Dual-redundancy hydraulic machinery clutch mechanism for mechanical backup actuator

A technology of hydraulic machinery and clutch mechanism, which is applied in the field of hydraulic pressure, can solve the problems of actuator working mode disorder, insufficient locking force, impact response, etc., and achieve the effect of avoiding mode conversion failure and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below.

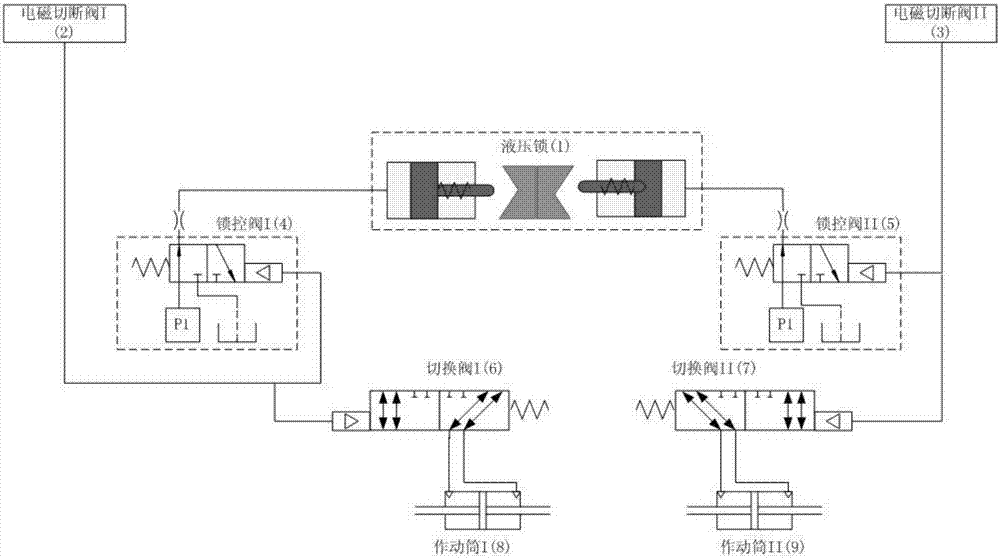

[0012] A double-redundancy hydraulic-mechanical clutch mechanism for a mechanical backup actuator is mainly used for the conversion between the manual operation state and other operation states of the actuator with the mechanical backup operation function. Actuators with mechanical backup control function generally have manual mechanical control function and other control functions, such as fly-by-wire control function, fault return function, etc. When it is necessary to switch to manual operation, the mechanical control lever system is connected with the mechanical control valve through the double-redundant hydraulic mechanical clutch mechanism, and combined with the switching valve to drive the actuator to follow the command movement in different working modes.

[0013] In the manual control mode, the hydraulic lock is used to realize the connection between the mechanical control lever system and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com