Ink-jet printing defect detection method and ceramic tile production process

An inkjet printing and detection method technology, which is applied to printing devices, printing, typewriters, etc., can solve the problems of difficult to find printed patterns, shallow defects, and increased production costs, so as to reduce the hidden danger of batch degradation, simplify monitoring, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1-a kind of detection method to inkjet printing defect and ceramic tile production technology thereof, comprises the following steps:

[0034] (1) Design the inkjet printing pattern of the green body, and a color bar is arranged on one side of the pattern; the color bar is a monochrome bar, and the color of the monochrome bar is the color of a single color channel in the inkjet printer. It is the color with the highest proportion in the pattern, and the monochromatic strip is arranged on the longitudinal side of the pattern along the movement direction of the adobe to obtain a pattern pattern with a color strip; wherein the color of the color strip is 2mm;

[0035](2) Inkjet printing: Inkjet printing patterned patterns with color bars on the surface of the adobe; wherein, the firing shrinkage of the adobe is 8, and the size of the adobe is 896*896mm;

[0036] (3) Distinguishing the gray scale: distinguish whether the gray scale of the same color in the color ...

Embodiment 2

[0038] Embodiment 2-a kind of detection method and ceramic tile production technology to inkjet printing defect, comprise the steps:

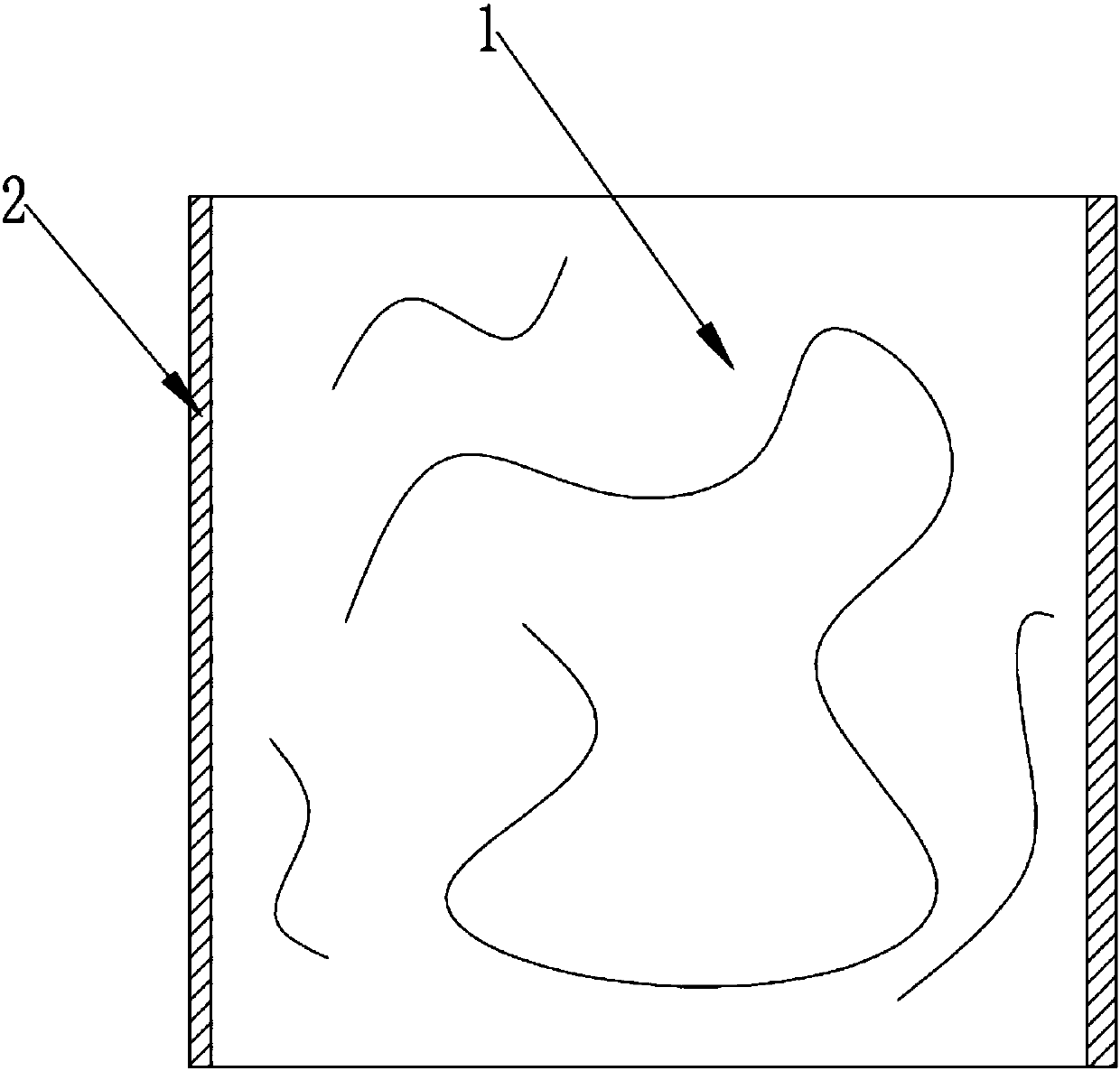

[0039] (1) Design the ink-jet printing pattern of the green body, and be provided with color bars on both sides of the pattern; The color bars are monochrome bars, and the color of the monochrome bars is the color of a single color channel in the ink-jet printer, one of which The color of the monochromatic strip is the color with the highest proportion in the pattern, and the monochromatic strip is arranged on the longitudinal two sides of the pattern along the movement direction of the adobe to obtain a pattern pattern with a color strip, such as figure 1 shown; wherein the color of the color bar is 2mm;

[0040] (2) Ink-jet printing: ink-jet printing of patterns and patterns with color bars on the surface of the adobe; wherein, the firing shrinkage of the adobe is 10, and the size of the adobe is 906*906mm;

[0041] (3) Distinguishing the gr...

Embodiment 3

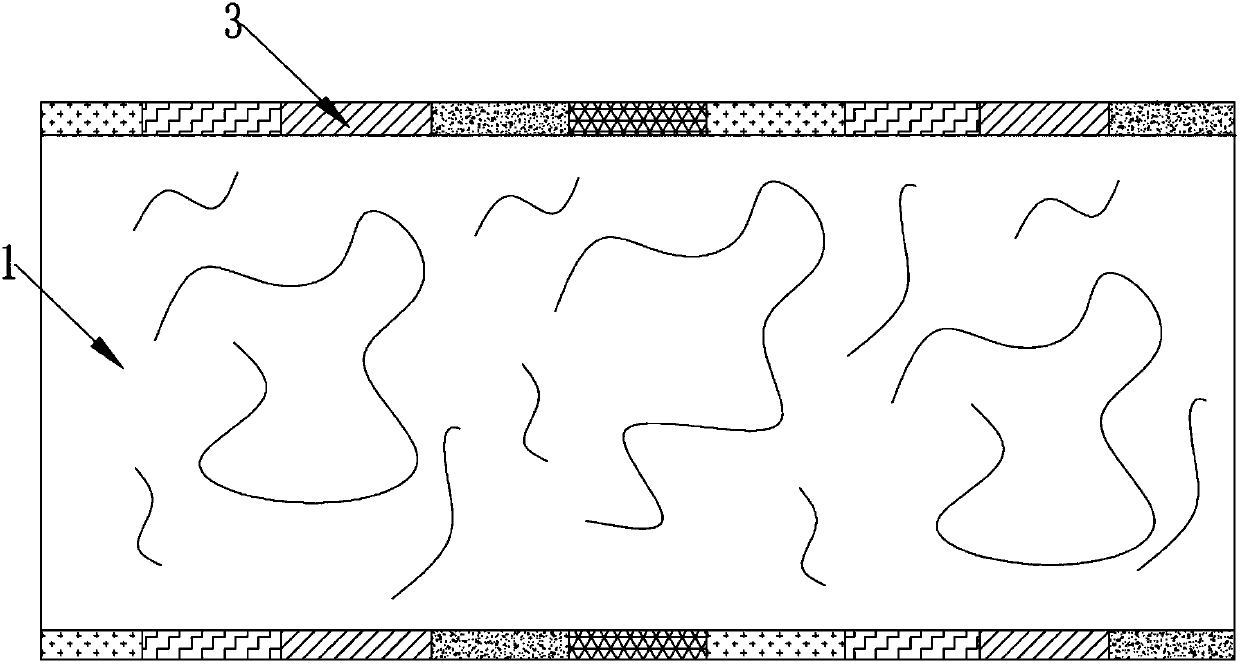

[0043] Embodiment 3-a method for detecting inkjet printing defects and its ceramic tile production process, comprising the steps of:

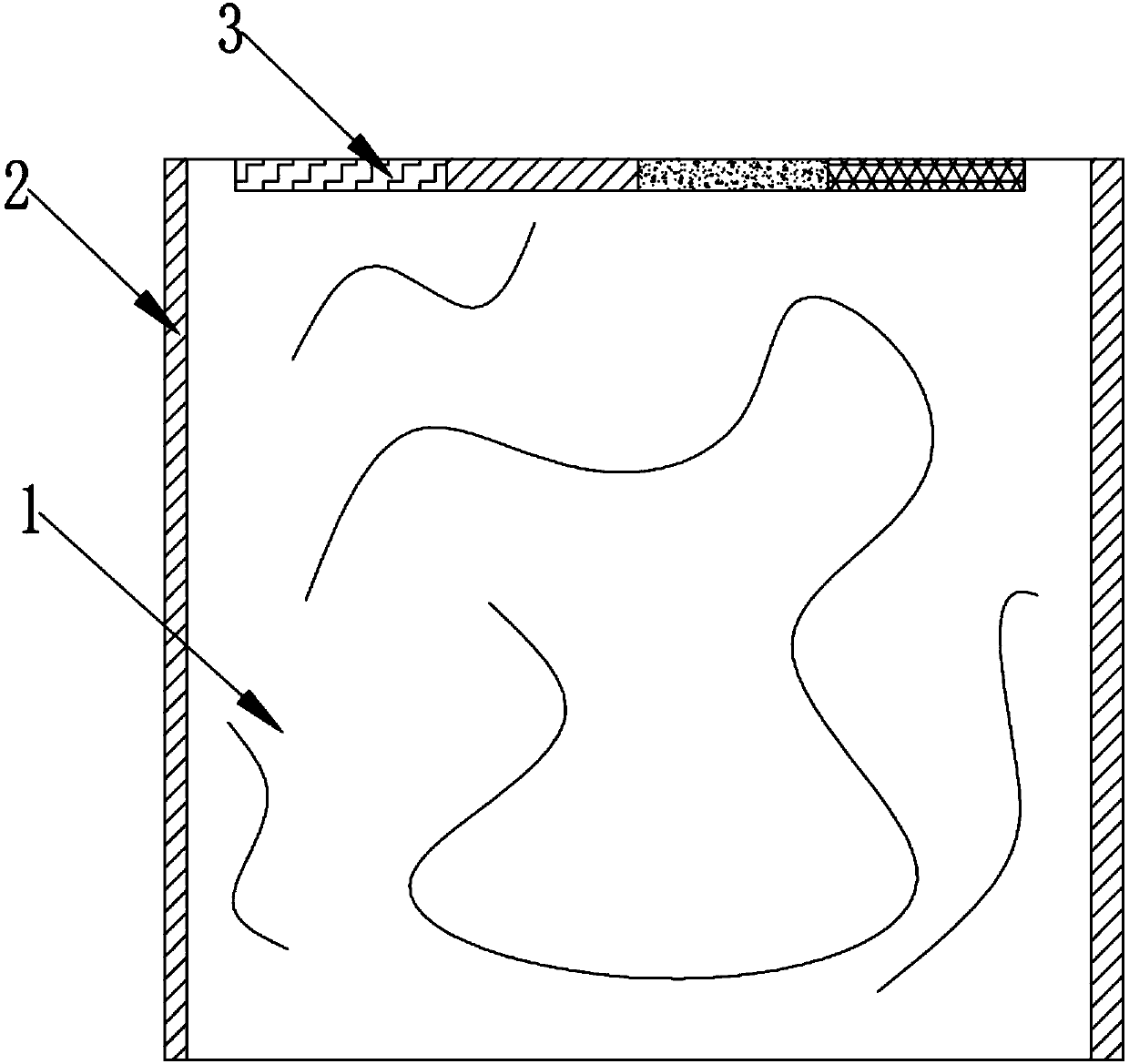

[0044] (1) design the ink-jet printing pattern of green body, and be provided with color bar on three sides of pattern; Described color bar is monochrome bar and color bar, and the color of described monochrome bar is the single color channel in the ink-jet printer Color, wherein the color of a monochromatic strip is the color with the highest proportion in the pattern, and the monochromatic strip is arranged on the longitudinal two sides of the pattern along the brick movement direction; the color of the color strip is the color of a plurality of color channels Permutation and combination, the color bar is arranged on the lateral side of the pattern along the direction of movement of the brick; obtain a pattern pattern with a color bar, such as figure 2 shown; wherein the color of the color bar is 2mm;

[0045] (2) Inkjet printing: Inkjet pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com