Polyaryl ether nitrile resin, polyaryl ether nitrile film and preparation method thereof

A polyarylene ether nitrile and resin technology, applied in the field of polymer materials, can solve the problems of destroying the flexibility of polyarylene ether nitrile, complicated heating process, high crosslinking density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

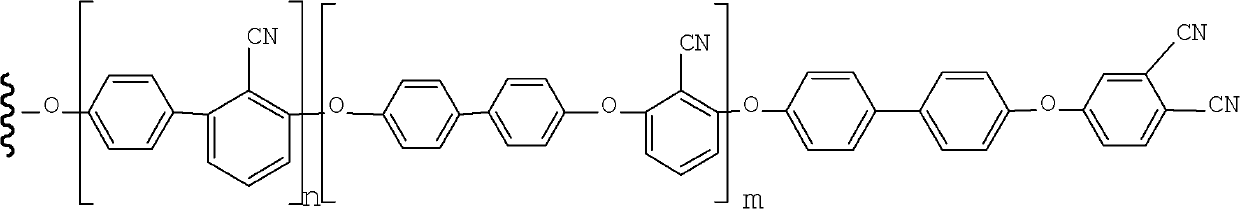

[0042] The second technical problem to be solved in the present invention is to provide the preparation method of above-mentioned polyarylether nitrile resin, comprising the following steps:

[0043] a, Weigh raw materials according to molar ratio: hydroquinone: biphenol: dichlorobenzonitrile: catalyst: 4-nitrophthalonitrile: anhydrous strong polar solvent: dehydrating agent=1~4 : 7~9: 9~11: 11~13: 1~3: 14~16: 4~6;

[0044] b. Dissolve hydroquinone, biphenol, dichlorobenzonitrile and catalyst in anhydrous strong polar solvent and dehydrating agent and react at 140-160°C for 1-3 hours, then remove dehydrating agent and water Reaction at 200-220°C for 3-5 hours;

[0045] c. Cool the product obtained in step b to 80-120° C., add 4-nitrophthalonitrile, react at this temperature for 4-6 hours, wash and dry to obtain polyarylether nitrile resin.

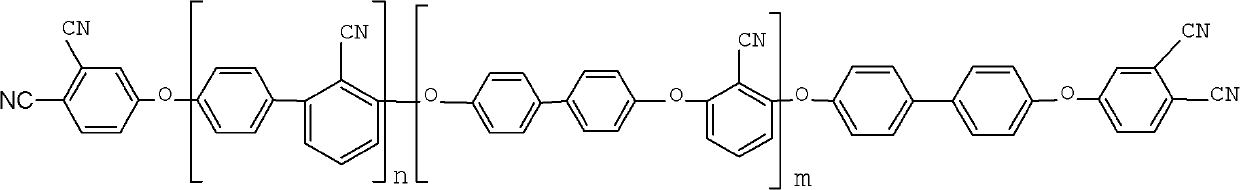

[0046] The equation for the above reaction is:

[0047]

[0048] The 3rd technical problem to be solved by this invention is to pro...

Embodiment 1

[0063] The synthesis of embodiment 1 polyarylether nitrile resin, the preparation and performance of polyarylether nitrile film

[0064] (1) Synthesis of polyarylether nitrile resin

[0065] Raw material consumption is (by mol):

[0066]

[0067]

[0068] Add hydroquinone, biphenol, dichlorobenzonitrile, potassium carbonate, N-methylpyrrolidone and toluene into the three-necked flask according to the above molar ratio, raise the temperature to 140-160°C for 2 hours, and then remove the toluene With water, the temperature is raised to 200-220°C to react for 4 hours, then the temperature is lowered to 80-90°C, and 4-nitrophthalonitrile is added to react for 6 hours. Pour the reaction mixture into 0.1M / L HCL solution for washing, filter, and wash the solid obtained several times with ethanol, and then place it in an oven for 24 hours at 100°C to obtain a polyarylether nitrile resin with a curing temperature of 305°C .

[0069] (2) Preparation of polyarylether nitrile fil...

Embodiment 2

[0071] The synthesis of embodiment 2 polyarylether nitrile resin, the preparation and performance of polyarylether nitrile film

[0072] According to the method and steps of Example 1, the molar ratio of hydroquinone and biphenol was changed to 1.05:9; the physical properties of the polyarylether nitrile film obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Initial decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com