Method for manufacturing semiconductor device suitable for image sensor

An image sensor and semiconductor technology, applied in semiconductor devices, radiation control devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of low yield of semiconductor devices, difficulty in minimization, and irregular thickness of oxide layer 16, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

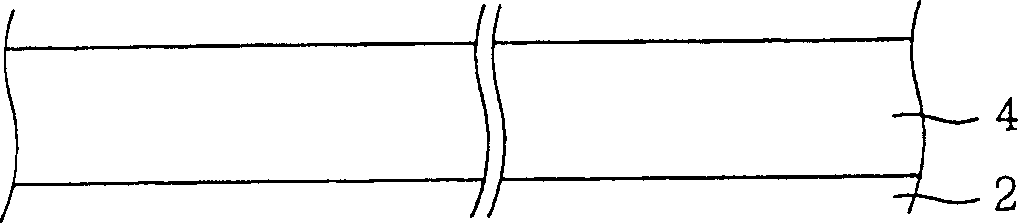

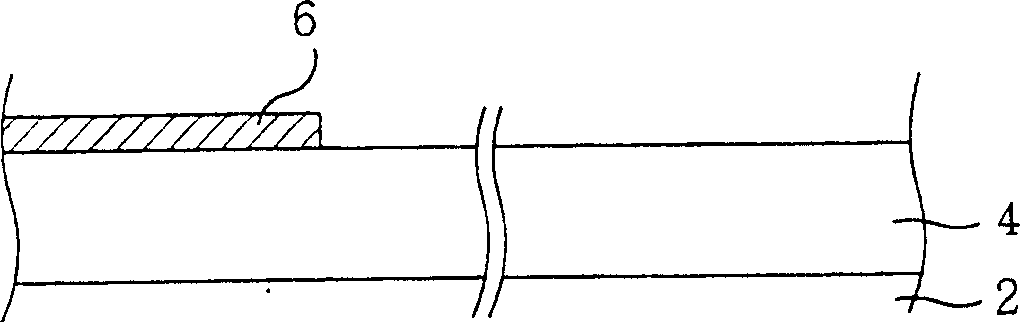

[0020] The following will refer to Figures 2A to 2H A method of manufacturing a semiconductor device suitable for an image sensor according to a preferred embodiment of the present invention will be described in detail. The same reference numerals denote the same parts in the figures.

[0021] In this preferred embodiment of the present invention, after the bonding area is exposed, a protective layer is formed to protect the bonding area, and then color filter elements, planar layers, and microlenses are sequentially formed on the protective layer. Therefore, the microlenses and color filter elements will not be affected during the process of forming the protective layer, so that a high yield of production can be achieved.

[0022] exist Figure 2A In this method, a lower insulating layer 104 is formed on the substrate 102 by deposition. The substrate 102 has a photoelectric conversion element (not shown) such as a charge-coupled device (CCD) or a photodiode, and logic circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com