Gallium antimonide wafer processing method

A processing method and technology of gallium antimonide, which is applied in the field of compound semiconductor wafer corrosion process, can solve the problems of reduced wafer value, wafer loss, waste of manpower and material resources, etc., and achieves controllable corrosion process, prevention of twinning distribution, and smooth and bright surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

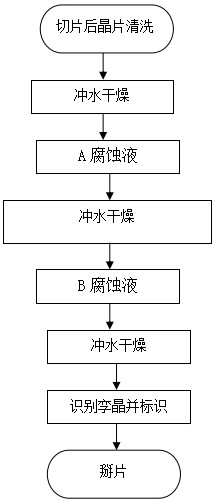

[0028] A processing method for a gallium antimonide wafer, comprising the following steps:

[0029] (1) Clean the sliced gallium antimonide wafer in alcohol to remove the cutting fluid on the surface;

[0030] (2) Rinse the surface of the gallium antimonide wafer with water and dry it after rinsing;

[0031] (3) Soak and corrode the dried gallium antimonide wafer in an etching solution with a mass ratio of sodium hypochlorite and sodium hydroxide of 2 for 50 seconds, clean the wafer with deionized water and dry it;

[0032] (4) After cleaning and drying, put the wafer into the corrosion solution with a volume ratio of hydrofluoric acid and acetic acid of 1 and soak for 30s;

[0033] (5) Then rinse the gallium antimonide wafer surface with deionized water and dry the gallium antimonide wafer to obtain a smoother and brighter wafer;

[0034] (6) Observe the twins on the surface of gallium antimonide wafer under fluorescent lamp and mark the distribution of twins;

[0035] (...

Embodiment 2

[0037] A processing method for a gallium antimonide wafer, comprising the following steps:

[0038] (1) Clean the sliced gallium antimonide wafer in alcohol to remove the cutting fluid on the surface;

[0039] (2) Rinse the surface of the gallium antimonide wafer with water and dry it after rinsing;

[0040] (3) Soak and corrode the dried gallium antimonide wafer in an etching solution with a mass ratio of hydrogen peroxide and sodium hydroxide of 4 for 40 seconds, clean the wafer with deionized water and dry it;

[0041] (4) After cleaning and drying, put the wafer into the corrosion solution with a volume ratio of hydrochloric acid and acetic acid of 1 and soak for 30s;

[0042] (5) Then rinse the gallium antimonide wafer surface with deionized water and dry the gallium antimonide wafer to obtain a smoother and brighter wafer;

[0043] (6) Observe the twins on the surface of gallium antimonide wafer under fluorescent lamp and mark the distribution of twins;

[0044] (7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com