Production control method for improving curvature of 42CrMo bar

A production control method and bending technology, applied in the direction of temperature control, metal rolling, etc., can solve the problems of unfavorable bars, prolong the delivery cycle, prolong the heat preservation time, etc., improve the processing efficiency and pass rate, and simplify the process route Feasible, the effect of reducing the rate of quenching cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0029] A production control method for improving the bending degree of 42CrMo bars, comprising the following steps:

[0030] (1) Heating: The billet is heated in a walking heating furnace, the temperature of the preheating section is 680°C, the temperature of the heating section is 1020°C, the temperature of the second heating section is 1100°C, and the temperature of the soaking section is 1095°C; the total heating time is 150min.

[0031] (2) Rolling: The whole line adopts continuous twist-free rolling, which consists of 6 roughing mills, 4 middle rolling mills, 4 middle rolling mills, 6 finishing mills, and 3 reducing and sizing mills. The starting rolling temperature is 990°C and the final rolling temperature is 870°C.

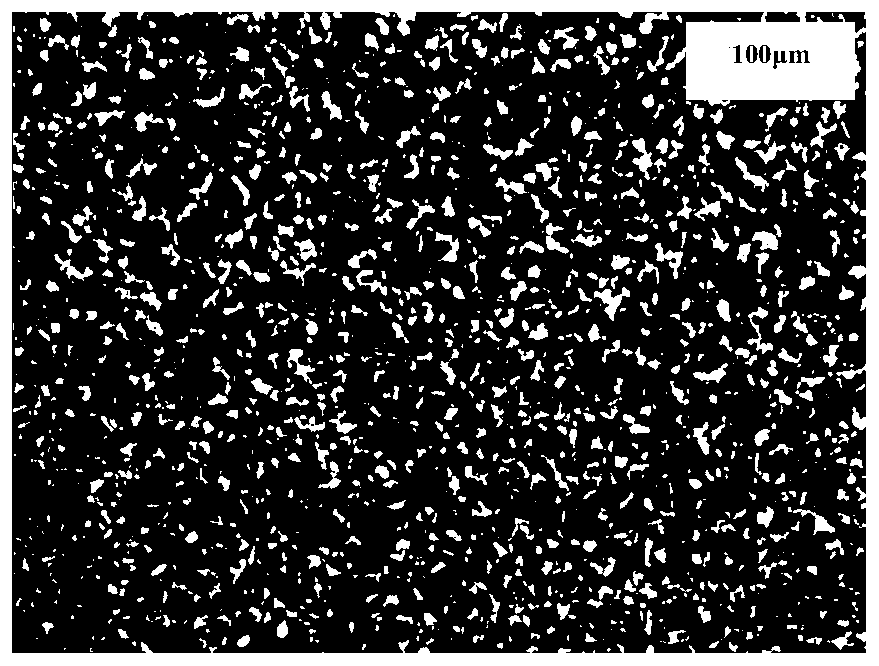

[0032] (3) Cooling bed cooling: the temperature of the cooling bed on the bar is 840°C, and it is cooled to 480°C in the high temperature and slow cooling zone of the cooling bed, the cooling time is 14.4min, and the average cooling rate is 25°C / min. Afte...

specific Embodiment 2

[0036] A production control method for improving the curvature of 42CrMo rods comprises the following steps.

[0037](1) Heating: The billet is heated in a walking heating furnace, the temperature of the preheating section is 600°C, the temperature of the heating section is 950°C, the temperature of the second heating section is 1060°C, and the temperature of the soaking section is 1080°C; the total heating time is 180min.

[0038] (2) Rolling: The whole line adopts continuous twist-free rolling, which consists of 6 roughing mills, 4 middle rolling mills, 4 middle rolling mills, 6 finishing mills, and 3 reducing and sizing mills. The starting rolling temperature is 950°C and the final rolling temperature is 880°C.

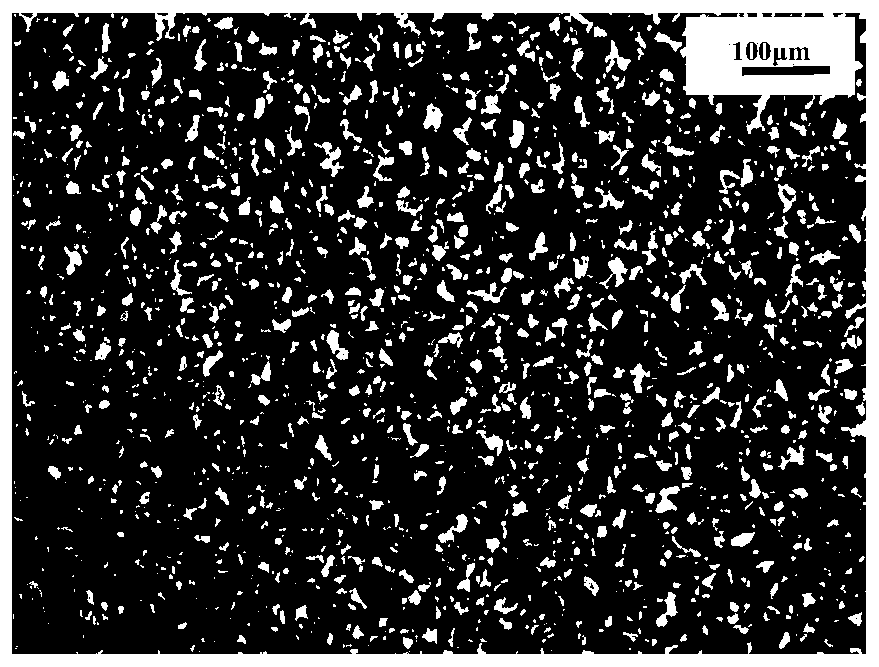

[0039] (3) Cooling bed cooling: The temperature of the cooling bed on the bar is 865°C, and it is cooled to 550°C in the high temperature and slow cooling zone of the cooling bed, the cooling time is 21 minutes, and the average cooling rate is 15°C / min. After bein...

specific Embodiment 3

[0043] A production control method for improving the curvature of 42CrMo rods comprises the following steps.

[0044] (1) Heating: The billet is heated in a walking heating furnace, the temperature of the preheating section is 720°C, the temperature of the heating section is 1060°C, the temperature of the second heating section is 1130°C, and the temperature of the soaking section is 1120°C; the total heating time is 120min.

[0045] (2) Rolling: The whole line adopts continuous twist-free rolling, which consists of 6 roughing mills, 4 middle rolling mills, 4 middle rolling mills, 6 finishing mills, and 3 reducing and sizing mills. The starting rolling temperature is 1010°C and the finishing rolling temperature is 920°C.

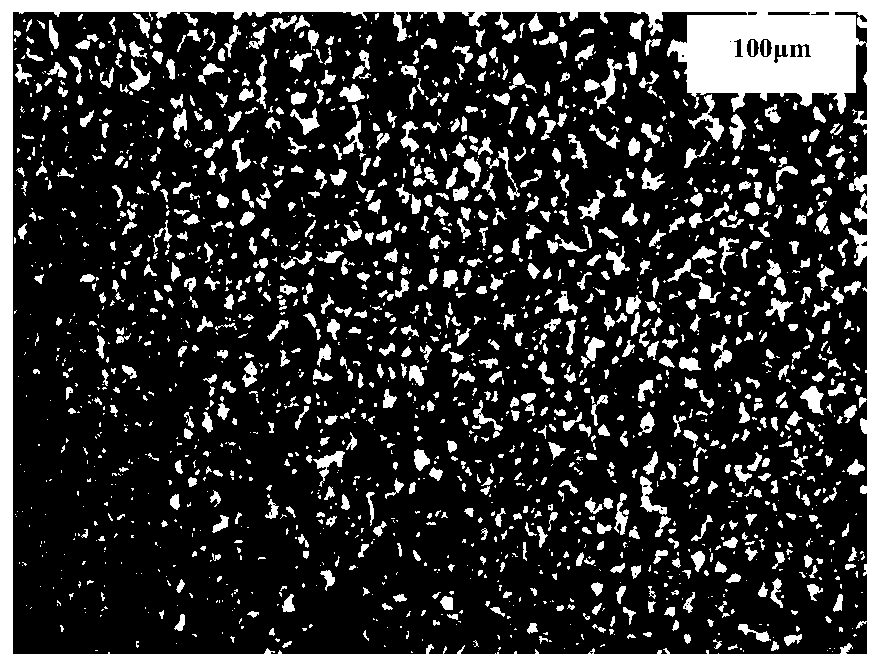

[0046] (3) Cooling bed cooling: the temperature of the bar on the cooling bed is 900°C, and it is cooled to 550°C in the high temperature and slow cooling zone of the cooling bed, the cooling time is 18.4min, and the average cooling rate is 19°C / min. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com