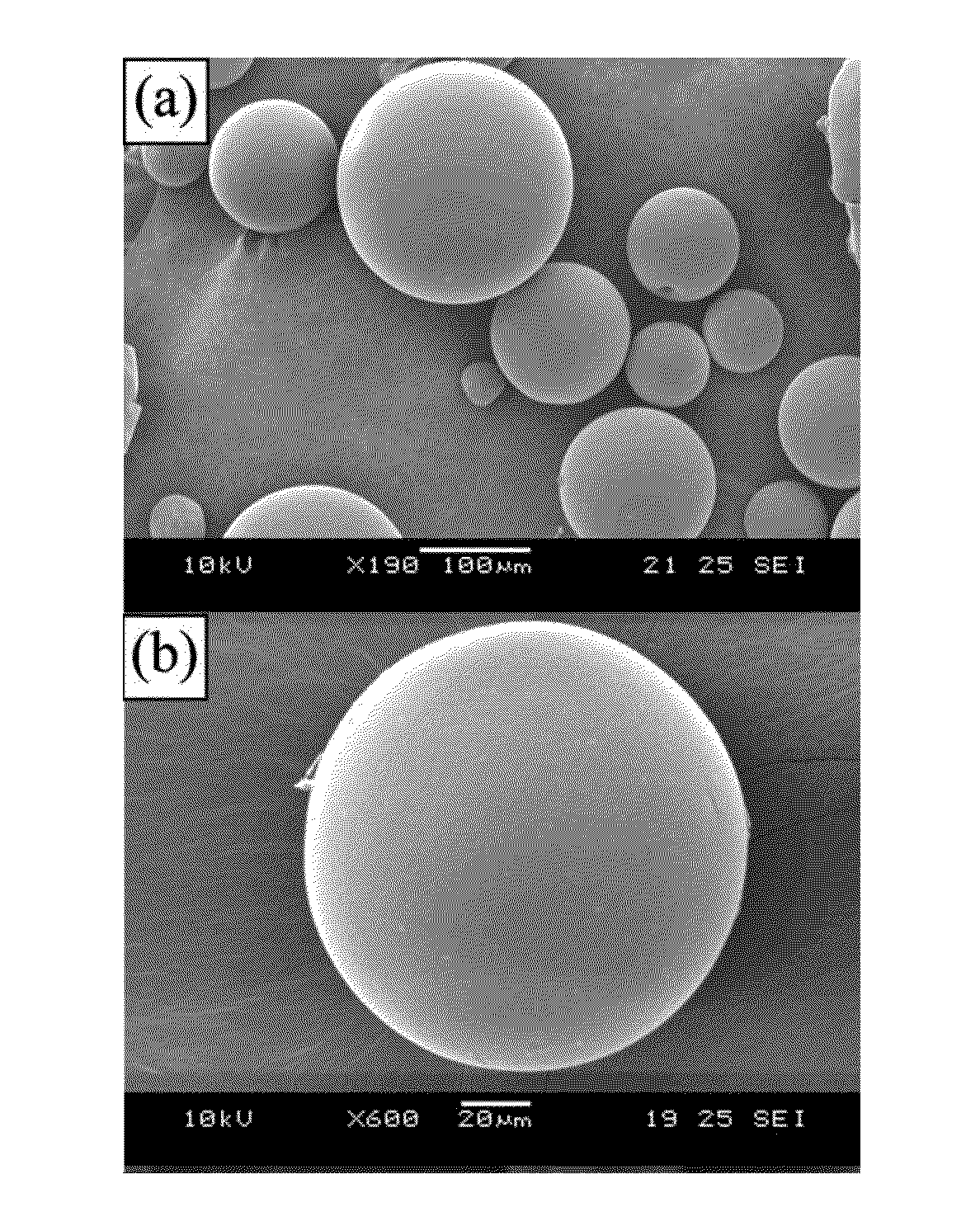

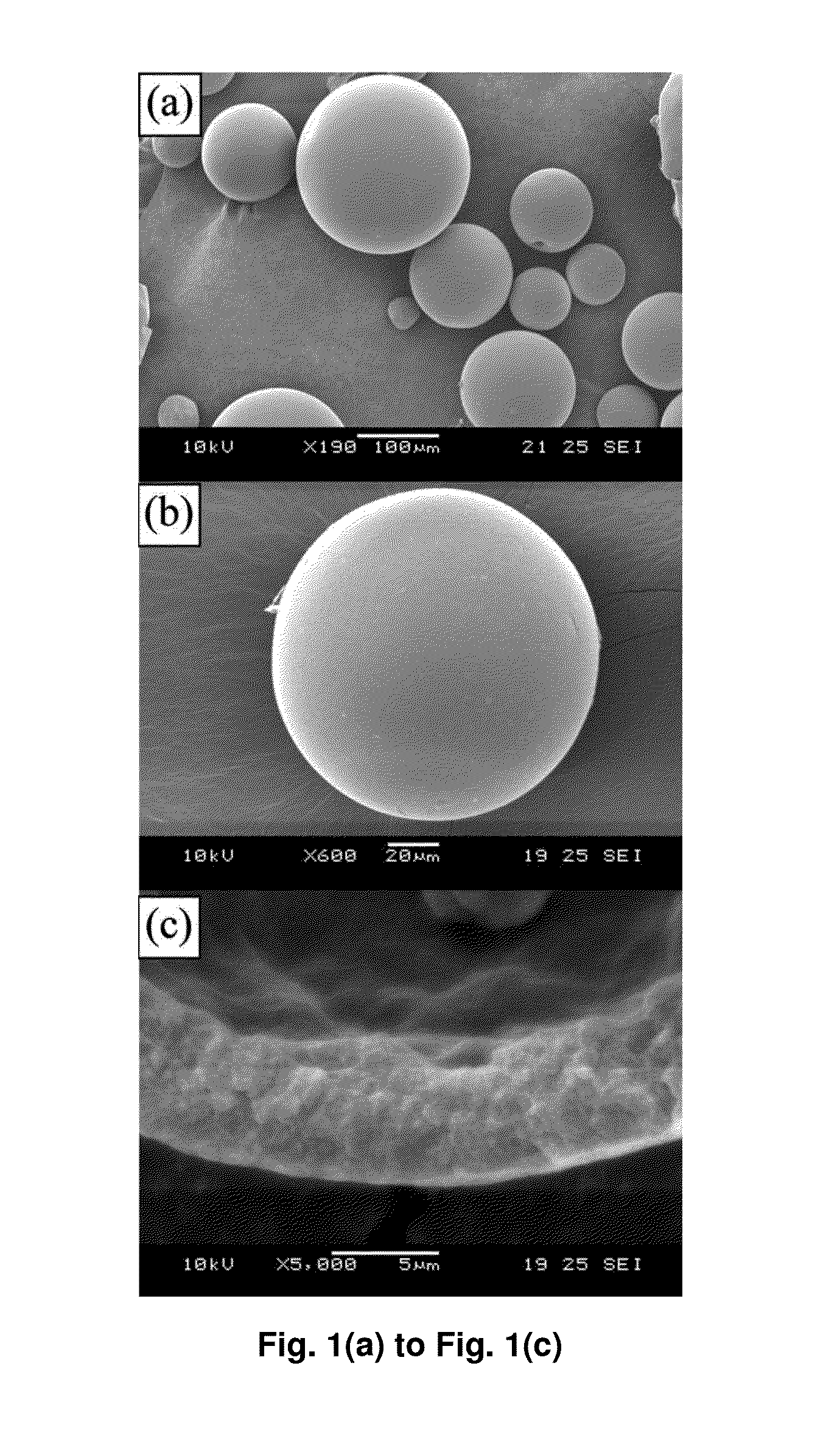

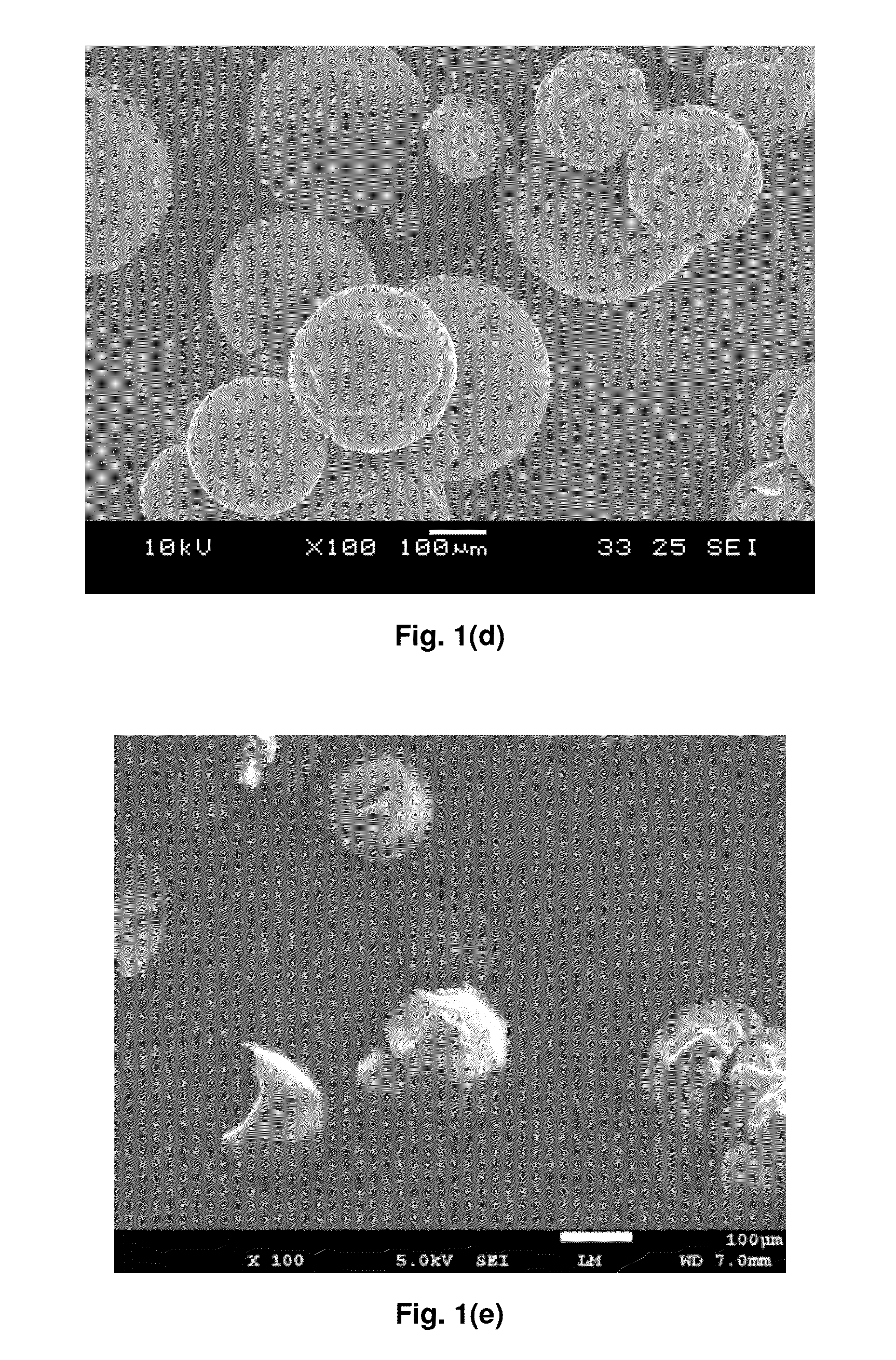

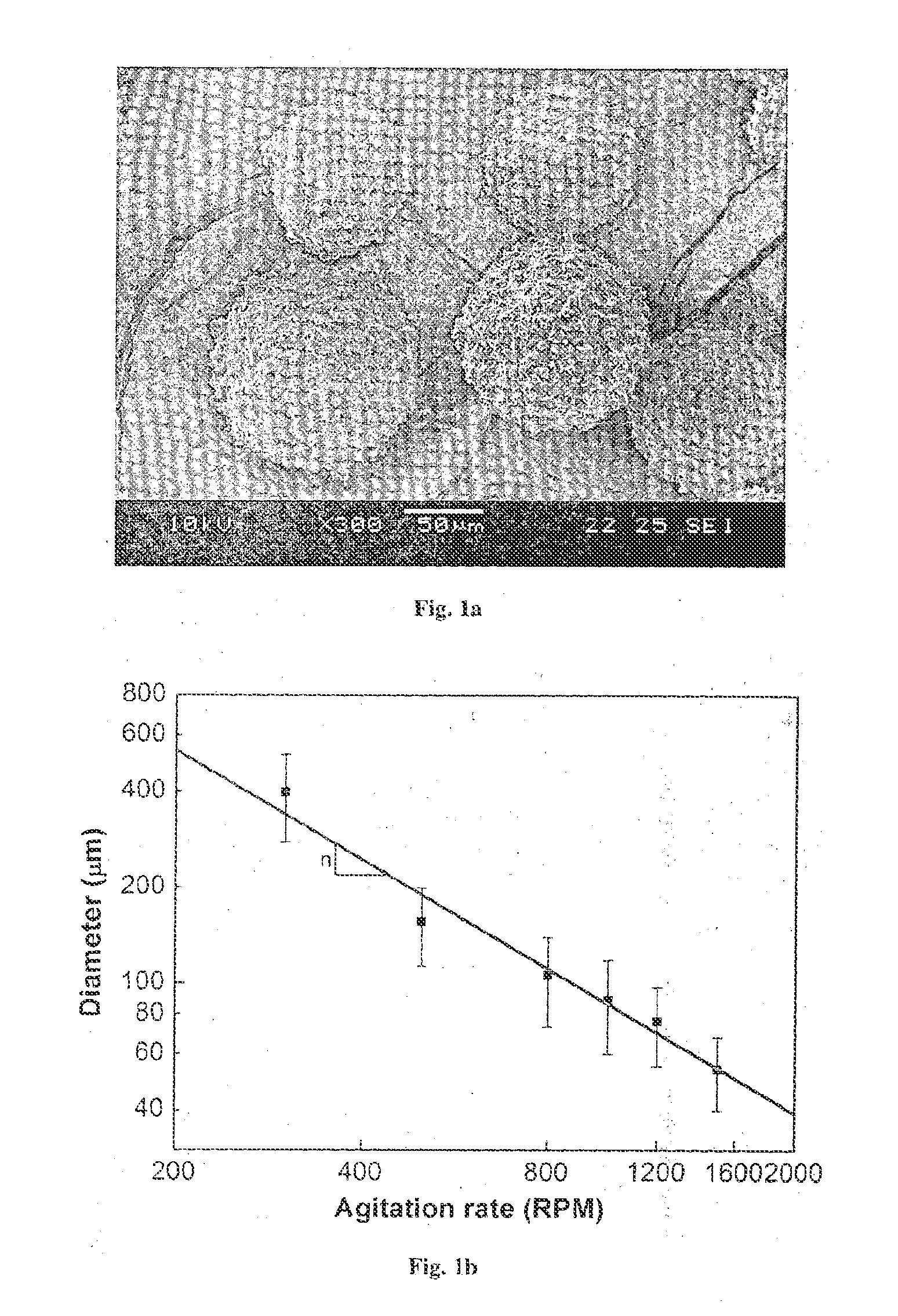

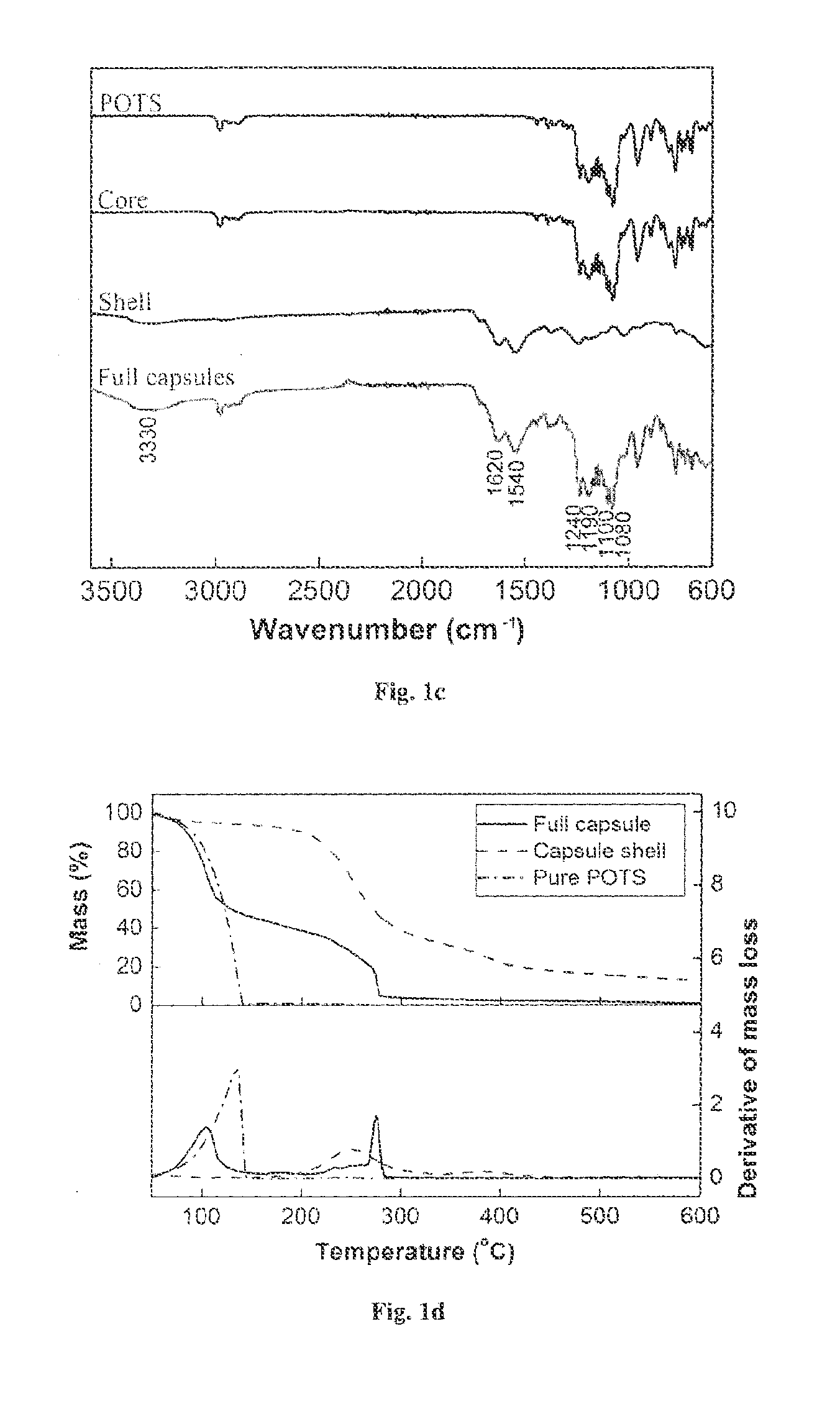

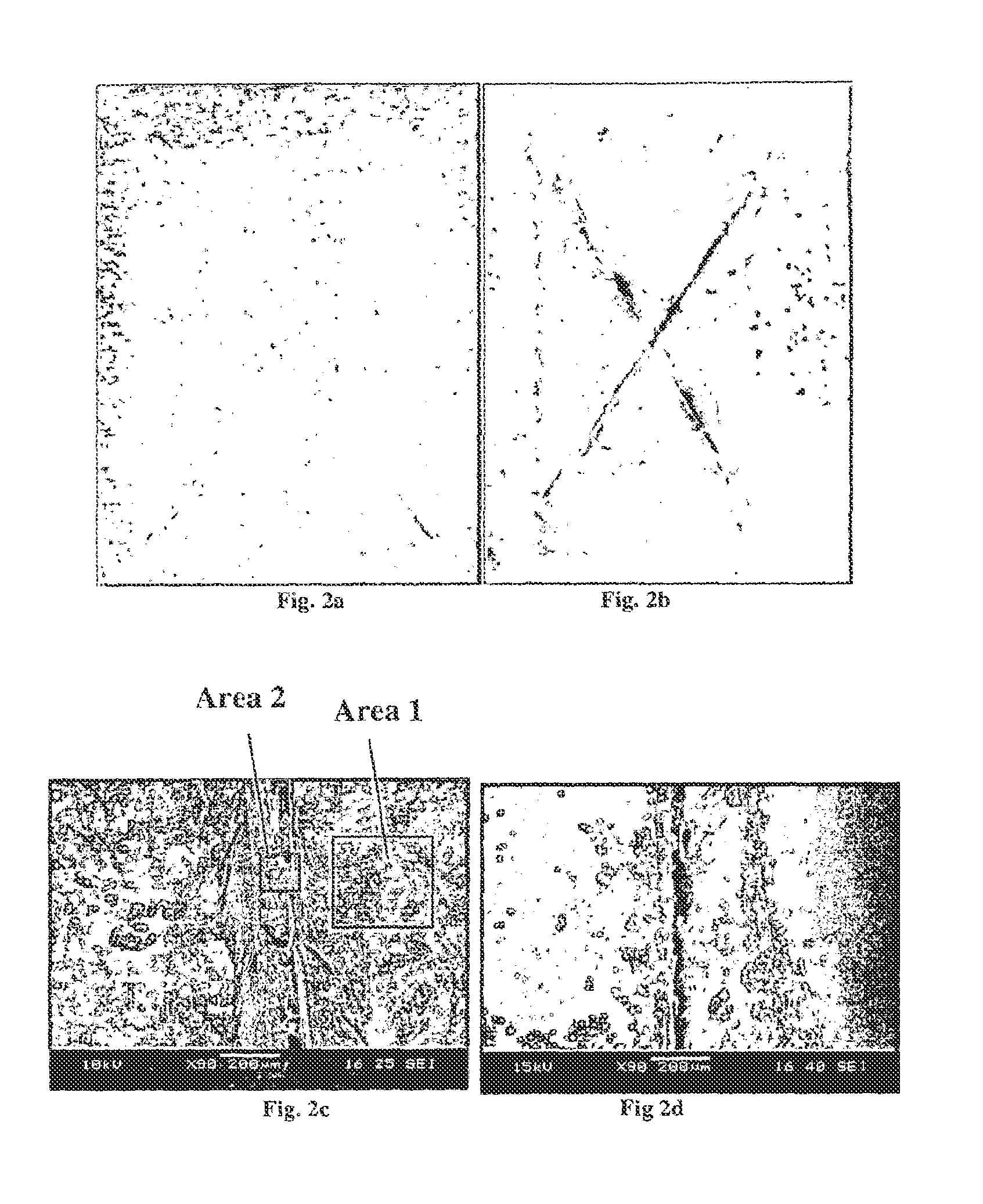

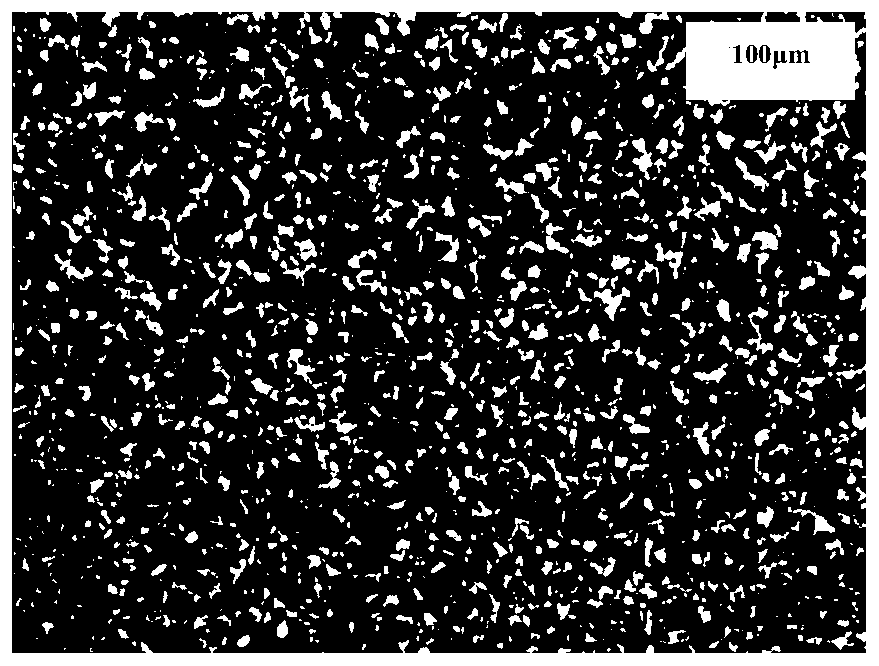

Microencapsulation of reactive diisocyanates and the application to self-healing anticorrosion coatings

InactiveUS20130196071A1Prevent downgradePreventing and slowing corrosionPretreated surfacesAnti-corrosive paintsSelf-healingPrepolymer

The disclosure provides a polyurethane microcapsule consisting of a polymerization product of methylene diphenyl diisocyanate (MDI) prepolymer with a polyol, the polyurethane microcapsule comprising a liquid isocyanate compound encapsulated within the microcapsule. The disclosure also provides self-healing coating compositions comprising such polymeric microcapsules and methods of preventing or slowing corrosion using such coating compositions.

Owner:NANYANG TECH UNIV

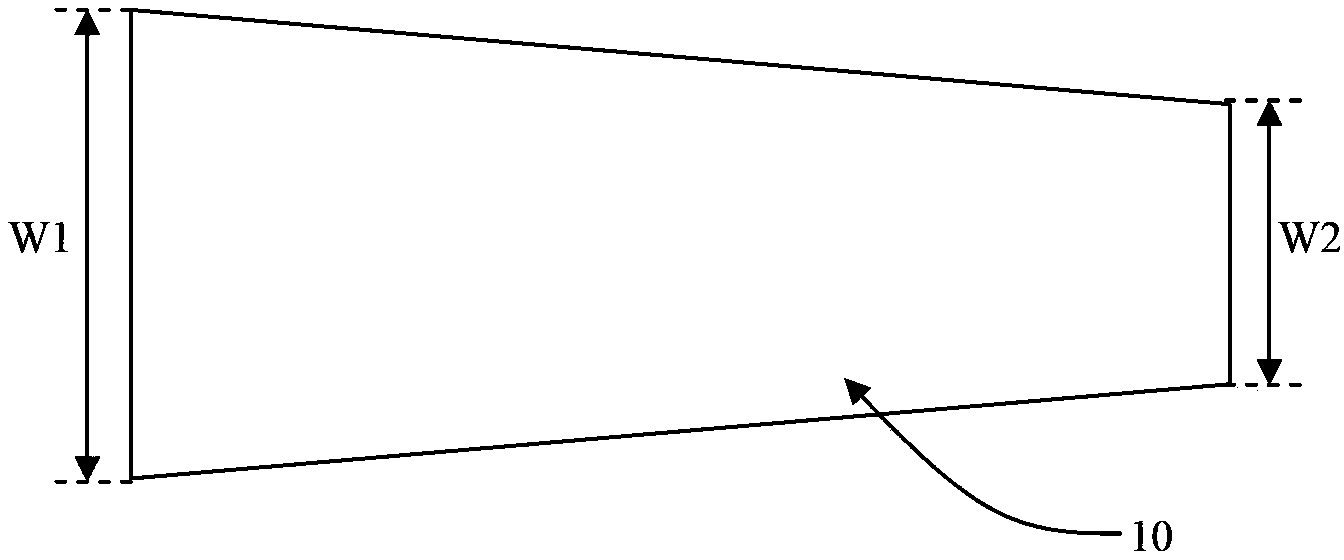

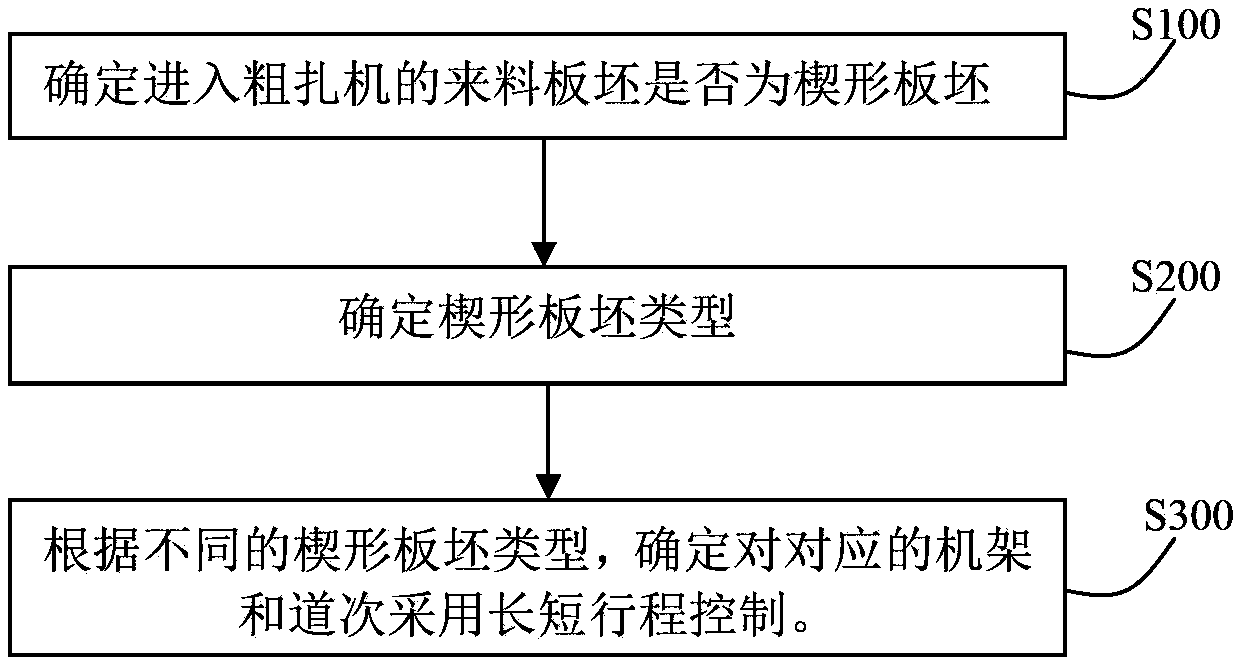

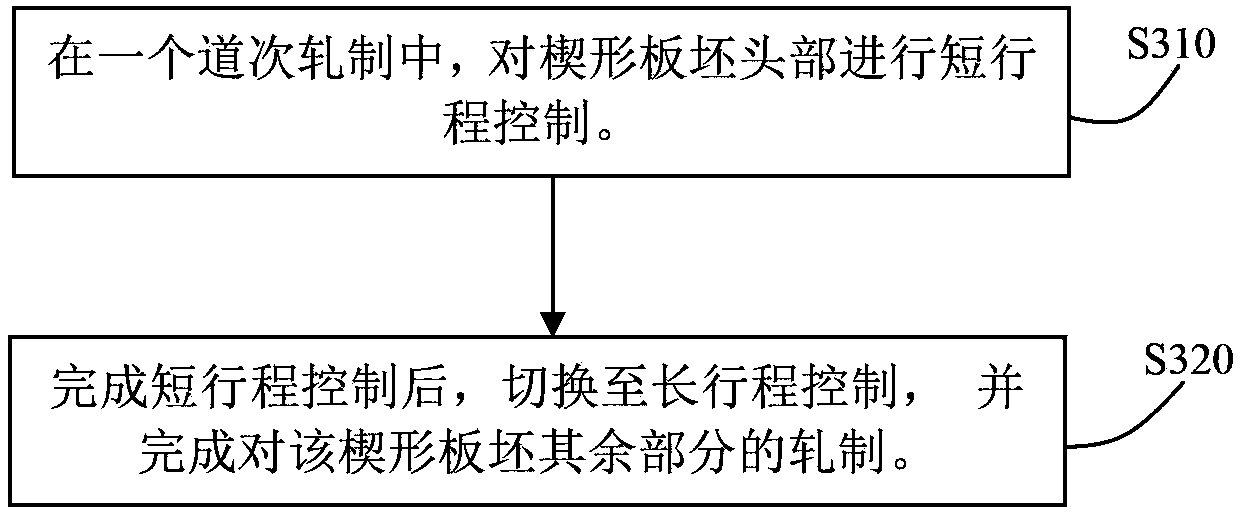

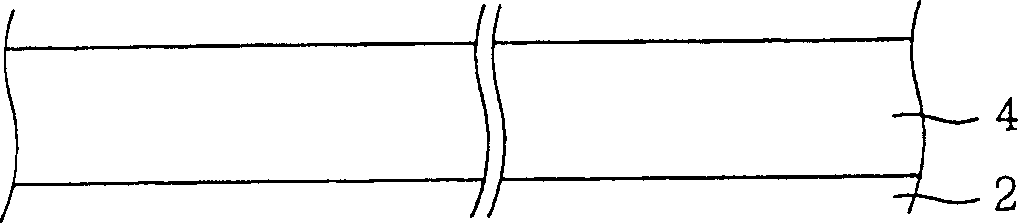

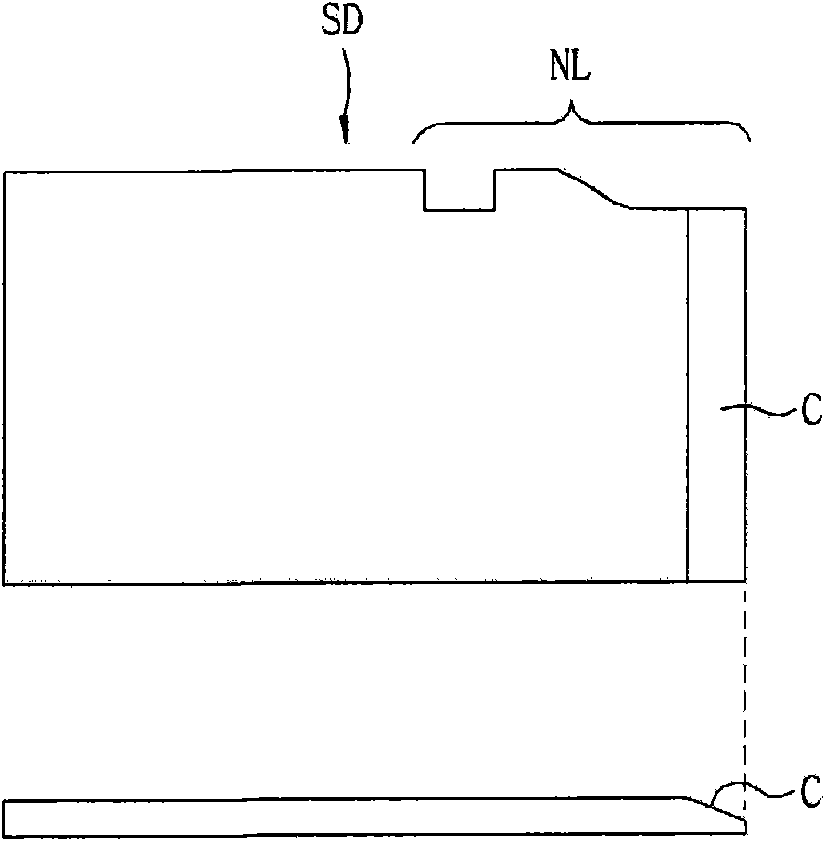

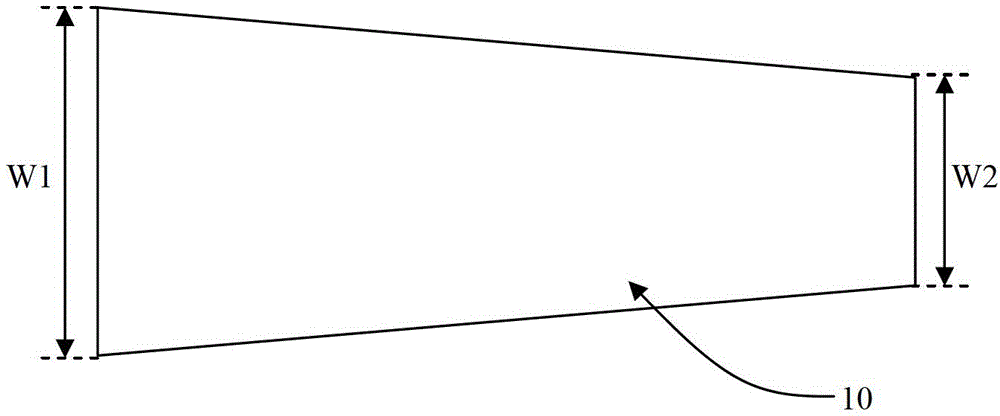

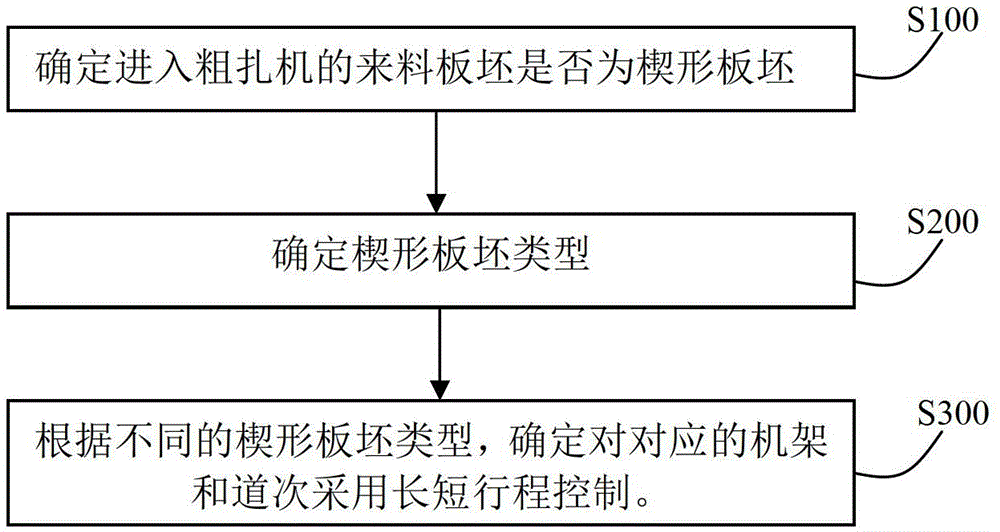

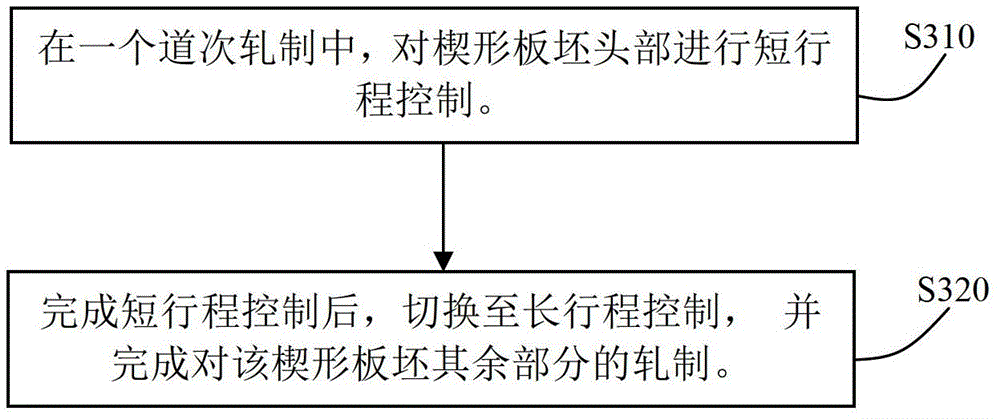

Control method of hot rolling width of wedge-shaped slab

ActiveCN103506403AImprove product qualityExpand the scope of useMetal rolling stand detailsWedge shapeRolling mill

The invention discloses a control method of a hot rolling width of a wedge-shaped slab. The control method is used in hot rolling of rough mills and used for controlling the hot rolling width of the wedge-shaped slab. The control method includes the following steps that firstly, whether an incoming slab is a wedge-shaped slab or not is judged according to the width difference of the head and the tail of the incoming slab which is to enter a rough mill to undergo rough rolling processing; secondly, when the incoming slab is determined to be the wedge-shaped slab, the type of the wedge-shaped slab is determined according to the width difference of the head and the tail; thirdly, width control is performed on wedge-shaped slabs in multiple racks in the rough mill which the wedge-shaped slab enters according to the wedge-shaped slab type which is determined in the second step. The control method of the hot rolling width of the wedge-shaped slab automatically controls widths of the wedge-shaped slabs which have the abnormal widths in the full length direction in the rough rolling process of a hot rolling mill.

Owner:BAOSHAN IRON & STEEL CO LTD

Microencapsulation of reactive diisocyanates and the application to self-healing anticorrosion coatings

InactiveUS8993066B2Prevent downgradePreventing and slowing corrosionPretreated surfacesAnti-corrosive paintsSelf-healingPrepolymer

The disclosure provides a polyurethane microcapsule consisting of a polymerization product of methylene diphenyl diisocyanate (MDI) prepolymer with a polyol, the polyurethane microcapsule comprising a liquid isocyanate compound encapsulated within the microcapsule. The disclosure also provides self-healing coating compositions comprising such polymeric microcapsules and methods of preventing or slowing corrosion using such coating compositions.

Owner:NANYANG TECH UNIV

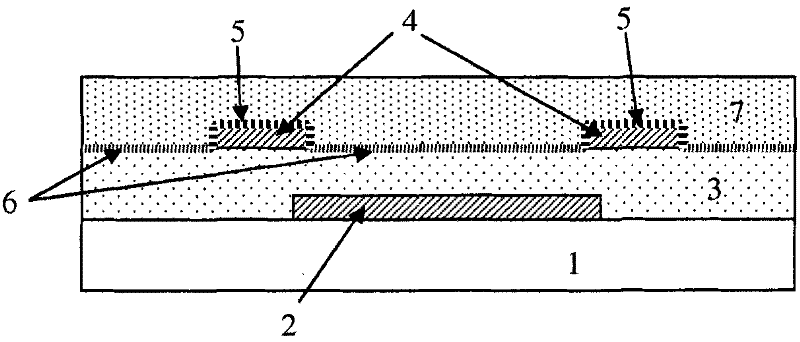

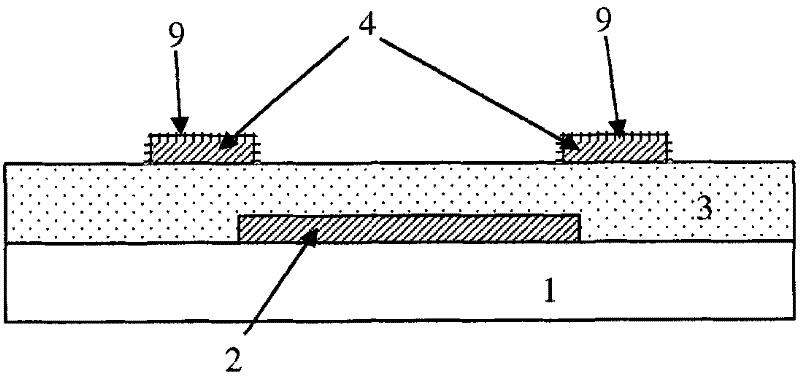

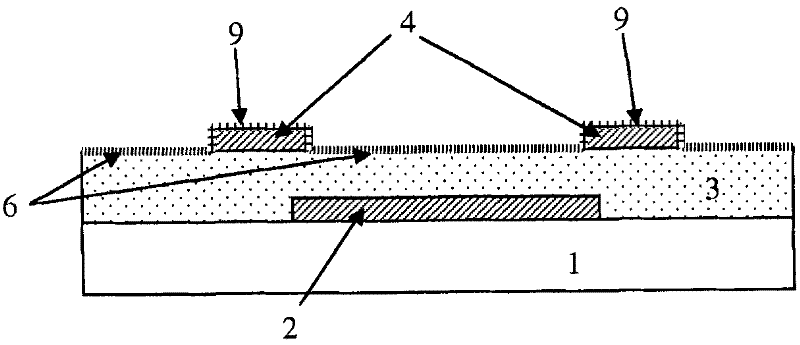

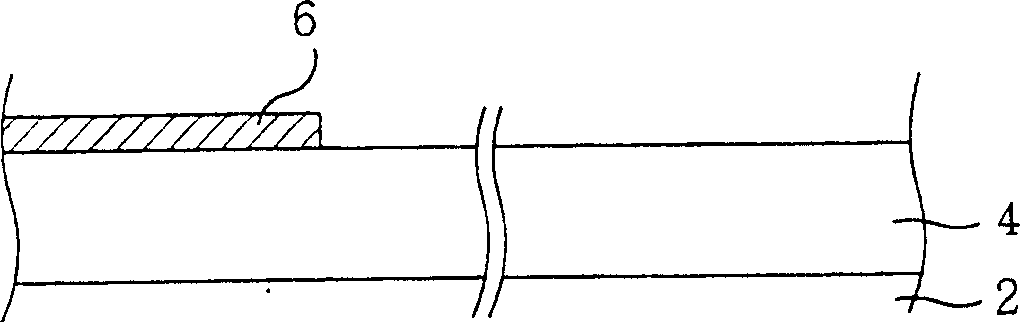

Method for fabricating organic devices

InactiveCN102598333APrevent downgradeAvoid formingSolid-state devicesSemiconductor/solid-state device manufacturingOrganic devicesEngineering

The present invention relates to a method for fabricating an organic device, said method comprising: (i) Providing a substrate (1) having a surface comprising electrical contact structures (4) and a dielectric portion (3), (ii) Providing a first temporary protection layer (9) on some or all of said electrical contact structures (4), (iii) Providing a first surface modification layer (6) on the dielectric portion (3) and / or providing a third surface modification layer (10) on said electrical contact structures (4) not protected in step (ii), (iv) Removing the first temporary protection layer (9), (v) Providing a second surface modification layer (5) on the electrical contact structures that where protected in step (ii), and (vi) Providing said first surface modification layer (6) on the dielectric portion (3), if it was not provided in step (iii), and (vii); Providing an organic semiconductor layer (7) on top of at least part of said first surface modification layer (6) and on top of said second (5) surface modification layer and if present on top of said third surface modification layer (10), thereby obtaining said organic device or providing an organic semiconductor layer of a first type (7) on top of said second surface modification layer (5) and part of said first surface modification layer (6) and providing an organic semiconductor layer of a second type (8) on top of said third surface modification layer and another part of said first surface modification layer (6), thereby obtaining said organic device.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Method for manufacturing semiconductor device suitable for image sensor

InactiveCN1445816AAvoid deformationPrevent downgradeTelevision system detailsOptical filtersEngineeringProtection layer

In a method of manufacturing a semiconductor device suitable for an image sensor, a bonding region is formed on the lower insulating layer after forming a lower insulating layer on a substrate. Then, an upper insulating layer is formed on the substrate to cover the bonding area. The upper insulating layer is selectively removed to expose a top portion of the bonding region. Subsequently, a protective layer is formed on the substrate. After forming several color filter elements on the protection layer, a planar layer is formed to cover the color filter elements. Finally, several microlenses are formed on the plane layer.

Owner:DONGBUANAM SEMICON

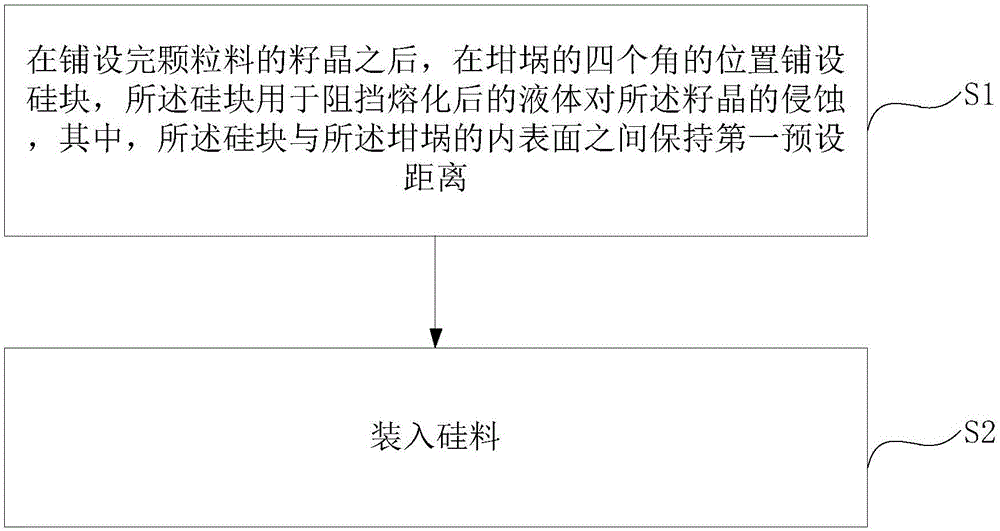

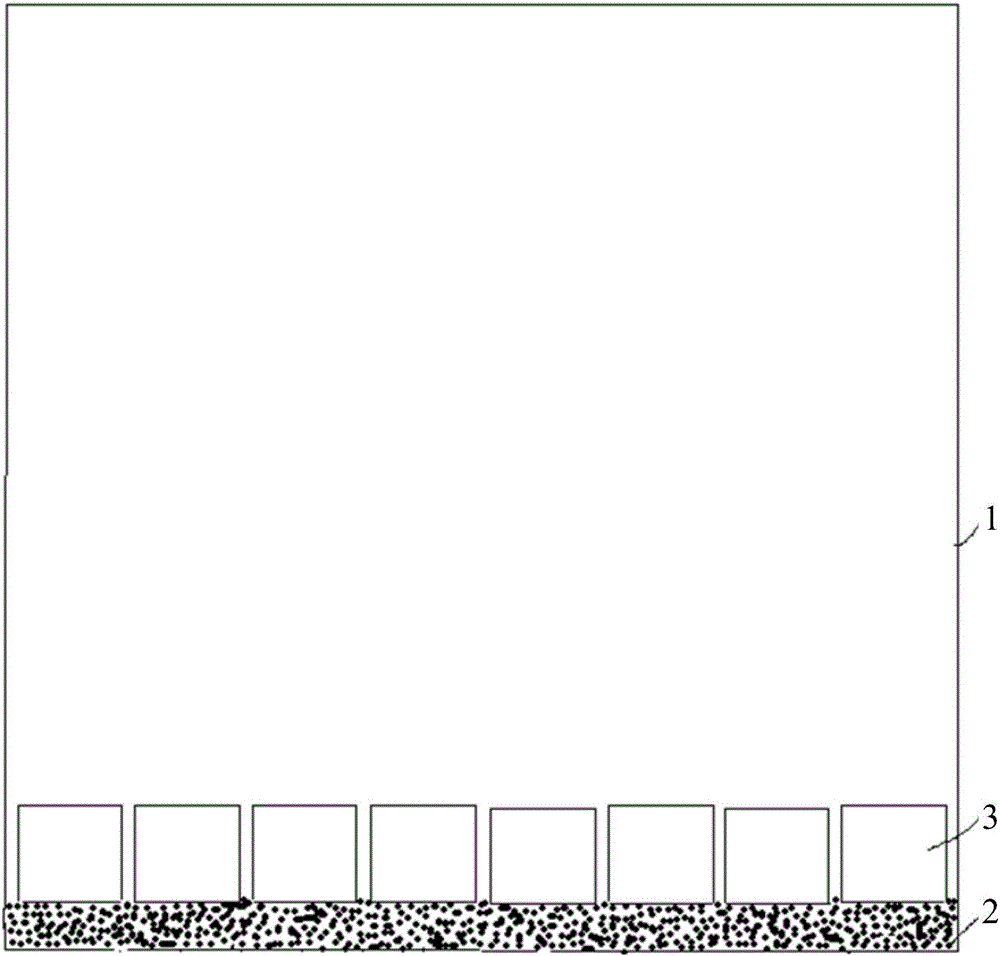

Charging method for polycrystalline silicon ingot casting process

InactiveCN106012008APrevent downgradeImprove conversion efficiencyPolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The present application discloses a charging method for polysilicon ingot casting process, which includes: after laying the seed crystal of the granular material, laying silicon blocks at the four corners of the crucible, the silicon blocks are used to block the melting after melting. erosion of the seed crystal by the liquid, wherein a first preset distance is maintained between the silicon block and the inner surface of the crucible; and silicon material is added. The above-mentioned charging method for the polysilicon ingot casting process provided by the present application can avoid too much melting of the corner and edge seed crystals, avoid crystal grain degradation, and improve the conversion efficiency of silicon wafers.

Owner:JINKO SOLAR CO LTD +1

Microencapsulation of organic silanes and their use as self healing materials

ActiveUS20150079290A1Prevent and slow corrosionPrevent downgradeOther chemical processesPretreated surfacesOrganosiliconPolyurea

The disclosure provides a poly(urea-formaldehyde) microcapsule, which comprises encapsulated in the poly(urea-formaldehyde) microcapsule an organofluorine silane of the general formula (I) A3C(CA2)xSiR1yX(3-y) (I), wherein in formula (I) A is either fluorine (F) or hydrogen (H), wherein at least 50% of atoms A are fluorine. X is chloro or a group RO, wherein R is a linear or branched alkyl radical of 1 to 4 carbon atoms, R1 is a linear, branched or cyclic alkyl group of 1 to 8 carbon atoms, n=0 or 2, y=0 or 1 or 2 and m=0 to 20, encapsulated within the microcapsule. The disclosure also provides self-healing coating compositions comprising such polymeric microcapsules and methods of preventing or slowing corrosion using such coating compositions.

Owner:NANYANG TECH UNIV

Production control method for improving curvature of 42CrMo bar

InactiveCN110918642APrevent downgradeAvoid lostTemperature control deviceMetal rolling arrangementsThermodynamicsHeating time

The invention relates to a production control method for improving the curvature of a 42CrMo bar, and the method comprises heating, rolling and cooling control procedures. A walking beam furnace is adopted in the heating procedure, and the heating procedure sequentially comprises a preheating section, a first heating section, a second heating section and a soaking section, wherein the temperatureof the preheating section ranges from 600 DEG C to 720 DEG C, the temperature of the first heating section ranges from 950 DEG C to 1,060 DEG C, the temperature of the second heating section ranges from 1,060 DEG C to 1,130 DEG C, the temperature of the soaking section ranges from 1,080 DEG C to 1,120 DEG C, and the total heating time ranges from 120 min to 180 min. The 42CrMo bar produced by themethod has better curvature index and uniform structure, the quenching cracking ratio of the 42CrMo bar is reduced in the subsequent machining process, and the machining efficiency and the percent ofpass of user products are improved.

Owner:HANDAN IRON & STEEL GROUP +1

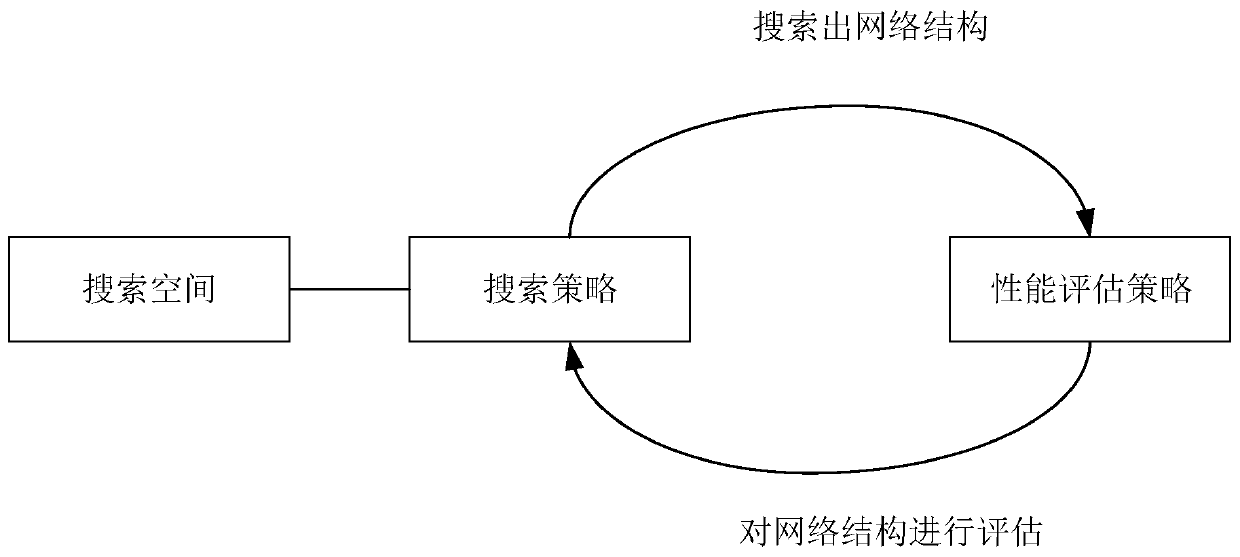

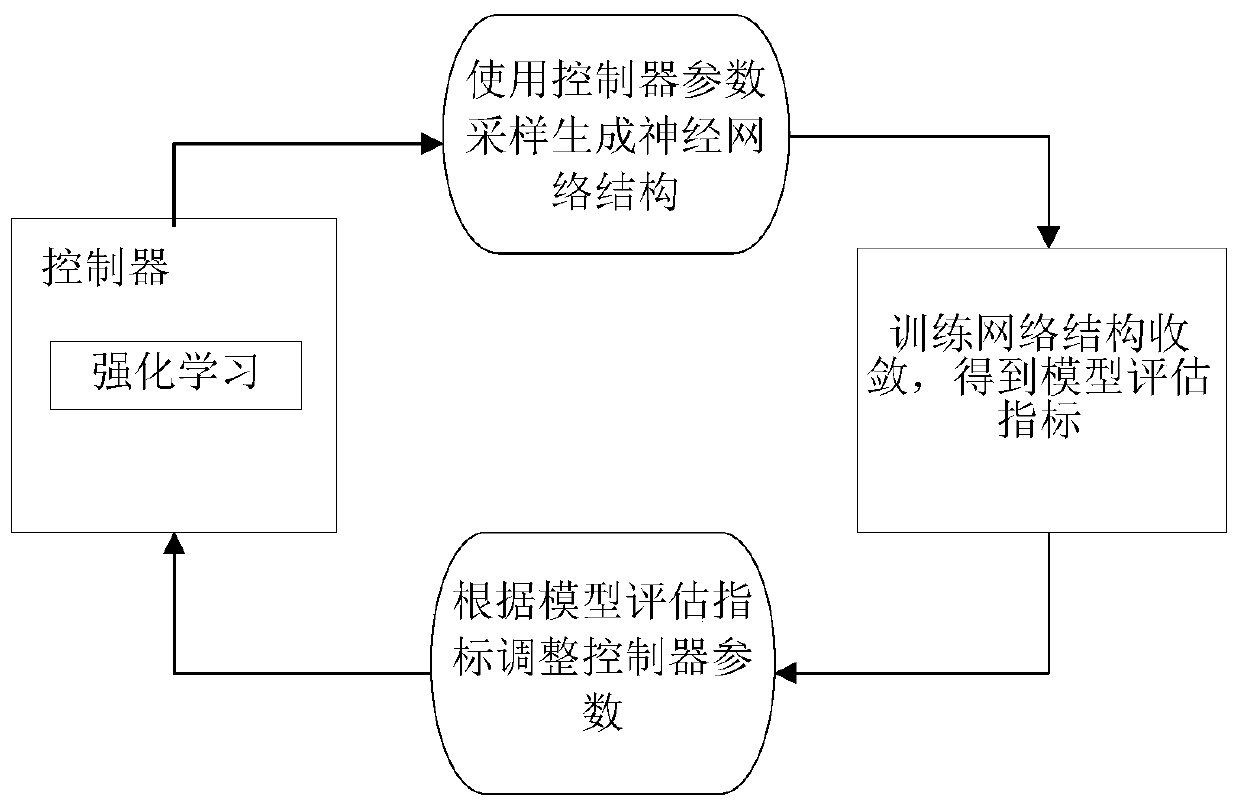

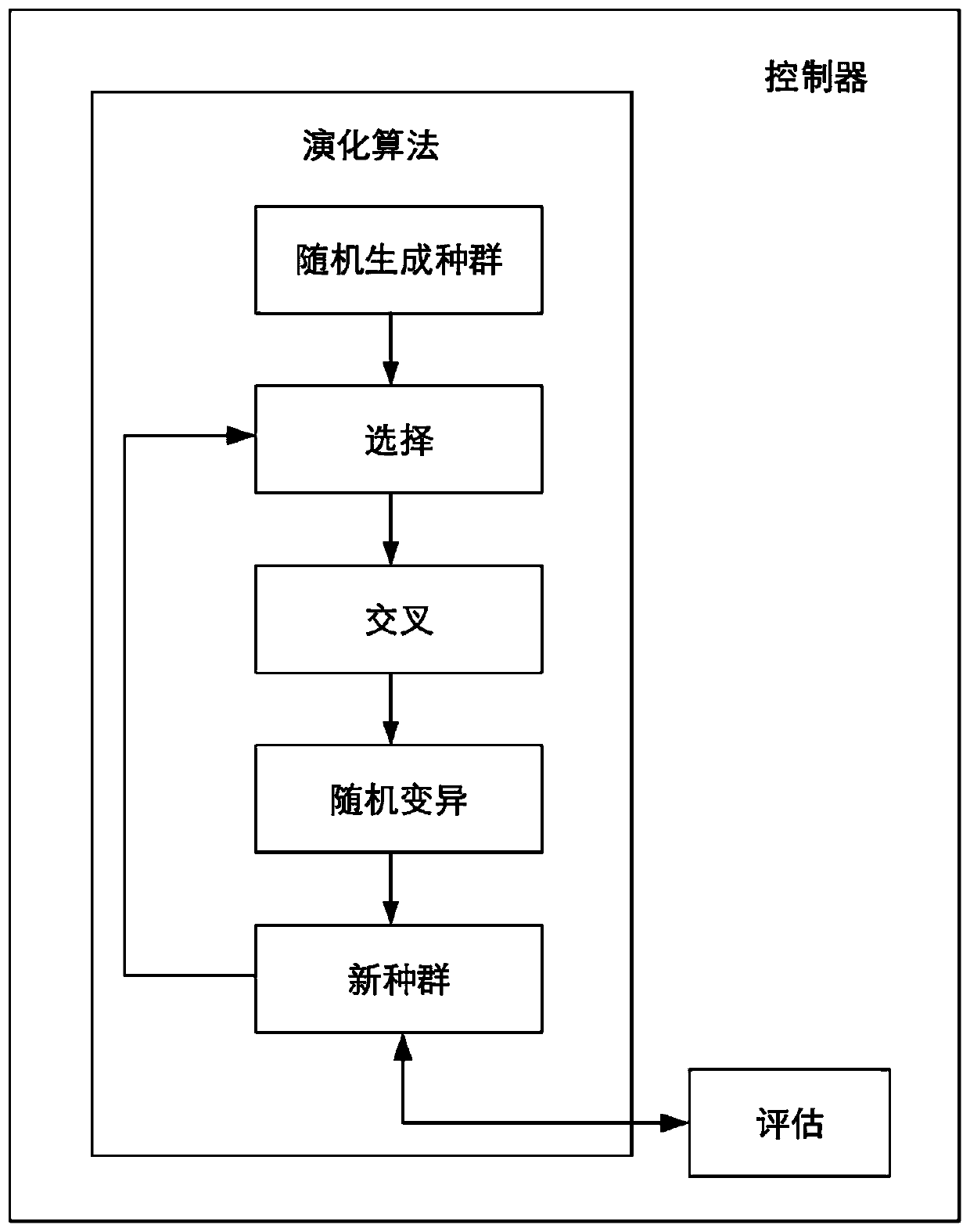

Neural network structure model search method and device and storage medium

ActiveCN110689127APrevent downgradeMathematical modelsRandom number generatorsNetwork structureEngineering

The invention relates to a neural network structure model search method and device and a storage medium. The method comprises: generating an initial-generation network model structure population basedon the multi-objective optimization hyper-parameters; selecting and crossing the current generation network model structure population; generating partial network model structures based on reinforcement learning variation, and performing random variation on the selected and crossed network model structures to generate other partial network model structures; generating a new population of a network model structure based on the network model structure generated by reinforcement learning variation and the network model structure generated by random variation; searching a next-generation networkmodel structure population based on the current-generation network model structure population and the network model structure new population; and taking the next generation of network model structurepopulation as the current generation of network model structure population, repeatedly executing the process until the optimal multi-objective optimization state is achieved, and selecting neural network structure models suitable for different scenes from the final generation of network model structure population.

Owner:BEIJING XIAOMI INTELLIGENT TECH CO LTD

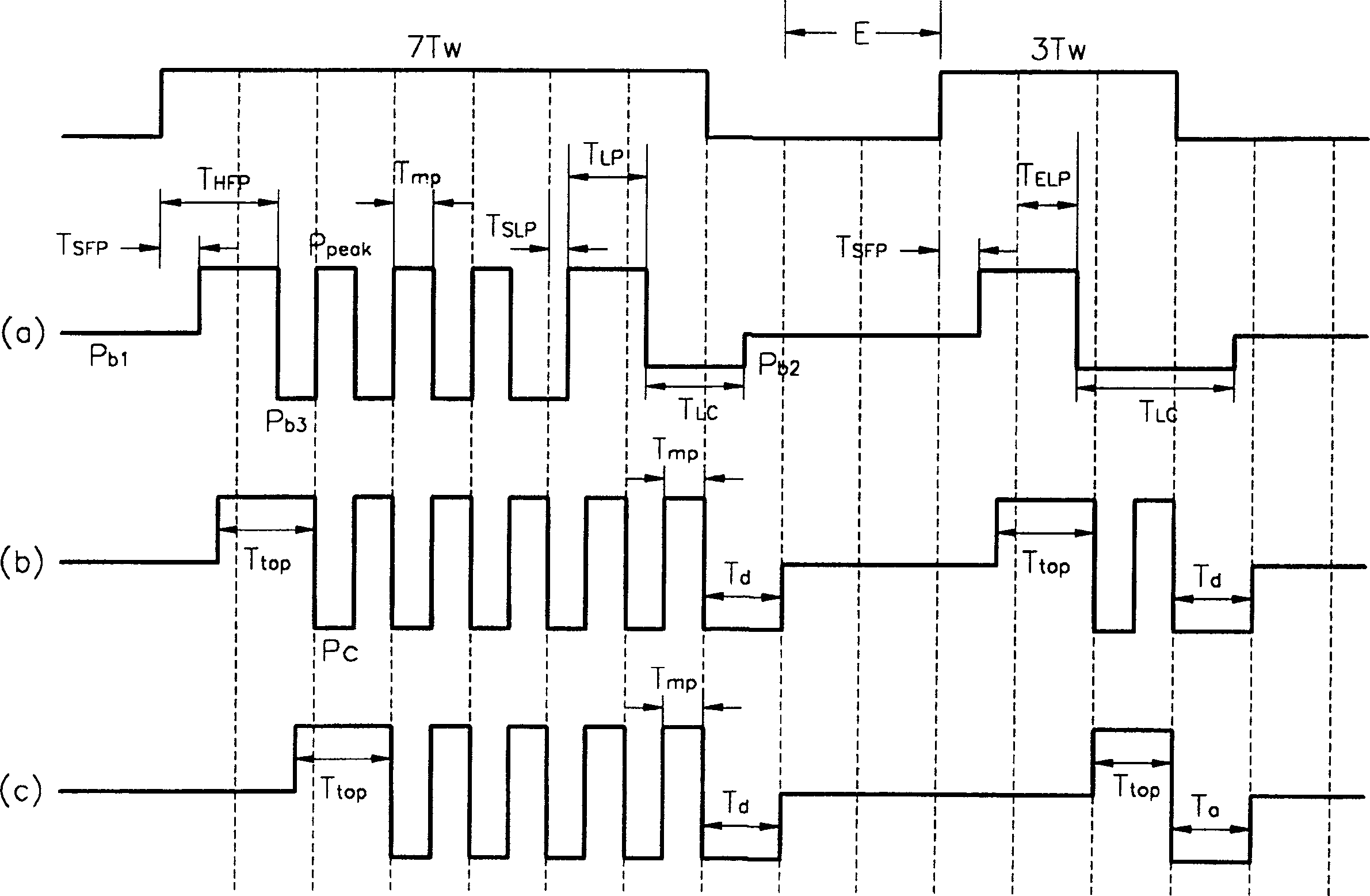

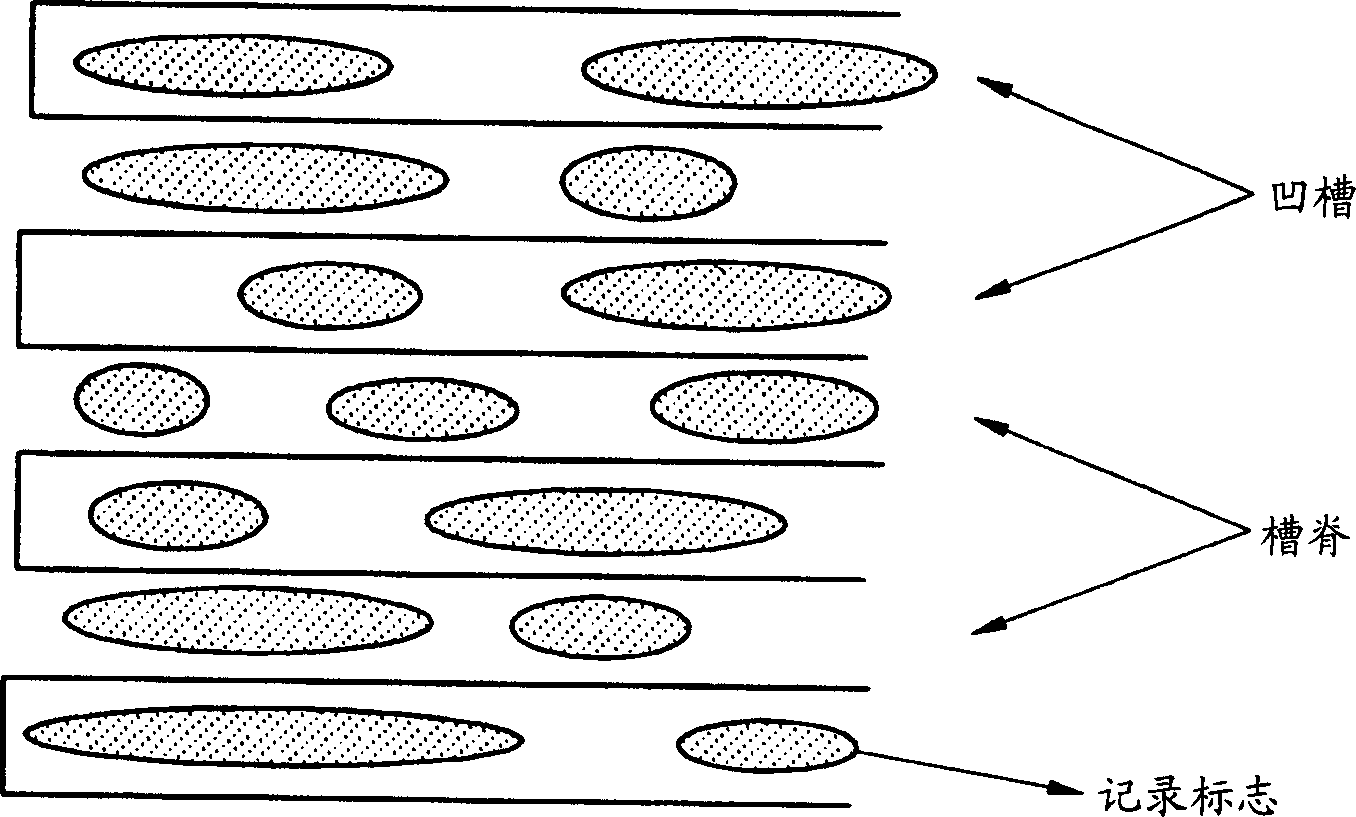

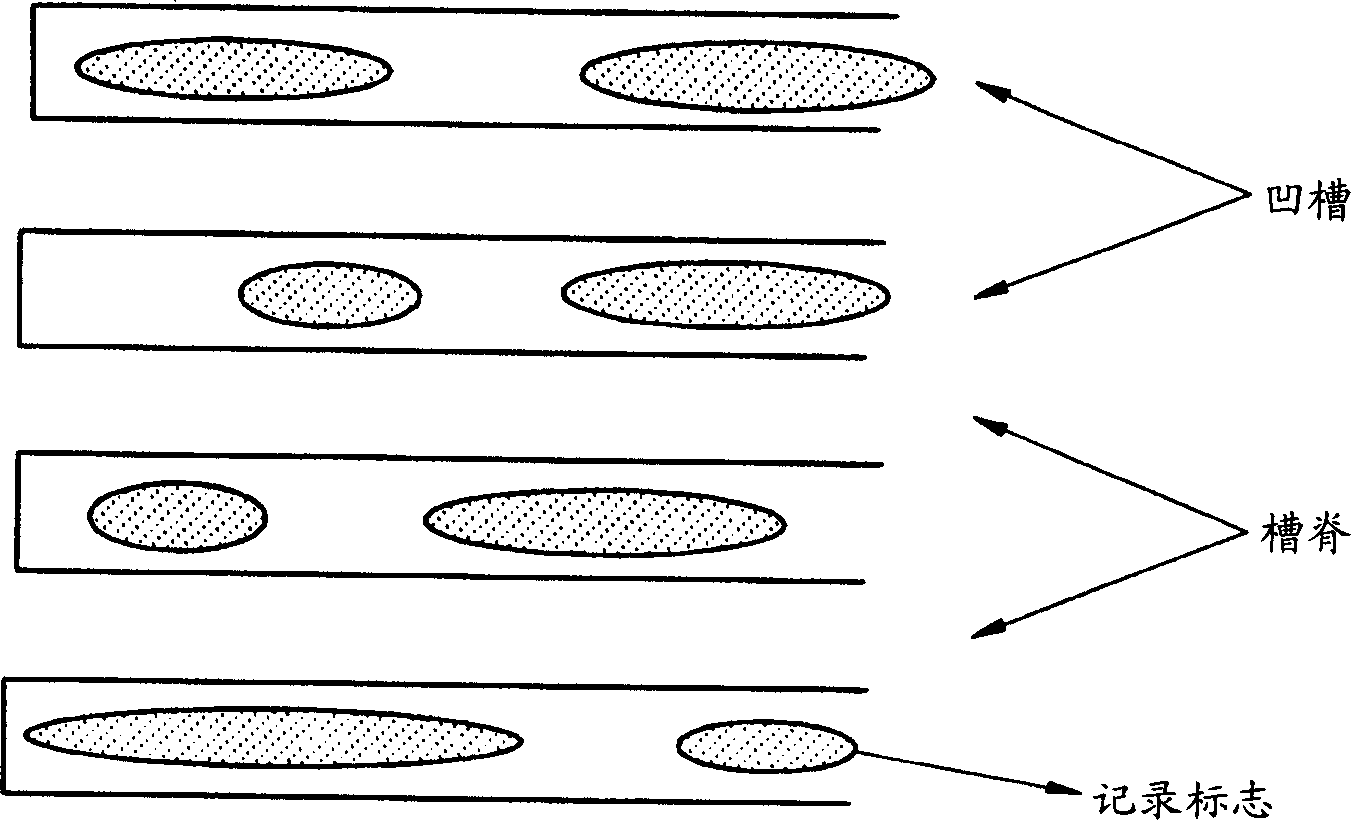

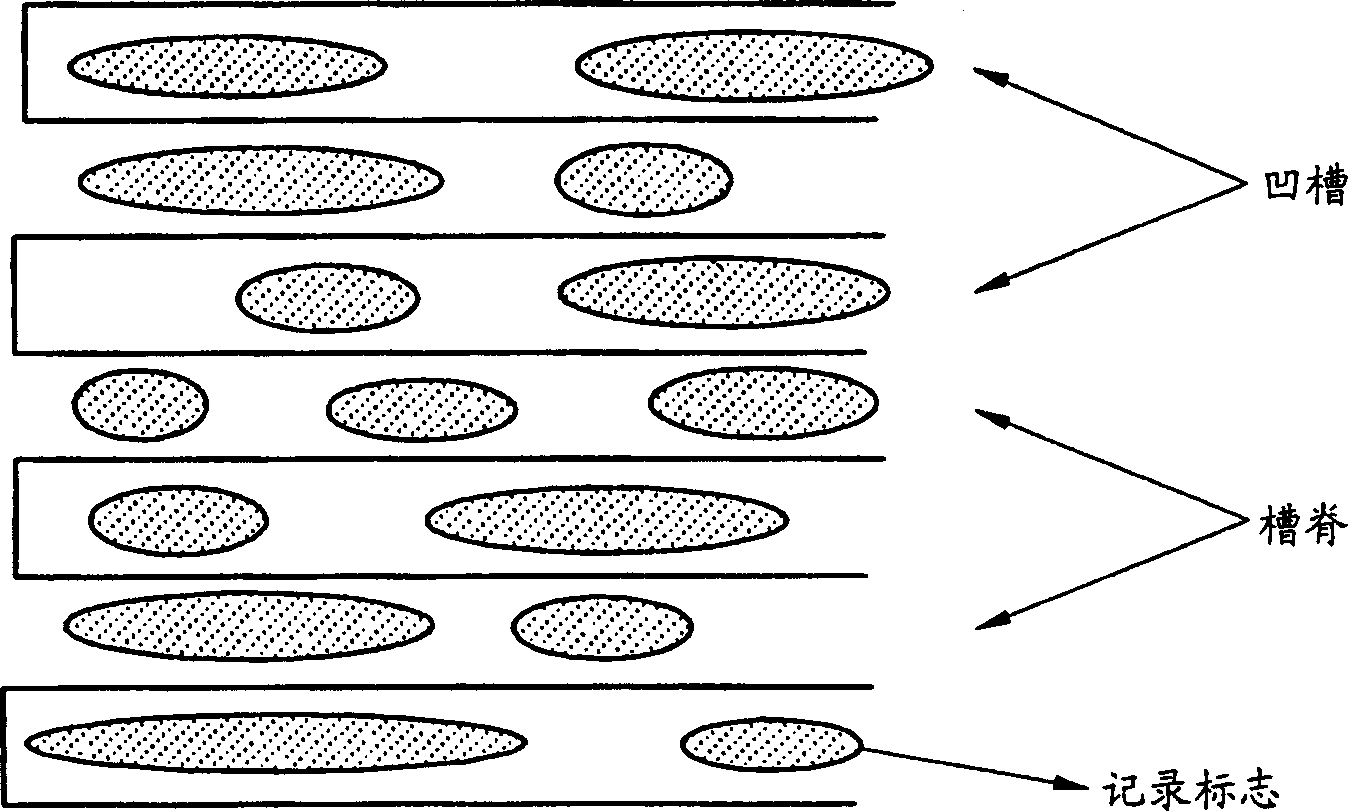

Method and device for recording data on optical recording medium

InactiveCN1441410APrevent downgradeImproved Elimination ModeInformation arrangementOptical beam sourcesComputer hardwareOptical recording

A method and apparatus for recording data on an optical recording medium are provided. In the method of recording data on the optical recording medium, a mark or a space is formed using a recording waveform having an erase pattern including a predetermined pulse whose high level is higher than an erase power level and whose low level is lower than the erase power level. Thus, the shape of the mark can be prevented from being distorted and be improved, which results in an improvement in the recording / reproducing characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

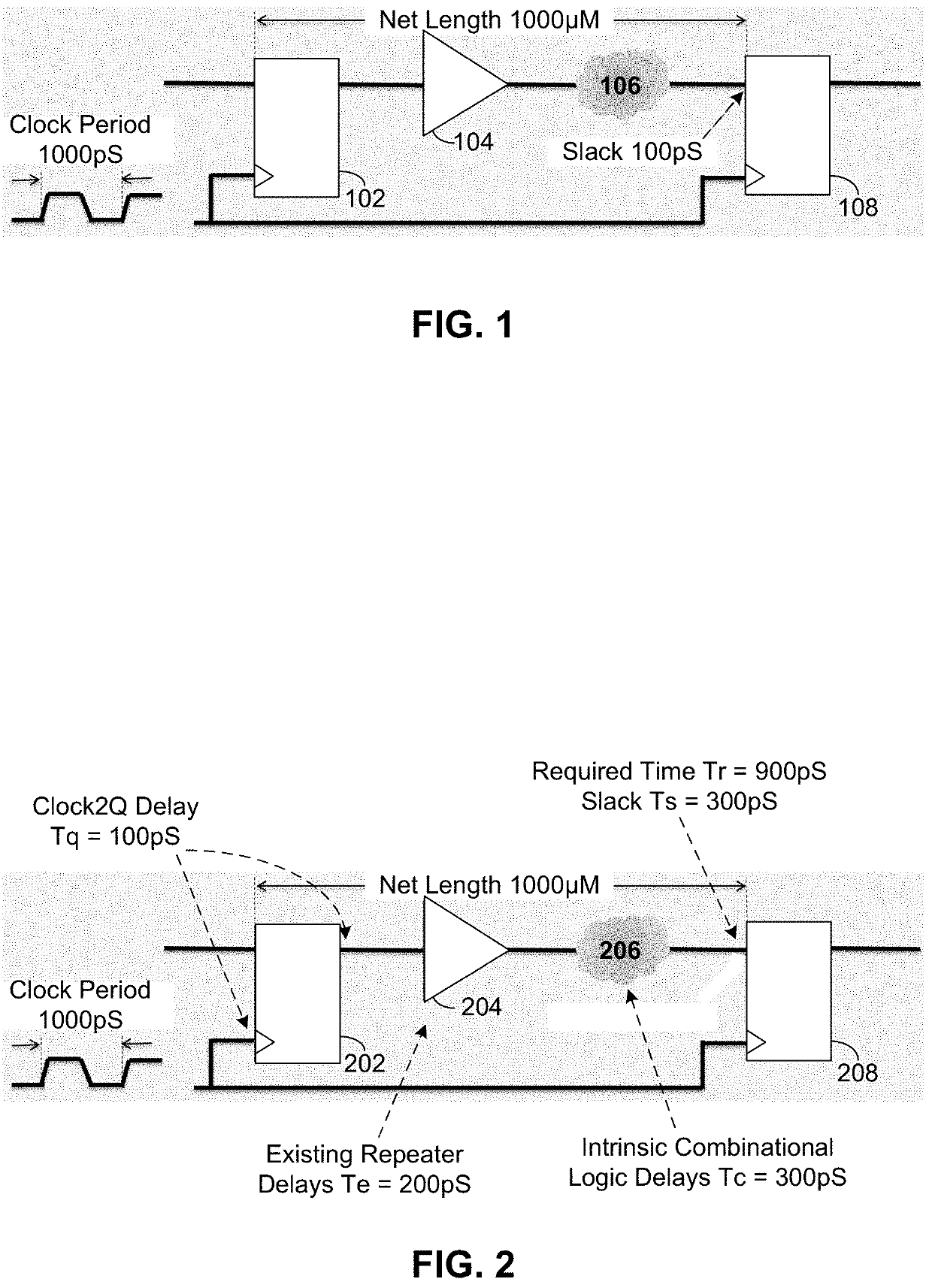

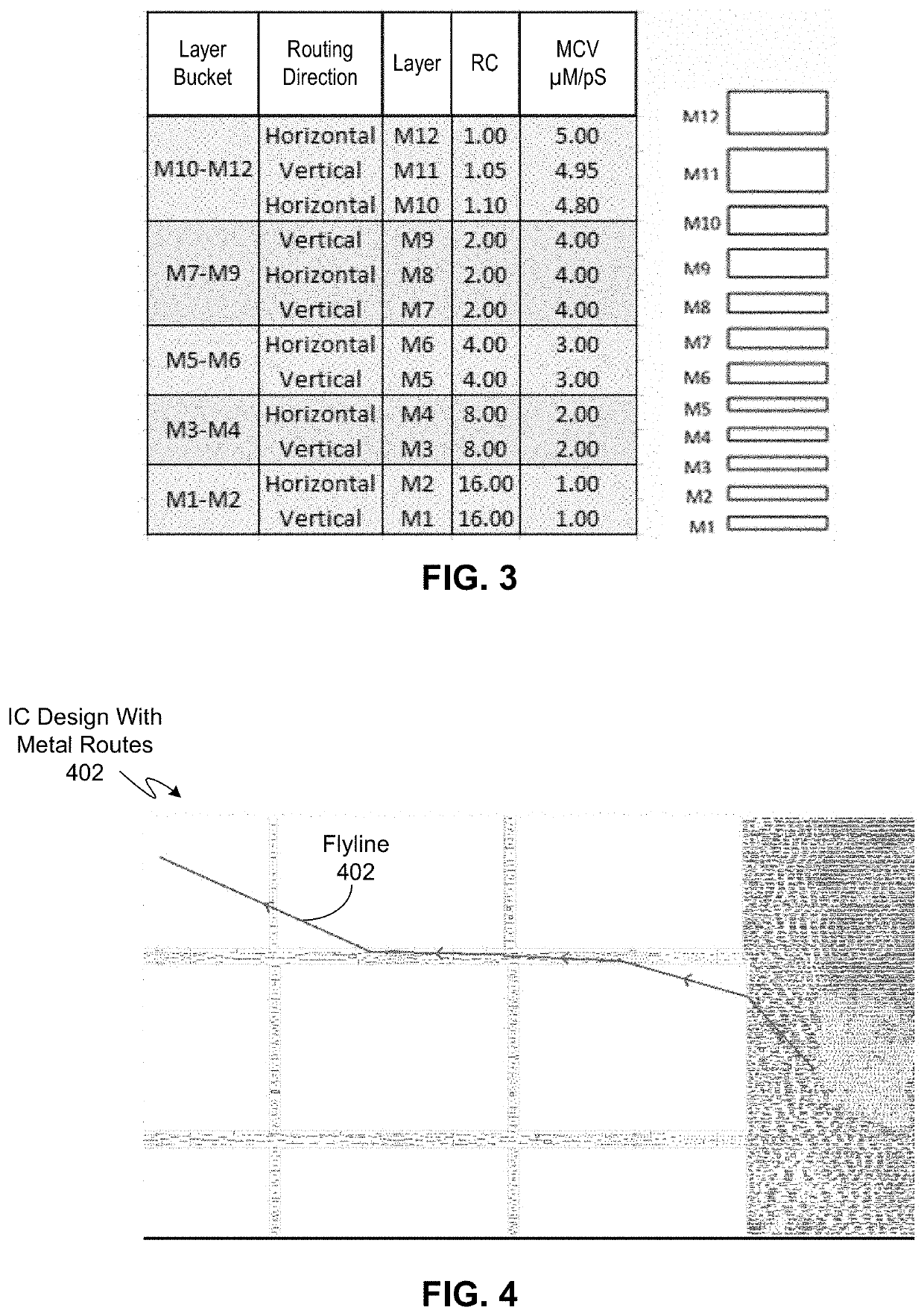

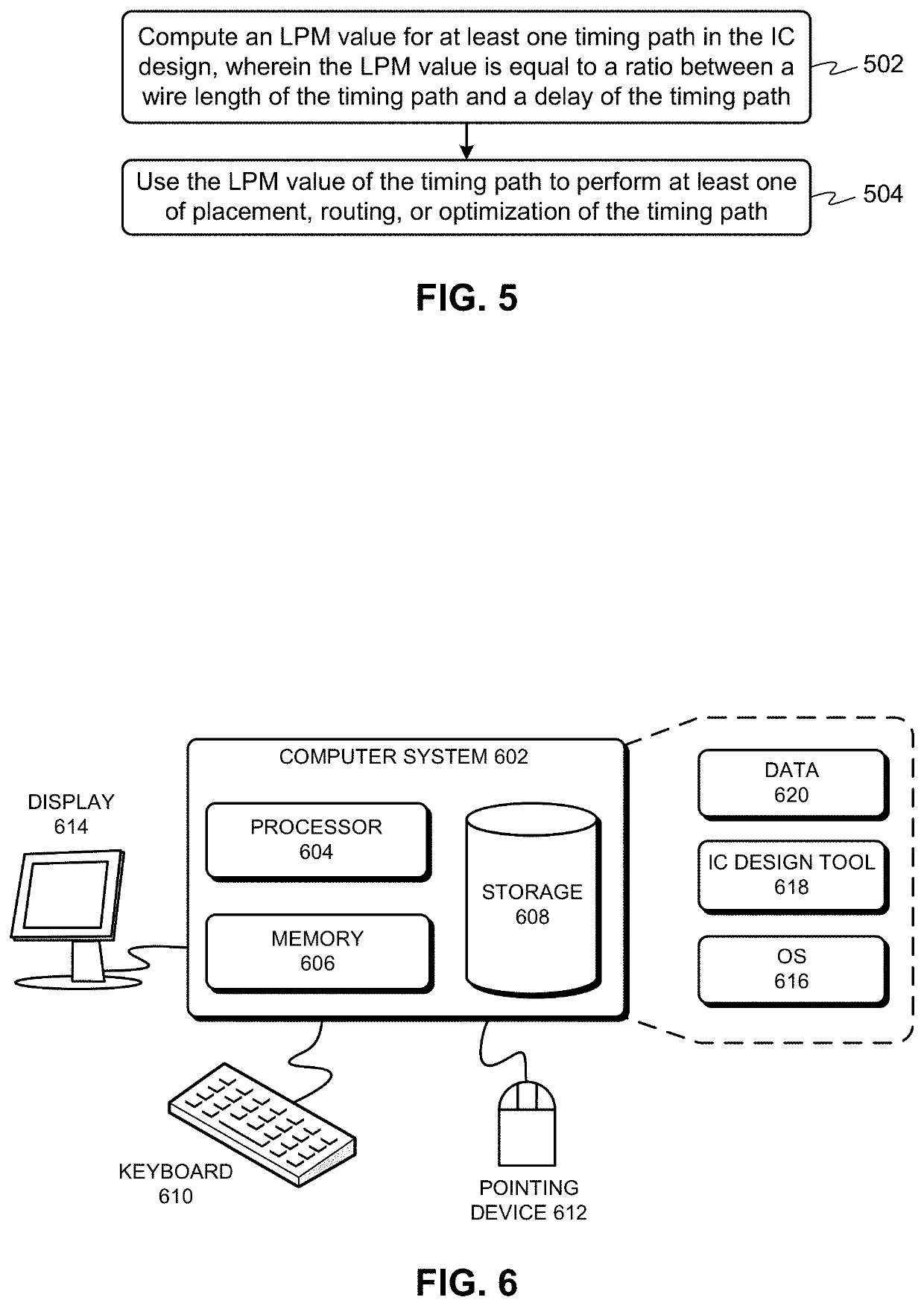

Using a layer performance metric (LPM) to perform placement, routing, and/or optimization of an integrated circuit (IC) design

ActiveUS10599882B1Improving IC designImprove manufacturing yieldCAD circuit designSpecial data processing applicationsLayoutIntegrated circuit design

Techniques and systems for using a layer performance metric (LPM) during integrated circuit (IC) design are described. Some embodiments can compute an LPM value for at least one timing path in the IC design, wherein the LPM value is equal to a ratio between a wire length of the timing path and a delay of the timing path. Next, the embodiments can use the LPM value of the timing path to perform at least one of placement, routing, or optimization of the timing path.

Owner:SYNOPSYS INC

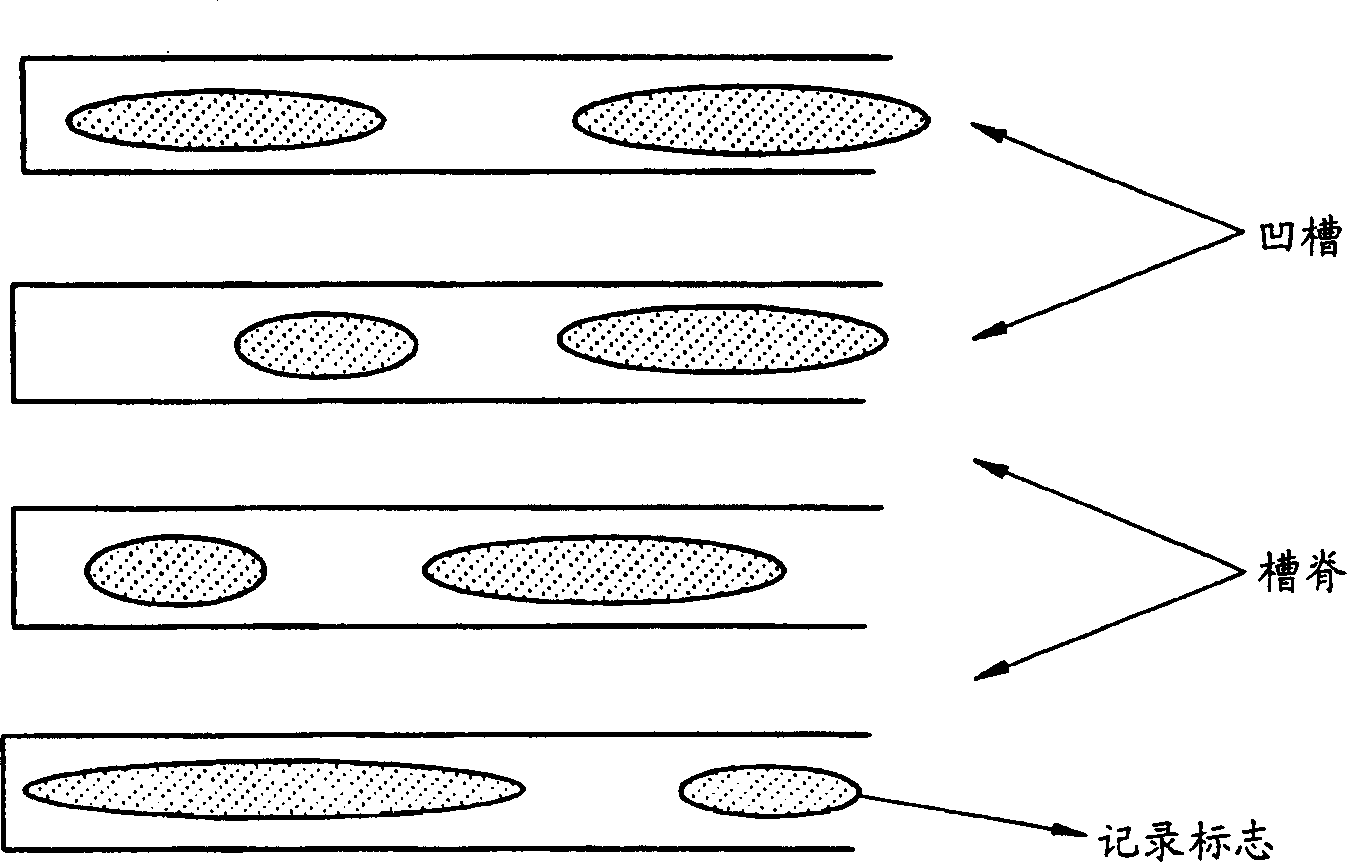

Apparatus for recording data on optical recording medium

InactiveCN1560837APrevent downgradeImproved Elimination ModeInformation arrangementOptical beam sourcesComputer hardwareLight irradiation

The invention provides a device for recording data on an optical recording medium. The device for recording data on an optical recording medium comprises a recorded-wave shape generator for generating a recorded wave shape which has a multi-pulse canceling mode, and a pick-up unit for implementing the light irradiation on an optical recording medium according to the generated recorded wave shape so as to form a label or an isolation, thereby preventing the labeled shape from deforming and improving the shape of the label, and further improving the recording and playing properties.

Owner:SAMSUNG ELECTRONICS CO LTD

Ink-jet printing defect detection method and ceramic tile production process

InactiveCN107745586AMonitor work statusEasy to monitorTypewritersOther printing apparatusBrickEngineering

The invention relates to an ink-jet printing defect detection method and a ceramic tile production process. The detection method comprises the steps of (1) designing an ink-jet printing pattern of a green body, setting color strips on at least one side of the pattern, wherein the color strips comprise monochromatic strips or / and colored strips, the color of the monochromatic strips is the color ofa single color channel in an ink-jet printer, and the color of the colored strips is permutation and combination of colors of multiple color channels, and acquiring a pattern with the color strips; (2) performing ink-jet printing, that is, ink-jet printing the pattern with the color strips on the surface of a tile blank; and (3) distinguishing the grayscale, that is, distinguishing whether the grayscale of the same color in the color strips printed at the surface of the tile blank is consistent or not, wherein it is indicated that the ink-jet printer has a fault if the grayscale of a part ishigh or low, and performing detection and adjustment on the ink-jet printer. According to the detection method provided by the invention and the ceramic tile production process, the monitoring is simpler and easier, the efficiency of ink-jet printing is improved, a problem of degradation of a large quantity of products is avoided, and the product quality is improved.

Owner:FOSHAN DONGPENG CERAMIC +2

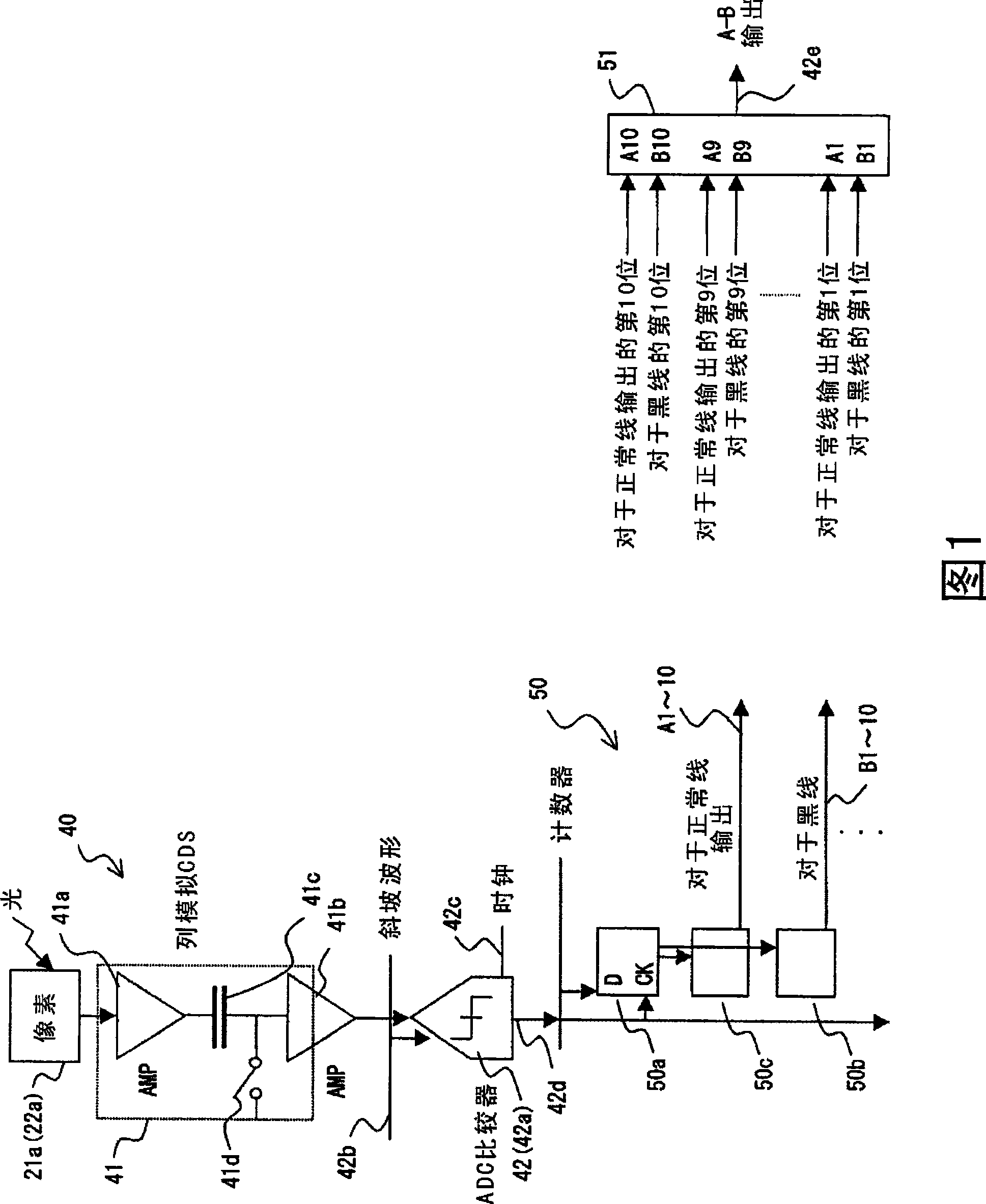

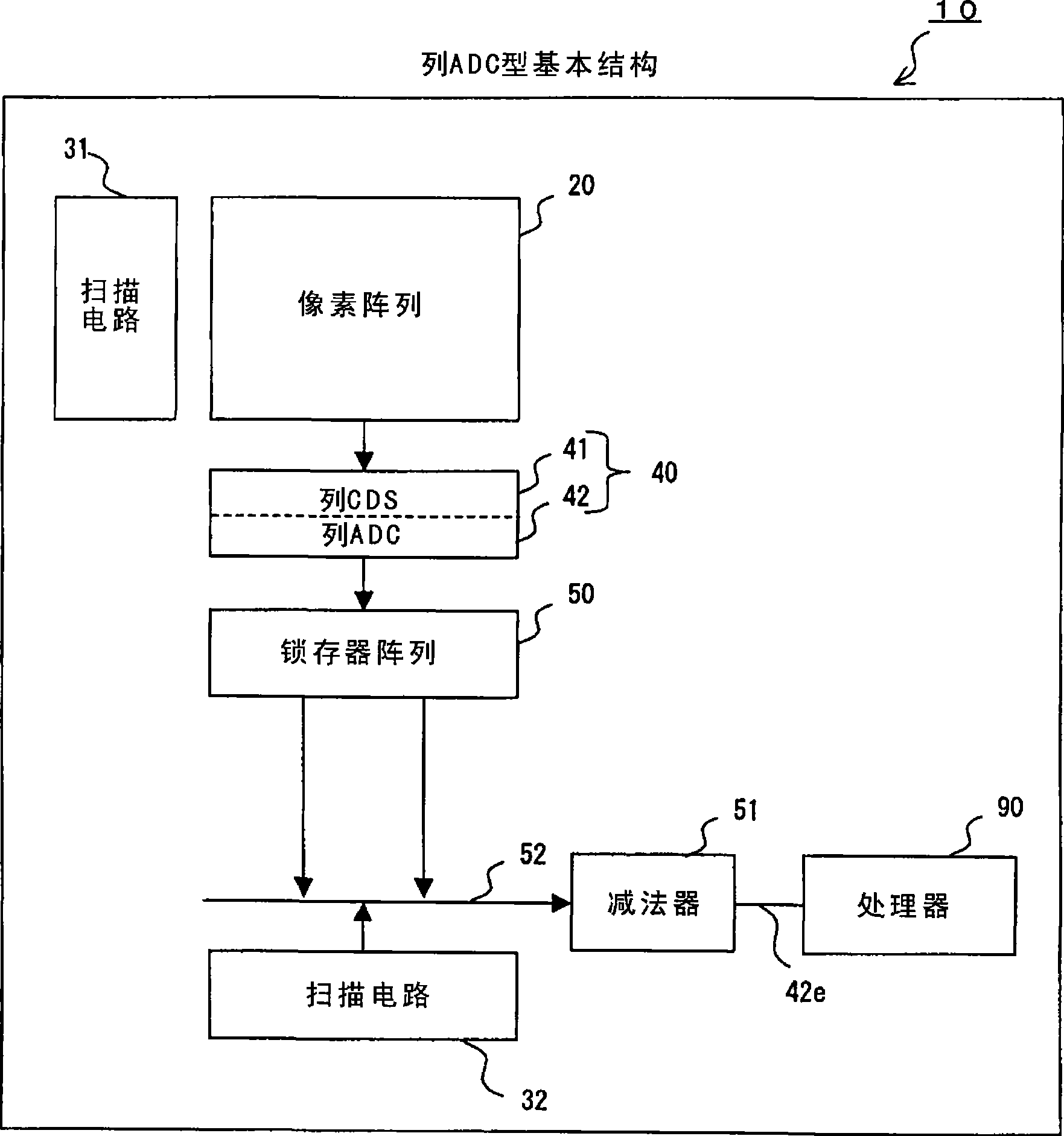

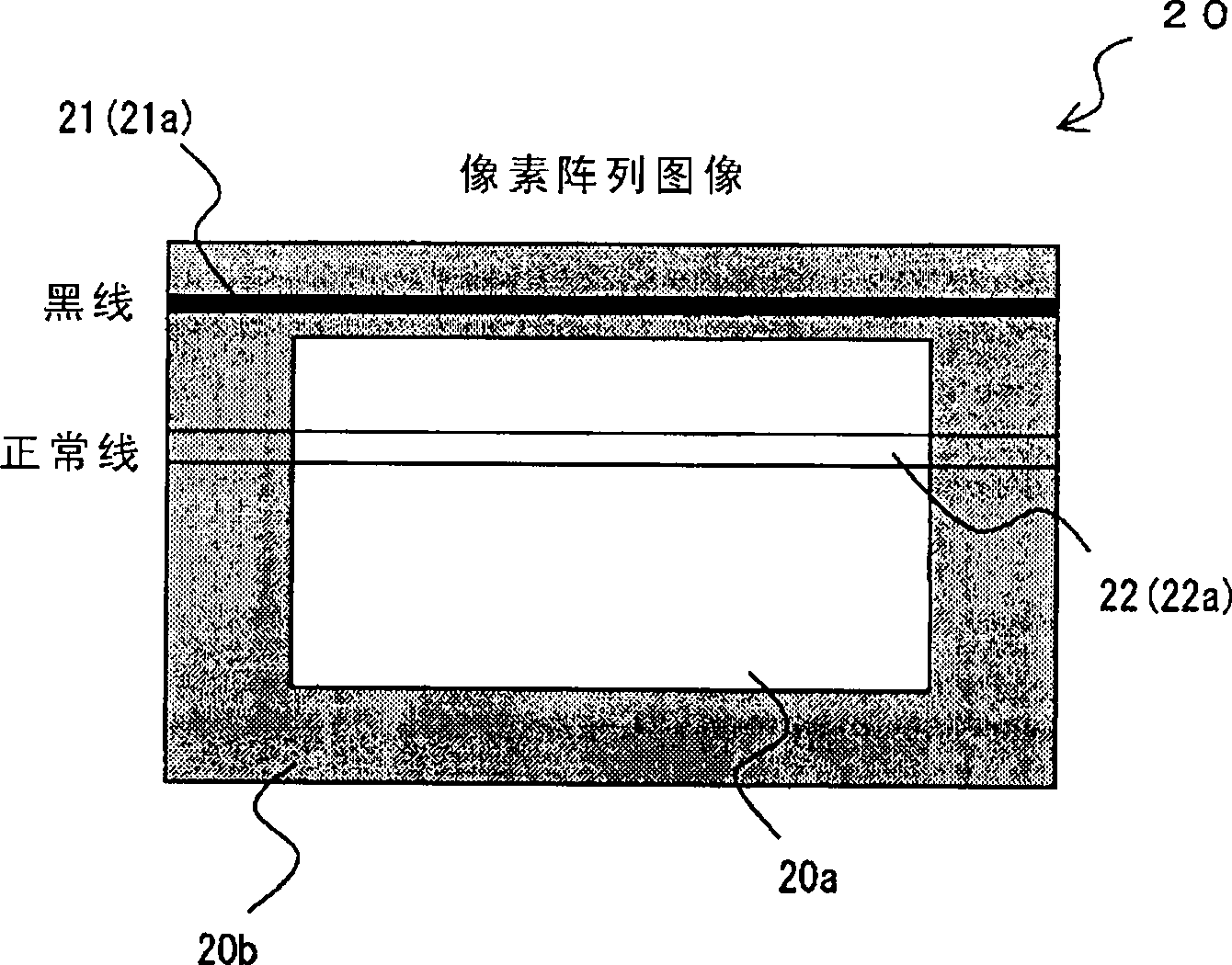

Imaging device, control method thereof and CMOS image sensor

InactiveCN101415072APrevent downgradeTelevision system detailsColor television detailsCMOSOptical probing

Owner:SOCIONEXT INC

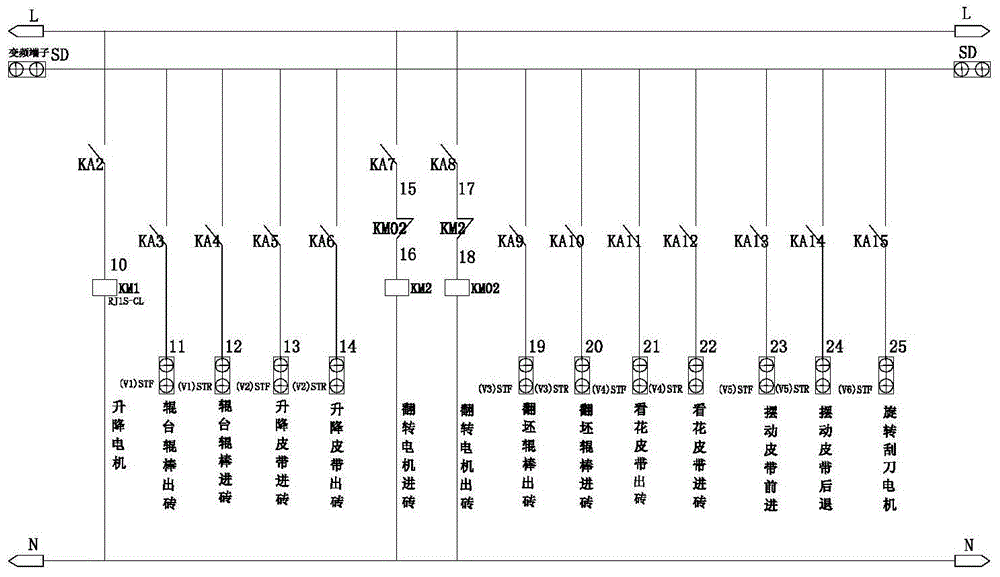

Automatic scratching control method for micropowder polished tile blank

ActiveCN104690813ATimely discovery of color abnormalitiesImprove detection efficiencyCeramic shaping apparatusProduction lineBrick

The invention relates to an automatic scratching control method for a micropowder polished tile blank. The method adopts a controller and segmented program control, and includes timed / manually-started automatic sending-out scratching control as follows: according to a tile feeding command, a glaze line lifting platform separates a tile blank from a production line and conveys the tile blank to a conveying platform; according to a conveying command, the conveying platform forwardly conveys the tile blank to an overturning mechanism; according to an overturning command, the overturning mechanism overturns the tile blank for the first time; according to a conveying command, the conveying platform forwardly conveys the tile blank to a scratching mechanism; according to a scratching command, the scratching mechanism drives an inner cutter head to scratch the tile blank back and forth in a rotating manner; according to a conveying command, the conveying platform sends the tile blank out of the scratching mechanism; according to an observing command, a drying mechanism lifts up an upper lampshade and turns on a lampshade for illuminating / drying; the automatic scratching control method further comprises manually-started sending-back control. According to the segmented program control method, through the segmented program control, manpower is reduced, operation mistakes and errors are avoided at the same time, and the inspecting efficiency and the inspecting result of blank spot inspection in ceramic tile production are greatly improved.

Owner:JIANGXI HEMEI CERAMICS

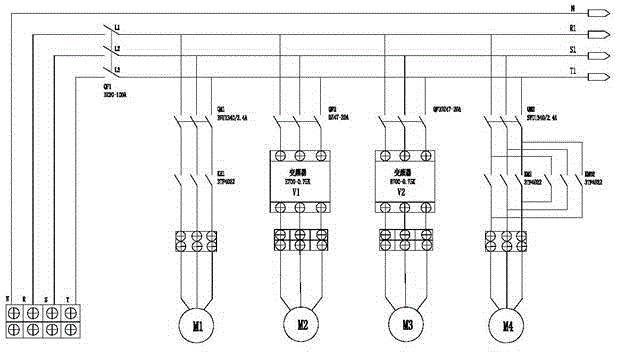

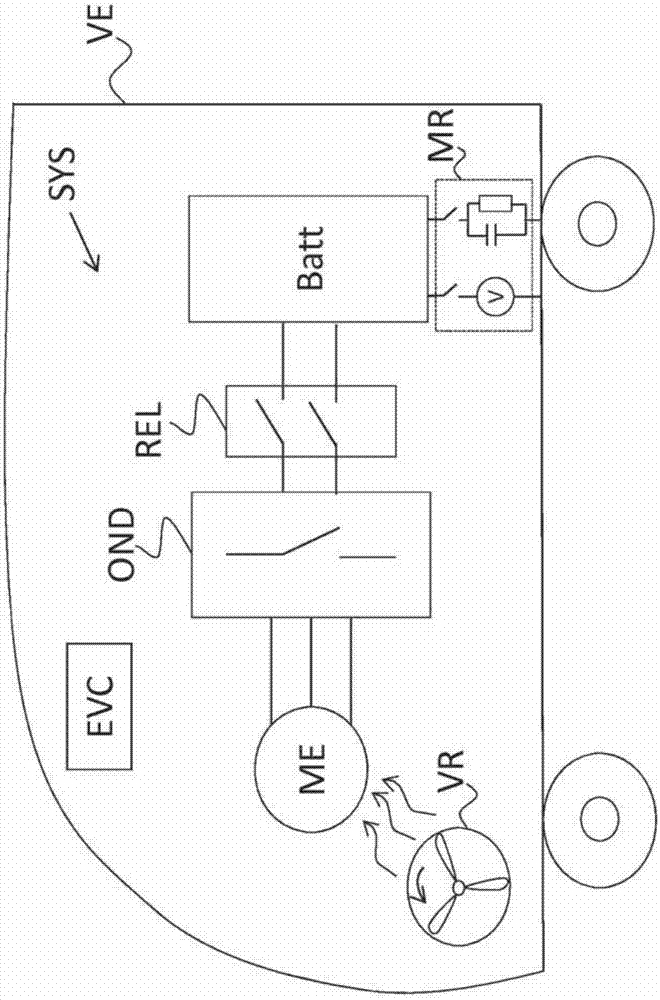

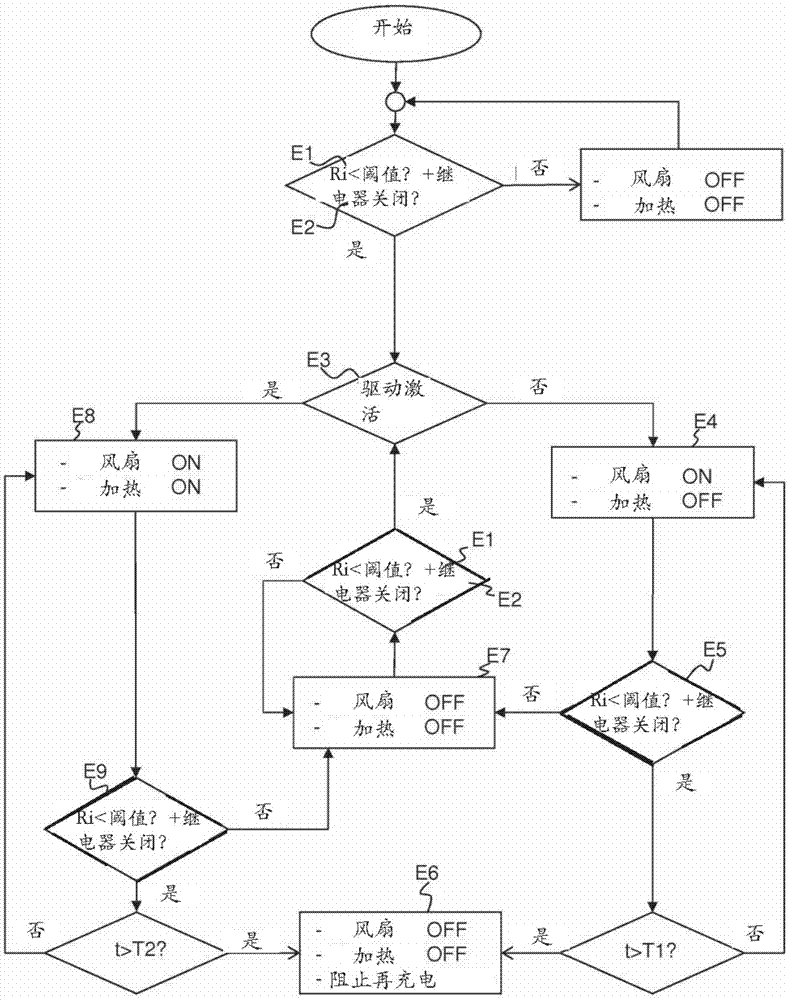

Method for controlling electric traction system and corresponding electric traction system

ActiveCN105492234BPrevent downgradeEasy to useSpeed controllerElectric devicesElectrical resistance and conductanceElectricity

A method controls an electric drive system of a vehicle including an electric drive motor, a drive battery, and a drive inverter. The method includes detecting that a measurement of an insulation resistance between the battery and a chassis of the vehicle is below a preset threshold, detecting a closed state of relays connecting the battery to the inverter, and following the detecting the measurement and the detecting the closed state, activating a cooling fan of the electric drive motor until detecting that a measurement of the insulation resistance is above the preset threshold, within a limit of a first preset duration.

Owner:RENAULT SA

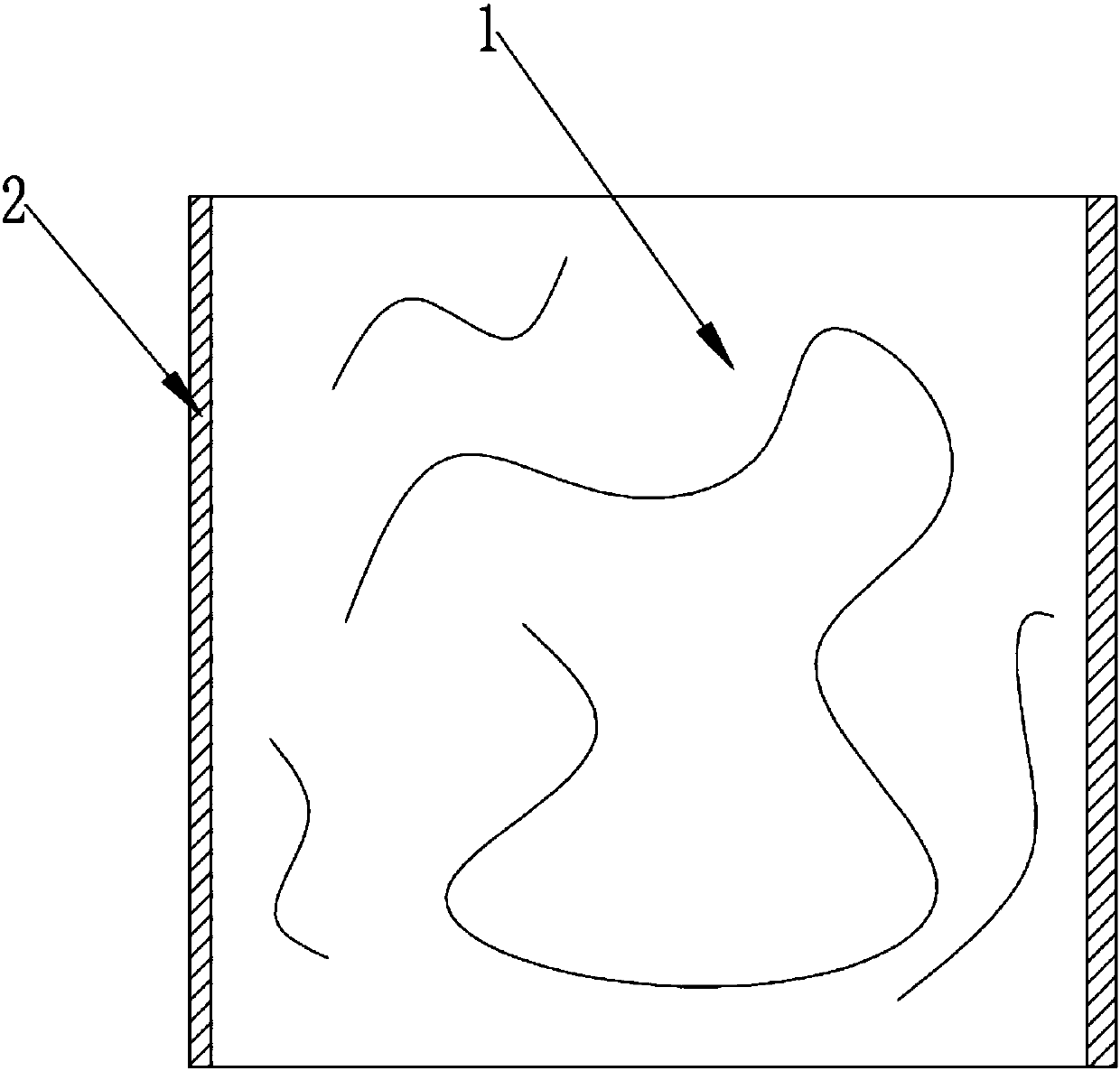

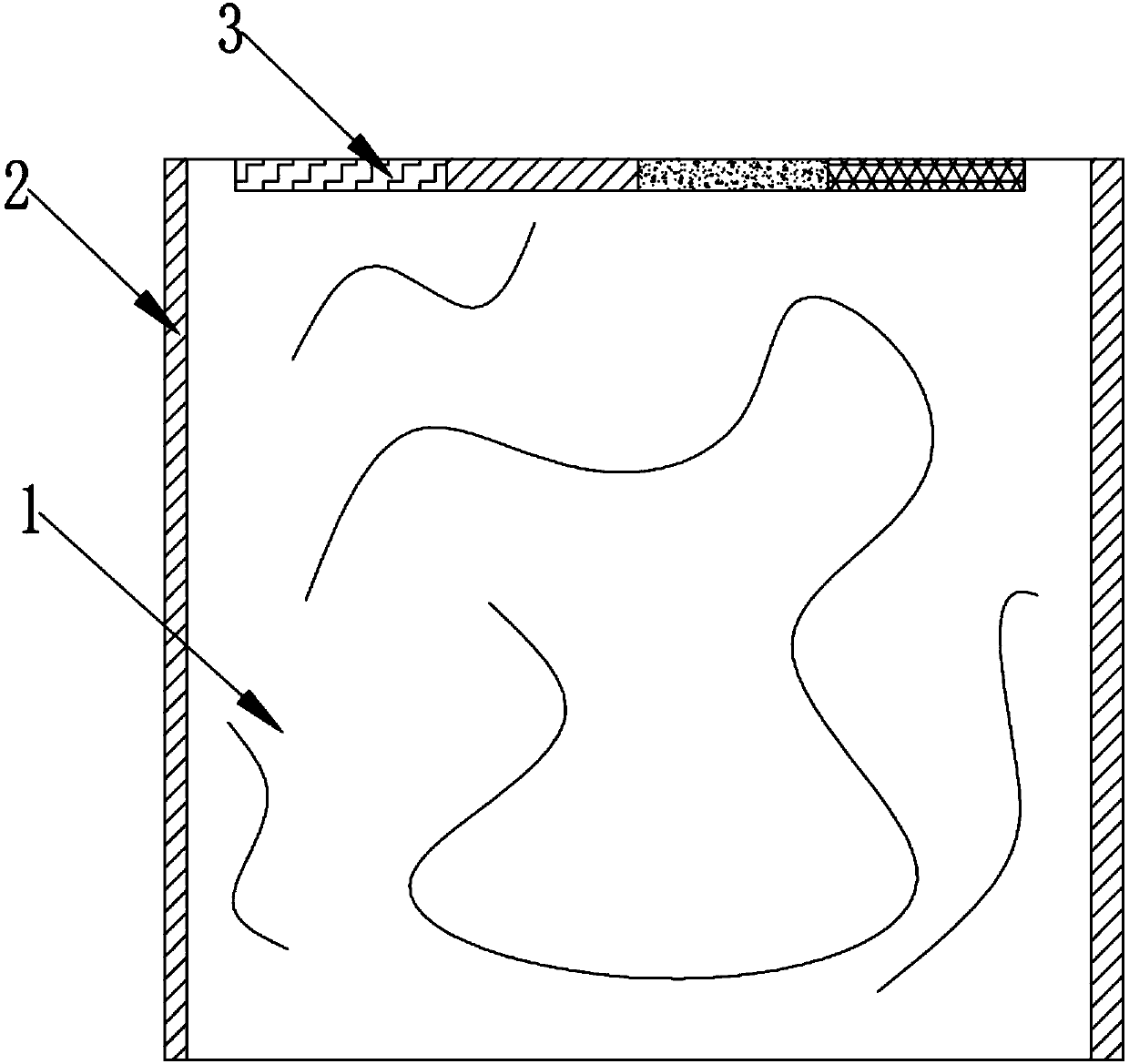

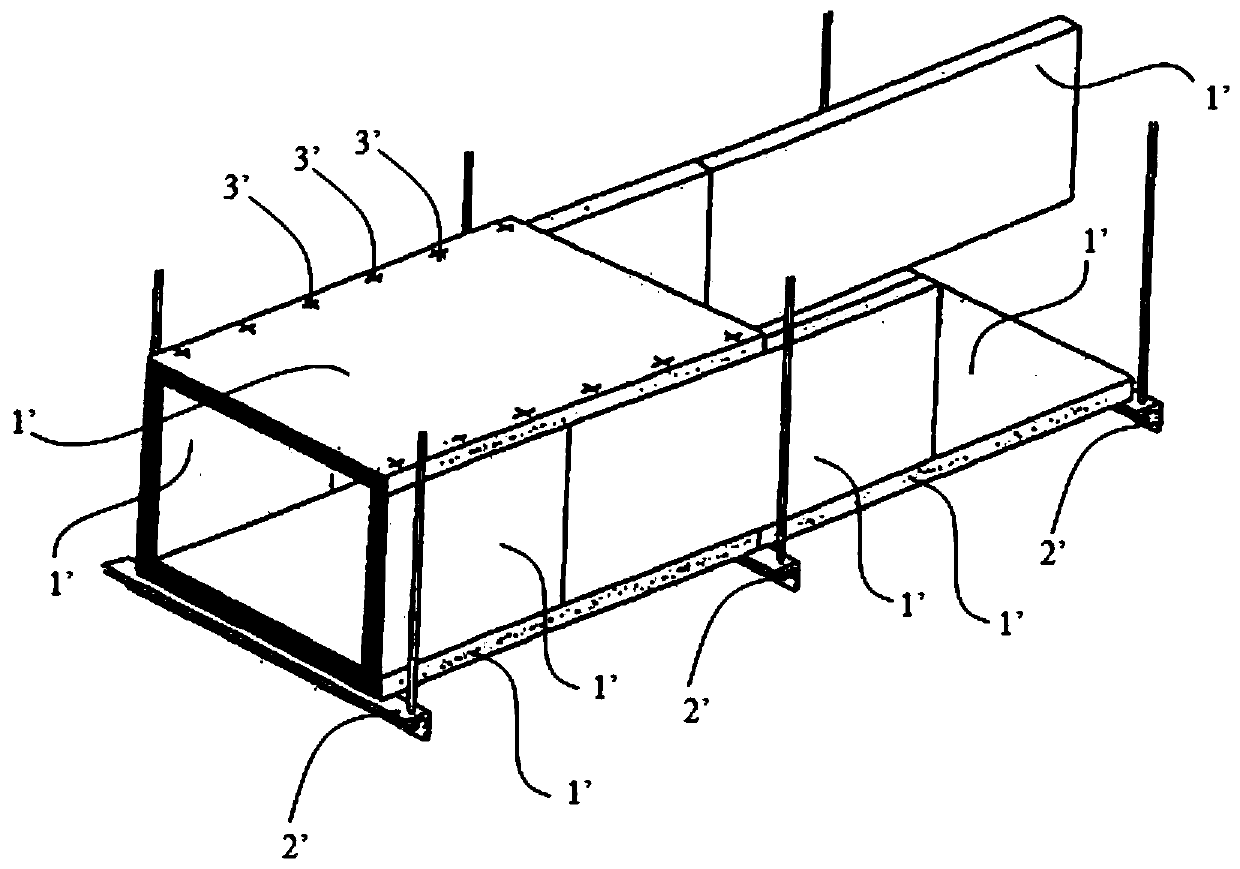

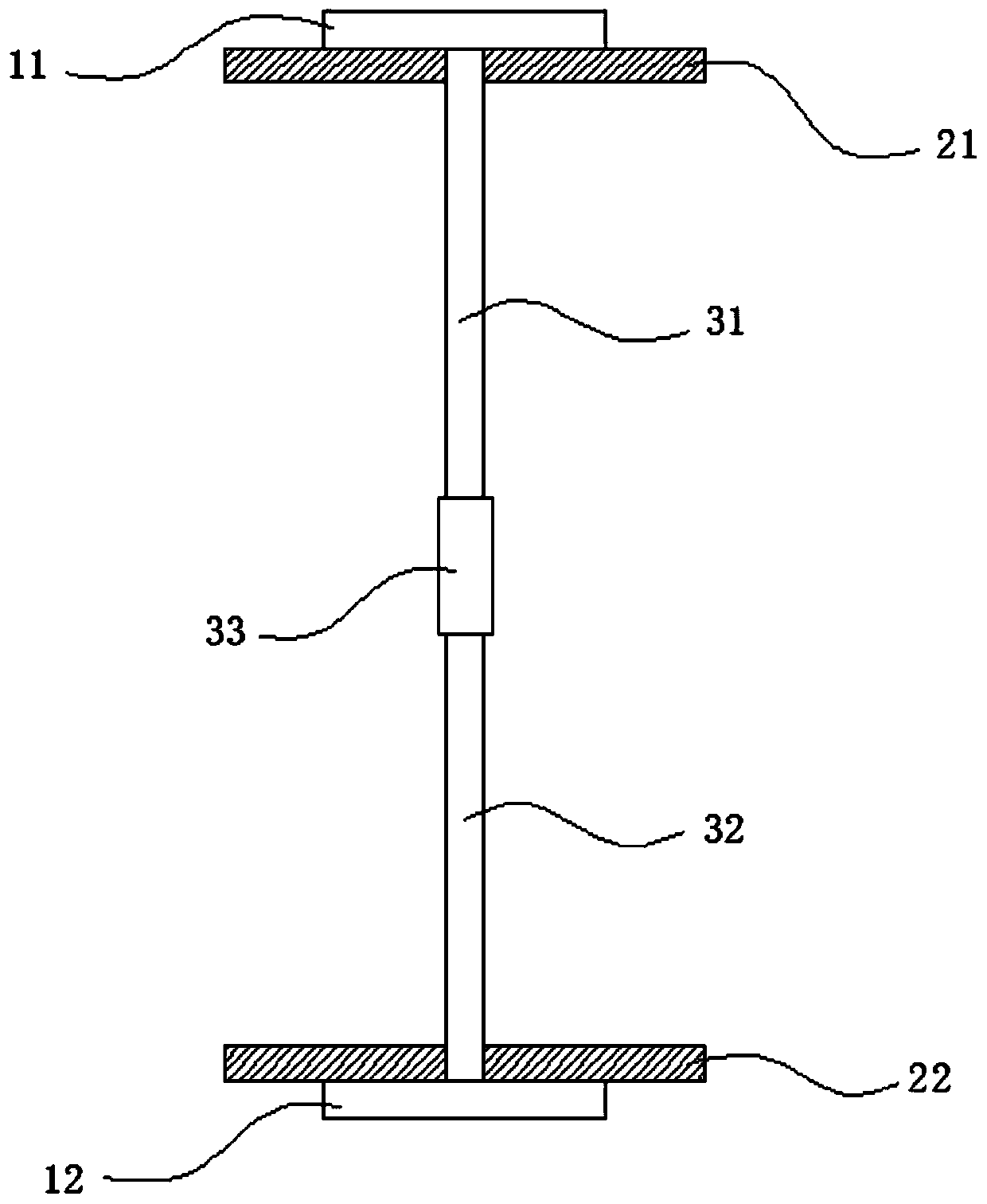

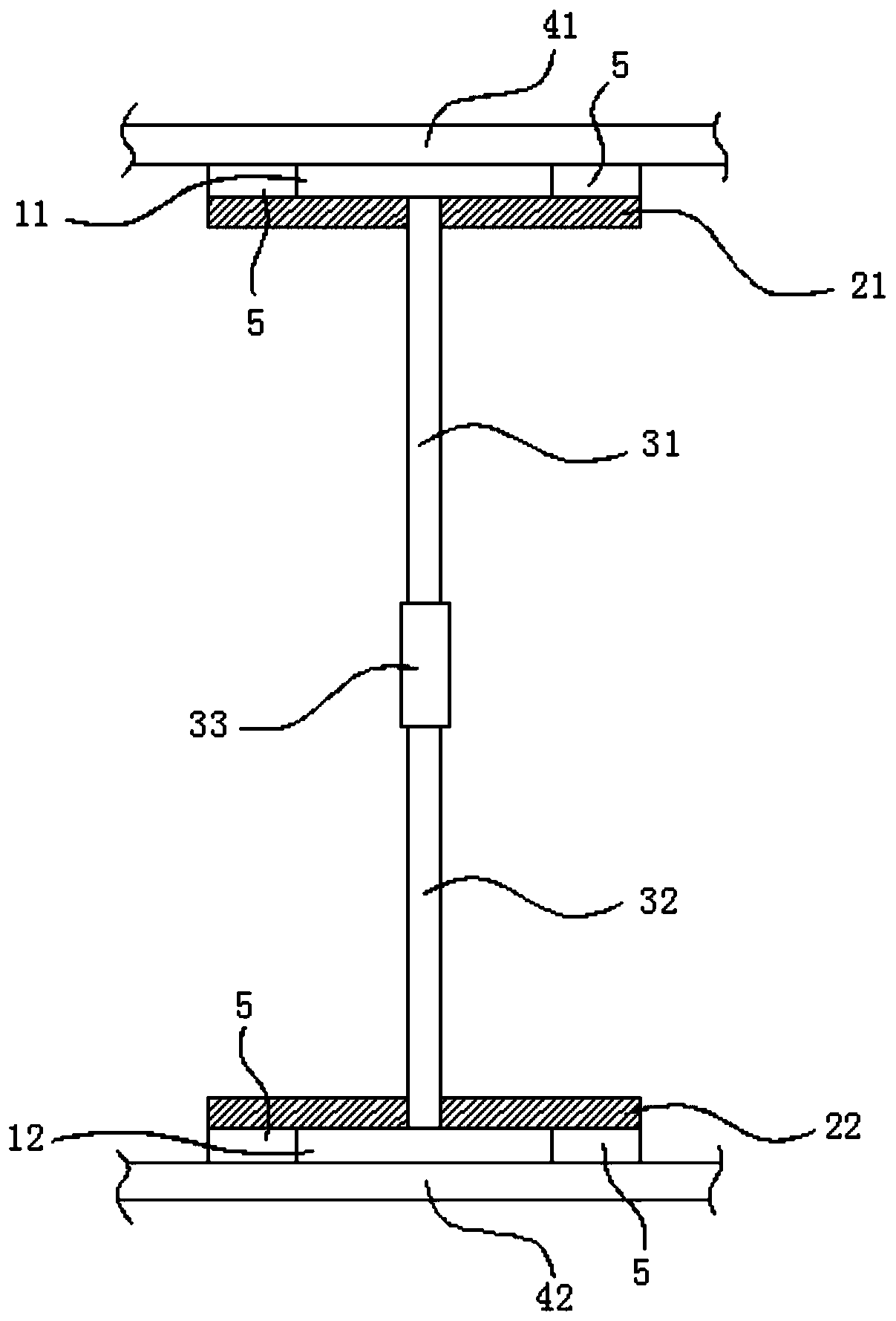

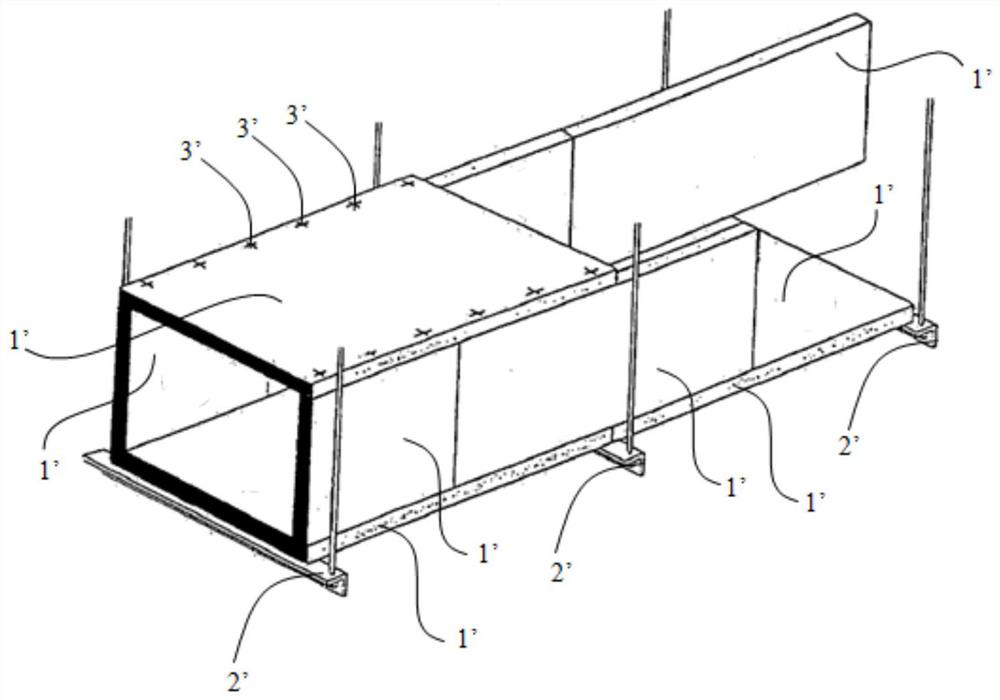

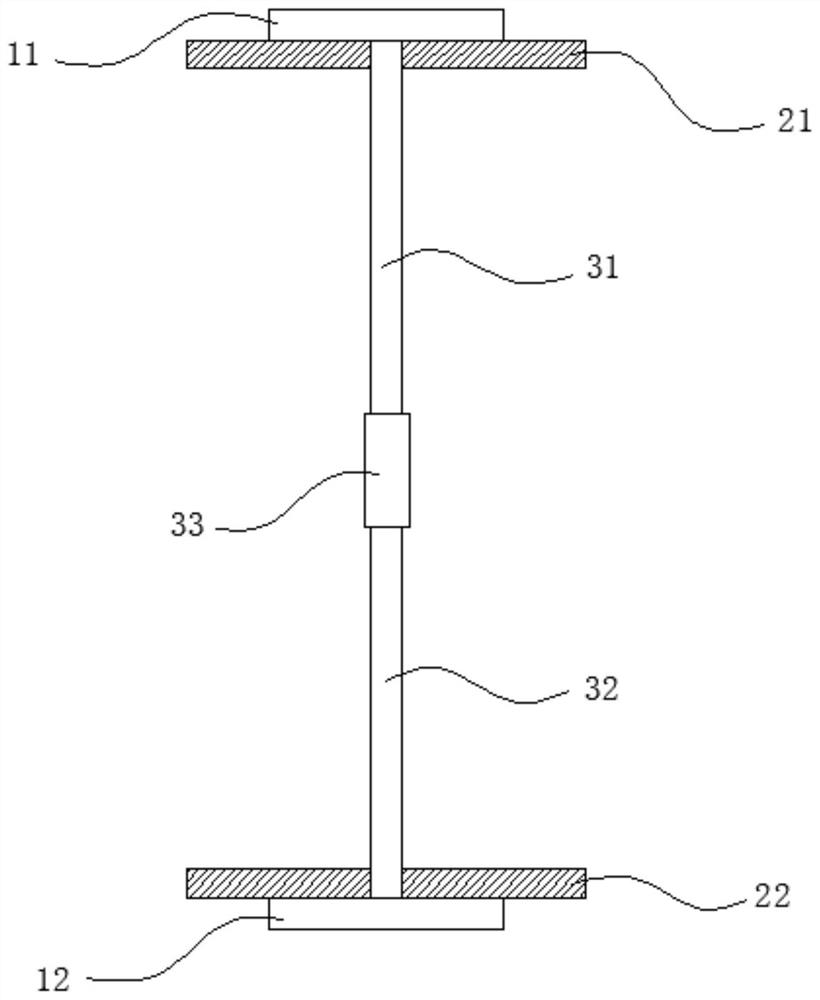

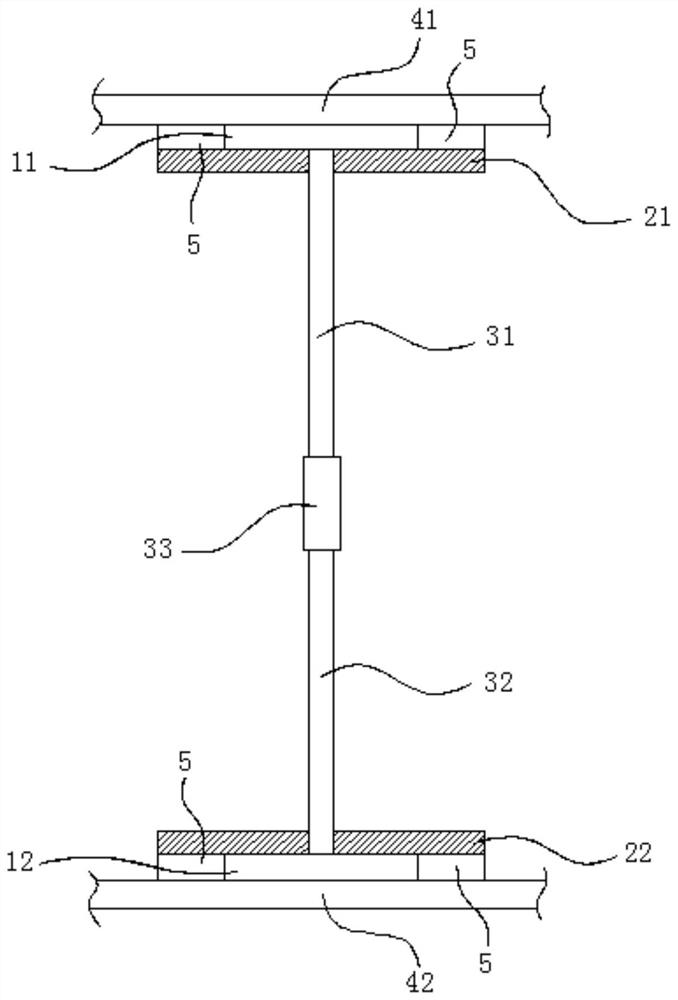

Reinforcing device for fire-resistant air pipe for nuclear power and fire-resistant air pipe

The invention discloses a reinforcing device for a fire-resistant air pipe for nuclear power and a fire-resistant air pipe. The reinforcing device comprises an upper top plate, a lower top plate, an upper supporting rod, a lower supporting rod, an intermediate connecting rod, an upper mounting plate and a lower mounting plate; the upper end of the upper supporting rod is connected with the upper top plate, and the lower end of the upper supporting rod penetrates through the upper mounting plate and is connected with the upper end of the intermediate connecting rod in an adjustable mode; the lower end of the lower supporting rod is connected with the lower top plate, and the upper end of the lower supporting rod penetrates through the lower mounting plate and is connected with the lower endof the intermediate connecting rod in an adjustable mode; the size of the upper mounting plate in at least one dimension is larger than the size of the upper top plate in the corresponding dimension;the size of the lower mounting plate in at least one dimension is larger than the size of the lower top plate in the corresponding dimension; the upper top plate and the lower top plate abut againstthe top wall and the bottom wall in the fire-resistant air pipe correspondingly; and the upper mounting plate and the lower mounting plate are correspondingly fixed with the top wall and the bottom wall in the fire-resistant air pipe. According to the reinforcing device, the fire-resistant air pipe is effectively supported, the strength of the fire-resistant air pipe is strengthened, and the integrity of a ventilation system is ensured.

Owner:SUZHOU NUCLEAR POWER RES INST +2

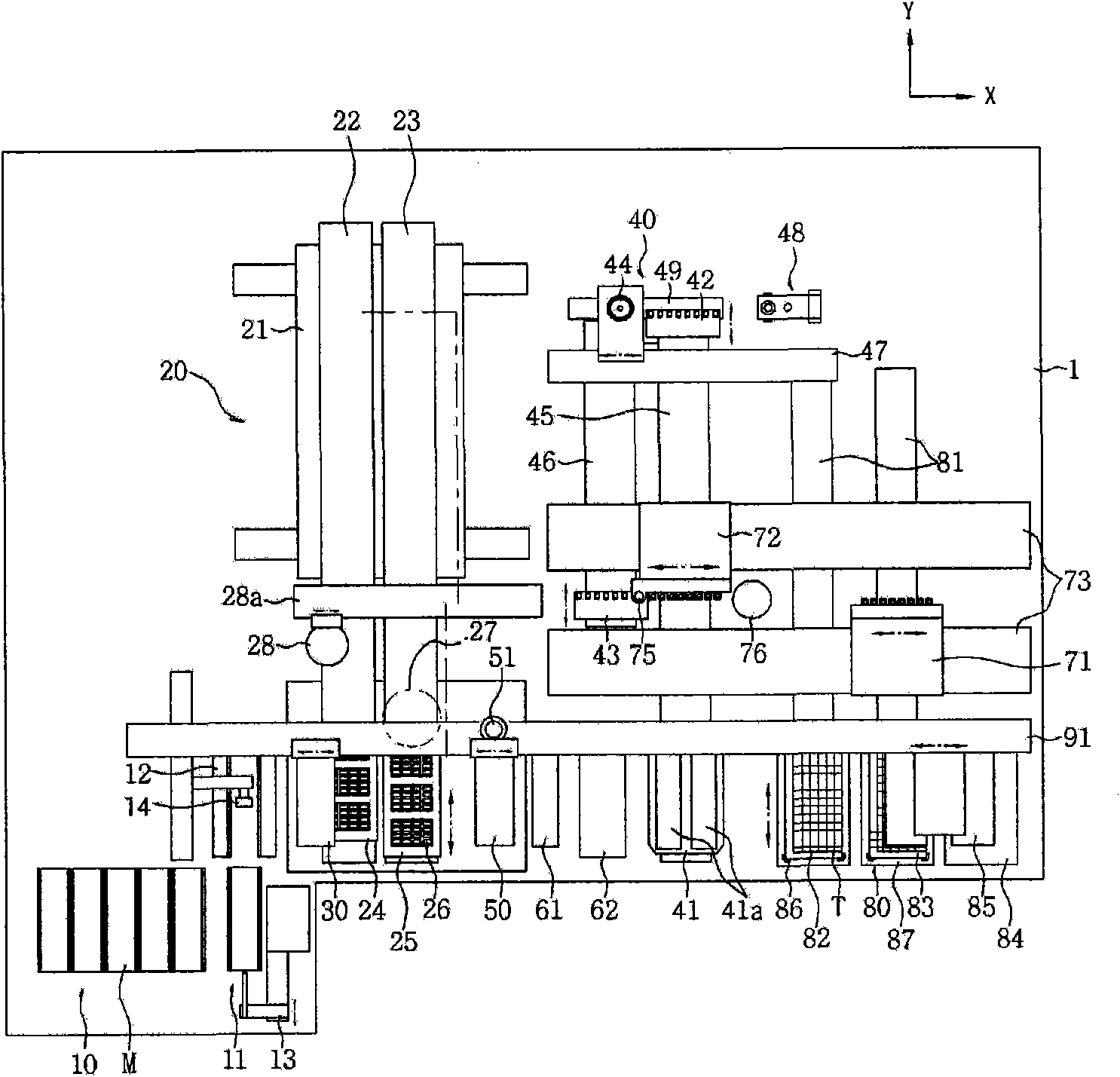

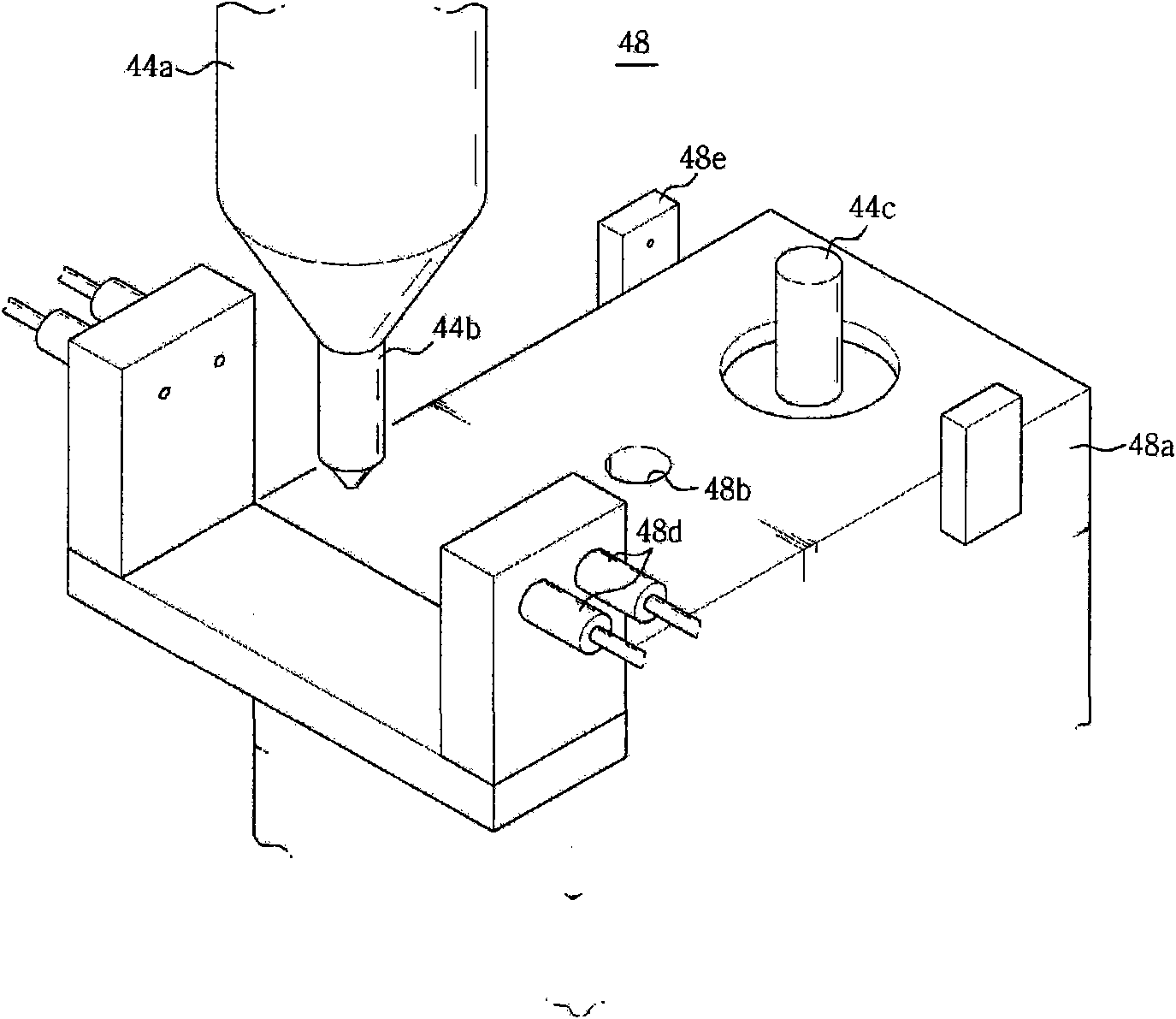

Apparatus for cutting processing memory card

ActiveCN101802997AReduce manufacturing costs and time required for cutting operationsImprove productivityConveyor partsMemory cards

Disclosed is a memory card processing apparatus capable of conducting overall outline processing and chamfer processing of memory cards having a nonlinear portion by a single piece of equipment in a rapid and efficient manner. The apparatus includes a strip loading unit supplied with strips having a plurality of memory cards arranged on a frame; an outline processing unit for cutting the memory cards on the strip delivered from the strip loading unit along an outline so that the memory cards are singulated; a strip delivery picker for delivering the strip from the strip loading unit to the outline processing unit; a chamfer processing unit for processing a slanted chamfer on a lateral edge portion of the memory cards delivered from the outline processing unit; a unit picker for delivering the memory cards, outline processing of which has been completed, from the outline processing unit to the chamfer processing unit; an unloading unit for placing the memory cards, chamfer processing of which has been completed, delivered from the chamfer processing unit on a designated tray; and an unloading picker for delivering the memory cards from the chamfer processing unit to the unloading unit.

Owner:HANMI SEMICON CO LTD

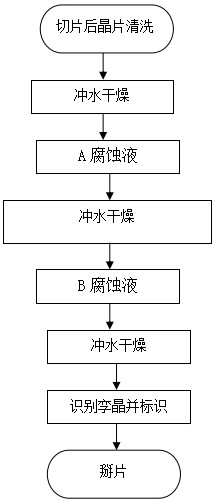

Gallium antimonide wafer processing method

PendingCN114267576APrevent downgradeOvercome expensiveSemiconductor/solid-state device manufacturingGallium antimonideWafering

The invention provides a method for processing a gallium antimonide wafer, which comprises the following steps of: S1, cleaning the sliced and cleaned gallium antimonide wafer, and removing cutting fluid on the surface of the gallium antimonide wafer; s2, the surface of the gallium antimonide wafer is washed and dried; s3, cleaning the gallium antimonide wafer by using a corrosive liquid A, wherein the corrosive liquid A is composed of an alkaline substance and an oxide; s4, cleaning the gallium antimonide wafer by using a corrosive liquid B, wherein the corrosive liquid B is composed of an acid solution and a buffer solution; s5, the surface of the gallium antimonide wafer is washed and dried; and S6, observing the surface of the gallium antimonide wafer under a fluorescent lamp and marking twin crystal distribution. The processing method is high in preferred corrosion stability, good in repeatability and controllable in corrosion speed, the crystal twin position of the corroded wafer is clear and can be well recognized, and therefore the accuracy and efficiency of wafer breaking are improved.

Owner:广东先导微电子科技有限公司

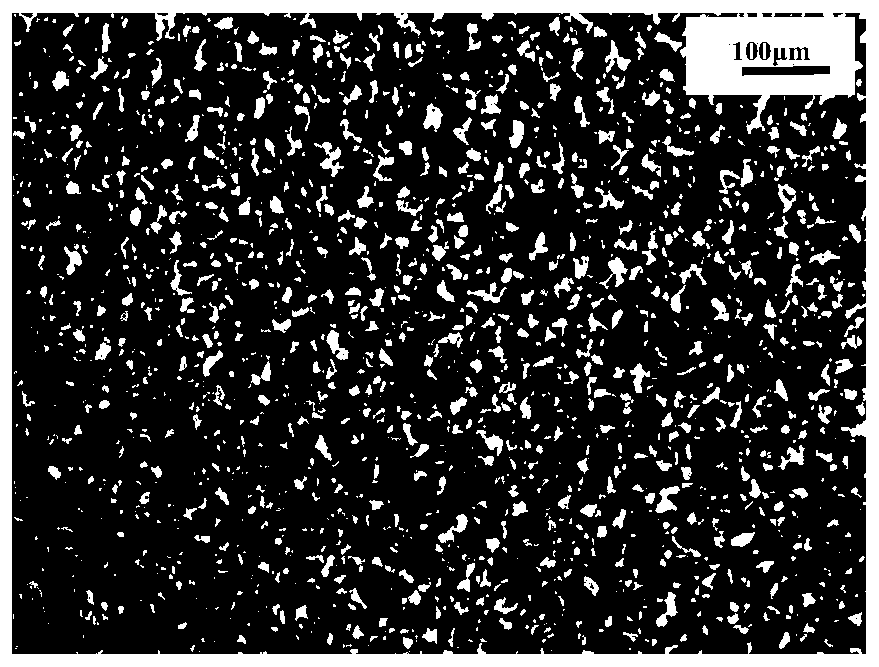

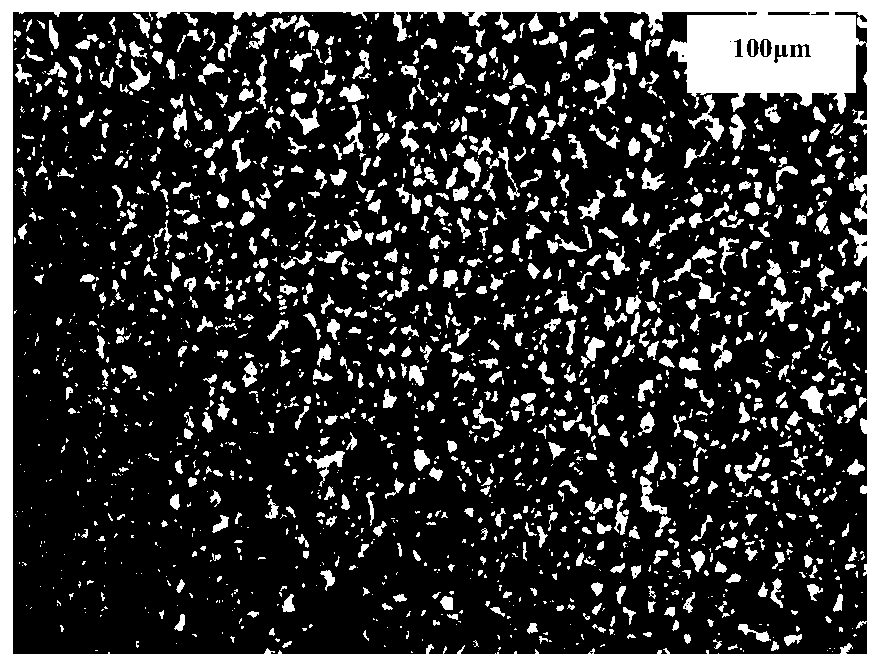

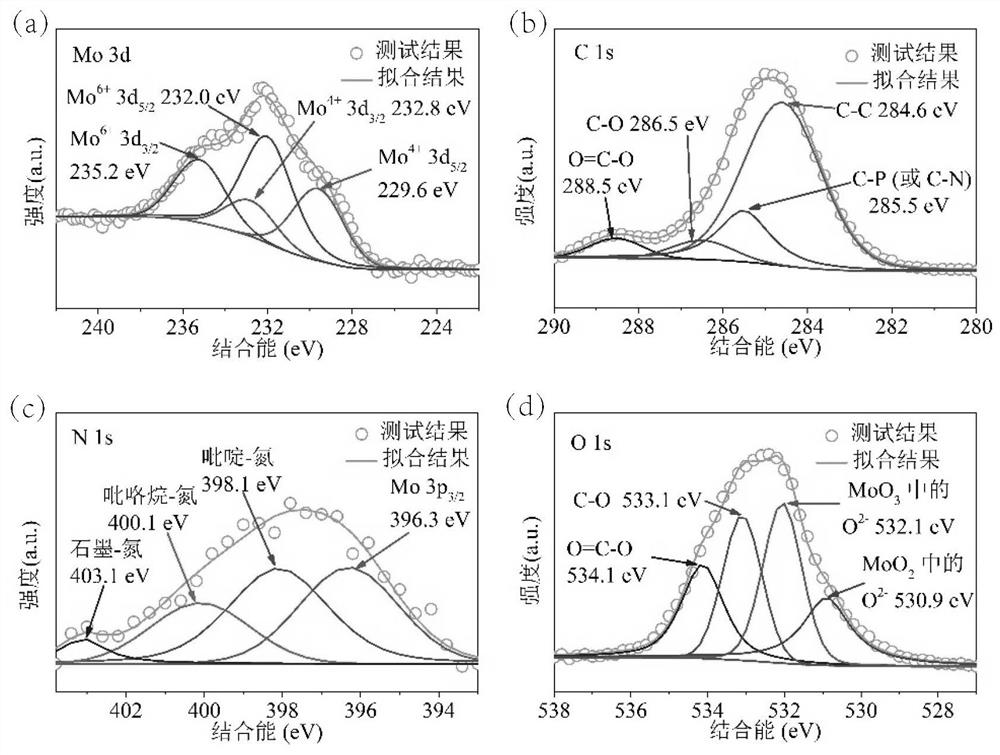

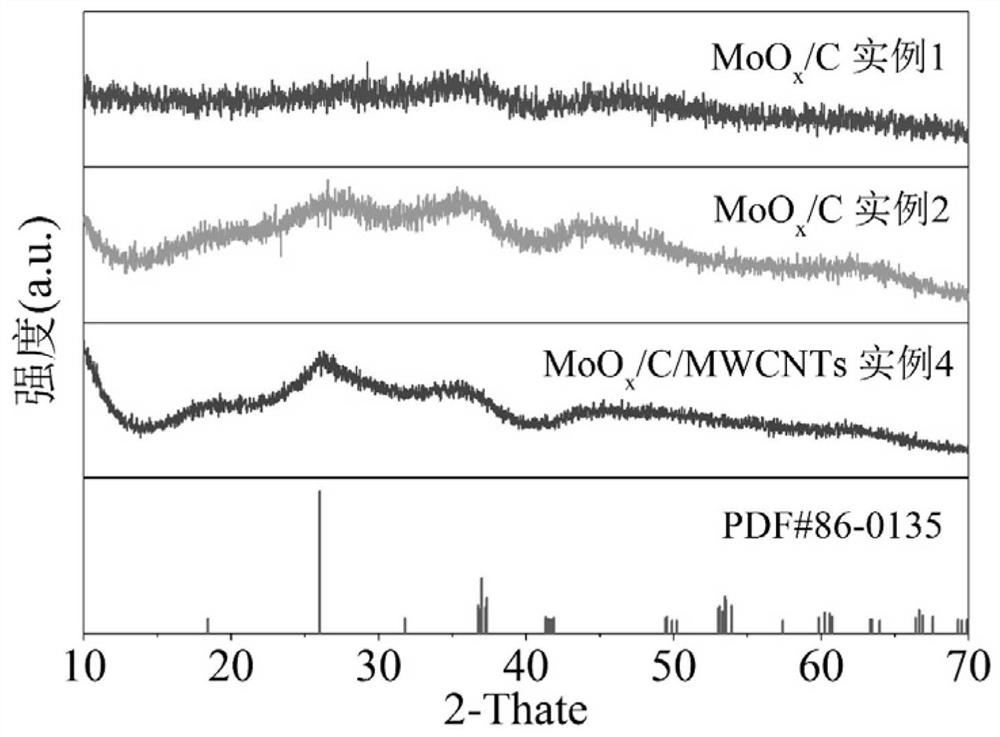

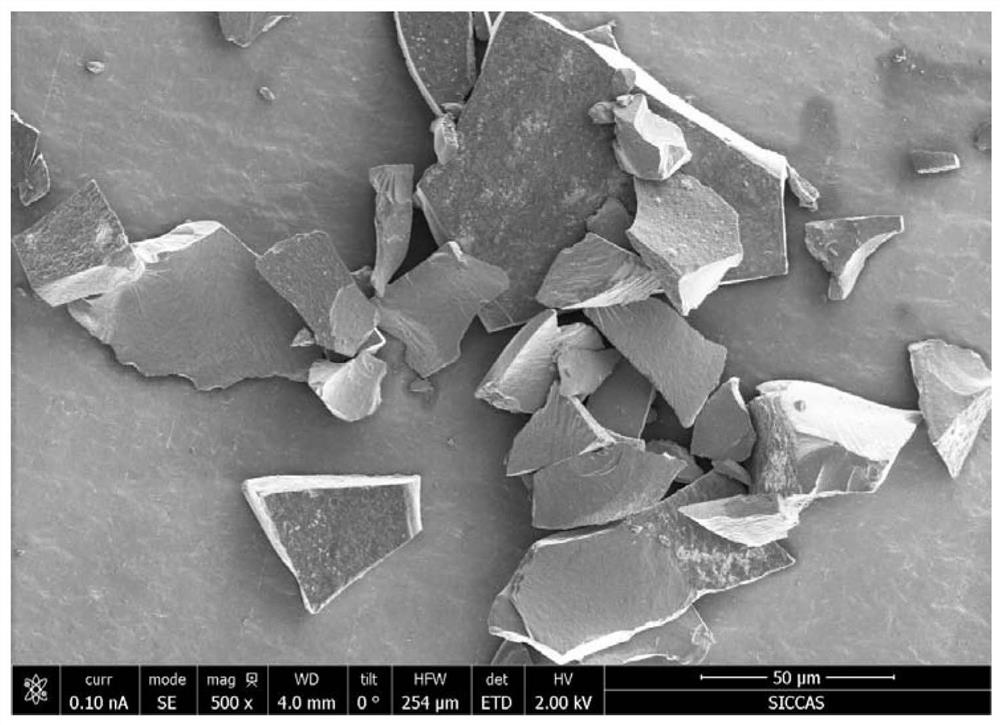

Anode material for high-capacity lithium-ion battery with micron particles based on conversion reaction and its preparation method and application

ActiveCN111490235BHigh tap densityLarge conversion reaction theoretical capacityMaterial nanotechnologyNegative electrodesPhysical chemistryBattery cell

The invention relates to a micron-particle high-capacity lithium-ion battery negative electrode material based on conversion reaction and its preparation method and application. The lithium-ion battery negative electrode material is a compound of molybdenum oxide and carbon, and its chemical formula is MoO x / C, x=2~3, where MoO x The content of 60 ~ 90 wt%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Control method of hot rolling width of wedge-shaped slab

ActiveCN103506403BImprove product qualityPrevent downgradeMetal rolling stand detailsEngineeringRolling mill

The invention discloses a control method of a hot rolling width of a wedge-shaped slab. The control method is used in hot rolling of rough mills and used for controlling the hot rolling width of the wedge-shaped slab. The control method includes the following steps that firstly, whether an incoming slab is a wedge-shaped slab or not is judged according to the width difference of the head and the tail of the incoming slab which is to enter a rough mill to undergo rough rolling processing; secondly, when the incoming slab is determined to be the wedge-shaped slab, the type of the wedge-shaped slab is determined according to the width difference of the head and the tail; thirdly, width control is performed on wedge-shaped slabs in multiple racks in the rough mill which the wedge-shaped slab enters according to the wedge-shaped slab type which is determined in the second step. The control method of the hot rolling width of the wedge-shaped slab automatically controls widths of the wedge-shaped slabs which have the abnormal widths in the full length direction in the rough rolling process of a hot rolling mill.

Owner:BAOSHAN IRON & STEEL CO LTD

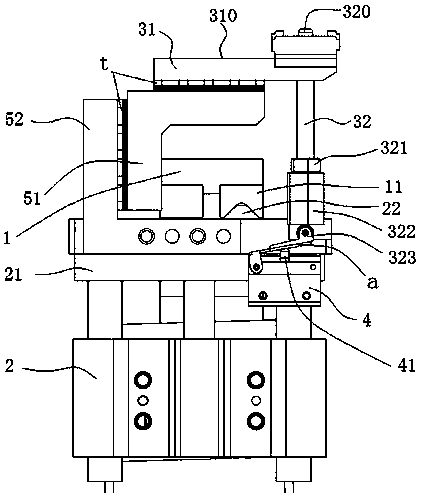

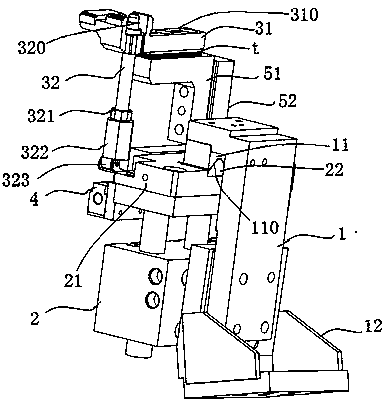

A projection welding nut leakage prevention and positioning welding mechanism

ActiveCN108581163BAvoid scrappingPrevent downgradeResistance welding apparatusStructural engineeringWelding

The invention provides a projection welding nut leakage resistance and positioning welding mechanism. With the projection welding nut leakage resistance and positioning welding mechanism, the problemsabout positioning and leakage resistance of projection welding nuts can be solved at the same time. The projection welding nut leakage resistance and positioning welding mechanism comprises a base. Aguide rod mechanism is arranged beside the base. A positioning guide mechanism is arranged above the guide rod mechanism. The positioning guide mechanism comprises a positioning guide block and a positioning pilot pin. The upper surface of the positioning guide block is a profile conforming face of an assembly part used for being attached to an installation nut. The upper end of the positioning pilot pin is connected with the positioning guide block and penetrates through the profile conforming face. The part, penetrating out of the profile conforming face, of the positioning pilot pin is provided with a circular-truncated-cone-shaped positioning portion with the reducing diameter. An inclined face with an adjustable inclination angle is arranged at the bottom of the lower end of the positioning pilot pin. A guide rod on the upper part of the guide rod mechanism is provided with a connecting plate. A mechanical valve is arranged beside the connecting plate. The mechanical valve is arranged below the inclined face. A positioning stop dog is arranged beside the connecting plate. A shape conforming positioning stop dog used in cooperation with the positioning stop dog in the travel of the guide rod mechanism is arranged on the base.

Owner:CHERY AUTOMOBILE CO LTD

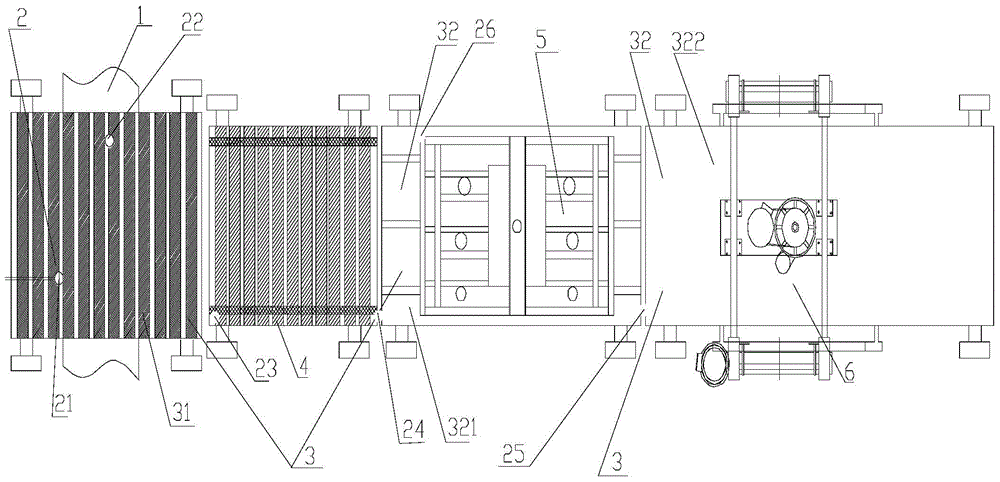

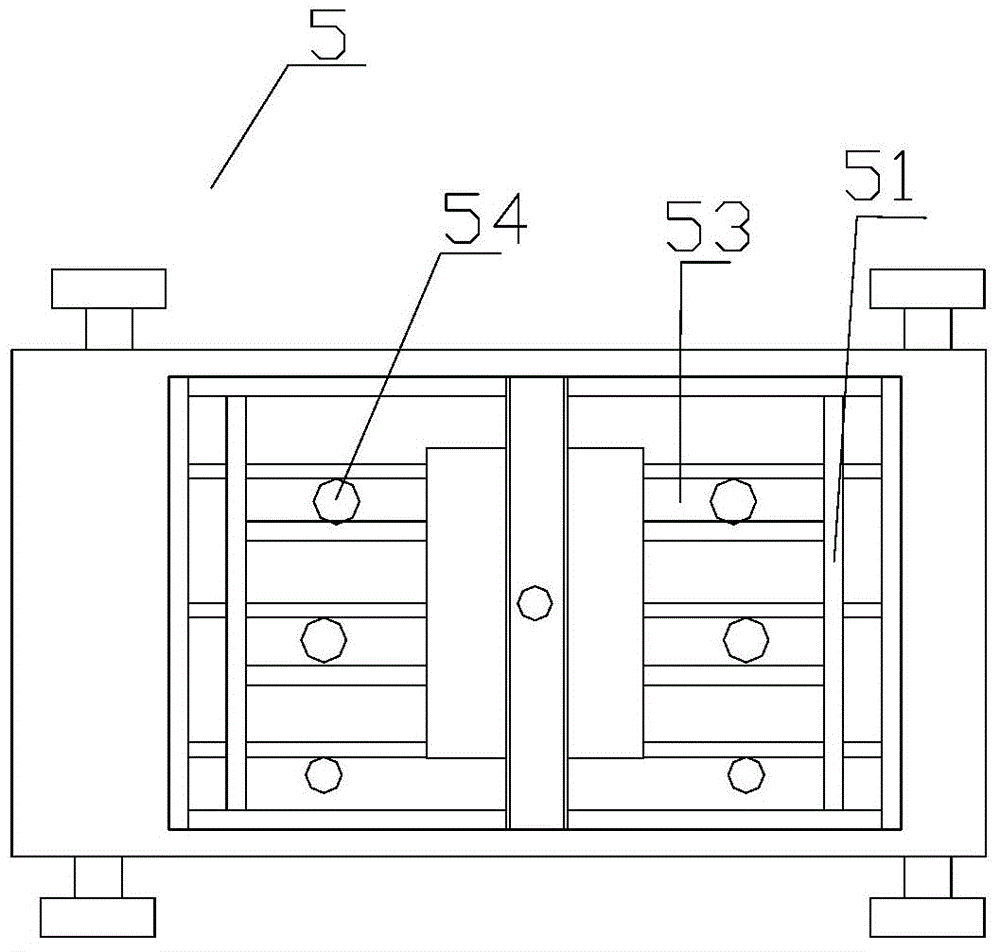

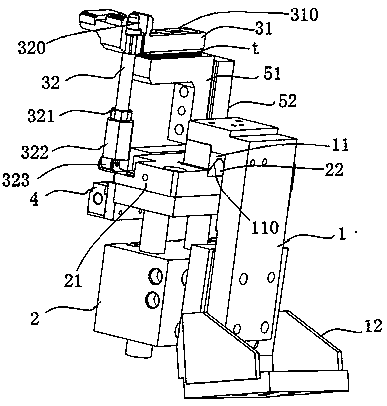

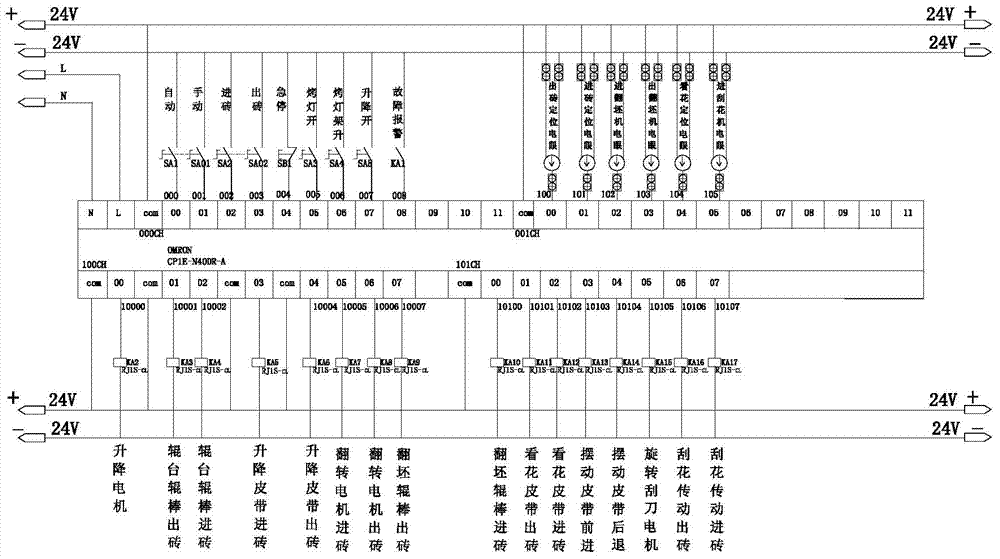

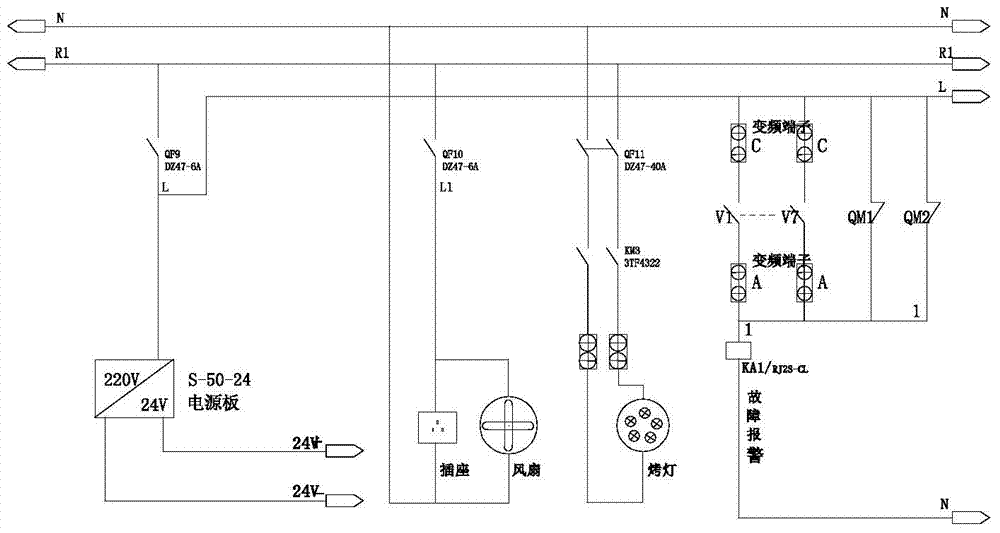

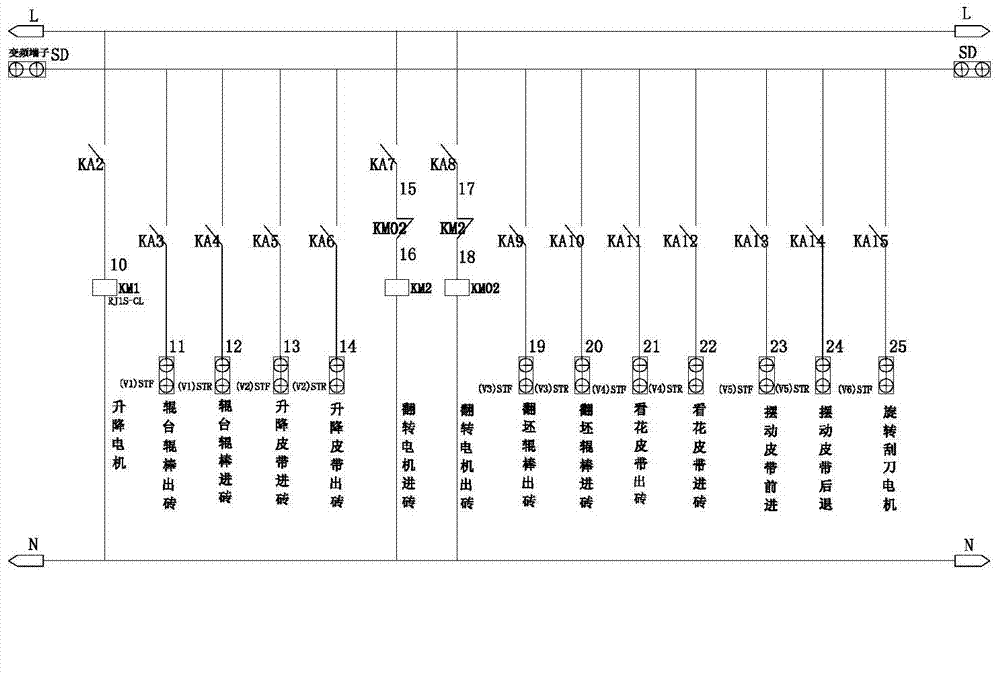

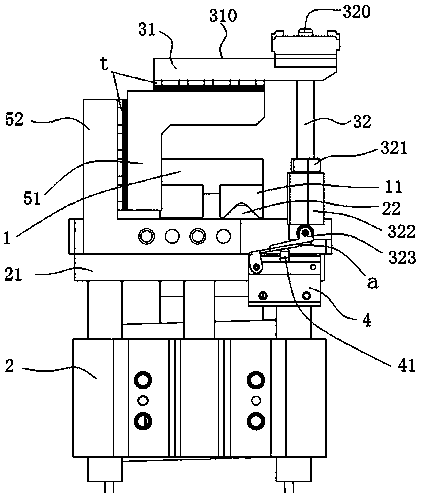

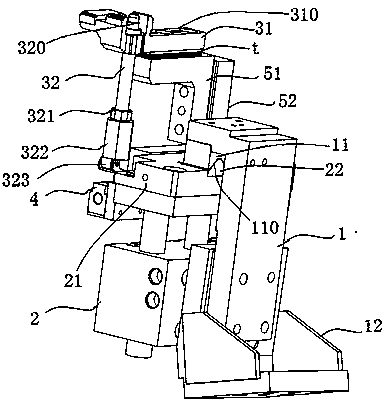

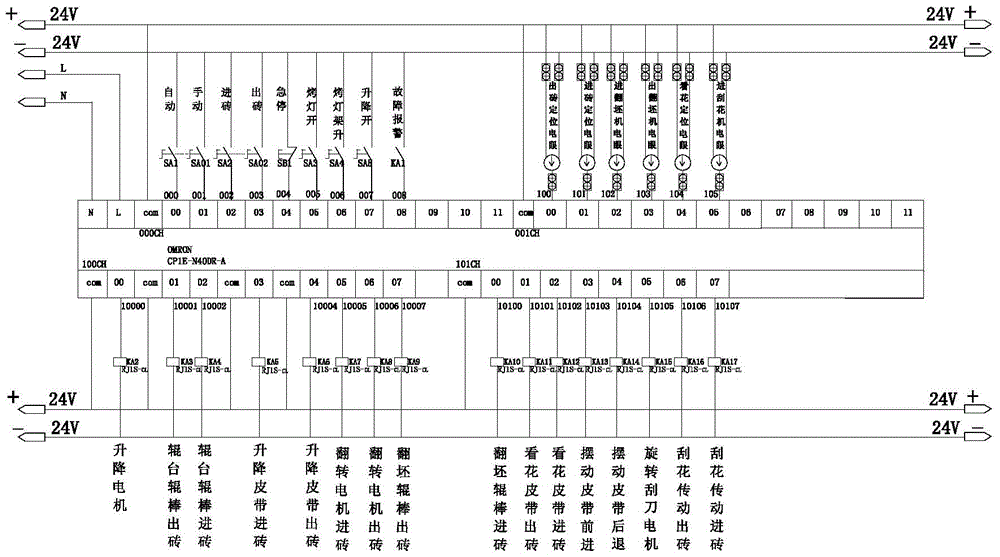

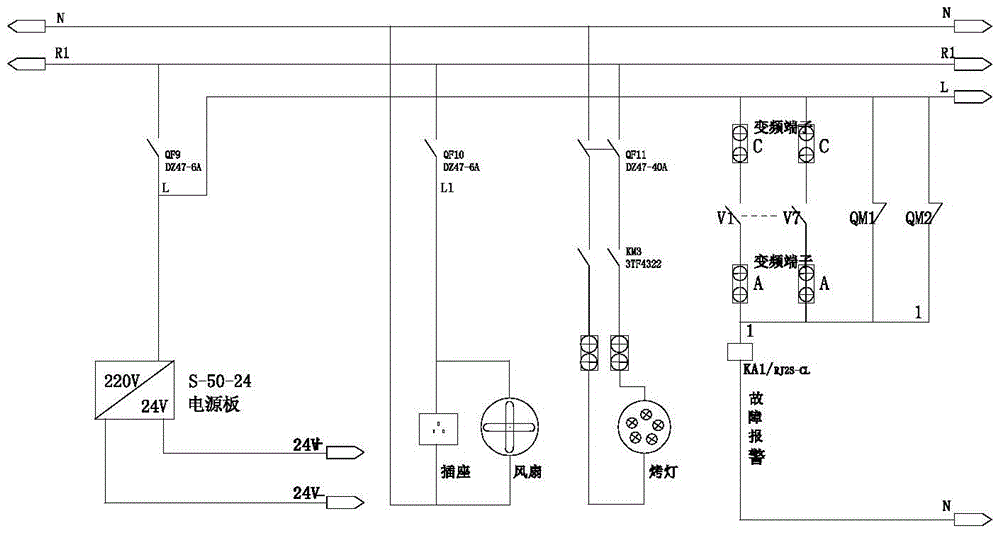

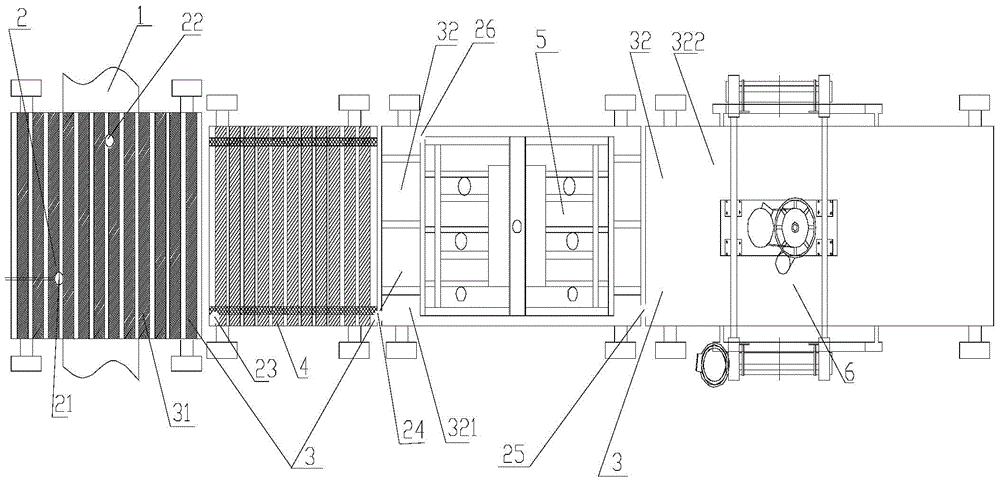

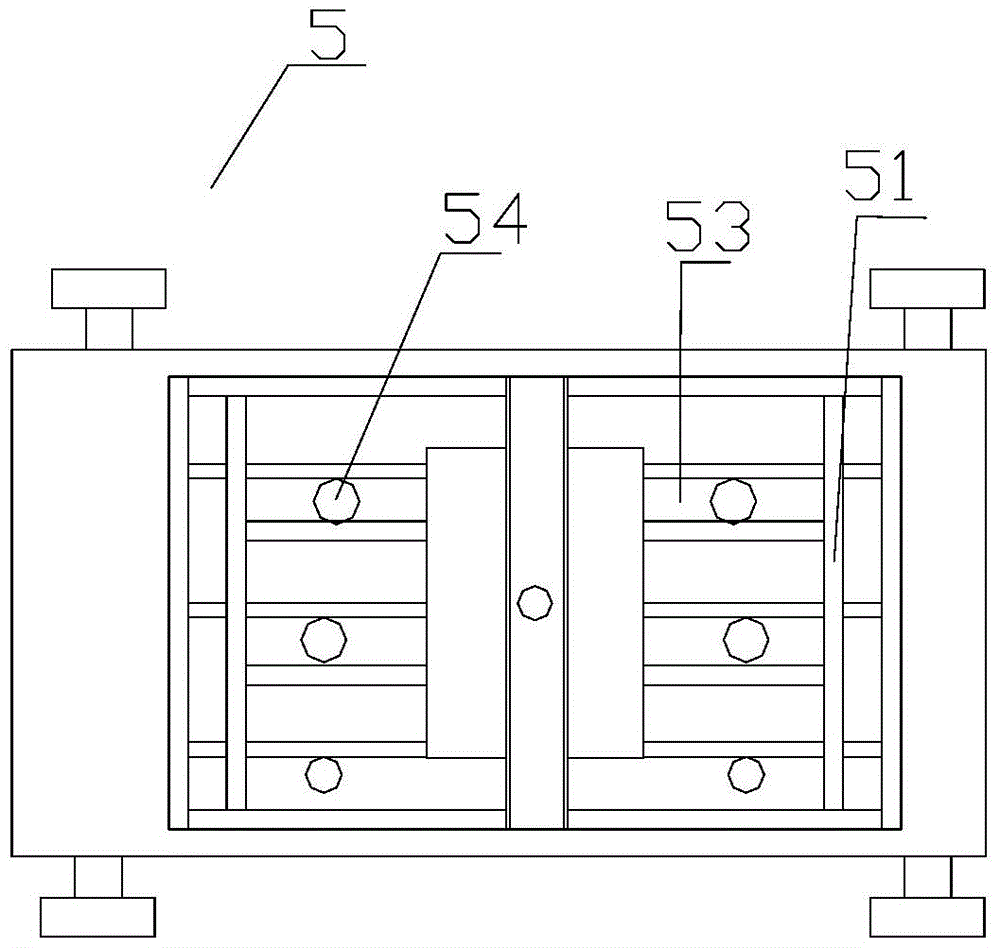

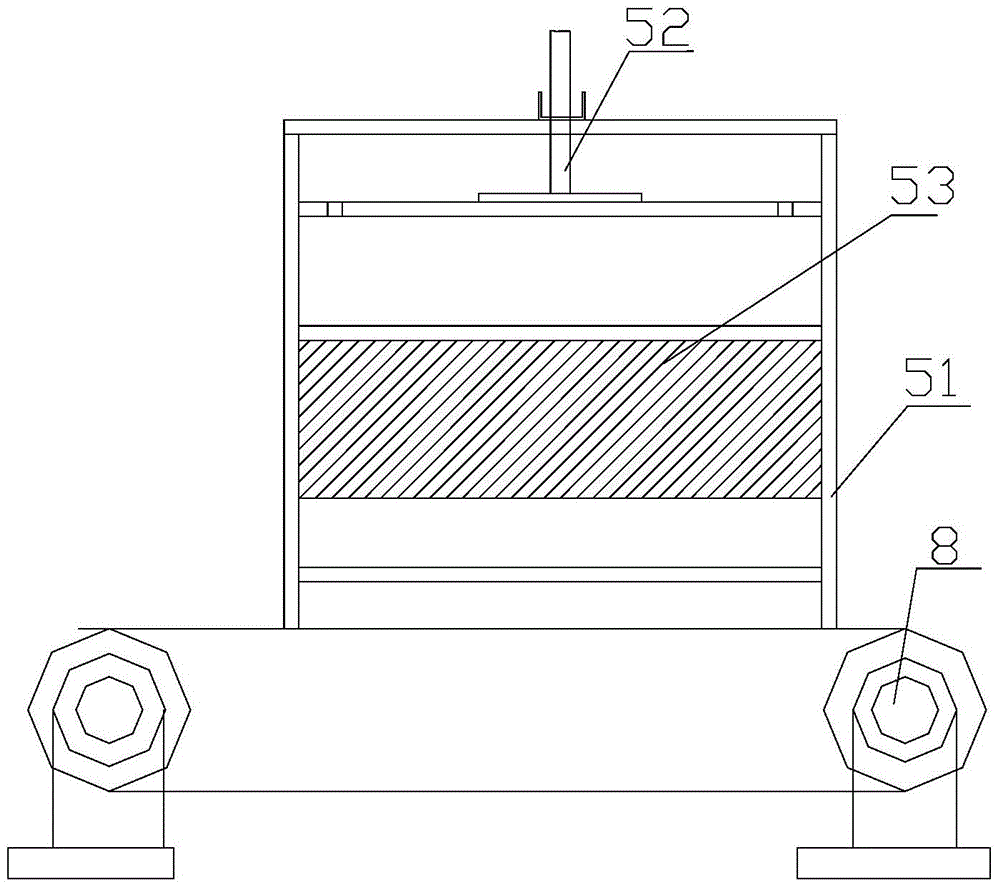

Automatic scratching device and method for micro-powder polishing brick green body

ActiveCN104760127AImprove efficiencyImprove detection efficiencyAuxillary shaping apparatusElectricityBrick

The invention relates to an automatic scratching device and method for a micro-powder polishing brick green body. The automatic scratching device comprises a glaze line lifting platform, a scratching auxiliary conveying platform, a positioning mechanism, a turnover mechanism, a drying mechanism and a scratching mechanism; the scratching auxiliary conveying platform is arranged above the glaze line lifting platform; the turnover mechanism, the drying mechanism and the scratching mechanism are arranged on the scratching auxiliary conveying platform in turn; the automatic scratching device also comprises a controller which is electrically connected with the positioning mechanism; the scratching auxiliary conveying platform, the turnover mechanism, the drying mechanism and the scratching mechanism are controlled by the controller through a signal transmitted through the positioning mechanism to run. According to the automatic scratching device and method for the micro-powder polishing brick green body, the integral yield of the integral semi-finished product production process can be effectively improved, the labor intensity of workers and the production cost can be reduced, the inspection is accurate, the consumed time is less, and the pollution to the equipment is less.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Projection welding nut leakage resistance and positioning welding mechanism

ActiveCN108581163AAvoid scrappingPrevent downgradeResistance welding apparatusMechanical valveWelding

The invention provides a projection welding nut leakage resistance and positioning welding mechanism. With the projection welding nut leakage resistance and positioning welding mechanism, the problemsabout positioning and leakage resistance of projection welding nuts can be solved at the same time. The projection welding nut leakage resistance and positioning welding mechanism comprises a base. Aguide rod mechanism is arranged beside the base. A positioning guide mechanism is arranged above the guide rod mechanism. The positioning guide mechanism comprises a positioning guide block and a positioning pilot pin. The upper surface of the positioning guide block is a profile conforming face of an assembly part used for being attached to an installation nut. The upper end of the positioning pilot pin is connected with the positioning guide block and penetrates through the profile conforming face. The part, penetrating out of the profile conforming face, of the positioning pilot pin is provided with a circular-truncated-cone-shaped positioning portion with the reducing diameter. An inclined face with an adjustable inclination angle is arranged at the bottom of the lower end of the positioning pilot pin. A guide rod on the upper part of the guide rod mechanism is provided with a connecting plate. A mechanical valve is arranged beside the connecting plate. The mechanical valve is arranged below the inclined face. A positioning stop dog is arranged beside the connecting plate. A shape conforming positioning stop dog used in cooperation with the positioning stop dog in the travel of the guide rod mechanism is arranged on the base.

Owner:CHERY AUTOMOBILE CO LTD

Micropowder polished brick green body automatic scraping device and scraping method

ActiveCN104760127BImprove efficiencyImprove detection efficiencyAuxillary shaping apparatusBrickWork in process

The invention relates to an automatic scratching device and method for a micro-powder polishing brick green body. The automatic scratching device comprises a glaze line lifting platform, a scratching auxiliary conveying platform, a positioning mechanism, a turnover mechanism, a drying mechanism and a scratching mechanism; the scratching auxiliary conveying platform is arranged above the glaze line lifting platform; the turnover mechanism, the drying mechanism and the scratching mechanism are arranged on the scratching auxiliary conveying platform in turn; the automatic scratching device also comprises a controller which is electrically connected with the positioning mechanism; the scratching auxiliary conveying platform, the turnover mechanism, the drying mechanism and the scratching mechanism are controlled by the controller through a signal transmitted through the positioning mechanism to run. According to the automatic scratching device and method for the micro-powder polishing brick green body, the integral yield of the integral semi-finished product production process can be effectively improved, the labor intensity of workers and the production cost can be reduced, the inspection is accurate, the consumed time is less, and the pollution to the equipment is less.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

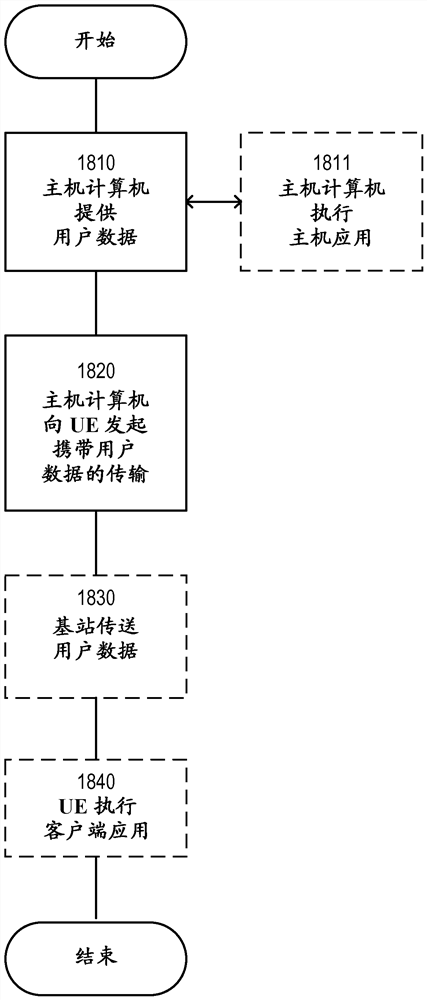

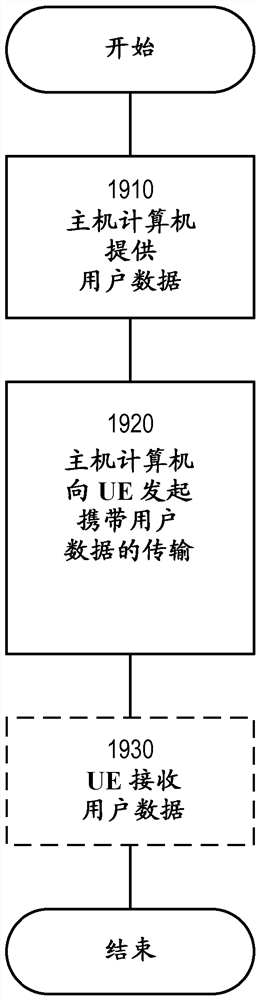

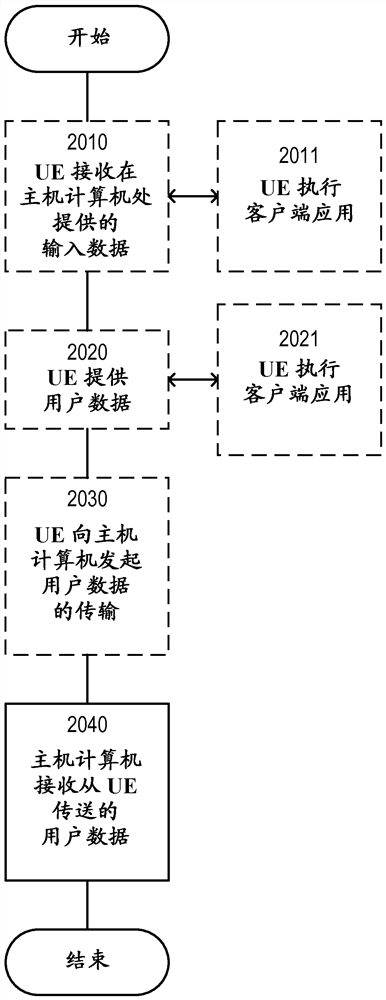

Application of integrity protection in a wireless communication network

PendingCN112534852APrevent downgradeLow costTransmissionSecurity arrangementComputer networkTelecommunications

A method in a first node of a wireless communications network comprises: inspecting a data packet or message to determine a characteristic of the data packet or message; and selectively activating integrity protection for onward transmission of the data packet or message to a second node of the wireless communications network based on the determined characteristic.

Owner:TELEFON AB LM ERICSSON (PUBL)

Reinforcing device for refractory air duct for nuclear power and refractory air duct

ActiveCN110726012BPrevent sagging or even collapsePrevent downgradeRigid pipesNuclear powerRefractory

A reinforcement device for a fire-resistant air duct for nuclear power and a fire-resistant air duct. The reinforcement device includes an upper top plate, a lower top plate, an upper support rod, a lower support rod, an intermediate connecting rod, an upper mounting plate, and a lower mounting plate; the upper end of the upper support rod is connected with the upper top plate, the lower end passes through the upper mounting plate and It is adjustable connected with the upper end of the intermediate connecting rod; the lower end of the lower support rod is connected with the lower top plate, the upper end passes through the lower mounting plate and is adjustable connected with the lower end of the intermediate connecting rod; the upper mounting plate is in at least one dimension The size on the top is greater than the size of the upper roof in the corresponding dimension; the size of the lower mounting plate in at least one dimension is greater than the size of the lower roof in the corresponding dimension; the upper roof and the lower roof are respectively connected with the fire-resistant air duct The top wall and the bottom wall abut; the upper mounting plate and the lower mounting plate are respectively fixed to the top wall and the bottom wall in the fire-resistant air duct. The reinforcement device enables the fire-resistant air duct to be effectively supported, strengthens the strength of the fire-resistant air duct, and ensures the integrity of the ventilation system.

Owner:SUZHOU NUCLEAR POWER RES INST +2

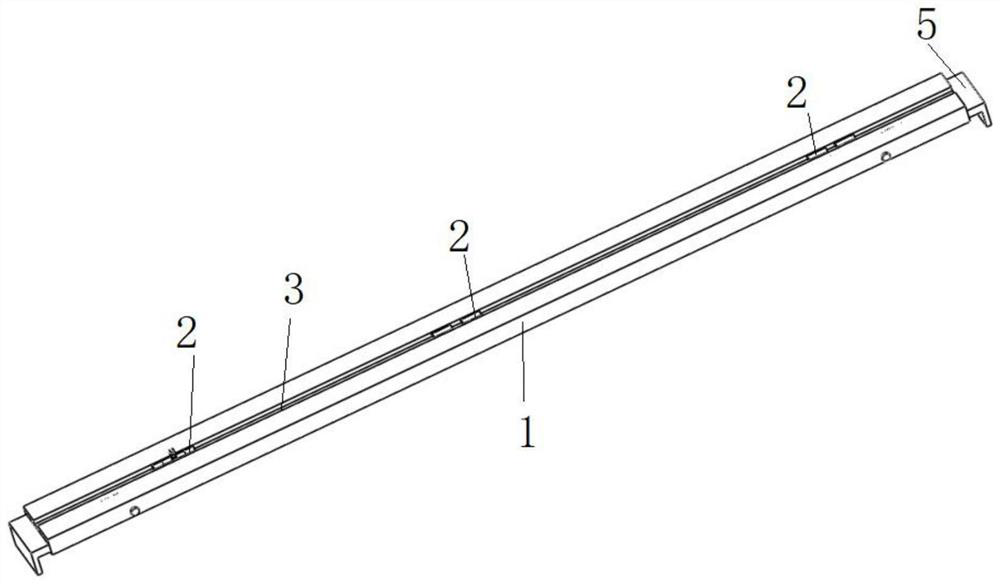

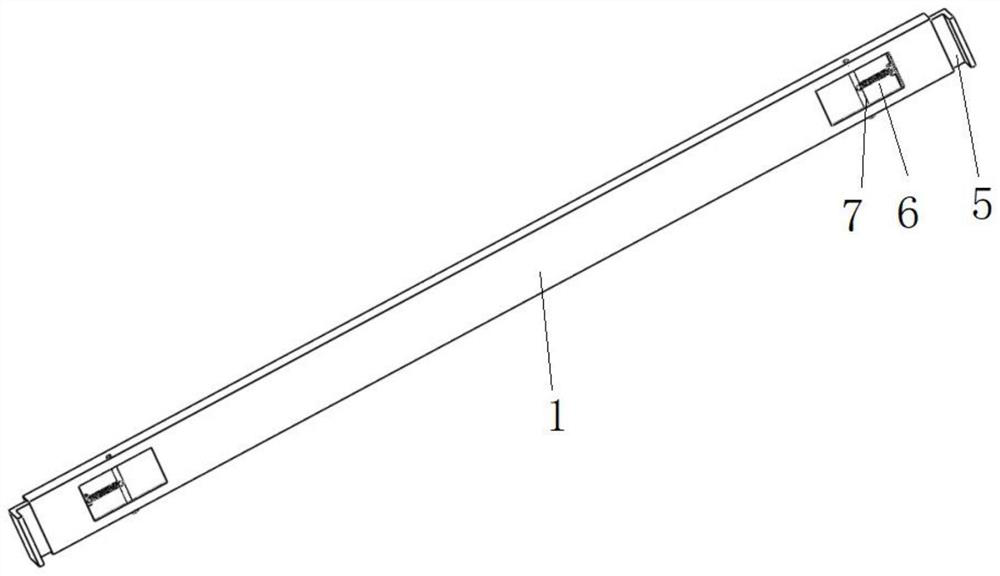

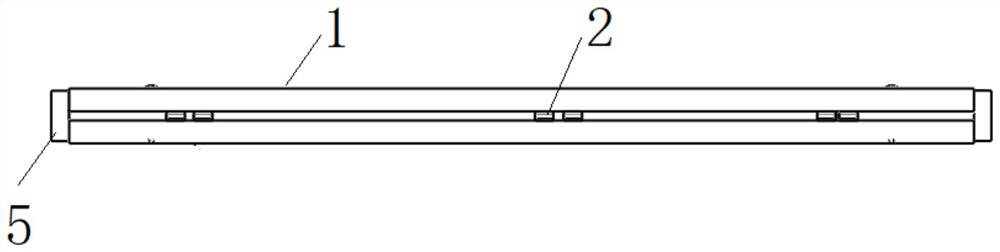

Simulation assembly of photovoltaic assembly and manufacturing method of welding tension sample

PendingCN114002040AAvoid damageAvoid difficultyPreparing sample for investigationMaterial strength using tensile/compressive forcesStructural engineeringSolar cell

The invention discloses a simulation assembly of a photovoltaic assembly and a manufacturing method of a welding tension sample of a junction box and a bus bar, which belong to the technical field of solar cells. The method is used for solving the problems that in the prior art, manual installation of a junction box and a bus bar is large in operation difficulty and long in time consumption, and a welding tension sample of the junction box and the bus bar is detached from a photovoltaic module, so that the quality of part of the photovoltaic module is abnormal. The simulation assembly comprises a sliding rail,at least one group of sliding blocks and at least one group of bus bars, wherein the at least one group of sliding blocks are connected with the sliding rails in a sliding manner, the number of the sliding blocks in each group is two, and the sliding blocks are provided with mounting grooves; the number of the bus bars in each group is two, one part of each bus bar detachably extends into the corresponding mounting groove, and the other part of each bus bar is exposed out of the corresponding sliding block and the corresponding sliding rail and is used for being connected with a junction box in a welded mode. By the adoption of the simulation assembly and the manufacturing method of the welding tension sample of the junction box and the bus bar, the welding tension sample of the junction box and the bus bar can be rapidly manufactured, and the application range is wide.

Owner:JA XINGTAI SOLAR CO LTD

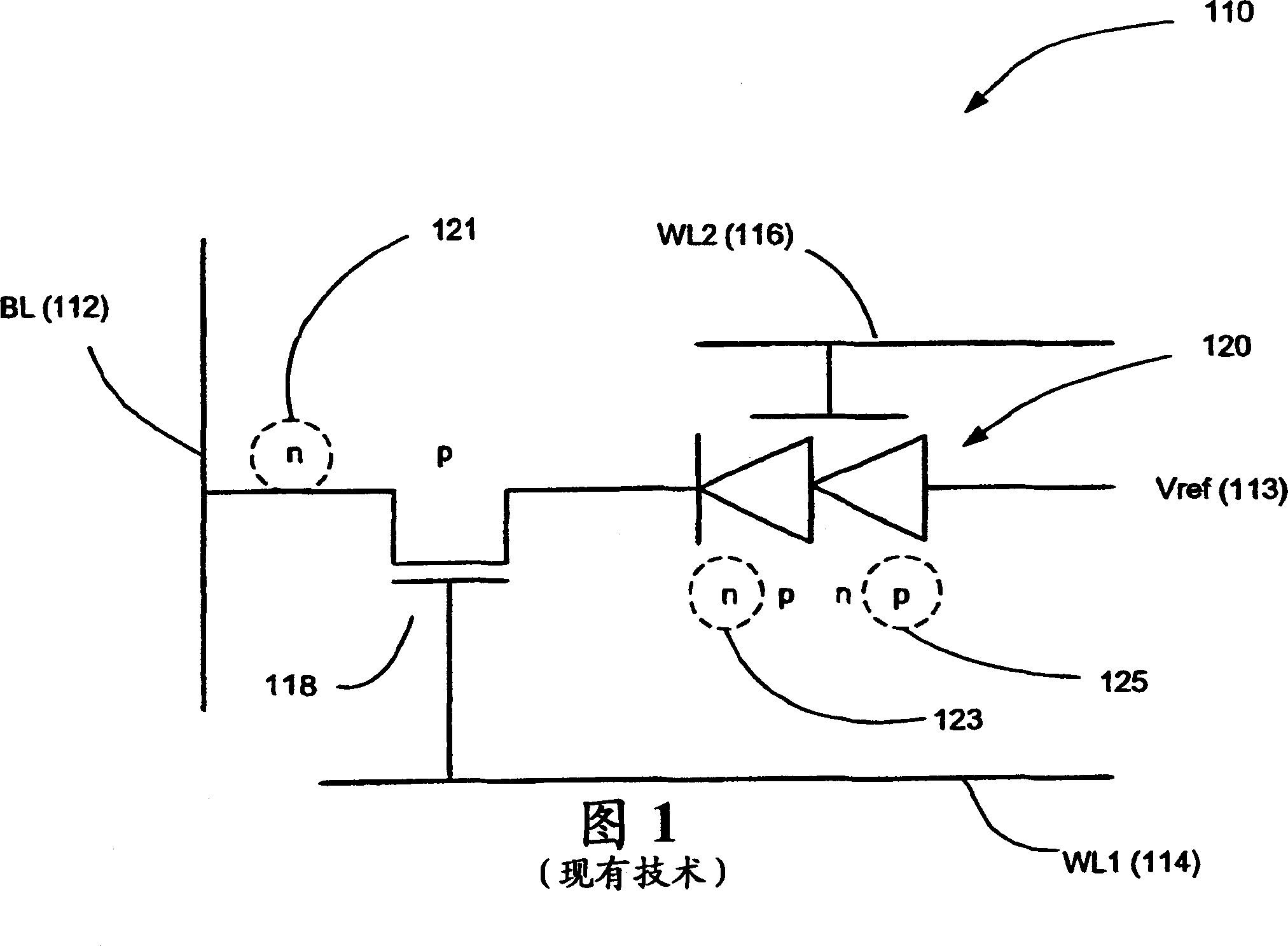

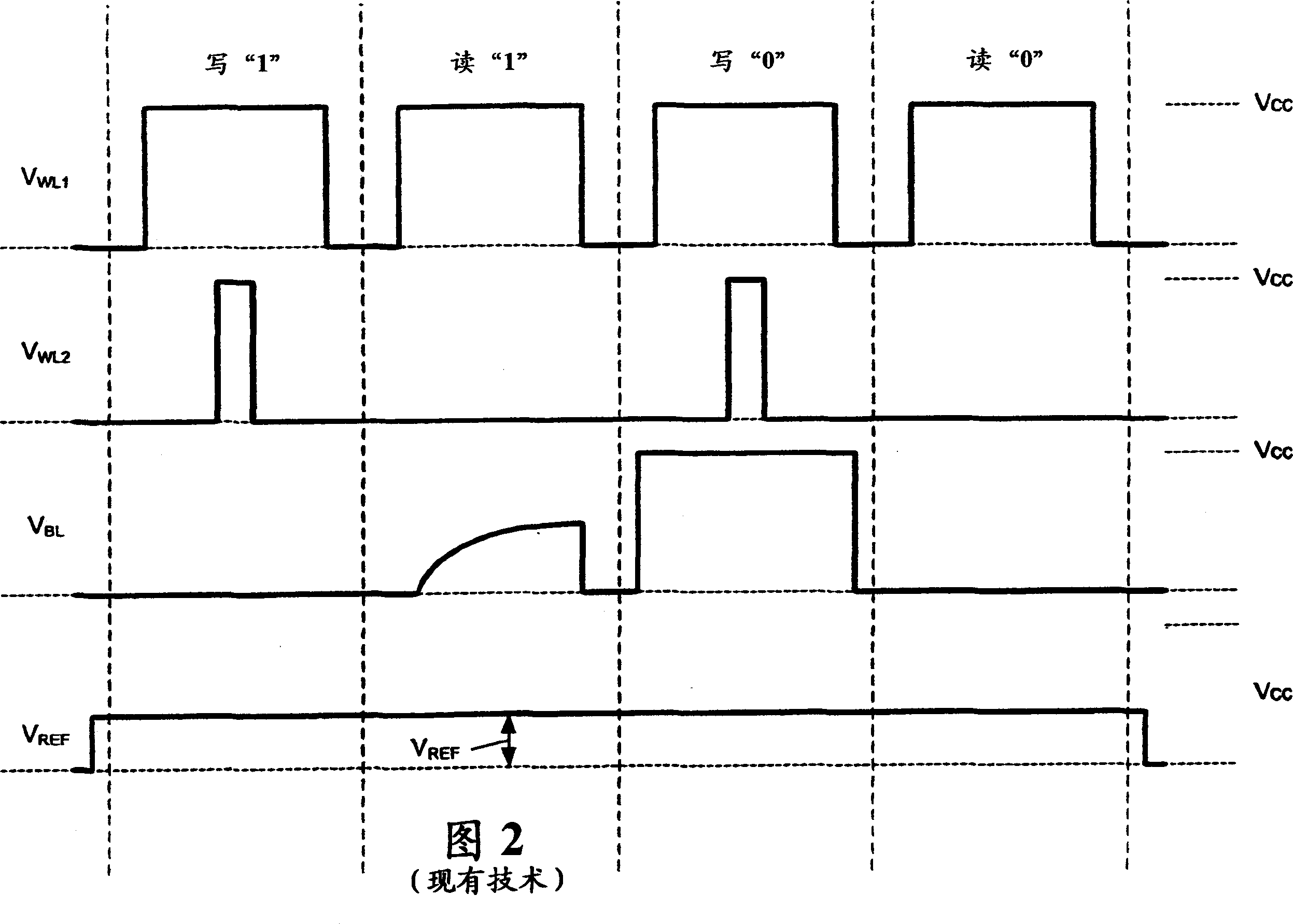

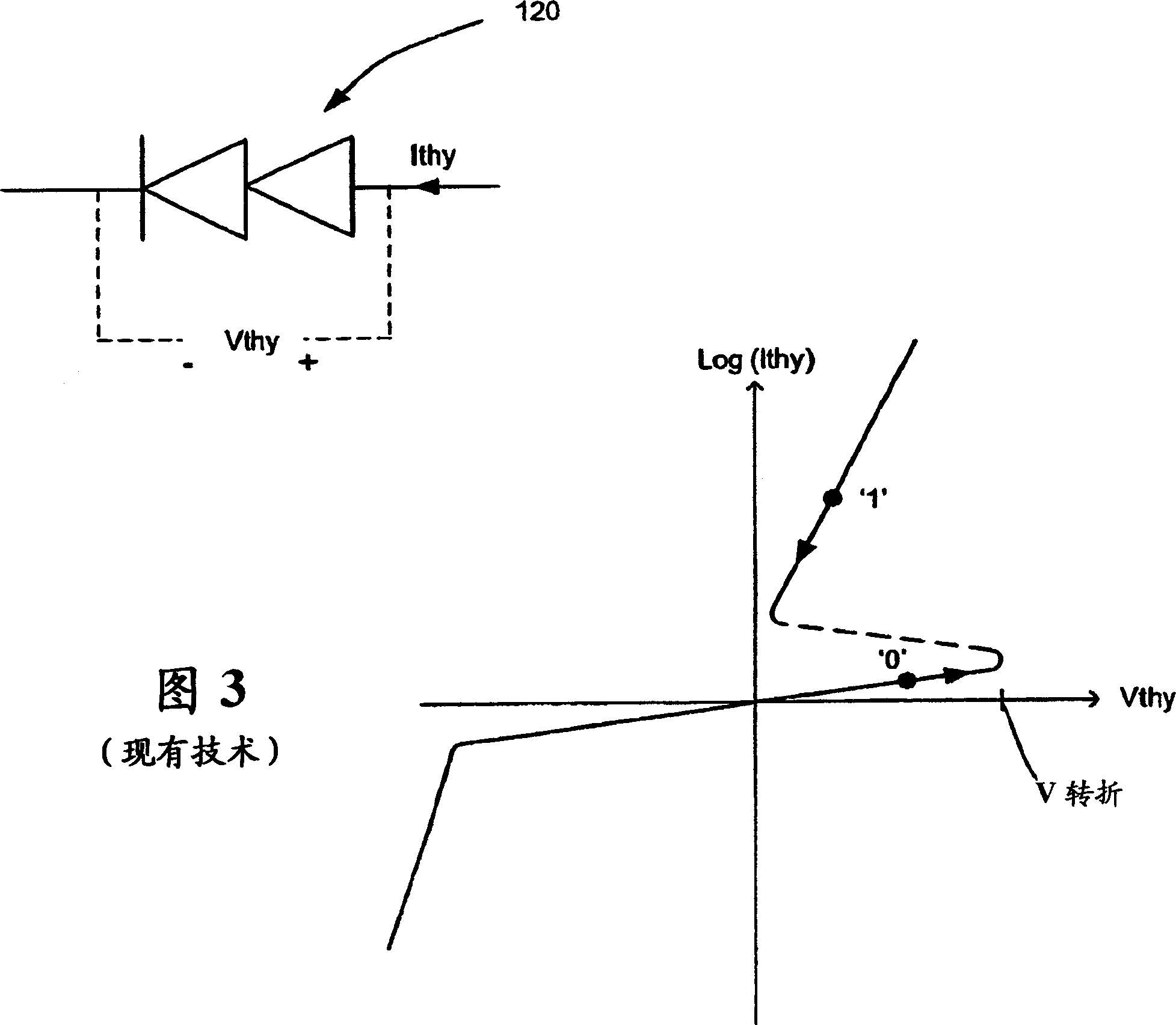

Silicon on insulator read-write non-volatile memory comprising lateral thyristor and trapping layer

Disclosed herein is an improved thyristor-based memory cell. In one embodiment, the cell is formed in a floating substrate using Silicon-On-Insulator (SOI) technology. The cell preferably incorporates a lateral thyristor formed entirely in the floating substrate, and which is gated by a second word line. The cathode of the thyristor also comprises a source of an access transistor, whose drain is connected to the bit line of the device, and which is gated by a first word line. A trapping layer is built into the floating substrate, and when writing to the cell, pulses are added to cause holes to be trapped on the trapping layer for a logic state '1' and to cause electrons to be trapped on the trapping layer for a logic state '0'. Trapping of charges on the trapping layer adds extra margin to the stored data states, prevents their degradation, and renders the cell non-volatile.

Owner:MICRON TECH INC

A method for automatic scratch control of green micropowder polished tiles

ActiveCN104690813BTimely discovery of color abnormalitiesImprove detection efficiencyCeramic shaping apparatusProduction lineBrick

The invention relates to an automatic scratching control method for a micropowder polished tile blank. The method adopts a controller and segmented program control, and includes timed / manually-started automatic sending-out scratching control as follows: according to a tile feeding command, a glaze line lifting platform separates a tile blank from a production line and conveys the tile blank to a conveying platform; according to a conveying command, the conveying platform forwardly conveys the tile blank to an overturning mechanism; according to an overturning command, the overturning mechanism overturns the tile blank for the first time; according to a conveying command, the conveying platform forwardly conveys the tile blank to a scratching mechanism; according to a scratching command, the scratching mechanism drives an inner cutter head to scratch the tile blank back and forth in a rotating manner; according to a conveying command, the conveying platform sends the tile blank out of the scratching mechanism; according to an observing command, a drying mechanism lifts up an upper lampshade and turns on a lampshade for illuminating / drying; the automatic scratching control method further comprises manually-started sending-back control. According to the segmented program control method, through the segmented program control, manpower is reduced, operation mistakes and errors are avoided at the same time, and the inspecting efficiency and the inspecting result of blank spot inspection in ceramic tile production are greatly improved.

Owner:JIANGXI HEMEI CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com