Reinforcing device for fire-resistant air pipe for nuclear power and fire-resistant air pipe

A reinforcement device and fire-resistant technology, applied in the field of nuclear power plant safety, can solve problems such as difficult support, concave or bent fireproof board 1', crack collapse of fireproof board 1', etc., to ensure integrity, ensure stability, and improve overall the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

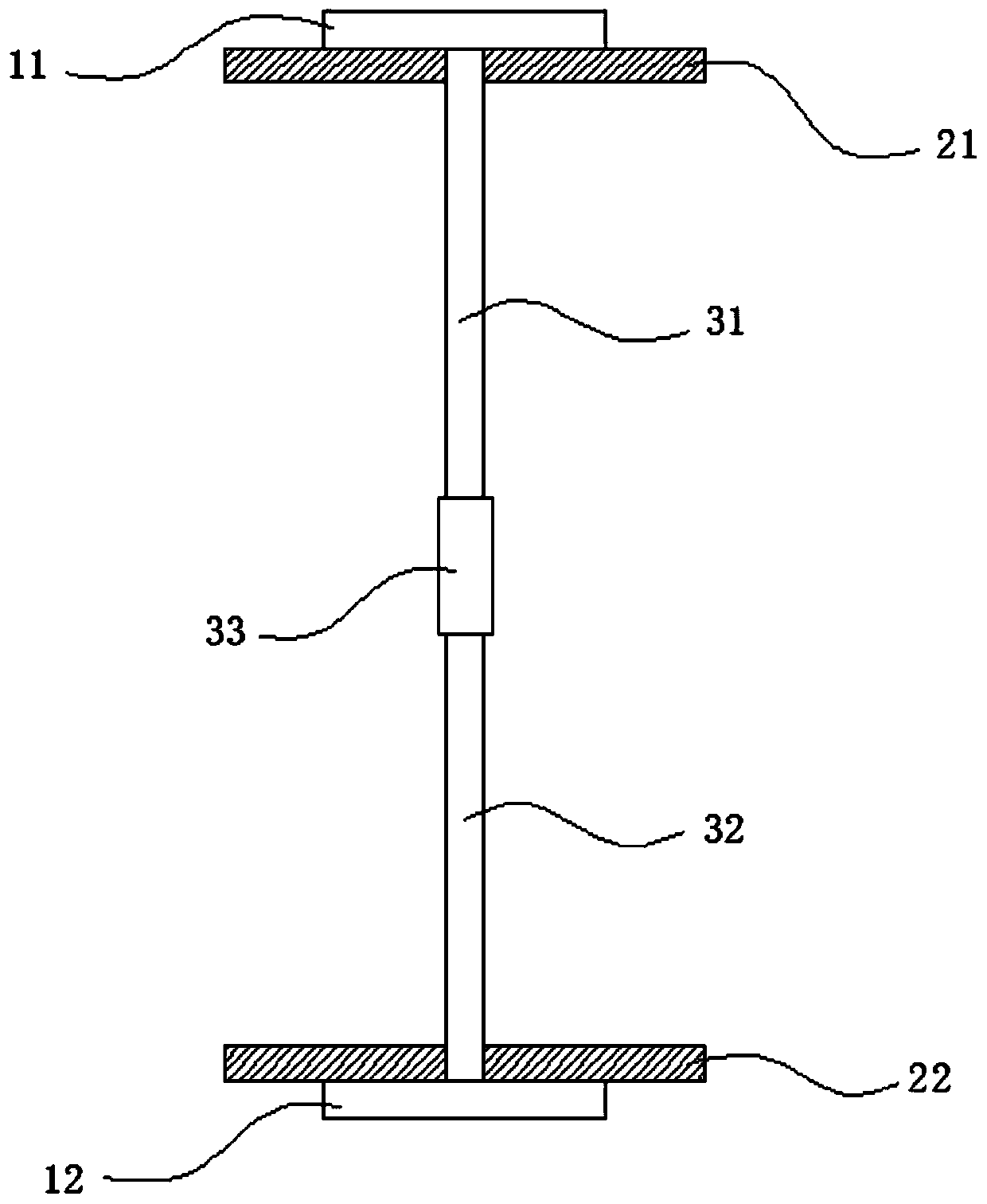

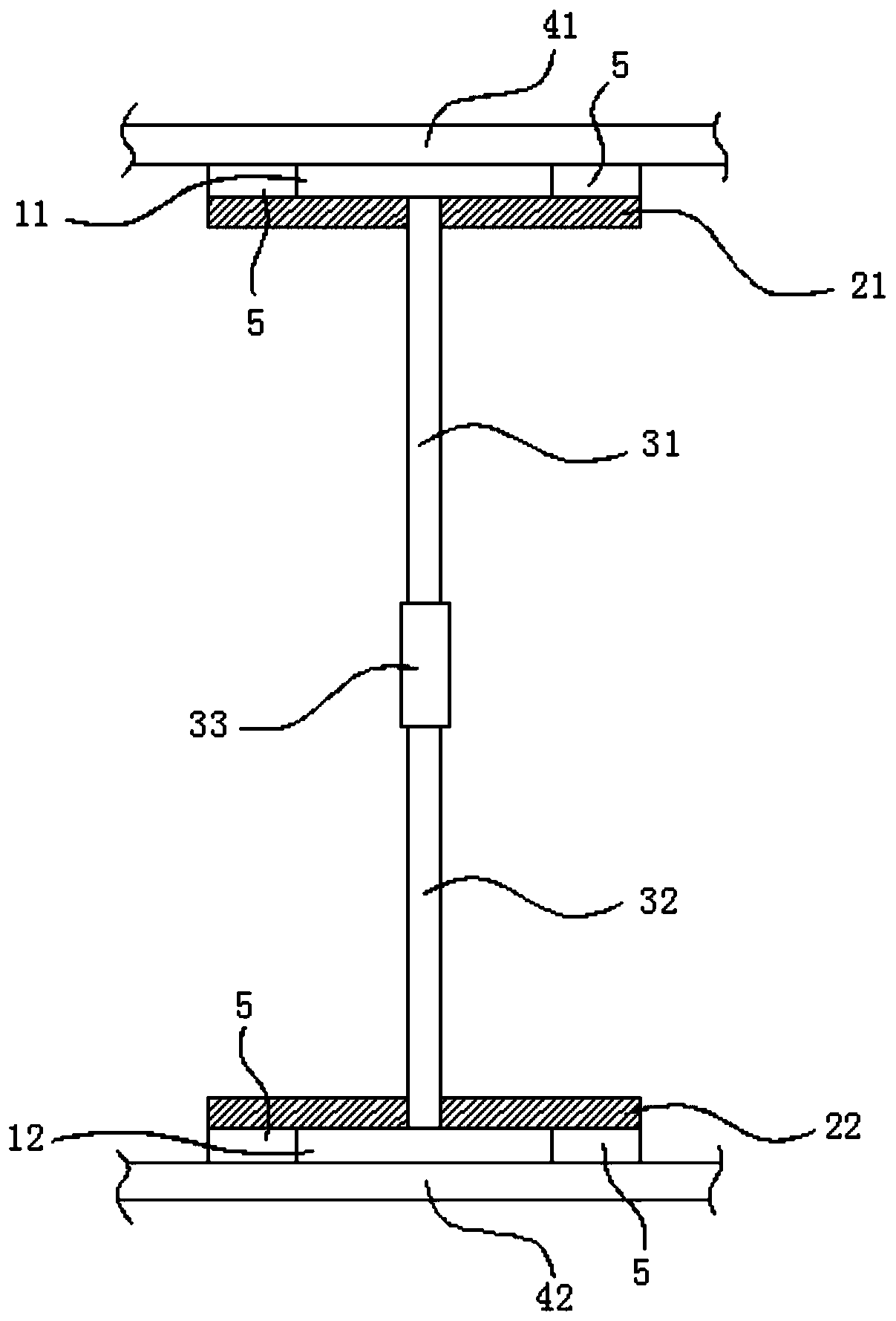

[0027] This implementation example provides a reinforcement device 100 for a fire-resistant air duct for nuclear power.

[0028] The first thing to explain is that the fire-resistant air ducts involved in this implementation example are widely used in the important ventilation systems of nuclear power plants. At present, many domestic PWR nuclear power plants have fire-resistant air ducts of this material. According to on-site observation, this kind of PROMATECT-L500 large-section fire-resistant air duct is prone to cracks and collapse defects in the absence of internal reinforcement. The reinforcement device 100 provided in this implementation example can optimize this defect, so that the fire-resistant air duct can be effectively supported, the strength of the fire-resistant air duct can be guaranteed, and the integrity of the important ventilation system of the nuclear island can be ensured.

[0029] see figure 2 and image 3 , the reinforcing device 100 includes an uppe...

Embodiment 2

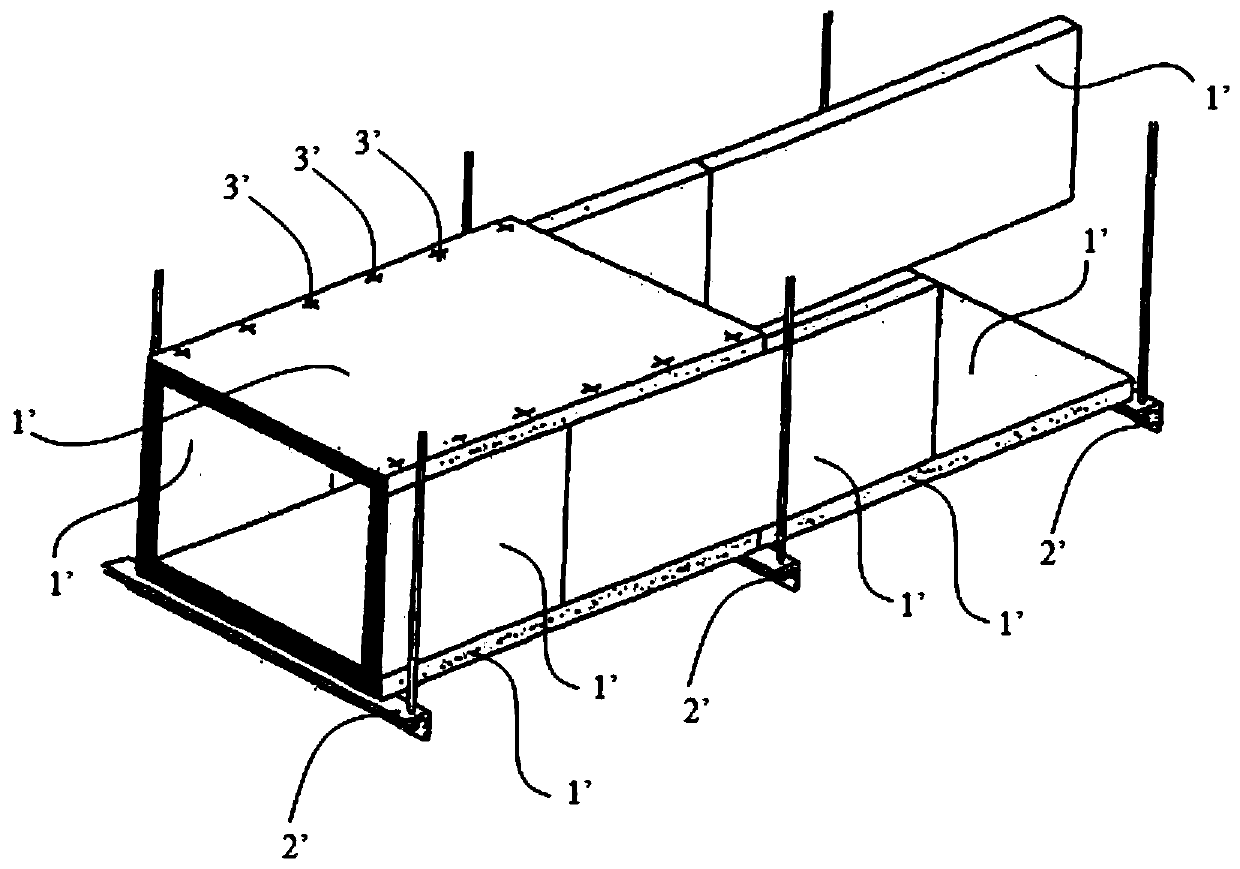

[0042] This implementation example provides a fire-resistant air duct 400 .

[0043] The fire-resistant air duct 400 includes a top wall (not shown), a bottom wall 42 and two side walls 43 connected between the top wall (not shown) and the bottom wall 42 , wherein the fire-resistant Multiple reinforcement devices 100 provided in Embodiment 1 are installed between the top wall (not shown) and the bottom wall 42 of the air duct 400 .

[0044] In this example, see Figure 4 , the length of the top wall (not shown) of the fire-resistant air duct 400 is 1200-2000 mm, and the fire-resistant air duct 400 has a row of reinforcing devices 100 arranged at equal intervals along the length direction, and two adjacent The spacing between the reinforcing devices 100 is less than or equal to 600mm.

[0045] In this embodiment, the fire-resistant air duct 400 has a better overall strength due to the installation of a row of reinforcement devices 100 between the top wall 41 and the bottom wa...

Embodiment 3

[0047] This implementation example provides a fire-resistant air duct.

[0048] The fire-resistant air duct includes a top wall, a bottom wall and two side walls connected between the top wall and the bottom wall, wherein a plurality of fire-resistant air ducts are installed between the top wall and the bottom wall The reinforcement device provided by Embodiment 1.

[0049] In this embodiment, the length of the top wall of the fire-resistant air duct is 2000-3000 mm, and there are two rows of reinforcement devices arranged at equal intervals along the length direction inside the fire-resistant air duct. The interval between the reinforcement devices is less than or equal to 600mm.

[0050] In this embodiment, two rows of reinforcing devices are installed between the top wall and the bottom wall of the fire-resistant air duct, so that the fire-resistant air duct has better overall strength, which can ensure the integrity of the important ventilation system of the nuclear islan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com