Modified resin for water-based material and preparation method thereof

A technology for modifying resins and water-based materials, which is applied in the field of materials, can solve the problems of restricting the application of water-based materials, VOC emission and safety, and achieve the effect of excellent curing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

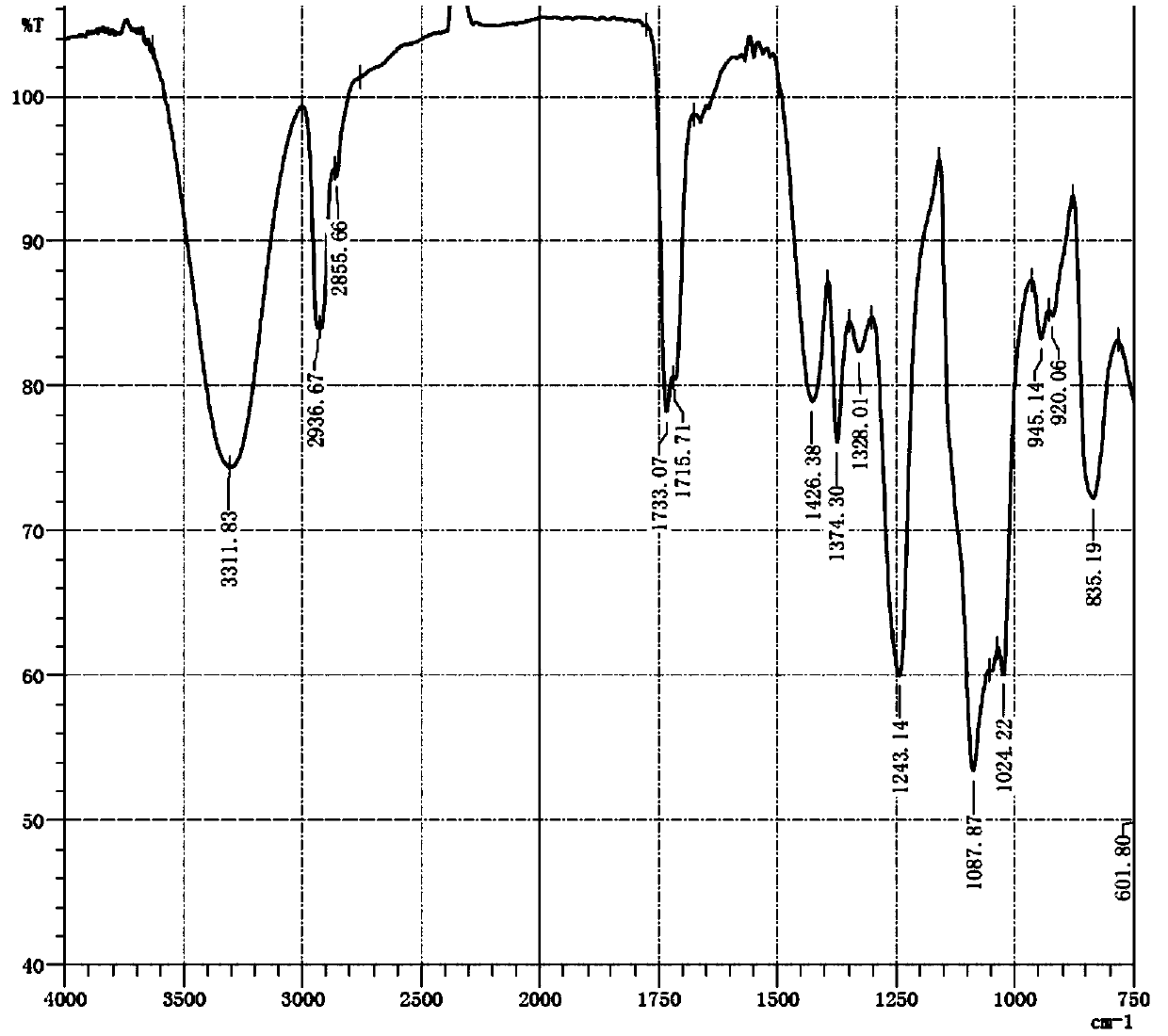

Embodiment 1

[0076] After fully dissolving 50g of PVA 1788 with 450g of dimethyl sulfoxide, add 0.5g of organotin catalyst under stirring, add 3g of ethyl acrylate-2-isocyanate and 10g of dimethyl sulfoxide dropwise at 60°C Solution, react for one hour to obtain ethyl acrylate isocyanate modified polyvinyl alcohol resin solution; slowly add the reaction solution to 1000ml ethanol for precipitation, take out the precipitate and dry it in vacuum at 70°C to constant weight to obtain acrylate isocyanate Modified polyvinyl alcohol resin.

Embodiment 2

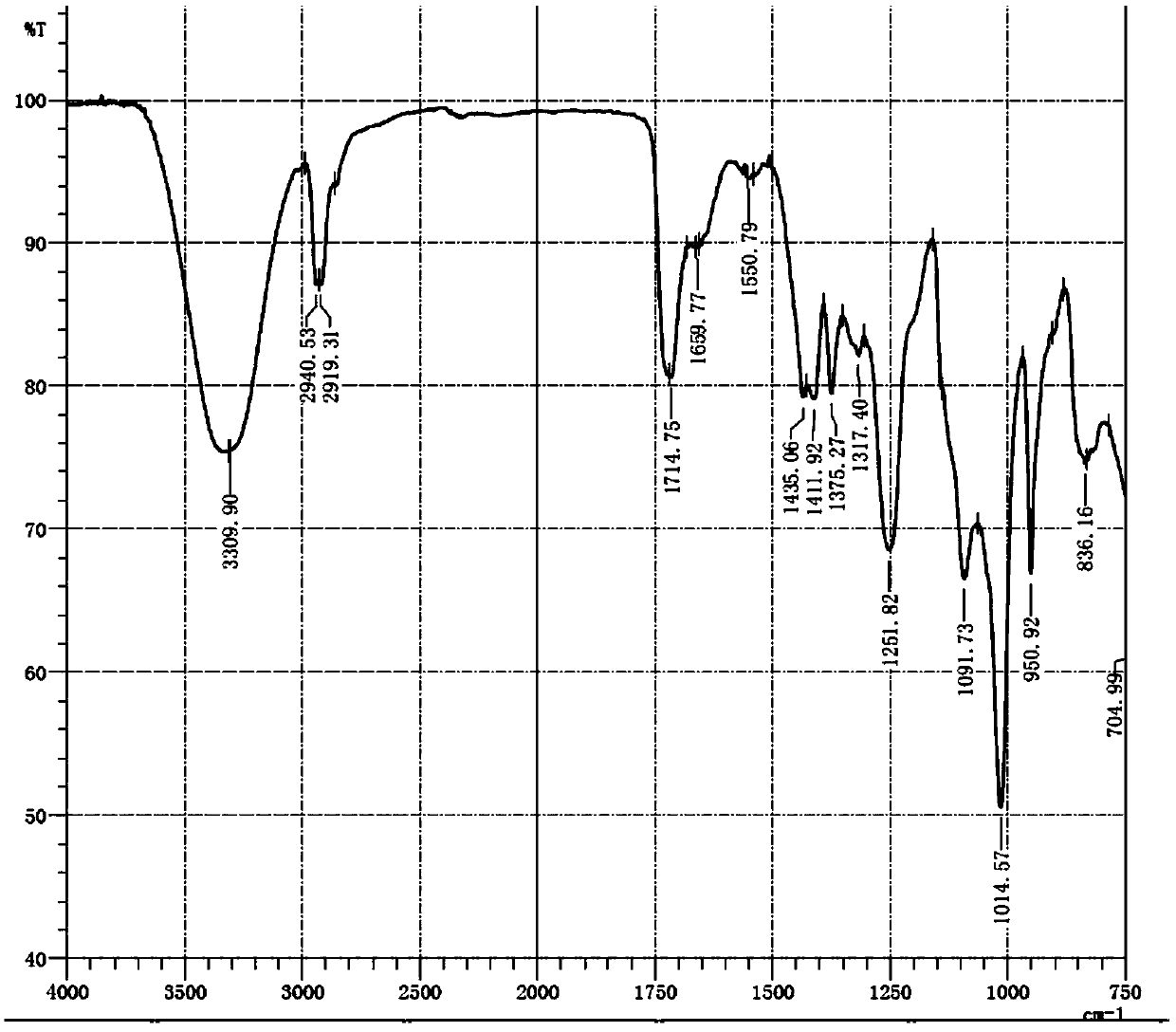

[0078] After fully dissolving 50g of PVA 1788 with 450g of dimethyl sulfoxide, add 0.5g of organotin catalyst under stirring, dropwise add the solution made of 5g of blocked ethyl acrylate-2-isocyanate and 20g of dimethyl sulfoxide, in React for one hour at 100°C to obtain ethyl acrylate isocyanate modified polyvinyl alcohol resin solution; slowly add the reaction solution to 1000ml of ethanol for precipitation, take out the precipitate and dry it in vacuum at 70°C to constant weight to obtain acrylic acid Isocyanate modified polyvinyl alcohol resin.

Embodiment 3

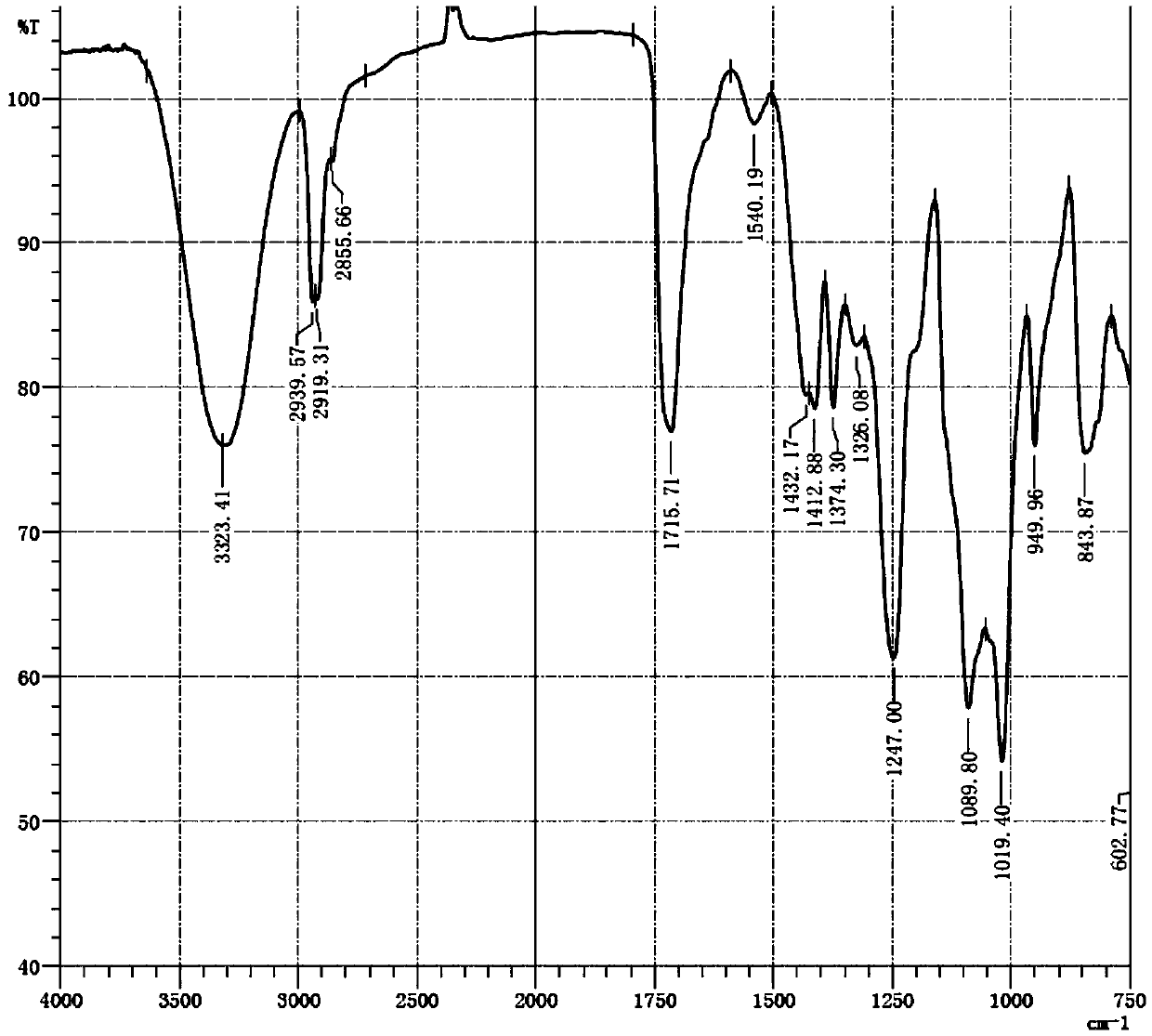

[0080] After fully dissolving 50g of PVA 1788 with 450g of dimethyl sulfoxide, add 0.5g of organotin catalyst under stirring, add 3.3g of ethyl methacrylate-2-isocyanate and 10g of dimethyl sulfoxide dropwise at 60°C The prepared solution was reacted for one hour to obtain the isocyanate ethyl methacrylate modified polyvinyl alcohol resin solution; the reaction solution was slowly added to 1000ml of ethanol for precipitation, and the precipitate was taken out and dried in vacuum at 70°C to constant weight , to obtain methacrylic acid isocyanate modified polyvinyl alcohol resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com