Simulation assembly of photovoltaic assembly and manufacturing method of welding tension sample

A technology for simulating components and photovoltaic components, applied in the field of solar cells, can solve problems such as difficult operation of junction boxes and bus bars, abnormal quality of photovoltaic components, damage or degradation, etc., to achieve wide application range, save time, increase stability and The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

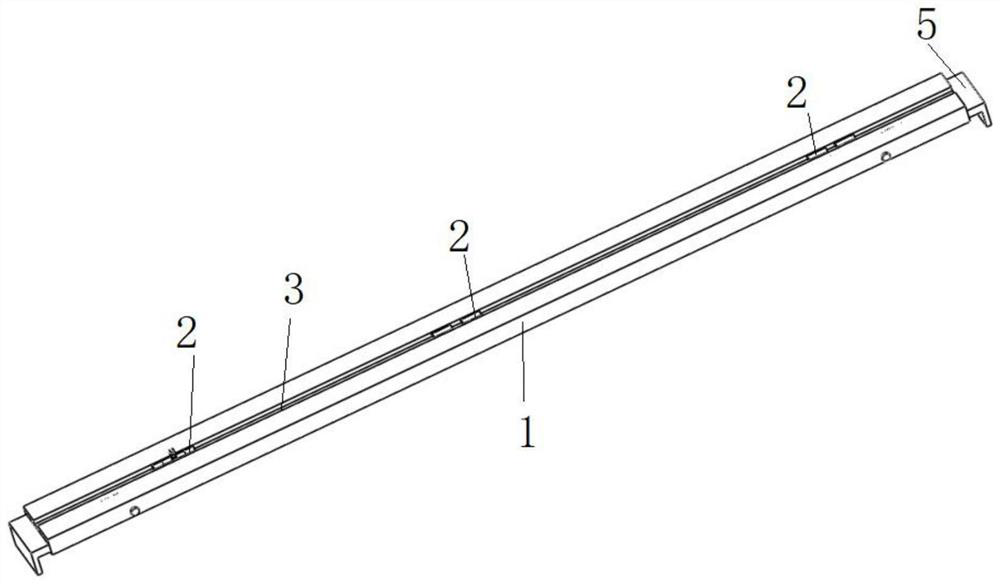

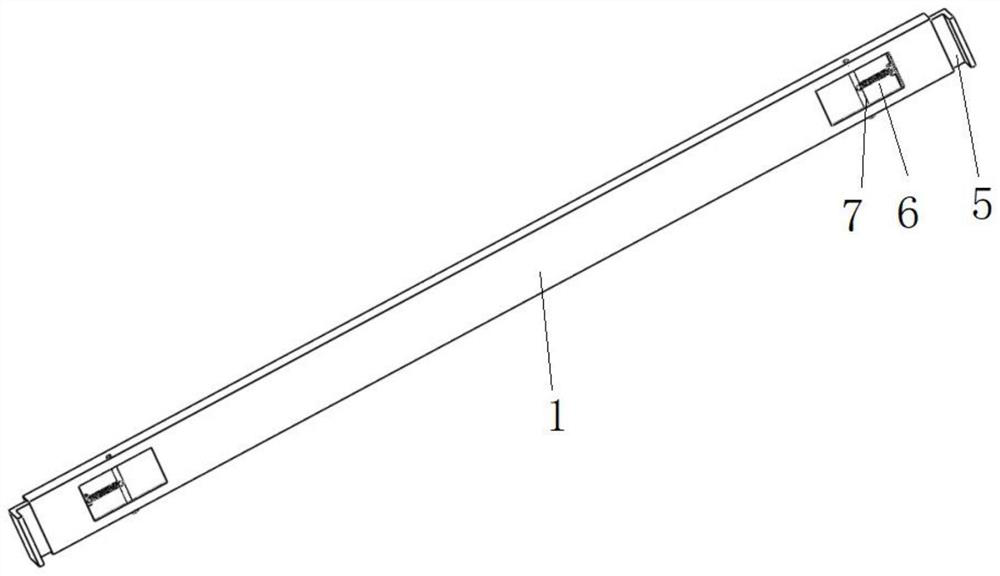

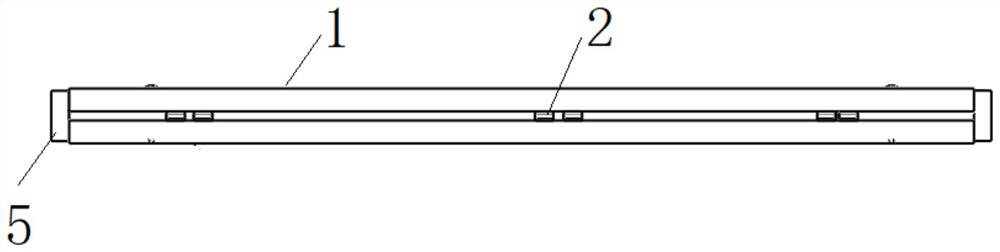

[0098] This embodiment provides an analog component of a photovoltaic module, see Figure 1 to Figure 14 , including a support 1, two bus bars 10 and 3 pairs of sliders 2, a chute 3 is provided on the surface of the support 1, the support 1 is a rectangular plate structure, and the chute 3 is formed by the support on one surface of the support 1 One end of 1 penetrates to the other end of the support 1, the slider 2 is located in the slide groove 3 and can slide in the slide groove 3, and the opposite side of each pair of slider 2 is provided with a mounting groove 4 for accommodating one end of the bus bar 10.

[0099] The top of the chute 3 is open, the chute 3 has a certain depth, and the opening size of the chute 3 is smaller than the middle size of the chute 3 and the bottom size of the chute 3 .

[0100] Specifically, the cross-sectional shape of the slider 2 perpendicular to the extending direction of the chute 3 is hexagonal, and at least four sides of the cross-sectio...

Embodiment 2

[0109] This embodiment provides a method for making a welding tensile sample of a junction box and a bus bar, comprising the following steps:

[0110] Step 1. Cut the bus bar 10 in the analog component into a strip with a length of 20mm, bend it into a right-angled "L" shape in the middle of the strip, and insert one side of the "L"-shaped bus bar 10 Enter the installation groove 4 on the slider 2, and slide the slider 2 to position according to the junction box 11 of different versions;

[0111] Step 2. After inserting the other side of the "L"-shaped bus bar 10 into the box hole of the junction box 11, press the part protruding out of the box hole. Figure 16 The direction of the arrow is bent to fit the bottom tin of the junction box;

[0112] Step 3, if Figure 17 As shown, the clamping component is clamped on the edge of the photovoltaic component 9, so that the simulation component and the photovoltaic component 9 are assembled;

[0113] Step 4, putting the assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com