Heat-resistant substrate resin and preparation method thereof

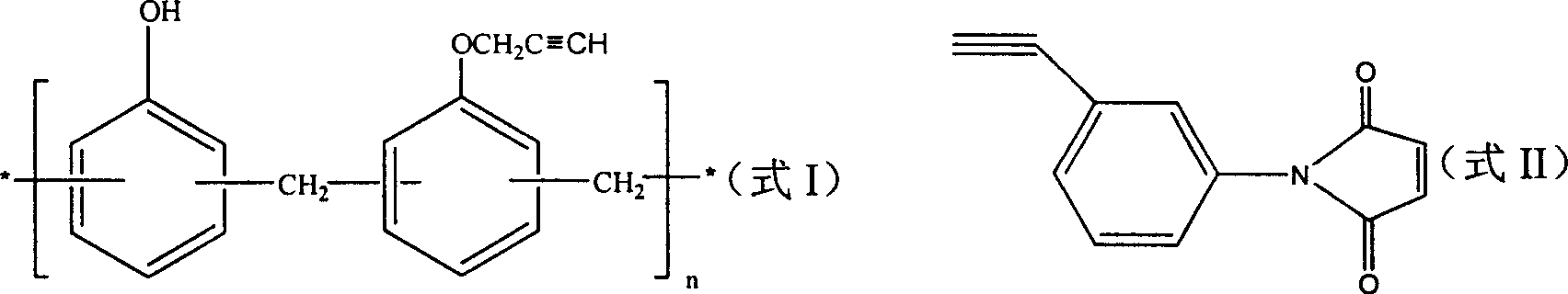

A matrix resin and heat-resistant technology, which is applied in the field of matrix resin for high-temperature-resistant composite materials and its preparation, can solve the problems of poor curing reactivity, difficult molding and processing of PN resin, and restrictions on wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, preparation PN-APMI-4-1 resin

[0017] Get PN resin (the number-average molecular weight is 750, and the degree of propargylation is 115%) 60g is added into a 250ml three-necked flask, and a mechanical stirrer, a reflux condenser and a thermometer are installed. Use an oil bath to heat, and heat up while stirring until the temperature of the system rises to 120°C. Weigh 15g of APMI monomer, quickly add it to the flask, increase the stirring force, keep heating, keep stirring for 30min after the resin system becomes transparent, and discharge, finally get 70g of PN-APMI-4-1 resin.

[0018] The gel time of resin PN-APMI-4-1 at 170°C was measured on a self-made flat plate round hole gel time meter by wire drawing method, and the results are shown in Table 1. The test results show that compared with PN resin, the gel time is shortened from 140min to 31.6min, and the curing reactivity of the resin is greatly improved.

[0019] The thermosetting properties of ...

Embodiment 2

[0021] Embodiment 2, preparation PN-APMI-2-1 resin

[0022] Get 40g of PN resin (the number average molecular weight is 750, and the degree of propargylation is 115%) and add it into a 250ml three-necked flask, and install a mechanical stirrer, a reflux condenser and a thermometer. Use an oil bath to heat, and heat up while stirring until the temperature of the system rises to 120°C. Weigh 20g of APMI monomer, quickly add it to the flask, increase the stirring force, keep heating, keep stirring for 32min after the resin system becomes transparent, and discharge, finally get 56g of PN-APMI-2-1 resin.

[0023] The gel time of the resin PN-APMI-2-1 at 170°C was measured by the wire drawing method on a self-made flat plate round hole gel time tester. The results are shown in Table 1, indicating that the gel time was shortened to 18.8min. The curing reactivity of the resin is greatly improved.

[0024] The thermosetting properties of the resins were characterized by DSC. The tes...

Embodiment 3

[0026] Embodiment 3, preparation PN-APMI-1-1 resin

[0027] Get 40g of PN resin (the number average molecular weight is 750, and the degree of propargylation is 115%) and add it into a 250ml three-necked flask, and install a mechanical stirrer, a reflux condenser and a thermometer. Use an oil bath to heat, and heat up while stirring until the temperature of the system rises to 130°C. Weigh 40g of APMI monomer, quickly add it to the flask, increase the stirring force, keep heating, keep stirring for 28min after the resin system becomes transparent, and discharge, finally get 76g of PN-APMI-1-1 resin.

[0028]The gel time of the resin PN-APMI-1-1 at 170°C was measured by the wire drawing method on a self-made flat plate round hole gel time tester. The results are shown in Table 1, indicating that the gel time was shortened to 8.7min. The curing reactivity of the resin is greatly improved.

[0029] The thermosetting properties of the resins were characterized by DSC. The test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com