Self-catalyzed resin monomer and synthesis method thereof

An autocatalytic resin and resin monomer technology, applied in the direction of organic chemistry, etc., can solve the problems of insufficient thermal stability of small molecular organic compounds, affecting the performance of composite materials, and the formation of pores in the cured product, achieving excellent thermal stability and low processing temperature. , the effect of excellent curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

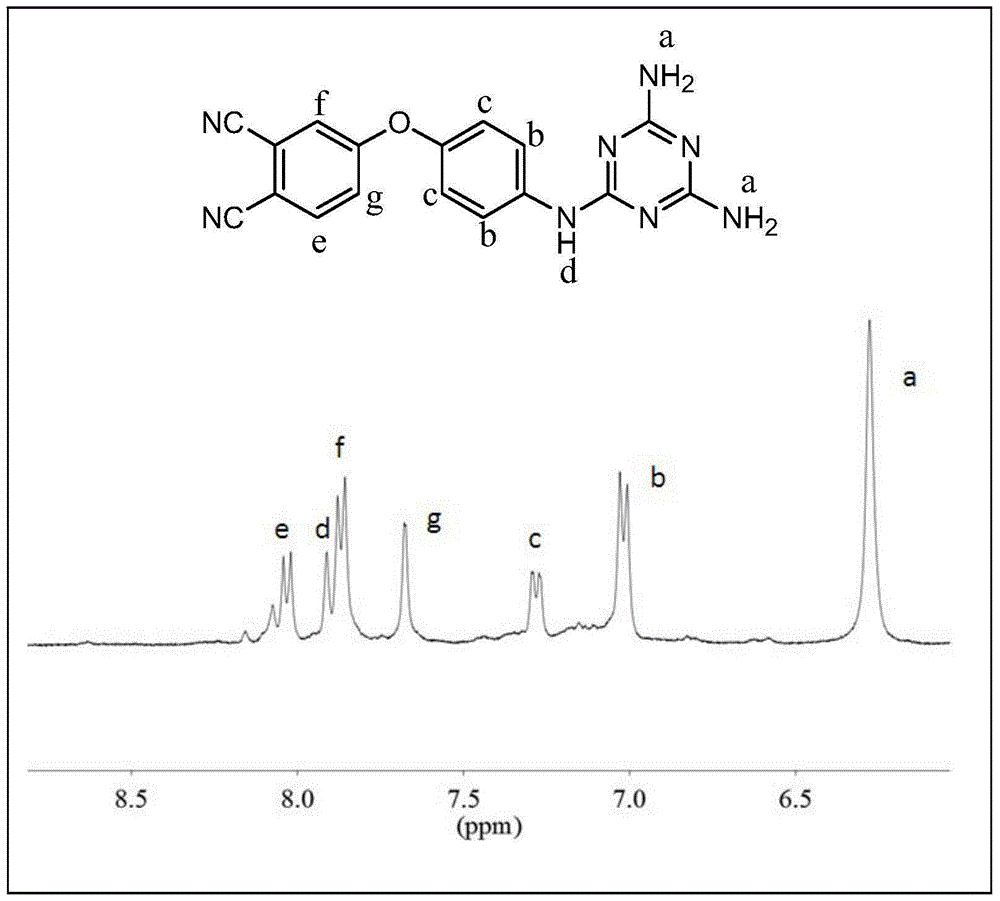

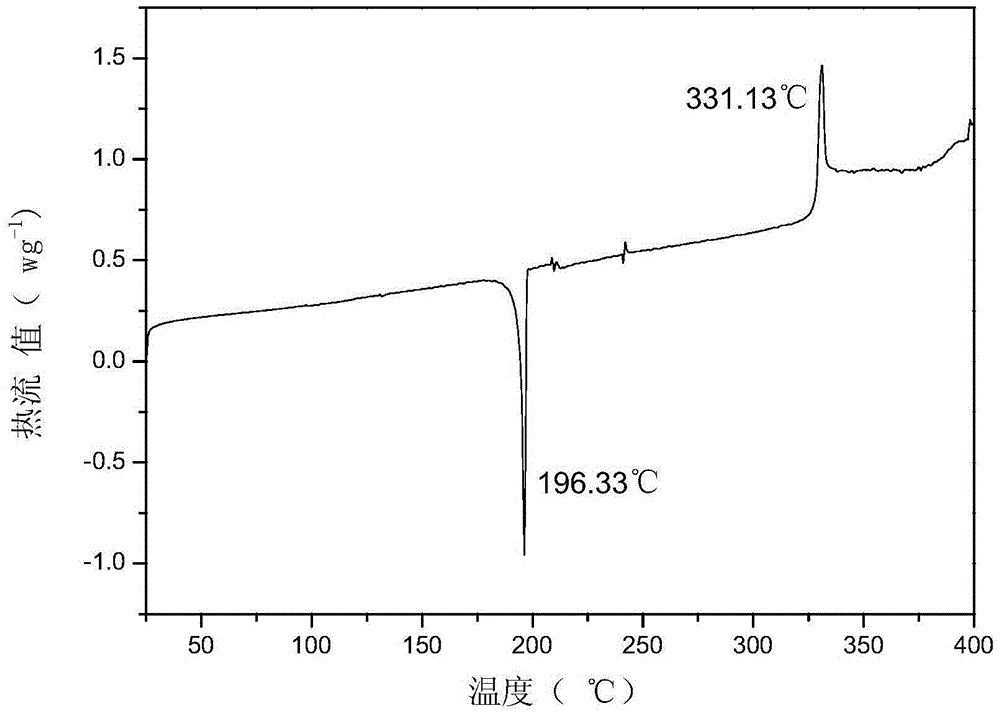

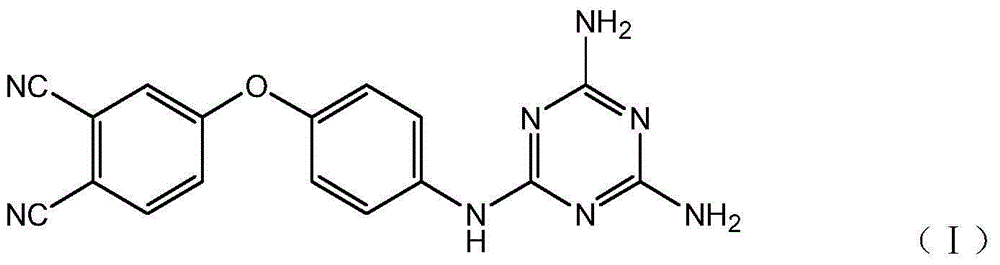

[0034] A self-catalyzed resin monomer of the present invention, molecular structural formula is following formula (I):

[0035]

[0036] A kind of synthesis method of the self-catalyzed resin monomer of above-mentioned present embodiment, comprises the following steps:

[0037] (1) Preparation of 4-p-aminophenoxyphthalonitrile

[0038] (1.1) Add 0.025mol of p-aminophenol, 0.0375mol of anhydrous potassium carbonate, and 30ml of N,N-dimethylformamide DMF (solvent) into a dry reaction vessel (such as a three-necked flask), vacuumize and change the nitrogen, and oil bath Heat to 85°C for 1 hour.

[0039] (1.2) Add 0.02 mol of 4-nitrophthalonitrile to the above reaction vessel, reflux at 90° C. for 4 hours, and then cool to room temperature.

[0040] (1.3) Add deionized water to the product solution obtained in step 1.2, a large amount of precipitation occurs, filter with suction, wash repeatedly with deionized water saturated with sodium chloride, filter and dry. After eluti...

Embodiment 2

[0047] A self-catalyzed resin monomer of the present invention is the same as in Example 1.

[0048] A method for synthesizing the self-catalyzed resin monomer of this embodiment, the steps are basically the same as in Example 1, the only difference is that in step (1) and step (2), the solvents used are all dimethyl sulfoxide, 90 ° C The reaction time under reflux was 8 hours.

Embodiment 3

[0050] A self-catalyzed resin monomer of the present invention is the same as in Example 1.

[0051] A method for synthesizing the self-catalyzed resin monomer of the present embodiment, the steps are basically the same as in Example 1, the only difference being: in step (1) and step (2), the solvents used are all 1,4-dioxane Ring, reflux reaction time is 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com