Automatic scratching device and method for micro-powder polishing brick green body

A technology for polishing bricks and scratching, which is applied in the direction of ceramic forming machines, manufacturing tools, auxiliary forming equipment, etc., can solve the problems of incomplete color and fineness of brick surface, inconsistent thickness of scraping, increased manpower allocation, etc., to reduce manual operation errors , smooth surface, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

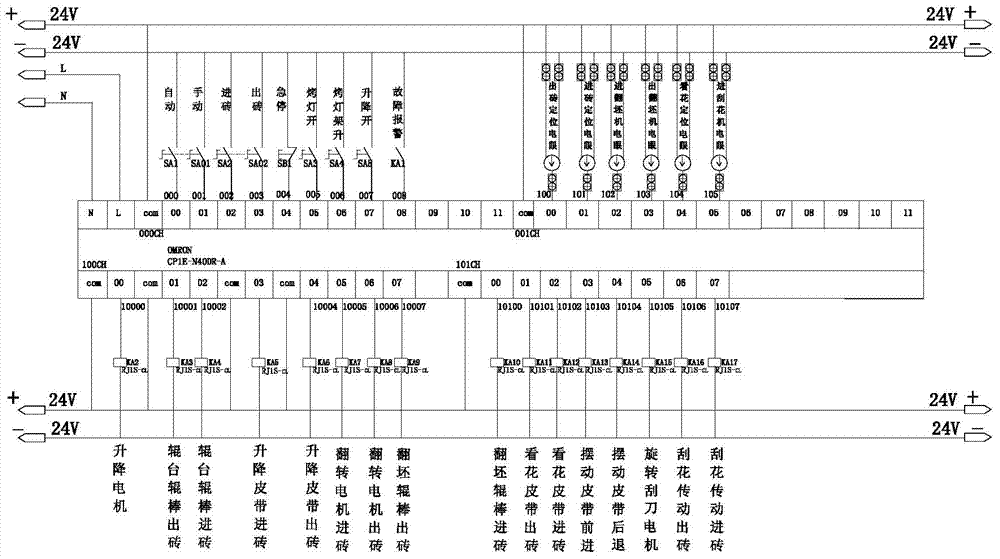

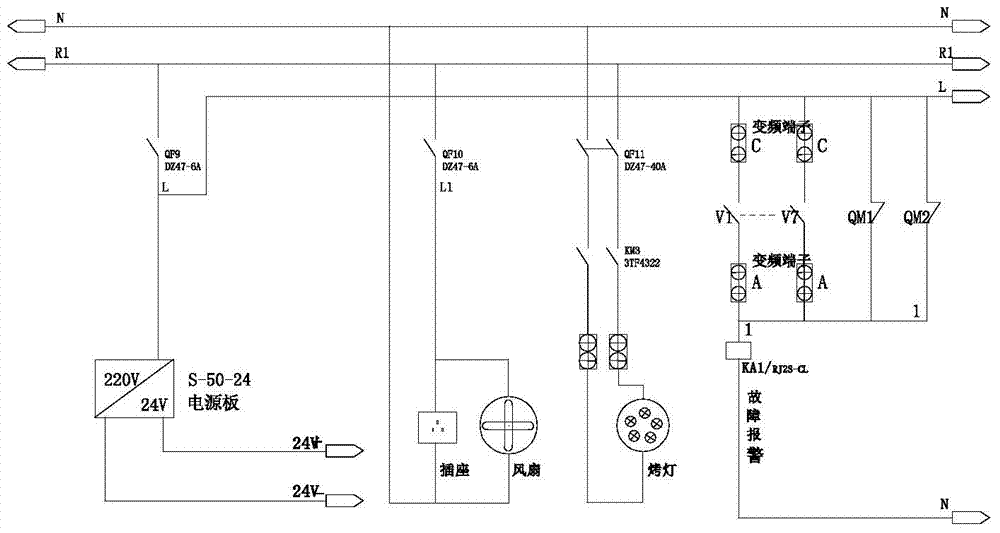

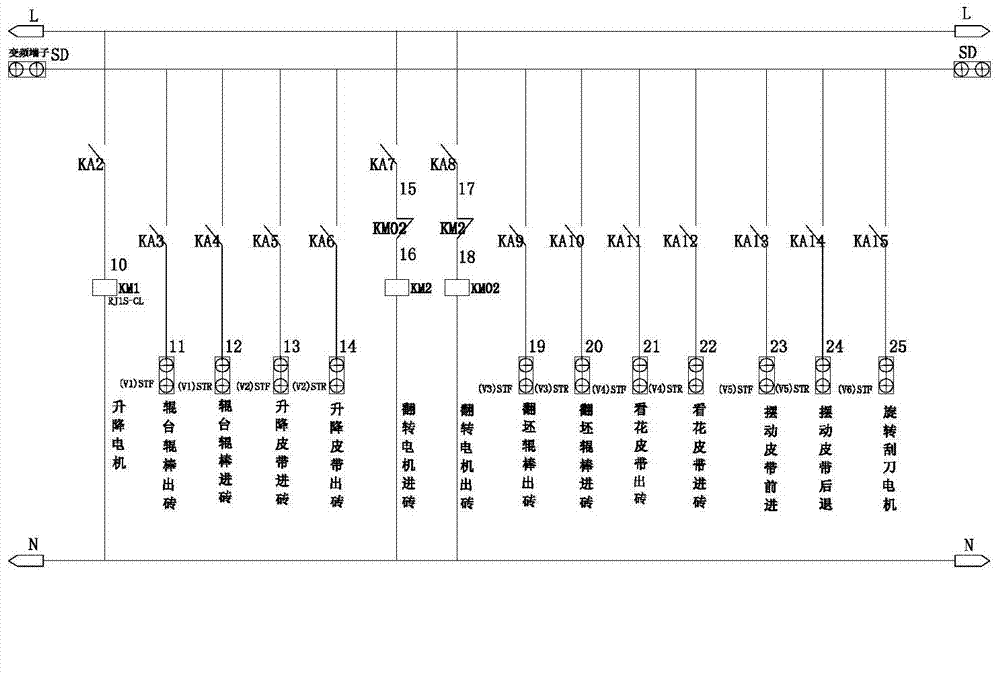

[0040] refer to figure 1 , the micropowder polished brick green body automatic scraping device according to the present invention, which includes a glaze line lifting platform 1, a positioning mechanism 2, a bracket 8, a scraping auxiliary transport platform 3, a turning mechanism 4, a drying mechanism 5 and a scratching mechanism 6. It also includes a controller 7, which respectively controls the electrical connection of the glaze line lifting platform 1, the positioning mechanism 2, the scraping auxiliary transport platform 3, the turning mechanism 4, the drying mechanism 5 and the scraping mechanism 6. signal to control the scraping auxiliary transport platform 3, the turning mechanism 4, the drying mechanism 5 and the scraping mechanism 6 to start or close. Among them, the glaze line lifting platform 1 is vertically arranged with the ceramic tile production line and the scraping auxiliary transport platform 3, and can be automatically lifted. Turning mechanism 4 is a blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com