Low-viscosity nitrile resin monomer, copolymer, cured material and preparation method thereof

A technology of viscosity nitrile-based resin and base resin, applied in the field of organic polymer materials, can solve the problems of affecting the performance of the resin system, reducing the viscosity of the system, poor heat resistance, etc., achieving low melt viscosity, simple and controllable method, and good flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

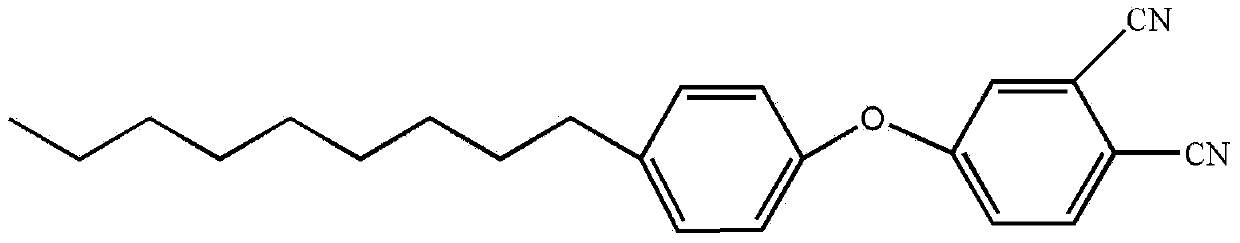

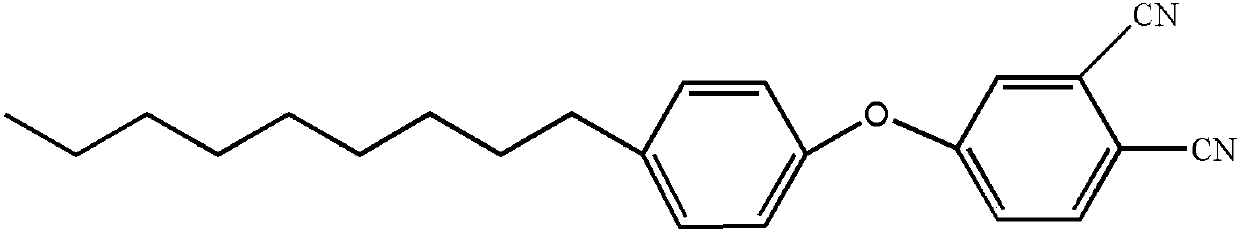

[0065] (1) Preparation of low viscosity and low melting point nitrile resin monomer:

[0066] Step 1: Add 4-nonylphenol, 4-nitrophthalonitrile, anhydrous potassium carbonate and N,N-dimethylformamide into a reaction vessel with a condensing reflux device and heat to 60°C The reaction was carried out for 8 hours.

[0067] Step 2: filter the reaction mixture in step 1, and collect the filtrate.

[0068] Step 3: Pour the filtrate obtained in Step 2 into clear water for precipitation and decantation, and the obtained oily product is washed with a large amount of distilled water and then fully dried to obtain the final product low-viscosity nitrile resin monomer.

[0069] Wherein, the molar volume ratio of 4-nonylphenol, 4-nitrophthalonitrile, anhydrous potassium carbonate and N,N-dimethylformamide is as follows:

[0070] 4-Nonylphenol 1 4-Nitrophthalonitrile 2 Anhydrous Potassium Carbonate 1 N,N-Dimethylformamide (ml) 50

[0071] The resulting l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com