Control method of hot rolling width of wedge-shaped slab

A wedge-shaped slab and width control technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, etc., can solve the problems that the width cannot be controlled automatically, and achieve the effect of widening the scope of use, improving product quality, and widely promoting the prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

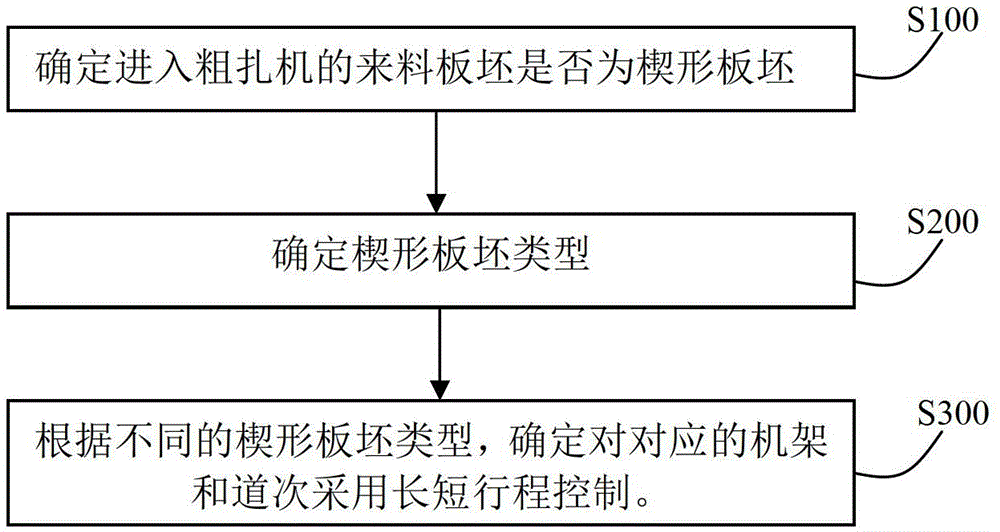

[0031] The specific steps of the method for controlling the hot-rolled width of a wedge-shaped slab of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

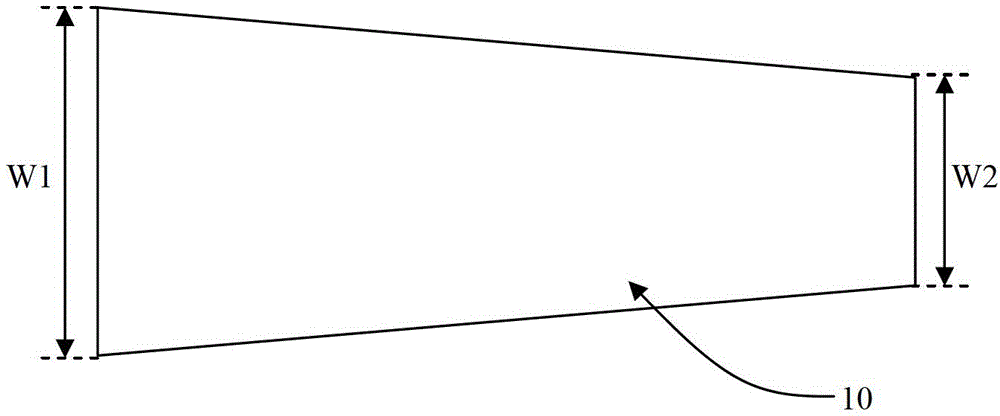

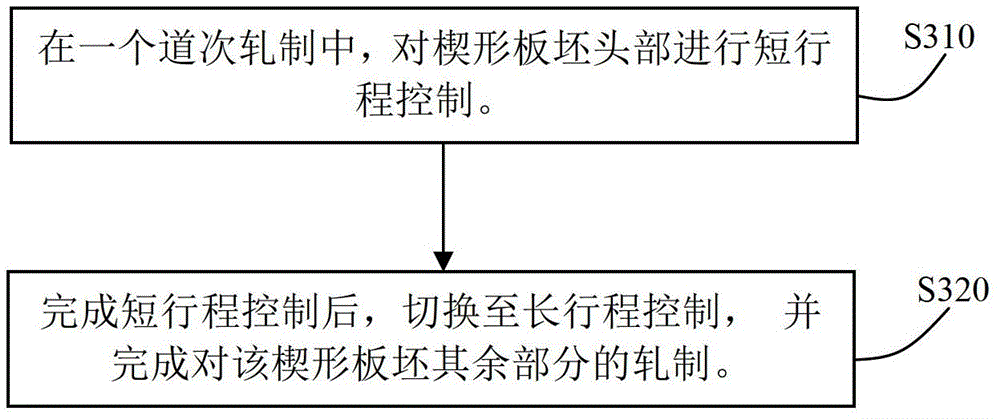

[0032] In general, the hot-rolled width control method for wedge-shaped slabs of the present invention is to classify the types of wedge-shaped slabs according to the head and tail widths of the wedge-shaped slabs to be rough-rolled, and then, according to different types, in specific The length of the stroke is controlled for a specific pass in the rack. In the present invention, the long-short stroke control refers to the width control of the head of the wedge-shaped slab in the length direction of the slab using conventional short-stroke control, while the remaining part of the wedge-shaped slab in the length direction is controlled by a long stroke, so that Realize the width control over the entire length direction of the wedge-shaped slab. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com