Preparation method and application of chitosan-natural plant pigment macromolecular dye solution

A technology of natural plant pigments and natural plant dyes, applied in the field of preparation of chitosan-natural plant pigment macromolecular dyes, can solve the problem of low combination fastness between natural plant dyes and textiles, poor color fastness of dyed fabrics, and high impurity content and other problems, to achieve the effect of good color fastness, strong coloring ability and deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

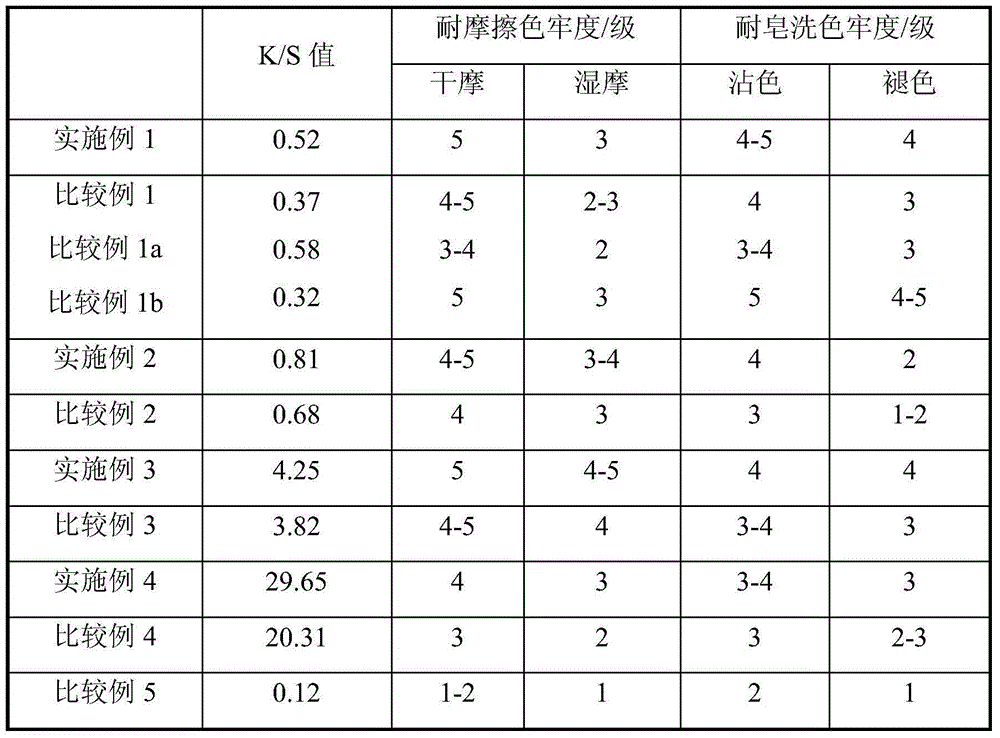

Examples

Embodiment 1

[0023] (1) the molecular weight 5 × 10 4 1. Chitosan with a deacetylation degree of 95% is dissolved in an acetic acid solution with a solute mass fraction of 0.5%, and a chitosan solution with a mass fraction of 5% is prepared. At this time, the chitosan is viscous. Mass fraction 5% hydrogen peroxide solution (the volume ratio of 5% hydrogen peroxide solution and chitosan solution is 0.2:1), after the dropwise addition is completed, the constant temperature reaction is carried out for 0.5h, and after the reaction is completed, it is cooled to obtain chitosan Dispersion liquid: at a height of 10 cm away from the liquid surface, with a No. 5 needle, the above-mentioned chitosan dispersion liquid is dripped into the concentration 10g / L NaOH solution drop by drop under magnetic stirring. The ball was filtered out, washed 3 times with distilled water, dried under vacuum at 50°C, and set aside;

[0024] (2) Dissolve 1 g of madder extract in 100 mL of water, then add 10 g of chitos...

Embodiment 2

[0034] (1) The molecular weight is 10×10 4 1. Chitosan with a deacetylation degree of 90% is dissolved in an acetic acid solution with a solute mass fraction of 1%, and a chitosan solution with a mass fraction of 3% is prepared. At this time, the chitosan is viscous. Mass fraction 5% hydrogen peroxide solution (the volume ratio of 5% hydrogen peroxide solution and chitosan solution is 0.4:1), after the dropwise addition is completed, the constant temperature reaction is carried out for 1.5h, and after the reaction is completed, it is cooled to obtain chitosan Dispersion liquid: at a height of 10 cm away from the liquid surface, with a No. 5 needle, the above-mentioned chitosan dispersion liquid is dripped into the concentration 20g / L NaOH solution drop by drop under magnetic stirring. The ball was filtered out, washed 5 times with distilled water, dried under vacuum at 80°C, and set aside;

[0035] (2) Dissolve 1 g of Scutellaria baicalensis extract in 100 mL of water, then a...

Embodiment 3

[0040] (1) the molecular weight 8 × 10 4 , Chitosan with a deacetylation degree of 92% is dissolved in an acetic acid solution with a solute mass fraction of 0.8%, and a chitosan solution with a mass fraction of 4% is prepared. At this time, the chitosan is viscous. Mass fraction 5% hydrogen peroxide solution (the volume ratio of 5% hydrogen peroxide solution and chitosan solution is 0.3:1), after the dropwise addition is completed, the constant temperature reaction is carried out for 1h, and after the reaction is completed, it is cooled to obtain chitosan dispersion solution; at a height of 10cm from the liquid surface, use a No. 5 needle to drip the above-mentioned chitosan dispersion into the NaOH solution with a concentration of 15g / L under magnetic stirring. After the addition, the chitosan microspheres Filtered out, washed 4 times with distilled water, dried under vacuum at 60°C, and set aside;

[0041] (2) Dissolve 1 g of turmeric extract in 100 mL of water, then add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com