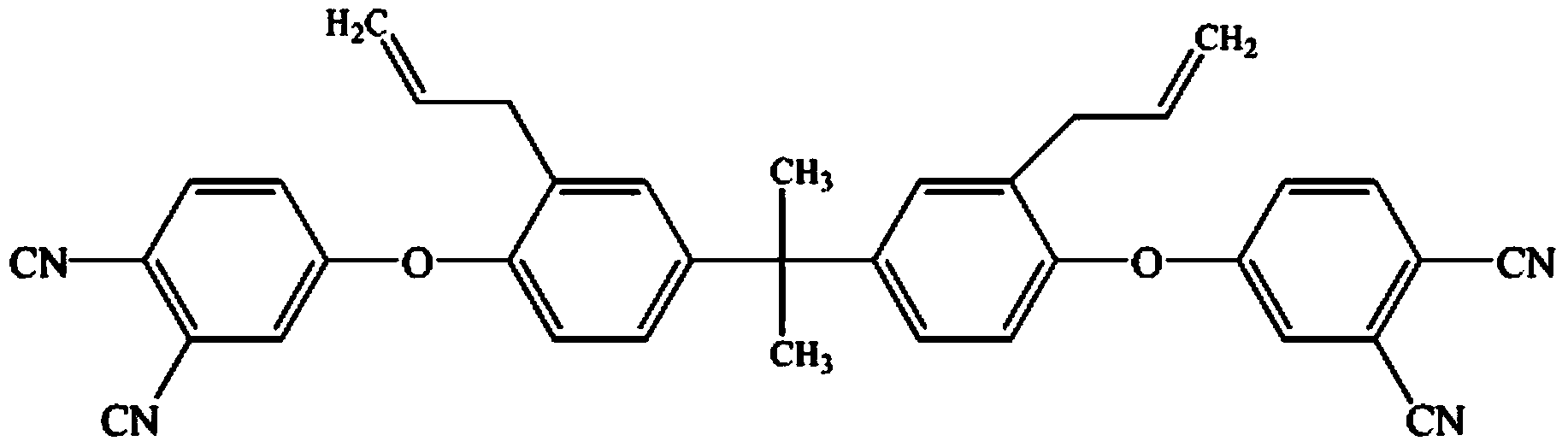

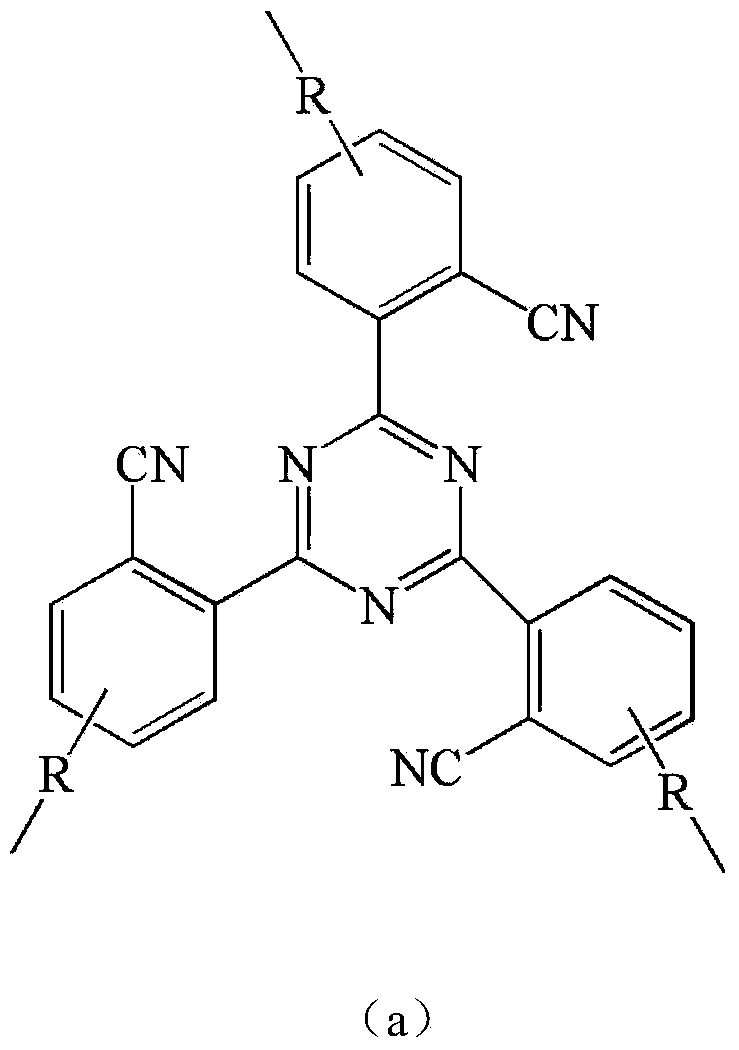

Autocatalytic nitrile resin monomer, polymer and preparation method of polymer

A nitrile-based resin and polymer technology, applied in the field of organic polymer materials, can solve the problems of limited resin processability and comprehensive application, slow thermal curing reaction, narrow processing temperature window, etc., and achieves low curing temperature suitable for industrial production. , The method is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

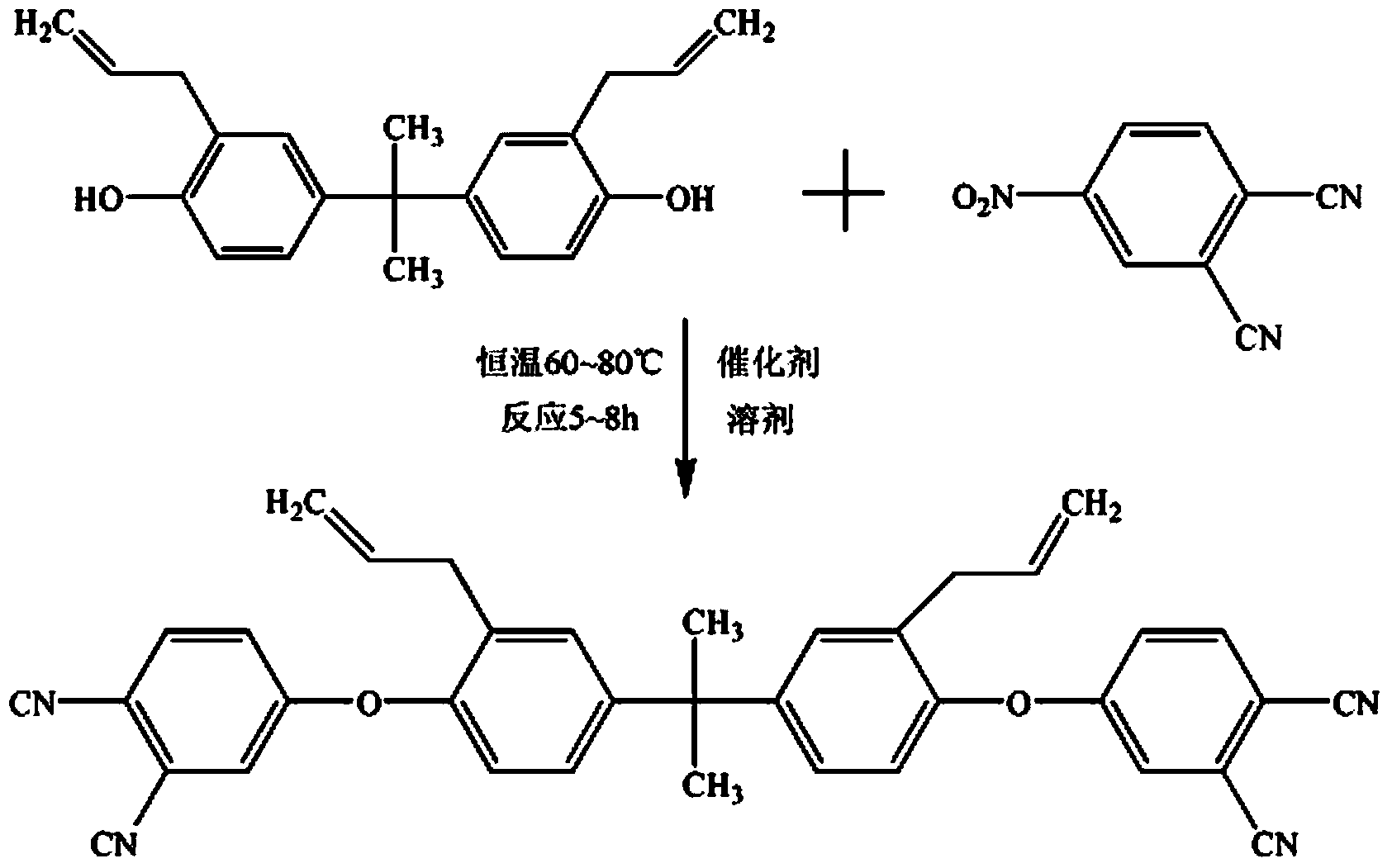

[0054] (1) A kind of synthetic method of described nitrile-based resin monomer

[0055] Step 1: Add diallyl bisphenol A, anhydrous potassium carbonate and dimethyl sulfoxide into a dry reaction vessel, heat in a water bath to 60° C., and reflux for 5 hours.

[0056] Step 2: Add 4-nitrophthalonitrile into the reaction vessel described in Step 1, and react under reflux at 60° C. for 3 hours.

[0057] Step 3: Filter the reaction mixture obtained in step 2 under anhydrous conditions.

[0058] Step 4: Pour the filtrate obtained in step 3 into clear water to precipitate and filter, and the solid obtained by filtering is washed with a large amount of clear water and then fully dried to obtain the final product nitrile resin monomer.

[0059] Wherein, the molar volume ratio of diallyl bisphenol A, anhydrous potassium carbonate, dimethyl sulfoxide and 4-nitrophthalonitrile is as follows:

[0060] Diallyl bisphenol A (grams)

137

Anhydrous Potassium Carbonate (g)

...

Embodiment 2

[0066] (1) A kind of synthetic method of described nitrile-based resin monomer

[0067] Step 1: Add diallyl bisphenol A, anhydrous calcium carbonate and N,N-dimethylformamide into a dry reaction vessel, heat in a water bath to 80°C, and reflux for 4 hours.

[0068] Step 2: Add 4-nitrophthalonitrile into the reaction vessel described in Step 1, and react under reflux at 80° C. for 2 hours.

[0069] Step 3: Filter the reaction mixture obtained in step 2 under anhydrous conditions.

[0070] Step 4: Pour the filtrate obtained in step 3 into clear water to precipitate and filter, and the solid obtained by filtering is washed with a large amount of clear water and then fully dried to obtain the final product nitrile resin monomer.

[0071] Wherein, the molar volume ratio of diallyl bisphenol A, anhydrous calcium carbonate, N,N-dimethylformamide and 4-nitrophthalonitrile is as follows:

[0072] Diallyl bisphenol A (grams)

123.3

Anhydrous calcium carbonate (g)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com